CNC machine tools have transformed the manufacturing process. They assist in creating products with remarkable accuracy and speed. These tools can cut within 0.001 inches and operate at speeds exceeding 2,300 inches per minute, making them significantly more efficient than traditional methods. They are capable of executing highly detailed tasks flawlessly.

Here’s why CNC machine tools are crucial in today's industry:

AI helps predict repairs, cutting costs by 25% and reducing unexpected stops by 40%, according to McKinsey.

AI scheduling tools enhance production speed by 20%, as noted in a 2024 study published in the International Journal of Production Economics.

Deloitte reports that 70% of manufacturers utilizing smart technology depend on AI to improve efficiency.

The market for CNC machine tools is projected to reach $129 billion by 2026, driven by demand in sectors such as automotive, defense, healthcare, and aviation.

If you’re a manufacturer, staying informed about these developments will enable you to leverage CNC machine tools more effectively, ensuring your business can grow and remain competitive.

Key Takeaways

CNC machines help factories by working fast and very accurately.

Knowing about types like turning, milling, and drilling helps pick the right one.

Industries like cars, planes, and medical tools use CNC machines to make tricky parts.

Choosing the right CNC tool means checking materials, shapes, and needs.

Taking care of machines and using smart tech saves money and time.

Types of CNC Machine Tools

CNC machine tools are vital for modern manufacturing. They provide unmatched accuracy and speed. Knowing the types of CNC tools helps you pick the right one. Below are three main types: CNC turning machines, CNC milling machines, and CNC drilling machines.

CNC Turning Machines

CNC turning machines shape materials by spinning them. A fixed cutting tool removes material during rotation. These machines make round parts like shafts and pulleys.

Key features of CNC turning machines:

High Precision Rates: They are very accurate, reducing mistakes and improving satisfaction.

Real-time Data Analysis: Advanced tools track production data to fix problems quickly.

Cost Efficiency: Less waste and better operations save money and boost profits.

Metric | Description | Impact on Precision and Productivity |

|---|---|---|

Precision Rates | Measures how accurate the machining is. | Better precision means fewer mistakes and happier customers. |

Turnaround Times | Time from order to delivery. | Faster delivery improves efficiency and customer trust. |

Defect Rates | Percentage of bad-quality products. | Fewer defects mean less waste and higher profits. |

Real-time Data Analysis | Tracks production data instantly. | Helps find and fix issues fast, improving productivity. |

Cost Efficiency | Compares costs to output. | Lower costs lead to better profit margins. |

CNC turning machines work well for industries needing accuracy and quick delivery, like aerospace and automotive.

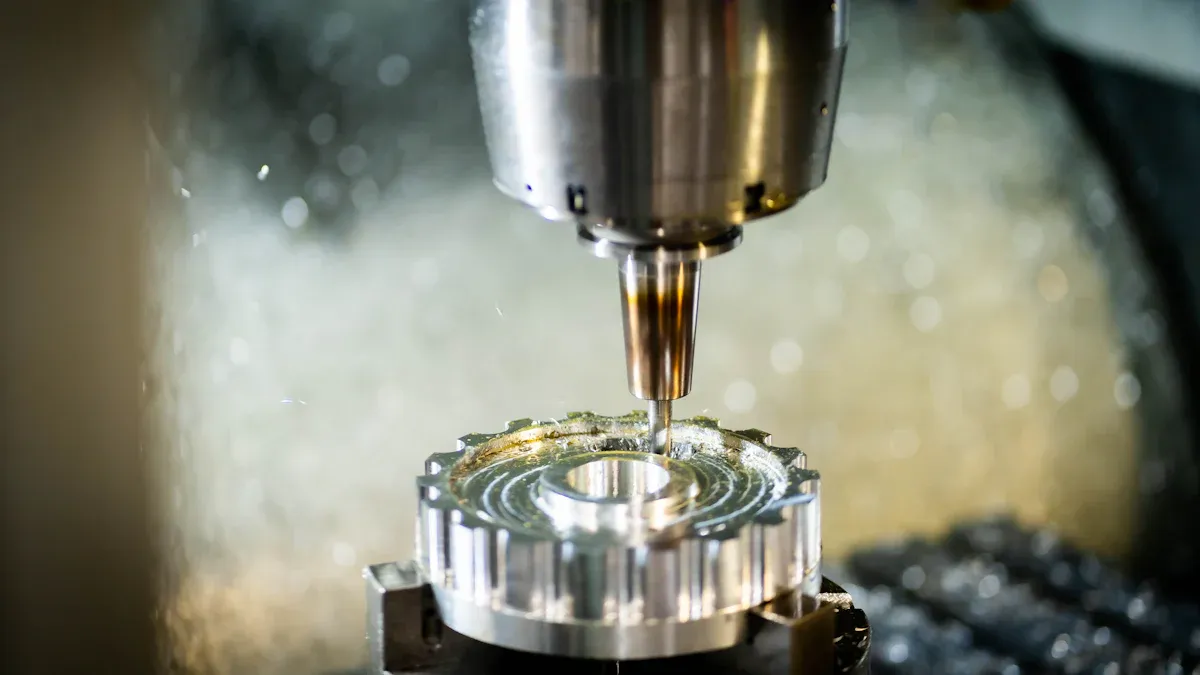

CNC Milling Machines

CNC milling machines use spinning tools to cut materials. The material stays still while the tool moves. These machines create detailed shapes and designs. They are faster and more accurate than older milling methods.

Advantages of CNC milling:

Automation: Machines work on their own, reducing human mistakes.

Speed and Accuracy: They produce items quickly and with great precision.

Tool Efficiency: Fewer tools are needed, making the process simpler.

Year | Market Size (USD Billion) | CAGR (%) |

|---|---|---|

2024 | N/A | |

2025 | 101.22 | N/A |

2032 | 195.59 | 9.9 |

CNC milling machines are used in electronics, medical devices, and prototypes where precision matters.

CNC Drilling Machines

CNC drilling machines make exact holes in materials. They are great for tasks needing accuracy and repeatability, like electronics and aerospace parts.

Benefits of CNC drilling:

High Precision: They drill holes within ±0.005 inches for perfect results.

Efficiency: These machines work faster than manual drilling, saving time.

Reduced Waste: Accurate drilling uses less material, cutting costs.

Repeatability: They make identical parts for reliable mass production.

CNC drilling machines are key for industries needing consistent quality and large-scale production.

CNC Grinding Machines

CNC grinding machines are used to make surfaces very smooth. They use abrasive wheels to remove material carefully. These machines are perfect for jobs needing high accuracy.

Why CNC Grinding Machines Matter

Industries like aerospace and automotive need these machines for quality work. Complex car parts and airplane pieces require precise grinding. Many manufacturers now use CNC grinding machines to improve accuracy and speed.

Key Benefits of CNC Grinding Machines

Unmatched Precision: They create finishes with tolerances as tight as ±0.0001 inches.

Versatility: These machines work on metals, ceramics, and composites.

Automation: They reduce mistakes by working without much human help.

Efficiency: Faster grinding saves time and reduces wasted materials.

Key Points | Description |

|---|---|

Demand for Precision Engineering | Aerospace and automotive need smooth, high-quality finishes. |

Growth in Grinding Machinery Market | More demand for precision drives the market forward. |

Importance of High-Precision Grinding | Tight tolerances need advanced grinding tools. |

Investment in Superior Technologies | Companies use CNC grinders for better results. |

CNC grinding machines are important for industries needing accuracy and speed. If you want perfect parts, these machines will improve your production.

Specialized CNC Tools (EDM, Laser Cutting, Waterjet Cutting, Plasma Cutting)

Specialized CNC tools help with unique manufacturing tasks. They cut, shape, and machine materials that older methods cannot handle.

EDM (Electrical Discharge Machining)

EDM uses electric sparks to remove material. It works well for detailed designs and tough materials. You can use it for molds and airplane parts. EDM is great for working with conductive materials.

Laser Cutting

Laser cutting uses focused light to cut materials very precisely. It works best on thin metals, plastics, and composites. If you need clean edges, laser cutting is a good choice.

Waterjet Cutting

Waterjet cutting uses high-pressure water with abrasives to cut materials. It is great for heat-sensitive items like glass, rubber, and stone. This method avoids heat damage and is good for delicate jobs.

Plasma Cutting

Plasma cutting uses ionized gas to cut metals like steel and aluminum. It is fast and works well for big projects. If you need to cut thick metals quickly, plasma cutting is ideal.

Each specialized CNC tool has its own strengths. Knowing what they do helps you pick the right one for your needs.

Applications of CNC Machine Tools

CNC machine tools are used in many industries. They help make products with precision, save time, and allow large-scale production. Below are examples of how CNC machines are used in different fields.

Automotive Industry

CNC machines are very important in making car parts. They create accurate items like engine blocks, transmission parts, and brake systems. CNC milling and turning ensure parts fit perfectly, which is needed for cars to work well.

Advantage | CNC Machining | Conventional Methods |

|---|---|---|

Precision | Removes material accurately, lowering mistakes and rework. | Less accurate, causing more defects. |

Cost-Effectiveness | Saves money over time as production grows. | Cheaper at first but costs more later due to waste. |

Waste Reduction | Uses less material, helping the environment. | Wastes more material because it’s less precise. |

Car makers use CNC machines to make custom and high-quality parts. Automation lowers labor costs and speeds up production. This makes CNC machining a key part of modern car manufacturing.

Aerospace Industry

The aerospace field depends on CNC machines for safe and high-quality parts. CNC milling makes complex items like turbine blades, landing gear, and flight control systems. These parts need to be very accurate to work safely and properly.

Engine Turbine Blades: CNC machines make blades exact and check for hidden flaws.

Landing Gear Components: Quality checks ensure the parts are strong and the right size.

Flight Control System Parts: CNC tools meet strict safety rules by making precise parts.

CNC machines also help make lighter parts, which save fuel and carry more weight. Using real-time monitoring, aerospace companies can spot problems early and improve production.

Medical Device Manufacturing

CNC machines are crucial for making medical devices with detailed designs. They create items like implants, surgical tools, and prosthetics with great accuracy. These machines make sure the devices are strong and work well for a long time.

CNC tools reduce mistakes, lowering risks of device failure.

Following ISO 13485 ensures devices meet strict safety and quality rules.

Multi-axis CNC milling makes implants fit better, helping patients recover faster.

Evidence Type | Description |

|---|---|

Material Selection | Special plastics like PEEK are used for safe implants. |

Advanced Manufacturing Techniques | CNC machines make parts with tiny tolerances, important for medical tools. |

Regulatory Compliance | Meeting FDA and ISO rules ensures safe and high-quality devices. |

CNC machines also check parts during production to keep them consistent and defect-free. Their ability to follow strict rules makes them essential for making medical devices.

Prototyping and Product Development

CNC machines are important for making prototypes and new products. They help turn ideas into real models quickly. This speed is vital in industries where being first matters.

Tip: Quick prototypes let you test and improve designs faster, ensuring the final product is perfect.

Benefits of CNC machines for prototyping:

They make working prototypes faster than older methods.

High-speed machining saves time and lowers costs.

Modern tools switch quickly, saving time without losing accuracy.

3D printing adds flexibility, allowing quick changes to designs.

Using these tools makes product development faster and easier. Rapid tooling shortens waiting times, helping you launch products sooner. This saves time and increases profits. Whether for gadgets or machines, CNC tools make sure prototypes are precise and ready for production.

Electronics and Semiconductor Industry

The electronics industry depends on CNC machines for precise work. As devices get smaller and more complex, accuracy becomes more important. CNC tools meet these needs, making them essential in this field.

Electronics cover many products, including semiconductors. Smaller, more detailed designs need CNC machines. These tools create precise parts like chips, circuit boards, and connectors.

Note: CNC machines provide consistent results, which is key for mass production in electronics.

Why CNC machines are crucial here:

They make detailed parts with exact measurements for proper function.

Automation reduces mistakes, improving quality and reliability.

Fast machining speeds up production to meet tight schedules.

The semiconductor market is very competitive, so efficiency is critical. CNC machines help deliver top-quality products quickly. These tools are widely used in manufacturing, showing their importance across industries.

Selection Criteria for CNC Machine Tools

Picking the right CNC tools is very important. It helps ensure precision, speed, and long-lasting performance. You need to think about material type, tool shape, size, and coatings. Knowing these things helps you improve machining and meet your goals.

Material Compatibility

The material you work with is a key factor. It decides what tools and methods you should use. For example, hard materials like steel need strong tools. Softer materials like aluminum need tools that cut faster.

Description | |

|---|---|

Workpiece Material | The material affects tool choice and machining method. |

Tool Materials | Tools must match the material being processed. |

Impact Resistance | Tools should handle vibrations during cutting. |

Wear Resistance | Tools must resist wear for high-speed cutting. |

For heat-sensitive materials, waterjet cutters are a good choice. They avoid heat damage. Tough alloys work best with carbide-tipped tools. These tools last longer and keep their shape.

Tip: Always match the tool to the material for better results.

Tool Geometry and Size

The shape and size of tools affect how well they work. Things like the angle, tip size, and grooves matter. Adjusting these can improve cutting and surface quality.

Changing the angle improved surface finish by 25% in tests.

Bigger tool tips reduced roughness by 15%.

Carbide tools worked 35% better at high speeds.

Four-fluted carbide tools are great for milling. They spread out stress, last longer, and work faster.

Note: Picking the right size tool prevents breakage and ensures accuracy.

Coatings and Durability

Coatings make tools last longer and work better. Special coatings like Titanium Nitride (TiN) and Titanium Aluminum Nitride (TiAlN) protect tools from heat and wear.

Coatings lower friction and improve surface quality.

They handle high heat and heavy use, making them reliable.

Coated tools last longer, saving time and money.

Tool/Method | Description |

|---|---|

QC20 Ballbar | Checks for tool alignment and smooth motion. |

Laser Interferometers | Measures movements precisely for better positioning. |

Tool Presetter Machines | Measures tool size before use for accurate machining. |

Choose tools with coatings that fit your needs. TiAlN coatings are great for fast milling. CrN coatings are good for resisting rust.

Callout: Coated tools save money by lasting longer and needing fewer replacements.

Operational Requirements (Speed, Precision, and Capacity)

Choosing the right CNC tools means knowing what your work needs. Things like speed, precision, and capacity affect how well the machine works. These factors decide how fast and accurate your production will be.

Important Metrics to Check Machine Performance

To get good results, you need to check certain numbers. These help you see if the machine is doing its job well:

Cutting Speed: Shows how fast the cutter works. Faster speeds save time but must suit the material.

Feed Rate: Tells how quickly the cutter moves toward the material. Higher rates make work faster but can affect smoothness.

Material Removal Rate (MRR): Measures how much material is cut each minute. Higher MRR means better efficiency.

Tool Wear: Tracks how quickly tools wear out. Worn tools lower accuracy and cost more.

Revolutions Per Minute (RPM): Counts how fast the spindle spins. Right RPM avoids tool damage and keeps cutting smooth.

Rejection Rate: Shows how many parts fail quality checks. Lower rates mean better accuracy.

Overall Equipment Efficiency (OEE): Combines machine speed, quality, and uptime to measure productivity.

Power Consumption: Tracks energy use to check efficiency.

Cost per Part: Compares the cost of making each item to see savings.

Tip: Watch these numbers often to keep machines working well and accurately.

Finding the Right Balance Between Speed and Precision

Balancing speed and precision is very important. Fast machines make more items but can lose accuracy. Using smart CNC tools with live tracking helps keep quality high even at fast speeds. This way, you get good results without slowing down.

Thinking About Capacity

Capacity means how much work a machine can handle. Bigger machines can make more items, which is great for large orders. But pushing a machine too hard can wear it out and lower accuracy. Always match the machine’s size to your workload to avoid problems.

Budget and Maintenance Considerations

CNC machines cost a lot, so planning for both buying and upkeep is key. A smart budget and care plan save money and keep machines running well.

Comparing Maintenance Types

Taking care of CNC machines helps them last longer. Two main ways are preventive and reactive maintenance. Here’s how they differ:

Aspect | Reactive Maintenance | |

|---|---|---|

Resource Use | Fixes problems early to save resources | Uses more resources during emergencies |

Scheduling | Keeps machines reliable for better planning | Can mess up plans due to sudden breakdowns |

Safety Rules | Meets strict industry safety standards | May fail to meet safety rules in some cases |

Cost | Costs more upfront but saves money later | Costs more over time due to surprise issues |

Strategy | Regular checks and fixes | Fixes only when problems happen |

Technology | Uses smart tools for better care | May lack organized data for fixes |

Callout: Preventive care costs more at first but avoids big problems later, saving time and money.

Benefits of Predictive Maintenance

Predictive care uses smart tools to spot problems early. This reduces downtime and repair costs. For example:

Sensors warn you when tools are wearing out.

Live data lets you plan fixes without stopping work.

Predictive systems keep quality high by avoiding errors.

Planning for CNC Automation Costs

Adding automation to CNC machines boosts speed and lowers costs. Automation tools make work smoother, reduce mistakes, and cut labor costs. Simulation software also helps avoid crashes and saves money.

Note: Automation costs more at first but saves money over time by improving efficiency.

Smart Ways to Save on Maintenance

To keep costs low, try these tips:

Check machines often to catch problems early.

Use strong tools and coatings to make them last longer.

Train workers to handle machines better and avoid mistakes.

These steps help keep machines working well while staying within your budget.

CNC machine tools are crucial for modern manufacturing. They help make precise parts quickly and with less waste. These tools, like CNC turning machines and laser cutters, handle different tasks. They are used in industries such as cars, airplanes, medical devices, and electronics.

New improvements make them better for the environment. Adjusting settings can lower pollution and save energy. For example, CNC machines made breathing aids during COVID-19 and created new surgical tools. These examples show how CNC tools help many industries.

Choosing the right CNC tools is important. It ensures they work well with materials and save money. Learning about CNC tools can improve your production, meet industry needs, and support eco-friendly practices.

FAQ

What makes CNC machines better than older methods?

CNC machines are faster and more accurate. They work automatically, which lowers mistakes and waste. This helps make high-quality parts quickly and in large amounts.

Can CNC machines work with different materials?

Yes, CNC machines can cut metals, plastics, wood, and more. But you need the right tools and settings for each material type.

How do CNC machines make factories more efficient?

CNC machines run nonstop with little help. They save time, make fewer mistakes, and let you check progress live. This means faster work and better results.

Are CNC machines good for small companies?

Yes, small businesses can use CNC machines to improve quality and save money. Cheaper models are easy to use and help grow your business.

How often should CNC machines be checked?

You should check CNC machines regularly. Do weekly or monthly checks based on how much you use them. Smart tools can find problems early to keep them running smoothly.

Start your project with LKprototype

LKprototype company simplifies procurement for custom manufacturing, Suitable for making your products or prototypes with a variety of materials, such as metal or plastic, silicone rubber, from 3D Printing to CNC Machined Parts and Urethane Casting Service , with a focus on speed and efficiency. Our platform provides instant quotes. With LKprototype, You can connect with the team to communicate your project to ensure quality and on-time delivery.

Start with an instant quote and experience how our technology and expertise can make custom part procurement faster and easier.

LKprototype

LKprototype