When you ask, "How much does CNC machining cost?" expect a wide range. Simple parts often cost $10 to $100 each, while complex parts can reach $1,000 or more. Several factors shape the final price:

Material selection

Design complexity

Machine type

Batch size

Labor and setup

Tooling and finishing

Overhead and profit margin

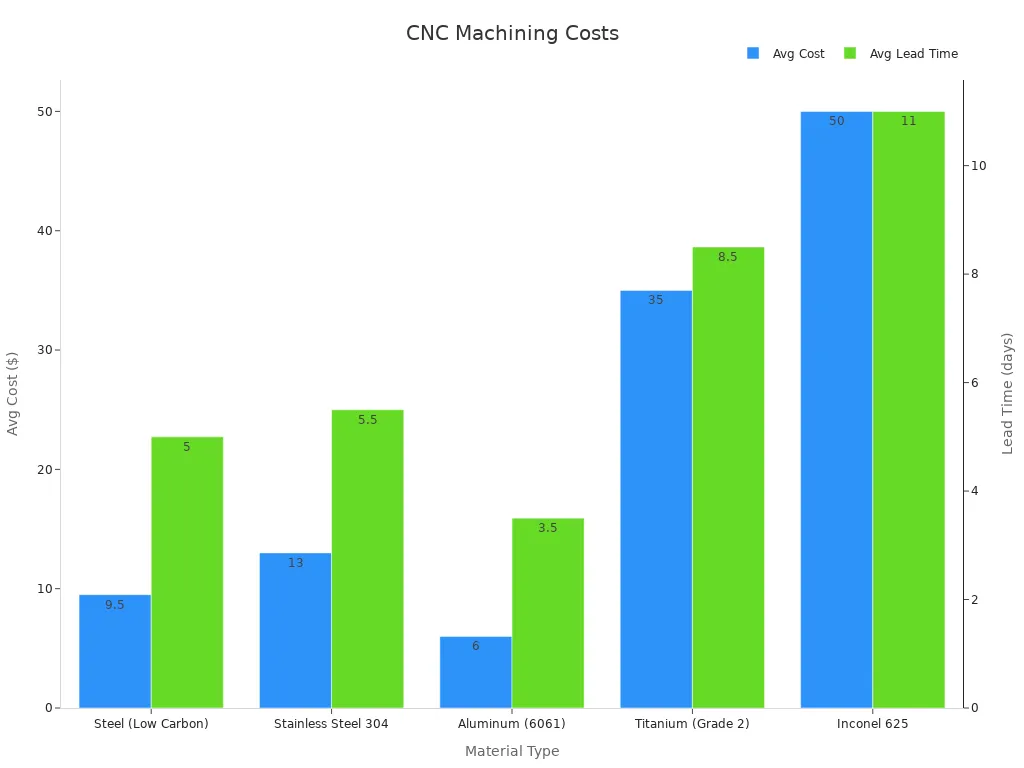

Material Type | Cost Range (per lb/part) | Lead Time (days) |

|---|---|---|

Steel (Low Carbon) | $4 – $15 | 3 – 7 |

Aluminum (6061) | $2 – $10 | 2 – 5 |

Titanium (Grade 2) | $20 – $50 | 5 – 12 |

Understanding the cost breakdown helps you plan your budget and see the true value in CNC machining. Market data shows that pricing and the right factors can make a big difference in your project’s success.

Key Takeaways

CNC machining costs can change a lot. The price depends on material, design, machine type, batch size, labor, and finishing.

Picking easy-to-machine materials like aluminum can save money. It can cost half as much as using expensive metals like titanium.

Making more parts at once lowers the cost for each part. This is because setup and tooling costs are shared.

If you make your design simpler, it takes less time to machine. There are fewer tool changes. This saves money but keeps the quality good.

Estimating costs one step at a time helps you plan your budget. It also helps you make smart choices for your project.

CNC Machining Prices Overview

Typical Hourly Rates

When you look up CNC machining prices, you will see big differences. The price depends on the CNC machine and the machinist’s skill. Entry-level CNC machines usually cost $75 to $100 per hour. Mid-range machines cost about $100 to $175 per hour. High-end machines can cost more than $250 per hour. These prices include both the machine and the person running it.

Machine Category | Purchase Price Range | Typical Hourly Rate |

|---|---|---|

Entry-Level | $150,000 - $300,000 | $75 - $100 |

Mid-Range | $300,000 - $700,000 | $100 - $175 |

High-End | $700,000 - $1.5M+ | $175 - $250+ |

Machinist pay also affects CNC machining cost. New machinists make about $14 to $17 per hour. Skilled machinists can earn over $33 per hour. Harder jobs and special machines can make these numbers go up.

Note: The CNC machine market is growing fast. By 2033, its value may almost double. More automation and smart factories could change prices in the future.

Per-Part Cost Range

The price for each CNC part depends on many things. Material, design, and how many you make all matter. Simple parts can cost as little as $10 each. Hard parts or expensive materials like titanium can cost $1,000 or more per part. Making more parts at once lowers the price for each one. This is because setup and tooling costs are shared.

Factor | Effect on Per-Part Cost | Example / Notes |

|---|---|---|

Material Selection | Harder materials take longer and wear tools faster | Titanium needs slower cutting than aluminum |

Design Complexity | Hard shapes need more programming and setups | More setups mean higher cost |

Machining & Cycle Time | Longer times mean higher cost | Includes time not spent cutting |

Tolerance & Precision | Tighter tolerances cost more for equipment and checks | ±0.001" costs more than ±0.005" |

Tooling & Setup Costs | Small batches have higher per-part cost | Custom setups add to the price |

Production Volume | Making more lowers the cost for each part | Making 5 instead of 1 can cut cost by over half |

When you think about CNC machining prices, remember the machine, material, and how many you need. Checking CNC machine prices helps you know all the costs. This way, you can make smart choices for your project.

CNC Machining Cost Factors

Knowing what affects cnc machining costs helps you see where your money goes. Every part, like material or finishing, changes the final cnc machining cost. Let’s look at these cost factors so you can make smart choices and save money on your project.

Material Selection

Material selection is a big reason why cnc machining costs change. The material you pick changes the price, how long it takes to machine, and how fast tools wear out. Some materials need special machines too. Here’s how different materials change your costs:

Plastic materials are cheaper and easy to machine, so they work well for prototypes.

Aluminum is not expensive and is easy to machine, so it keeps costs low.

Stainless steel and brass cost more to machine because they are harder to work with than aluminum.

Titanium alloys need special tools and take longer to machine, so they are the most expensive metals.

Both the price of the material and how easy it is to machine affect the total cost. If you use aluminum instead of titanium, you can save up to 50% if the part still works for your needs.

Factor | Impact on Machining Costs | Details / Data |

|---|---|---|

Raw Material Price | High-performance plastics and titanium cost more than aluminum | Raises total machining cost |

Machinability | Easier-to-machine materials reduce tool wear and machining time | Tool wear drops by 50%, cycle time by 30–60% |

Cost Savings | Choosing machinable materials lowers total part cost | Can reduce part cost by 30–50% |

Material Substitution | Switching to aluminum from titanium lowers expenses | Must match mechanical requirements |

Material selection changes not just the cost of cnc machines but also the total cnc machining cost. Suppliers can help you find the best mix of price and performance.

Design Complexity

Design complexity changes how much cnc machining costs. If your part is more complex, it takes more time and work to make. You should think about how many features, sizes, tightness, and how much material is removed. Harder models need better cnc technology and more setups, which makes machining take longer and cost more.

More features and tricky shapes mean more time for programming and machining.

Lots of features and tight tolerances need more tool changes and setups.

Complex models might need to be machined on more sides, which costs more.

Manufacturers use models and charts to guess how design complexity will change machining costs. Color maps on digital models show which spots need more machining time. If you make your design simpler, you can lower machining costs and cnc machine prices.

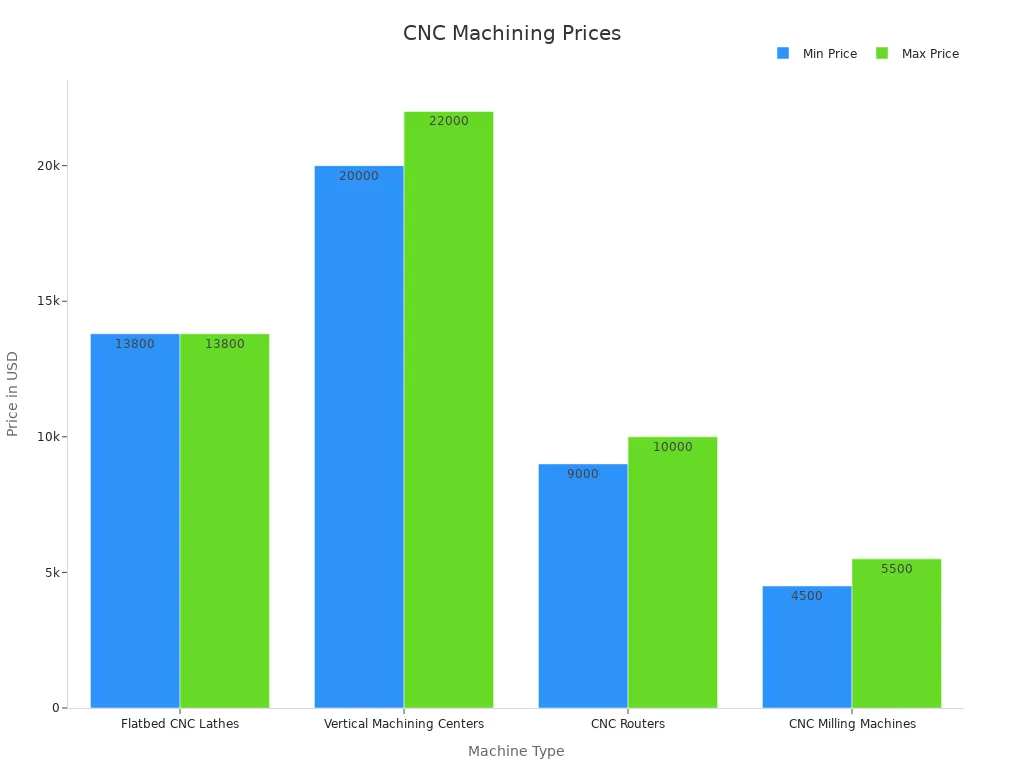

Machine Type

The type of cnc machine you use also changes the final cnc machining cost. If you compare different machines, like 3-axis and 5-axis, you will see big differences in what they can do and how much they cost. Better machines can make more detailed parts but cost more per hour.

Machine Type | Cost Range (USD/hour) |

|---|---|

Entry-level CNC milling | $25 – $50 |

Mid-range CNC milling | $50 – $100 |

High-end CNC milling | $100 – $200 |

Entry-level CNC lathe | $30 – $60 |

Mid-range CNC lathe | $60 – $120 |

High-end CNC lathe | $120 – $240 |

High precision machines, like 5-axis, cost more to run but are better for tricky parts. Picking the right machine helps you balance cnc machine costs with what your project needs.

Batch Size

Batch size is important for figuring out how much each cnc part costs. Small batches have higher setup and programming costs for each part. Bigger batches spread these costs over more parts, so each one costs less.

Batch Size Range | Setup Cost per Part | Material Cost | Total Cost per Part |

|---|---|---|---|

1-10 pcs | Very High | Standard | Highest |

11-50 pcs | High | Slight Discount | High |

51-200 pcs | Medium | Better Rates | Medium |

201+ pcs | Low | Best Rates | Lowest |

For example, making 10 parts can cost two or three times more for each part than making 1,000 parts. If you order more parts, you can save a lot on machining costs.

Labor and Setup

Labor and setup costs are a big part of cnc machining costs. Skilled workers are needed to program, run, and fix cnc machines. Good operators make $20 to $50 per hour, depending on where they live and how much they know. Setup costs include getting machines ready, loading programs, and checking everything.

Skilled workers make sure the parts are good and machines work well.

Setup time depends on how hard the part is, how exact it must be, and what steps are needed.

Training and hiring good workers adds to the total cnc machining cost.

You can lower labor and setup costs by making your design easier and picking suppliers who use good cnc technology.

Tolerances and Finishing

How exact your part must be and how smooth it needs to look can change cnc machining cost a lot. Tighter tolerances and smoother finishes need better machines, slower speeds, and more checks. These things make machining take longer and cost more.

Aspect | Description / Data | Impact on Machining Price |

|---|---|---|

Tolerance Grade | F01 (very high) to F16 (no tolerance) | Tighter grades need more precise machines/tools |

Geometric Tolerances | Flatness (0.02 mm), circularity (0.05 mm), position (±0.1 mm), profile (±0.01 mm) | Stricter tolerances raise calibration/inspection |

Surface Finish (Ra) | 1.6 µm to 6.3 µm | Finer finishes increase machining time/cost |

Equipment & Tooling | Advanced machines, carbide/diamond tools | Higher investment and replacement costs |

Quality Control | CMMs, laser scanners, micrometers | Adds inspection time and equipment cost |

If you need very exact parts, you will need better cnc technology and more checks, which makes the price go up.

Tip: You can save money on cnc machining by making tolerances and finishes less strict if your part will still work.

By knowing these factors, you can control cnc machining costs and make better choices for your next project.

CNC Machining Cost Breakdown

When you know the cnc machining cost breakdown, you can see where your money goes. There is a simple formula to help you guess the total price:

Total Cost = Material Cost + Machining Cost + Post-Processing Cost + Overhead + Profit Margin

Each part of this formula is important for the final price. Let’s check what each part means and how it changes your project.

Material Costs

Material costs are the starting point for your cnc machining cost. The kind and amount of material you pick will change the price. Some materials, like aluminum, are cheaper and easy to machine. Others, like titanium, cost more and need special tools.

Here is a table that shows how material costs can be different for each part:

Part Type | Material | Machine Type | Material Cost (per part) | Batch Size | Notes |

|---|---|---|---|---|---|

Medical Screw | Titanium | Swiss Lathe | $1 | 100 | Tight tolerance ±0.001 in |

Aerospace Pin | Aluminum | 5-axis Mill | $0.10 | 50 | High precision, ±0.001 in |

Car Gear | Steel | 3-axis Mill + Hobber | $0.50 | 30 | Standard precision, ±0.005 in |

You can see that parts needing high precision, like medical screws, use costly materials and tight tolerances. This makes both material and machining costs go up. If you pick a material that is easier to machine, you can lower your total cost.

Machine Time

Machine time is one of the biggest parts of your machining costs. You pay for the hours the cnc machine works on your part. The machine type and how exact it must be both change the hourly rate.

Here is a table with normal hourly rates for different cnc machines:

Machine Type | Hourly Rate Range (USD) |

|---|---|

3-Axis CNC Mill (Standard Quality) | $40 – $80 per hour |

3-Axis CNC Mill (High Precision) | $80 – $120 per hour |

4-Axis CNC Mill | $100 – $150 per hour |

5-Axis CNC Mill (General Purpose) | $150 – $200 per hour |

5-Axis CNC Mill (High Speed/Aerospace) | $200 – $300 per hour |

If your part is more complex, the machine runs longer. High precision parts need slower speeds and more careful work, so the cost goes up. If you order only a few parts, setup time makes each part cost more. Bigger batches spread out this cost, so each part is cheaper.

Note: If you need your parts fast or want something special, your machine time cost can double. Try to plan ahead to save money.

Tooling and Consumables

Tooling and consumables are another big part of your machining costs. Every cnc job needs tools like drill bits, end mills, and clamps. Some tools wear out fast and must be replaced. Others, like clamps and dies, last longer.

If you change the shape or size of your part, you may need new tools, which costs more.

Consumables, like cutting tools, add extra costs to every job.

Setting up and buying tools can be expensive, especially for tricky or exact parts.

Basic cnc setups start at $50,000, but better machines and tool changers cost much more.

You also pay for calibration, software, and training workers.

If your part needs lots of tool changes or special tools, your machining costs will go up. You can save money by making parts that use normal tools.

Overhead and Profit Margin

Overhead means all the extra costs of running a cnc shop. This covers things like rent, power, coolant, and oil. Shops add these costs together and share them across all jobs by machine hours.

Profit margin is what helps a business keep going. After adding all the costs, shops add a margin so they can make money. If you want a lower price, you can ask about ways to cut overhead or machining costs, but every shop needs to pay its bills and earn profit.

Overhead includes things like rent, power, and fixing machines.

Shops use automation and software to guess costs better and keep profit steady.

Good cost estimates help shops stay in business and not lose money.

Some shops may lower their profit margin to get your order, but they still need to cover all costs.

Tip: Ask your cnc supplier how they figure out overhead and profit margin. Clear answers help you see your cost breakdown and find ways to save.

When you know how each part of the cnc machining cost breakdown works, you can make better choices for your project. You can balance material, machining, and overhead to get the best value and accuracy for your needs.

Estimating CNC Machining Cost

Step-by-Step Guide

You can figure out your CNC machining costs by using a simple process. This helps you plan your money and not get surprised. Here is an easy guide you can follow:

Calculate Material Cost

Find out how much your material costs for each unit. Multiply that price by how much material you need.Estimate Tooling and Setup Cost

Write down the tools and fixtures you will use. Add the price for new tools and the time to set up.Determine Machine Time Cost

Guess how long the machine will work on your part. Multiply that time by the hourly rate for your machine. For example, a 3-axis mill might cost $50 to $100 each hour.Add Labor and Overhead

Count the cost for skilled workers, programming, and checking parts. Add a part of the shop’s rent and bills.Include Post-Processing and Finishing

If your part needs extra steps like polishing or coating, add those costs too.Apply Profit Margin

Most shops add a profit margin to make sure they earn money.

Tip: You can use a cnc machining cost calculator or a spreadsheet to keep track of these numbers. Some special software can guess costs within 2% of the real price.

Example Calculation

Let’s look at an example for a simple aluminum bracket:

Cost Component | Example Value | Calculation | Subtotal |

|---|---|---|---|

Material Cost | $5 per part | $5 × 1 | $5 |

Setup Cost | $60 (shared over 10 pcs) | $60 ÷ 10 | $6 |

Machining Time | 0.5 hr per part | 0.5 × $75/hr (3-axis mill) | $37.50 |

Finishing Cost | $3 per part | $3 × 1 | $3 |

Overhead & Profit | $8 per part | Estimated | $8 |

Total Cost | $59.50 |

You can see how each step adds to the total cost. If you use a cnc machining cost calculator, you can quickly change numbers for different materials or batch sizes. Skilled machinists often use real job data and their own experience to make better guesses. For harder parts, you might need to add more machine time or special tools.

Note: The better your input numbers are, the closer your guess will be to the real cnc machining costs.

Reducing CNC Machining Costs

Design Optimization

You can save money on cnc machining by making smart design choices. If you make your part simple, it takes less time to machine. This also means fewer tool changes. Try these ideas: - Make cavities shallow and walls thicker so parts are easier to machine. - Pick hole sizes that are common, so you do not need special tools. - Only use tight tolerances where you really need them. - Design parts so they need fewer setups to finish. - Keep shapes simple so you do not need custom fixtures. - Break up hard models into smaller, easy pieces for assembly. These tips help you use less time and material, so your project costs less.

Material Choices

Picking the right material is important for saving money. Choose metals like aluminum or steel because they are easy to machine and easy to find. Aluminum alloys are good because they move heat well and are simple to cut. This helps tools last longer and lowers cost. Stainless steel is strong and does not rust, but you need tougher tools for it. Always think about what you need and do not pick expensive materials if you do not have to.

Material | Machinability | Cost Impact | Notes |

|---|---|---|---|

Aluminum | High | Low | Fast machining, less wear |

Stainless Steel | Medium | Medium | Durable, needs strong tools |

Steel | High | Low | Versatile, many grades |

Batch Production

Making many parts at once helps you save money. When you make a big batch, setup costs are shared, so each part is cheaper. Use SPC to watch your process and find mistakes early. This stops waste and keeps your work running well. Checking quality in every batch makes sure all parts are good and cuts down on waste.

Make bigger batches to lower the cost for each part.

Use data to find problems fast.

Keep quality high to stop expensive errors.

Efficient Programming

Good programming and new cnc technology help you save time and make better parts. Use smart tool paths and standard parts to skip extra steps. Only use high precision where it matters most. Train workers and use new software to make better models and plans. Automation and checking machines before they break keeps them working and saves money.

Tip: Talk to your cnc supplier early when you design your part. They can help you find ways to save money and make your part better.

You get the most out of CNC machining when you know what affects the cost. Things like material, labor, technology, and how many parts you make all change the price. If you guess costs well, you can plan your money and check different quotes. Studies show that knowing about cnc machining costs helps you make better choices and have better projects.

Follow the steps for estimating and use tips to save money. For the best results, talk to cnc suppliers who can make a plan just for you.

Cost Factor / Investment Area | Estimated Range / Benchmark | Supporting Statistic / Survey Data |

|---|---|---|

CAD/CAM Software Licensing | $10,000 – $50,000 | 80% of businesses report enhanced productivity |

Machinery Investment | $200,000 – $500,000 | Energy-efficient machines can save up to 20% in energy costs |

Labor & HR | $60,000 – $80,000 per skilled employee/year | Labor costs represent 25-30% of total expenses |

FAQ

How can you get an accurate CNC machining quote?

You need to give a detailed CAD file. Tell them what material you want. Say how many parts you need. Share what finish you want on your parts. Giving clear details helps the supplier give a good quote. Ask for a cost breakdown so you know what you pay for.

Why do CNC machining prices vary so much?

Prices change for many reasons. The material you pick matters. The part’s shape and size also matter. The type of machine used changes the price. How many parts you order is important too. Shops also set their own profit margins. You can ask different shops for quotes to find the best deal.

Can you reduce CNC machining costs without losing quality?

Yes, you can save money and still get good parts. Make your design simple. Use common materials. Order more parts at once. Ask your supplier for ways to save money. Only use tight tolerances where you really need them.

What is the minimum order quantity for CNC machining?

Most shops will make even one part for you. But small orders cost more for each part. If you order more, each part costs less. This is because setup costs are shared.

How long does CNC machining usually take?

How long it takes depends on your part and the shop. Simple parts can be done in a few days. Hard or big orders can take weeks. Ask your supplier for a timeline when you ask for a quote.

LKprototype

LKprototype