Looking for ideas on what CNC machine products you can create and sell? The rise of affordable CNC machines has democratized the ability to produce custom items for small businesses and hobbyists. This article highlights the top 30 items, from custom signs and phone cases to jewelry and spare parts, showcasing the wide range of possibilities CNC technology offers.

Key Takeaways

CNC machining offers vast customization options for various products, such as custom signs, phone cases, and key holders, allowing businesses to cater to diverse customer preferences.

High-quality materials and precise manufacturing enable CNC-created items like toys, jewelry, and lampshades to combine aesthetic appeal with functionality, enhancing their marketability.

Niche markets, such as car emblems and tactical survival tools, present unique opportunities for CNC product creators to attract dedicated customer bases through tailored products.

Custom Signs

CNC machining presents a great opportunity for crafting custom signs, an ideal product for displaying distinctive names, emblems, or messages. These products are in high demand for both individual and commercial purposes due to their versatility. By using robust materials such as metal and acrylic, the signs can withstand outdoor conditions and maintain longevity under various weather influences. The meticulous nature of CNC technology facilitates the production of intricate designs that can be customized to align with the specific marketing requirements of companies, ensuring each sign is a remarkable display piece.

The range of customization possibilities extends through different typefaces, hues, and surface finishes. This breadth allows you to meet diverse customer tastes whether they prefer a clean contemporary style or something more elaborately traditional.

Visualize your clientele’s satisfaction upon receiving a meticulously crafted sign that uniquely reflects their desired aesthetic. With proper tools and precise design files at your disposal via CNC machining techniques, creativity is essentially boundless in what you can produce.

Phone Cases

In today’s era of ubiquitous smartphones, there is a thriving demand for individualized phone cases. The application of CNC technology facilitates the manufacturing of these accessories with distinctive textures and emblems, providing an element of customization that off-the-shelf cases simply lack. Not only are they visually attractive, but they are also robust. They’re made from high-quality materials designed to endure the rigors of everyday use. Thanks to the precision inherent in CNC machining, each case is tailored to fit any model flawlessly, making them highly adaptable and desirable to a wide-ranging consumer base.

The personalization phase can incorporate complex carvings and original patterns which serve to elevate the unique charm found within each piece. From simple silhouettes to elaborate artistry, there exists a range of design options for CNC-crafted phone cases suited for various preferences.

These tailor-made products can be paired with other items produced through CNC methods such as mobile device stands or storage containers that together form elegant matching collections. Offering singular artifacts not only aids you in vending your collection, but distinguishes you within a saturated market place—thereby drawing more patrons towards your offerings.

Key Holders

With the use of CNC machining, key holders can be elevated from mundane items to functional and fashionable attachments. The flexibility in working with a variety of materials such as metals, plastics, and glass allows for the creation of robust and aesthetically pleasing key holders. By incorporating added functionalities like bottle openers or personalized engravings, they become even more distinctive.

Given that most available key holders lack flair, there is an excellent chance to inject innovation and exclusive patterns into the market. Regardless if you are running your own machine shop or engaged in machining as a pastime enthusiast, CNC technology simplifies the production process for bespoke key holders that capture attention.

Targeting specific interest groups like automobile enthusiasts or individuals who appreciate belt-mounted accessories offers access to a constant influx of potential clients eager for these unique products. This focused approach has proven effective at fostering sustained growth in sales figures within this niche market segment.

Phone Stands

CNC machines enable the production of phone stands that are not only practical but also highly customizable. These stands serve the essential purpose of securing a phone and providing an optimal viewing angle, making them indispensable in both domestic and office environments. Through CNC machining, it’s possible to fabricate these accessories from diverse materials like wood or metal while customizing their dimensions to accommodate different models and designs of phones.

Some phone stands crafted using CNC technology incorporate features such as amplification for added utility and desirability. The precision afforded by CNC allows for the creation of elaborate patterns, resulting in distinctive pieces tailored to suit individual preferences and requirements. Whether customers prefer a minimalist contemporary look or something more elaborately classic, CNC-machined phone stands can enhance any space with sophistication—and they make excellent presents too.

Item Organizers

Organizers for items are essential tools that help people streamline their environment and neatly arrange their possessions. Through CNC technology, these organizers can be specifically fashioned to accommodate a variety of objects such as personal accessories, office supplies, or tools. The personalized nature of these storage solutions not only optimizes the use of space, but also elevates the aesthetic appearance of the area where they are used.

Incorporating item organizers into one’s daily life can remarkably diminish the time dedicated to locating belongings, thus fostering a more productive and serene atmosphere. Organizers crafted using CNC machining are devised with thoughtful layouts that simplify both locating and reaching for specific items with ease.

By delivering unique designs coupled with premium materials in manufacturing these item organizers, it is possible to provide distinctive products tailored for niche markets and fulfill precise consumer requirements.

Portraits

CNC machines craft more than mere images. They produce exquisite pieces of art. Whether capturing the essence of human subjects or crafting abstract forms, portraits created using CNC are distinguished by their extraordinary precision and distinctive allure. Beginning with an elegant blueprint, these designs are meticulously realized through the artistry of CNC machining, culminating in a sophisticated and standout work that can serve as a centerpiece in any space.

The capacity for producing elaborate and intricate shapes allows each portrait to embody a singular design that caters to individual customer preferences. Leveraging computer numerical control technology grants access to levels of intricacy and personalization previously unattainable via conventional artistic techniques, opening possibilities ranging from personalized family mementos to bespoke abstract creations.

Whether treasured as sentimental heirlooms or displayed as bold decorative elements, these portraits offer invaluable enhancement for both residential and professional environments.

Car Emblems

Vehicle badges represent a specialized market with considerable opportunities for customization and individual expression. CNC machining enables the production of bespoke designs, encompassing everything from custom logos to images, phrases, and taglines that can either augment or substitute standard vehicle emblems. This holds particular attraction for car owners interested in preserving their vehicle’s visual appeal or infusing it with personal flair.

By venturing into the tailored automobile badge sector, you have the chance to serve auto enthusiasts who are passionate about customizing their rides. Offering distinctive, customized creations provides an array of products that not only captures attention but also cultivates a loyal clientele.

Leveraging top-notch substances and meticulous craftsmanship processes, emblems produced through CNC machining can significantly elevate any automobile’s appearance.

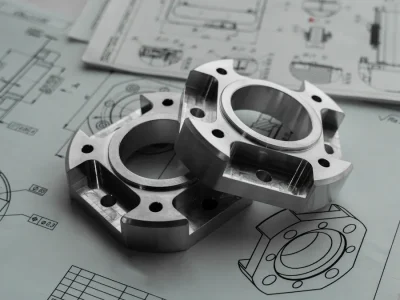

Spare CNC Machine Parts

Maintaining a supply of spare parts for CNC machines is essential to preserve operational effectiveness and reduce the likelihood of prolonged machine inactivity. Companies often keep an inventory of these components on hand so that they can swiftly address any malfunctions that arise, thus preventing interruptions to their manufacturing processes. Consistent upkeep and the prompt substitution of worn-out parts play a significant role in improving both the dependability and the lifespan of CNC equipment.

Parts such as chucks, control panels, and coolant systems are among those frequently replaced due to their importance in upholding CNC machine performance. Providing access to premium quality spare parts enables companies to maintain seamless operation within their CNC tasks. This approach helps mitigate potential downtime while also boosting the accuracy and precision capabilities inherent in machining activities.

Custom Engravings

Customized engravings imbue an array of items, from home furnishings to paper products, with a distinctive flair. The application of CNC techniques facilitates the engraving process on diverse substrates such as wood, metal, and glass. This adaptability makes it ideal for adding unique touches like individual designs or personal inscriptions that increase the emotional significance of these pieces.

The capacity to engineer intricate patterns with exceptional precision ensures that each engraved piece can be customized according to client specifications. These personalized details are perfect for momentous events like weddings or anniversaries as well as day-to-day objects including kitchenware and hand tools, allowing them to stand out with distinctiveness.

By providing services in bespoke engraving, businesses tap into the market segment craving gifts that carry deeper meanings and possess singular appeal.

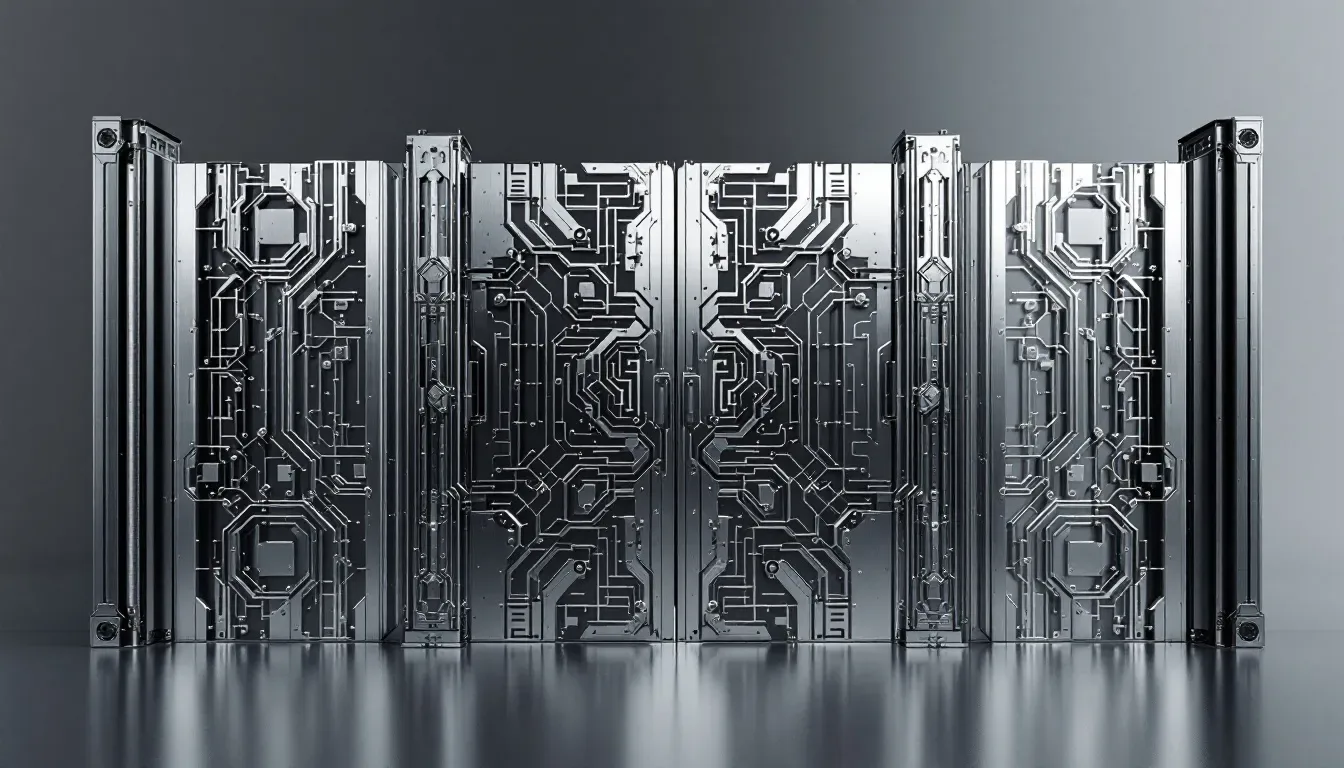

Decorative Fences and Gates

CNC machining facilitates the production of decorative fences and gates that not only serve a practical purpose but also elevate the visual attractiveness of a property. This technology enables the crafting of exquisite designs with detailed patterns, merging both aesthetic charm and enhanced security. Utilizing materials of superior quality assures that these structures are sturdy and capable of withstanding corrosion, thus maintaining their protective function and design appeal over time.

Ornamental gates crafted through CNC processes can markedly boost the curb appeal while simultaneously offering formidable protection for any property. The adaptability in customization provided by CNC machining allows for precise adjustments to be made according to particular measurements and desired aesthetics, meeting diverse architectural requirements. Such personalized service ensures unique and elaborate designs are available for clients who desire an amalgamation of heightened safety measures along with upgraded aesthetic value on their premises.

Lampshades

CNC technology is capable of elevating ordinary lighting fixtures into extraordinary decorative elements. By employing materials such as wood and metal, CNC machines are adept at carving out distinctive and complex patterns that infuse a custom flair into any interior space. The process offers numerous customization options, including varying shapes and bespoke engravings, providing ample scope for individual expression.

Thanks to the exactitude afforded by CNC machining processes, it’s possible to produce lampshades with ornamental designs that not only look appealing but also serve their purpose well. Whether your preference leans towards sleek, contemporary styles or you favor more intricate and embellished looks, lampshades fashioned through CNC techniques can be tailored to suit an array of aesthetic preferences. These singular creations are sought-after for their ability to transform the atmosphere within a living environment, thereby making them favored selections in home decoration trends.

Stamps

CNC machining plays a critical role in manufacturing stamps that are both precise and robust, which is vital for businesses and personal users alike. The swift production of intricate designs afforded by CNC-machined stamps renders them an important commodity on the market.

These stamps serve various purposes, from corporate branding to individual usage, satisfying a broad spectrum of requirements and tastes.

Gift Boxes

Utilizing CNC technology, storage boxes are crafted to add an opulent flair to any gift-giving occasion. Crafted from a variety of materials including wood, acrylic, or metal, these boxes boast intricate designs that elevate their suitability for bespoke presents. They effortlessly combine practicality and aesthetics by serving as both storage solutions and ornamental objects which enhance the overall value beyond just the initial gifting moment.

For those seeking a personalized touch, options such as engraving names, dates or heartfelt messages onto these materials is available – transforming each box into a distinct keepsake perfect for commemorating life’s milestone events like weddings and anniversaries.

Once the contents have been revealed, these exquisitely constructed containers continue their usefulness as decorative storage units – offering lasting functionality while maintaining their charm.

Nutcrackers

Crafted using CNC machines, nutcrackers not only serve their functional purpose, but also offer an aesthetic appeal. They can be tailored to align with diverse themes, which allows them to cater to a broad spectrum of consumers for numerous events.

CNC machining’s accuracy guarantees uniformity in quality and intricacy across these pieces, thereby elevating their decorative and practical worth.

Rolling Pins

CNC machining transforms ordinary kitchen rolling pins into exquisite pieces of art. These essential baking tools, typically crafted from wood through CNC methods, can be adorned with complex patterns ranging from floral motifs and geometric configurations to festive designs suited for celebratory events or as thoughtful presents. The high level of accuracy provided by CNC machine tools significantly elevates the quality of these items.

Employing the precision inherent in CNC machining techniques guarantees that every rolling pin meets stringent standards, ensuring uniform excellence and utility. Whether utilized for culinary purposes or displayed as an ornamental object, rolling pins produced via CNC offer a harmonious fusion of functionality and aesthetic appeal that is sure to enhance any culinary space.

Toys

The advent of CNC technology has markedly transformed the toy industry, making it possible to produce toys with complex and robust designs. With this advancement, an array of playthings including fidget spinners and spinning tops have seen a surge in quality and design complexity. It extends. To intricate miniature vehicles and dollhouses which are not only visually appealing but also constructed to endure vigorous usage, offering longevity that surpasses traditional toys.

A key benefit derived from utilizing CNC machining is its capacity for creating bespoke toys designed according to individual tastes. Such personalization can manifest in distinct patterns, vibrant colors, or exclusive designs that render each toy a one-of-a-kind creation. The unparalleled precision inherent in CNC processes ensures enhanced performance characteristics for certain products like fidget spinners—resulting in prolonged spinning durations and improved equilibrium—which boosts both their practical utility and their desirability as fun objects.

Wall Tiles

Utilizing CNC technology to fabricate wall tiles presents an economical solution for elevating the aesthetic appeal of diverse environments. These versatile tiles can be applied to enhance floors, walls, or even desks and come in a multitude of sizes, hues, and motifs due to the flexibility offered by CNC machining. This method accommodates varying tastes and interior design demands.

The installation process of these CNC-machined wall tiles is notably straightforward. They are frequently designed with interlocking features that allow them to be set up effortlessly using simple tools. Consequently, this convenience broadens their appeal among various consumer demographics. The precision of CNC machines enables the production of elaborate and distinctive designs for each tile piece—effectively transforming them into individual artistic expressions that contribute a unique flair within any room they adorn.

Jewelry and Accessories

CNC machining presents an excellent opportunity for the crafting of jewelry and accessories due to its high precision and ability to be customized. The technology is adept at generating complex designs on items such as rings, bracelets, earrings, and necklaces, which might prove challenging when done manually. This aspect fosters inventiveness within the fashion industry by facilitating the creation of distinctive pieces.

CNC machined jewelry offers a personalization feature that can engrave special names, dates or elaborate patterns onto these wearable art pieces. It holds great appeal for consumers who are in search of memorable gifts with sentimental value. CNC machining contributes to efficient mass production while maintaining consistent quality across all identical items produced.

Employing precious materials like gold and silver in conjunction with CNC machining not only guarantees precise detailing but also delivers an elevated finish that significantly improves the aesthetic appeal of each piece.

Phone Amplifiers

Phone amplifiers that have been CNC machined offer practicality and visual appeal. As passive devices, they enhance audio without needing any electrical power, providing an environmentally friendly choice for sound amplification. The use of CNC machinery ensures exact carving of the acoustic cone to achieve superior sound fidelity.

These amplifiers are fashioned out of materials such as laminated wood and double as ornamental elements that improve the aesthetic value of a room or area.

Minimalist Wallets

Minimalist wallets are crafted to securely store money, identification cards, and bank cards while epitomizing a slim and unobtrusive design. The employment of CNC technology allows for the production of robust wallets that can feature personalized patterns and unique opening mechanisms tailored to individual preferences. The meticulousness afforded by CNC machining guarantees that each wallet meets precise measurements, ensuring they serve their purpose with an aesthetically pleasing appearance.

These minimalist wallets utilize premium materials which ensure longevity, perfectly marrying resilience with sophistication in their construction. Whether opting for a subdued and refined look or desiring intricately patterned options, customers find favor in CNC-machined minimalist wallets due to their ability to accommodate diverse fashion tastes without compromising on practicality.

Bike Pedals

The precision customization of bike pedals is made possible through CNC machining, which caters specifically to the demands of cyclists. This method translates CAD designs into G-code to achieve precise manufacturing and ensure superior quality in the finished product. Depending on what’s needed for a given design, various materials such as die-cast aluminum or molded nylon can be used to make these bike pedals.

Throughout production, rigorous quality control measures are taken including sample testing to guarantee that all products meet the required specifications and tolerance levels. This meticulous process ensures that every pedal is both durable and dependable. As part of this careful attention to detail, axles and bearings are fitted during final assembly so that each set of pedals stands ready for immediate use.

Cyclists who are passionate about enhancing their performance will find great appeal in customized bike pedals crafted with high-quality standards. These specially tailored components promise an improved riding experience by meeting individual needs with precision-made equipment.

Coasters

Even a seemingly straightforward item like coasters can be transformed into both ornamental and practical pieces through the use of CNC machining. Employing common materials such as wood, stone, and acrylic that are amenable to CNC processes, it’s possible to produce coasters adorned with elaborate patterns tailored to various themes and special events. These aren’t merely utilitarian. They also enhance the visual appeal.

CNC machining brings an unparalleled level of uniformity in terms of dimension and contour for each coaster, resulting in a superior caliber product distinguished from ordinary ones. Ideal for personal enjoyment or as sophisticated presents, these precision-crafted coasters provide an element of refinement on any dining table setup and have become sought-after by those seeking distinctive and fashionable domestic embellishments.

Interior Decorations

CNC technology elevates interior spaces by producing visually captivating and practical decorations. The precision of CNC machines facilitates the crafting of distinct items ranging from detailed wall art to bespoke furniture pieces, infusing modern interiors with a unique flair. Such decorations can become central highlights in any room, reflecting an individual’s taste.

CNC-machined decor leverages diverse materials such as wood, metal, and reclaimed resources to suit different aesthetic inclinations and design needs. These sustainably fashioned elements appeal particularly to those who prioritize ecological responsibility within their interior designs.

By delivering custom-made, superior quality interior ornaments, businesses can attract clientele looking for distinctive and tailor-made accents that personalise their living environments.

Board Games

Utilizing CNC technology can significantly enhance the board game industry by allowing for the production of distinctive and complex pieces that capture attention. These bespoke elements not only increase a game’s appeal among collectors, but also motivate aficionados to acquire customized items. By employing precision machining, unique boards and parts are fabricated which bring an individual flair while enriching gameplay quality. Delving into various CNC project ideas could lead to groundbreaking designs and advances in board game development.

Incorporating creative design concepts in creating board games piques interest among hobbyists, guaranteeing each set is as aesthetically pleasing as it is playable. The meticulous nature of CNC ensures uniformity in manufacturing, providing gamers with components that consistently fulfill their high expectations.

By supplying personalized gaming sets within this niche market, you cater to consumers seeking out exclusive products—a strategy that distinguishes your offerings from mainstream competitors’ selections.

Lighters

CNC machining is employed to create elegant lighters that boast both customizable shapes and ornamental features, captivating the interest of collectors as well as those who use them regularly. This advanced manufacturing technique employs a range of intricate machining processes along with various tools, which results in high-quality and robust products. An exemplar product such as the XO LIGHTER MINI showcases an industrial look complete with distinctive textured tool marks and visible machining grooves, making it a fashionable yet practical item.

Such lighters are prime candidates for being promoted as collector’s items due to their exceptional designs coupled with superior manufacturing standards. By providing meticulously crafted lighters, businesses can cater to clients who prioritize both utility and aesthetic value in their everyday implements.

Ashtrays

Ashtrays aren’t solely utilitarian. They can double as ornamental elements that improve the ambiance of a room. The advent of CNC technology facilitates the production of innovative designs, rendering each ashtray distinct and attractive.

By employing materials such as epoxy resin and ceramic, it is possible to produce artistic ashtrays that align with diverse decorative themes, ranging from vintage to contemporary styles.

Tactical Survival Tools

Outdoor adventurers value tactical survival tools for their adaptability and utility in different scenarios. The use of CNC technology facilitates the production of multi-tools and knives tailored to meet the requirements of these explorers, allowing for bespoke designs with enhanced functionality. Such tools are customizable to align with each user’s particular needs, ensuring that every item is distinctively suited for its intended purpose.

CNC-machined examples like Swiss army knives and various combination tools merge practicality with personalization opportunities. Providing top-notch, made-to-order survival gear appeals to consumers looking for reliable and multifaceted equipment suitable for outdoor excursions.

Flashlights

CNC machining is key in producing sturdy and practical flashlight designs that are indispensable for numerous outdoor pursuits. Flashlights crafted through CNC technology benefit from casings that are both waterproof and resistant to impacts, ensuring their dependability in severe conditions. The incorporation of LED technology allows these flashlights to be not only energy-efficient but also compact while delivering bright light with extensive duration.

The advancement of CNC techniques facilitates the development of ergonomic flashlight designs that enhance user experience by simplifying handling. By presenting advanced flashlights imbued with cutting edge technology, manufacturers can meet the demands of consumers who prioritize dependable and effective lighting tools for their outdoor escapades.

Salt and Pepper Shakers

CNC machines are employed to produce salt and pepper shakers that serve as both practical tools and ornamental pieces. These machines have the capability of carving detailed patterns into various materials like wood and metal, elevating the visual charm of these commonplace kitchen accessories. They can be personalized with distinctive touches such as engraved names or initials, giving each set its own exclusive identity.

Thanks to the exactitude afforded by CNC machining, each salt and pepper shaker maintains uniformity in dimensions and contour, resulting in a superior standard item that becomes a focal point on any dining table. The allure of bespoke artistic designs for these condiment holders makes them particularly appealing to consumers looking for items that combine style with utility in their kitchens.

Guitar Bodies

CNC technology facilitates the crafting of complex designs for guitar bodies, meeting the demands of musicians in search of custom-made instruments. The accuracy inherent in CNC machining guarantees meticulous carving and profiling of guitar bodies, which improves ergonomic features and elevates playing comfort.

By employing various wood types, tailor-made guitar bodies can attain an exclusive visual charm and acoustic quality, rendering them greatly appealing to artists who prioritize a signature tone and style.

Summary

The versatility and precision of CNC machining open up endless possibilities for creating unique and high-quality products. From personalized phone cases and custom car emblems to intricate jewelry and functional survival tools, CNC technology allows for the creation of items that cater to a wide range of markets and preferences. By exploring these CNC project ideas, you can tap into growing markets and meet the demand for customized and high-quality products. The journey of turning raw materials into beautiful and functional items is both exciting and rewarding, offering endless opportunities for creativity and innovation.

Frequently Asked Questions

What materials can be used in CNC machining for these products?

CNC machining can work with metals, plastics, wood, and composites, providing flexibility for diverse product customization. This versatility ensures you can achieve the desired specifications for your project.

How precise is CNC machining for creating intricate designs?

The process of CNC machining is exceptionally precise and reliable, which makes it an ideal choice for creating complex designs with a consistent level of quality. Its precision guarantees that projects with detailed requirements are carried out accurately.

Can CNC-machined products be customized to individual preferences?

Yes, CNC technology enables extensive customization, allowing for personalized engravings, unique patterns, and tailored designs to meet individual preferences.

What industries benefit from CNC machining?

Industries such as automotive, aerospace, medical devices, consumer electronics, and industrial equipment experience the advantages of CNC machining through its ability to deliver both high efficiency and precision.

In these sectors, this technology is vital for boosting productivity and elevating the quality of products.

How quickly can CNC-machined products be produced?

CNC-machined products can be produced in as little as one day, depending on the design complexity and material availability.

This capability allows for rapid prototyping and efficient production timelines.

Introduction to CNC Machining

CNC machining, or Computer Numerical Control machining, is a cutting-edge manufacturing process that leverages computerized controls to guide the movement of cutting tools and machinery. This technology allows for the precise and efficient production of complex parts and components, making it a cornerstone in modern manufacturing. Whether you’re crafting intricate jewelry or robust automotive parts, CNC machining offers unparalleled accuracy and versatility.

What is CNC Machining?

At its core, CNC machining involves the use of computer software to control machine tools. These tools can include lathes, mills, routers, and grinders, among others. The process begins with a digital design, often created using CAD (Computer-Aided Design) software. This design is then converted into a set of instructions, known as G-code, which the CNC machine follows to execute precise cuts and movements.

The beauty of CNC machining lies in its ability to produce highly intricate designs with consistent quality. This technology is widely used across various industries, including aerospace, automotive, electronics, and healthcare, to manufacture high-quality products that meet stringent specifications. From creating intricate patterns on jewelry to producing critical components for aircraft, CNC machining is a versatile and indispensable tool in modern manufacturing.

Benefits of CNC Machining

CNC machining offers a multitude of benefits that make it a preferred choice for manufacturers. One of the most significant advantages is its precision. CNC machines can produce parts with extremely tight tolerances, ensuring that each piece meets exact specifications. This level of accuracy is particularly crucial in industries like aerospace and medical devices, where even the smallest deviation can have serious consequences.

Another key benefit is efficiency. CNC machines can operate continuously, 24/7, without the need for breaks. This capability significantly boosts production rates and reduces lead times. Additionally, CNC machining minimizes the need for manual labor, which not only cuts down on labor costs but also reduces the risk of human error.

CNC machining is also highly versatile, capable of working with a wide range of materials, including metals, plastics, and composites. This flexibility allows manufacturers to choose the best material for their specific application, whether it’s a lightweight plastic for consumer electronics or a durable metal for automotive parts. Overall, CNC machining is a cost-effective and efficient manufacturing process that delivers high-quality results.

Starting a CNC Business

Embarking on a CNC business venture requires careful planning and strategic decision-making. The first step is to choose the right CNC machine for your needs. Factors to consider include the type of products you plan to create, the materials you’ll be working with, and your budget. Vertical milling machines, for example, are ideal for producing intricate designs, while CNC routers are perfect for cutting and shaping large sheets of material.

Next, it’s essential to identify your target market. Are you aiming to serve the automotive industry, the aerospace sector, or perhaps the consumer electronics market? Understanding your niche will help you tailor your products and marketing strategies to meet the specific needs of your customers.

Developing a solid business plan is also crucial. This plan should outline your marketing strategies, financial projections, and operational procedures. Consider how you’ll differentiate your business from competitors. Will you offer custom designs, quick turnaround times, or perhaps eco-friendly materials? By carving out a unique selling proposition, you can attract a loyal customer base and set your business up for success.

Outsourcing CNC Machining

Can I Sell CNC Products Without a CNC Machine?

Absolutely! You can sell CNC products without owning a CNC machine by outsourcing the manufacturing process. Many companies offer custom CNC services, allowing you to focus on designing and marketing your products while they handle the production. This approach is particularly beneficial for startups and small businesses that may not have the capital to invest in expensive CNC equipment.

Outsourcing CNC machining provides access to state-of-the-art machines and expert operators, ensuring that your designs are brought to life with precision and quality. Companies like LKprototype.com offer industry-leading CNC services, providing flexible order sizes and cost-effective solutions. By partnering with a reputable CNC service provider, you can tap into the benefits of CNC technology without the significant upfront investment.

When selecting a CNC service provider, it’s essential to do your research. Review their portfolio to ensure they have experience with similar projects, ask about their lead times and pricing, and check customer reviews. By choosing a reliable partner, you can ensure that your products are manufactured to the highest standards, allowing you to focus on growing your business and meeting customer demands.

By outsourcing CNC machining, you can leverage cutting-edge technology to create high-quality products without the need for significant capital investment. This approach allows you to bring your creative designs to market quickly and efficiently, helping you stay competitive in a fast-paced industry.

Still, need help? Contact Us: [email protected]

Need a PROTOTYPE or PARTS machining quote? Quote now

LKprototype

LKprototype