Imagine a CNC machine metal device that turns raw metal into precise parts. That’s what CNC machines do. They change manufacturing by using automation and programming to make perfect results every time.

CNC machines have changed industries by working faster, wasting less, and repeating tasks perfectly.

Here’s how they’ve made a difference:

Valve factories using CNC machine metal technology cut setup time a lot between 1997 and 2002.

Companies using CNCs needed more workers with engineering skills (from 52% to 72%) and programming skills (from 14% to 43%).

CNC machines run fast all the time, saving time and keeping products the same.

This ability to work better and more accurately makes CNC machines very important in today’s factories.

Key Takeaways

CNC machines make manufacturing easier, giving accurate and consistent results.

Industries like aerospace, cars, and healthcare use CNC machines for safe parts.

CAD and CAM software help design and make parts faster and better.

CNC machines save materials and money, working well for big or small jobs.

CNC machines can handle metals, plastics, and more for many industries.

Understanding CNC Machines

What Are CNC Machines

CNC machines, short for Computer Numerical Control machines, are high-tech tools. They automate making things by following pre-set software instructions. These machines shape materials like metal, plastic, or wood into exact parts. Unlike doing it by hand, CNC machines need little human help and give the same results every time.

These machines are key to modern factories. They mix automation with accuracy, making them perfect for industries needing top-quality parts. For instance, CNC machine metal methods are common in making airplane parts, cars, and medical tools. With CNC technology, you can create detailed designs and meet strict size rules that are hard to do by hand.

Tip: CNC machines are a big part of Industry 4.0, where smart factories use live data to improve production.

Core Components of CNC Machines

To see how CNC machines work, you should know their main parts. Each part helps turn raw materials into finished items:

Controller: The machine's brain, it reads instructions and sends commands.

Spindle System: Spins the cutting tool or material for exact shaping.

Tool Magazine: Holds and swaps tools automatically during work.

Feed System: Moves the tool or material for accurate cutting.

Bed and Frame: Keep the machine steady and supported.

These parts are built to handle tough jobs. Research shows parts like the spindle system and tool magazine are very reliable. However, they might need care to avoid bigger problems later.

Component | Function |

|---|---|

Controller | Reads instructions and controls the machine's actions. |

Spindle System | Spins tools or materials for cutting and shaping. |

Tool Magazine | Holds and changes tools automatically. |

Feed System | Moves tools or materials for precise cutting. |

Bed and Frame | Keep the machine stable and supported. |

How CNC Machines Work

CNC machines follow steps to turn raw materials into exact parts. Here's how they do it:

Programming: First, you design a part using CAD (Computer-Aided Design) software. Then, CAM (Computer-Aided Manufacturing) software turns the design into machine instructions.

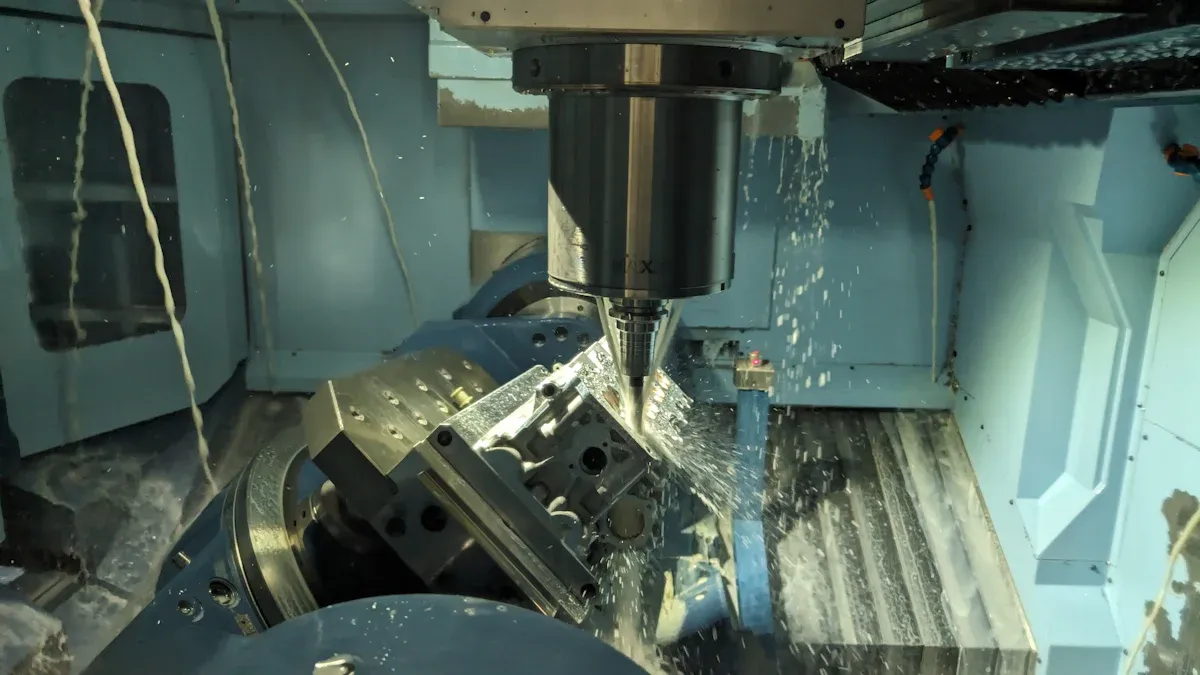

Setup: The raw material, like a metal block, is placed on the machine. The right tools are loaded into the tool magazine.

Machining: The controller follows the instructions, guiding the spindle and feed system to cut, drill, or shape the material. CNC machine metal processes often hit 98-100% accuracy, making sure parts are exact.

Monitoring: Modern CNC machines use live data and smart tech to watch operations. This boosts efficiency and cuts waste.

Finishing: After machining, the part is checked and polished to match the design.

Note: New CNC machines have features like live monitoring and AI-based maintenance. These upgrades make them more reliable and reduce downtime.

CNC machines are great at being precise and fast. They keep accuracy high across many parts, cutting mistakes and saving materials. This makes them a smart choice for making lots of products at once.

The Process of CNC Machine Metal Transformation

Designing with CAD Software

The process starts by designing the part using CAD software. This software helps create a detailed digital plan of the part. You can draw, model, and test the design to ensure it meets your needs before production.

CAD software is very useful for CNC machining. It helps make parts with exact measurements, which is important for industries like aerospace and medical. You can also quickly improve designs, saving time in product development. Below is a table showing key benefits of CAD software:

Performance Metric | Description |

|---|---|

Makes parts with tiny tolerances, vital for aerospace and medical fields. | |

Design Iteration Speed | Lets you quickly improve designs, speeding up product development. |

Integration with CNC | Works smoothly with CNC machines for consistent production. |

Parametric Modeling | Creates flexible models that adjust to changes for better performance. |

Virtual Prototyping | Tests designs virtually, lowering costs and improving quality. |

Using CAD software ensures your designs are accurate and ready for manufacturing. This step is the base for the CNC machining process.

Converting Designs into Machine Instructions

After designing, the next step is turning it into machine instructions. CAM software is used to create codes like G-code and M-code. These codes tell the CNC machine how to move and work.

G-code: Guides the machine’s movements for cutting, drilling, or shaping. For example, it ensures precise drilling in aerospace parts.

M-code: Controls machine functions like turning the spindle on or off and managing coolant flow. This keeps the machine running smoothly.

Algorithms: Advanced programs translate the codes into actions, ensuring high precision and tight tolerances.

Programming the CNC machine improves accuracy and saves materials. It also reduces energy use, making production more efficient.

Preparing the Machine and Material

Before machining, the machine and material must be prepared. This step ensures smooth and efficient operations. Key tasks include:

Machine Setup: Load tools into the tool magazine and adjust settings based on the design. Modern CNC machines use real-time data to improve setup speed.

Material Preparation: Secure the raw material, like a metal block, onto the machine. Check the material for defects to ensure it meets quality standards. For example, tests can confirm the material’s strength.

Calibration: Align the spindle and feed system to match the design’s dimensions for accuracy.

Data is important for improving this step. The table below shows how data helps in preparation:

Evidence Type | Description |

|---|---|

Machine Tool Data | Shares real-time data to analyze and improve machine operations. |

Setup Efficiency | Finds the best methods to reduce setup time and improve performance. |

Data-Driven Insights | Uses data like run time and part count to reduce errors and downtime. |

By preparing the machine and material carefully, you can avoid mistakes and delays, making the machining process smoother.

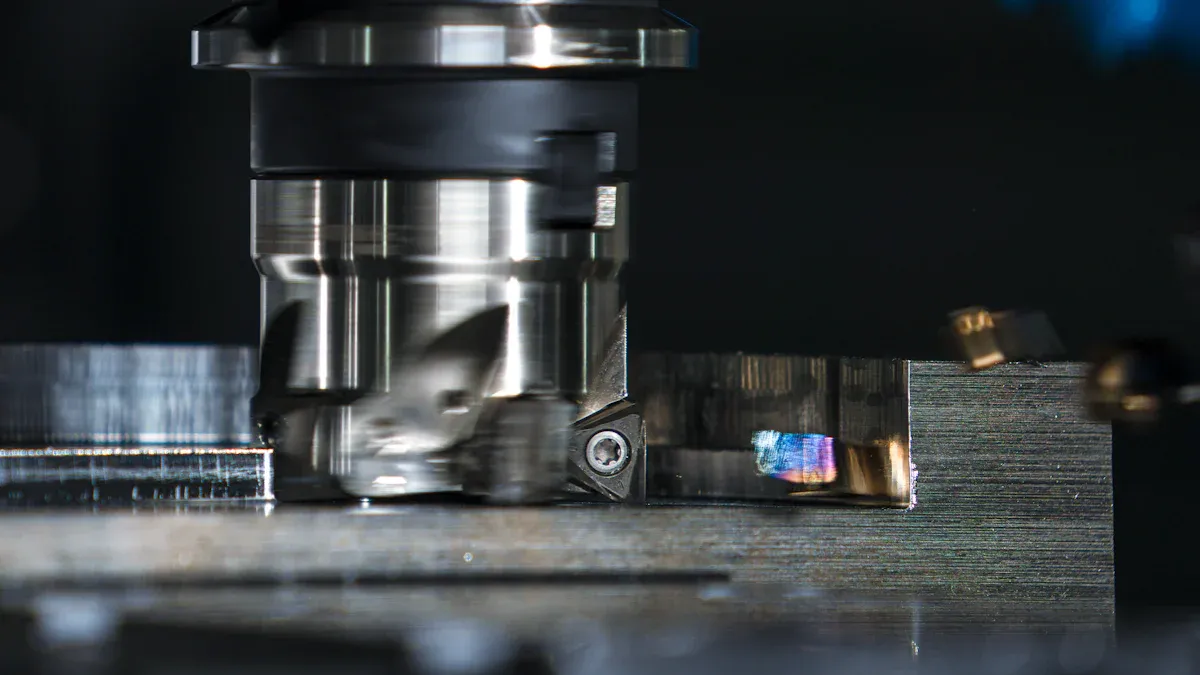

Machining the Metal

Machining is where raw metal becomes precise parts. The CNC machine follows programmed instructions to shape the metal. Different techniques are used for specific tasks:

Milling: This method creates detailed shapes with high accuracy. It works on many materials and is great for complex designs.

Turning: This technique makes round parts quickly and with smooth finishes.

Drilling: It creates holes accurately, which is important for assembly.

Grinding: This method gives smooth surfaces and exact sizes, especially for hard metals.

The CNC machine performs these tasks with great precision. It cuts, shapes, and refines the metal based on the design. Operators watch the process to ensure it runs well. If needed, they adjust the machine to keep it accurate.

Here’s how raw metal becomes a finished part step by step:

Step | Description |

|---|---|

Design Preparation | Engineers make a 3D model of the part using CAD software. |

CAM Processing | The CAD file is turned into a CNC program using CAM software. |

Machine Setup | Operators prepare the machine by loading tools and securing the metal. |

Machining | The CNC machine cuts and shapes the metal as per the design. |

Post-processing | The part is polished and finished for a smooth surface. |

Machining is the most important step in CNC work. It uses advanced tools and careful processes to make parts that meet strict standards.

Quality Control and Finishing

Quality control checks if parts meet the required standards. After machining, operators measure parts with special tools. They check sizes, angles, and shapes for accuracy. If something is wrong, they fix the machine and remake the part.

Good quality control includes:

Quality Control Practice | Description |

|---|---|

Early Detection of Defects | Stops waste and saves money by fixing issues early. |

Regular Maintenance | Keeps machines working well and avoids breakdowns. |

Comprehensive Training | Teaches operators how to keep parts accurate. |

Accurate Documentation | Tracks details for future improvements. |

Regular Inspection | Makes sure parts meet size and tolerance rules. |

Finishing adds the final touches to the part. Polishing, removing rough edges, and coating improve how it looks and works. These steps make sure the part is strong and ready for use.

By combining careful quality checks with good finishing, you get parts that meet high standards and work perfectly.

Achieving Precision in CNC Machining

Multi-Axis Machining

Multi-axis machining makes CNC machines more advanced. Tools can move in many directions. This helps create detailed parts in one setup, saving time and improving accuracy. For example, a 5-axis CNC machine can tilt and rotate tools. It’s perfect for making complex items like turbine blades or custom prosthetics.

Industries like aerospace, cars, and medicine use multi-axis machining a lot. In aerospace, it makes turbine blades with great precision, cutting production time by 40%. Car companies use it to make engine blocks, reducing setups by 30% and improving accuracy. In medicine, it creates custom surgical tools and implants, helping patients recover better.

Tip: Turning vertical machining centers into 4-axis machines saves time and reduces mistakes, keeping parts accurate.

Maintaining Tight Tolerances

Tight tolerances are key for making high-quality parts. CNC machines are great at this, achieving tolerances as exact as ±0.001″. This ensures parts fit perfectly, cutting waste and rework. Industries like aerospace and medical need this precision for safety and performance.

Here’s a simple chart of tolerances for CNC processes:

CNC Process | Standard Tolerance |

|---|---|

3-axis Milling | ±0.005″ or 0.13 mm |

5-axis Milling | ±0.005″ or 0.13 mm |

Lathe | ±0.005″ or 0.13 mm |

Router | ±0.005″ or 0.13 mm |

Screw Machining | ±0.005″ or 0.13 mm |

Engraving | ±0.005″ or 0.13 mm |

Steel Rule Die Cutting | ±0.015″ or 0.381 mm |

Rail Cutting | ±0.030″ or 0.762 mm |

Keeping tight tolerances ensures consistent quality. It also reduces waste, making CNC machining a smart choice for precision work.

Automation and Feedback Systems

Automation and feedback systems improve CNC machine accuracy. These systems watch the process live, spotting problems and fixing them. For example, feedback systems check tool wear and vibrations. They adjust automatically to keep the machine working well.

Closed-loop controls make accuracy even better. They compare the machine’s position to the programmed position. This reduces manual work, cutting mistakes and improving efficiency. Automation also lets CNC machines run nonstop, boosting productivity and cutting downtime.

Note: Real-time feedback systems improve precision and help tools last longer by spotting wear early.

Using automation and feedback systems ensures consistent results. It also makes CNC machine metal processes more efficient and reliable.

Materials Used in CNC Machining

Common Metals: Aluminum, Steel, Titanium

CNC machining often uses metals like aluminum, steel, and titanium. Each has special qualities for different projects.

Aluminum: This metal is light but very strong. It’s common in airplanes like the Boeing 787, which uses it to save fuel. It’s easy to cut at speeds up to 600 m/min, making it great for large-scale production.

Stainless Steel: This metal doesn’t rust and is used in medical tools like scalpels. Cutting it is slower (under 30 m/min) to avoid overheating and damage.

Titanium: Strong and rust-resistant, titanium is used in rockets like SpaceX Falcon. It’s hard to machine and needs slow speeds (30 m/min or less) but makes tough, precise parts.

These metals are key for industries needing strong and exact materials.

Specialty Alloys and Their Applications

Specialty alloys are made by mixing metals for better performance. They are stronger, resist heat, or don’t rust easily. For example, Inconel, a nickel alloy, is used in jet engines because it handles high heat. Brass, made of copper and zinc, is easy to machine and used in plumbing and decorations.

Material Type | Cost Impact | Efficiency | Ease of Machining |

|---|---|---|---|

Metals | High | High | Varies |

Alloys | Medium | High | High |

Choosing the right alloy can save money and meet project needs.

Non-Metal Materials in CNC Machining

CNC machines also work with non-metals like plastics and composites. Plastics such as ABS and polycarbonate are light, cheap, and easy to shape. They’re used in electronics and everyday items. Composites like carbon fiber are strong but light, making them perfect for cars and planes.

Knowing these materials helps you pick the best one for your project.

Benefits of CNC Machine Metal Processes

High Accuracy and Consistency

CNC machines are great at making accurate and consistent parts. They follow exact programs to ensure every piece matches the design perfectly. This is very important for industries like aerospace and medical, where even small mistakes can cause big problems.

One big advantage of CNC machines is their ability to make many identical parts. For example, they can produce thousands of parts without any differences. This is hard to do by hand. This consistency reduces the need to fix mistakes and ensures all products meet high standards.

Benefit | Description |

|---|---|

CNC machines work nonstop, saving money on labor costs. | |

Material Wastage Minimization | CNC processes use materials efficiently, wasting less compared to older methods. |

Consistent Quality | CNC machines make sure all parts are accurate and uniform, which is key for large production. |

Tip: Keep CNC machines well-maintained to ensure they stay accurate and last longer.

Efficiency and Reduced Waste

CNC machines are built to work fast and efficiently. Automation helps them finish tasks quickly, cutting down production time. Unlike manual work, CNC machines can do many steps in one setup, saving even more time.

High precision reduces mistakes that happen with manual work.

Automation speeds up production and shortens work cycles.

CNC machines can handle complex shapes, making them versatile.

Repeating tasks perfectly reduces errors caused by people.

Detailed designs are easier to make than with older methods.

Automation lowers labor costs, making big projects cheaper.

CNC machines also use materials wisely. They follow exact plans, so there’s less waste. This makes them better for the environment and saves money on materials.

Cost-Effectiveness for Various Production Scales

CNC machining is cost-effective for both small and large projects. Automation cuts down on labor needs, saving money. For businesses, this means more profits and better use of resources.

Automation in CNC machining lowers costs and improves efficiency.

Improving automation helps businesses stay competitive and successful.

CNC machines need to run 90-95% of the time to be worth the cost.

Long machine downtime can hurt productivity and increase costs.

Well-managed CNC operations often see profit margins of 10% to 20%.

By keeping productivity high, CNC machines help businesses meet demand while controlling costs. Whether making a few custom items or thousands of parts, CNC machining is a flexible and affordable option.

Versatility Across Industries

CNC machining is a flexible tool used in many industries. It works with different materials and meets various production needs. This makes it a key part of modern manufacturing. Whether in aerospace, automotive, or electronics, CNC machines deliver accuracy and speed.

In aerospace, CNC machines make parts with tight tolerances. These parts often have complex shapes that need exact measurements. For example, turbine blades and airplane parts must be precise for safety. CNC machines handle these tasks easily, making them vital for this industry.

The automotive industry also depends on CNC machining. It helps create engine parts, gears, and prototypes quickly. This allows carmakers to adjust to new designs and improve production. CNC machines make it easier to meet market demands.

Electronics like phones and laptops also use CNC machining. These devices need detailed designs and lightweight materials. CNC machines shape metals, plastics, and composites to make sleek products. Their ability to work with many materials ensures high-quality results.

Here’s how CNC machining supports industries:

Aerospace: Makes precise parts with complex shapes.

Automotive: Quickly adapts to design changes for parts and prototypes.

Consumer Electronics: Shapes detailed designs using various materials.

Material Flexibility: Works with metals, plastics, wood, and composites.

CNC machining offers precision, speed, and flexibility for all industries. Its ability to handle different tasks makes it essential for modern manufacturing.

Applications of CNC Machining

Aerospace Components

CNC machining is very important for making airplane parts. These parts must work well in tough conditions. CNC machines make them with great accuracy and reliability. For example, turbine blades need detailed designs and exact sizes. CNC machines handle these tasks easily, ensuring the parts are safe and strong.

Airplane makers benefit a lot from CNC machining. It speeds up production and lowers costs by using automation. It also ensures all parts are made the same, which is crucial for safety. Below is a table showing how CNC machining helps in aerospace manufacturing:

Metric | Description |

|---|---|

Precision | Makes parts that can handle extreme conditions. |

Consistency | Creates parts that are always the same for better performance. |

Efficiency | Speeds up production and uses resources wisely. |

Cost Reduction | Saves money by reducing labor needs. |

Complex Geometries | Makes detailed designs with exact sizes for important parts. |

Safety & Reliability | Ensures airplane parts are safe and work well. |

CNC machines are great at making high-quality airplane parts quickly and accurately.

Automotive Parts

CNC machining is also useful for making car parts. It creates engine pieces, gears, and other important items with high precision. Big car companies like Tesla and Ford use CNC machines to improve production. Tesla makes complex parts faster, while Ford uses CNC machines for accurate engine pieces, saving money and improving quality.

Here’s why CNC machining is helpful for car manufacturing:

Precision and Accuracy: Makes sure car parts fit perfectly for safety.

Automation and Efficiency: Speeds up production and saves time.

Flexibility and Adaptability: Quickly adjusts to new designs or market needs.

Cost-Effectiveness: Saves money over time, even with upfront costs.

Using CNC machines helps carmakers produce better parts while keeping costs low.

Medical Devices

CNC machining is very important in healthcare. It makes tools, implants, and equipment with exact sizes. These parts must be perfect to keep patients safe. CNC machines make sure everything fits well, reducing problems during surgeries.

This process also follows strict rules for quality. For example, CNC machining meets ISO 13485 standards, which ensure safety and reliability. Below is a table showing how CNC machining helps in medical manufacturing:

Evidence | Description |

|---|---|

Precision | Makes parts with tight tolerances for patient safety. |

Improved Outcomes | Creates implants that fit better, helping patients recover faster. |

Regulatory Compliance | Follows strict rules like ISO 13485 for quality and safety. |

Adaptability | Works with many materials for different medical needs. |

CNC machines are key to making safe and reliable medical tools and devices.

Electronics and Consumer Products

CNC machining helps make electronics and everyday products. It ensures accuracy and uniformity for items like phones, laptops, and appliances. These devices need detailed designs and exact measurements, which CNC machines handle well.

A key use is making printed circuit boards (PCBs). PCBs are the base of electronic devices. CNC machines cut tiny paths and shapes on PCBs. This allows circuits to fit into small spaces, keeping devices compact and powerful.

Heat sinks also rely on CNC machining. These parts control heat in gadgets like computers and gaming systems. CNC machines create unique designs and sizes for better cooling. This helps devices work longer and perform better.

Semiconductors, essential for modern tech, need CNC machining too. The process ensures they are made with extreme precision. Without this, chips and processors wouldn’t work as efficiently.

Here’s how CNC machining supports electronics and consumer products:

Component Type | Application Description |

|---|---|

Printed Circuit Boards | CNC machines cut tiny paths and shapes for compact circuits. |

Heat Sinks | Custom designs improve cooling for computers and gaming systems. |

Semiconductors | High precision ensures chips and processors work efficiently. |

Consumer Electronics | CNC machining creates sleek, reliable, and durable products. |

CNC machining is also used for smartwatches and earbuds. It helps make stylish designs while keeping them functional. The process ensures every product is made to the same high standard, giving you dependable devices.

By using CNC machining, companies can meet the demand for better electronics. This technology makes sure your gadgets are both useful and long-lasting.

CNC machines have changed how things are made. They turn raw metal into exact parts with great accuracy. These machines use smart technology to work automatically, keeping quality high and saving time. Industries like airplanes, cars, and healthcare trust CNC machines to meet strict rules. They help make more products while wasting less material. CNC machines are very important for today’s factories. They keep improving industries by creating better products and new ideas.

FAQ

What is the biggest benefit of CNC machining?

CNC machining is very precise and consistent. It makes sure every part is made exactly right, cutting down on mistakes and waste. This is why it’s great for industries like airplanes and healthcare that need perfect parts.

Can CNC machines work with materials besides metal?

Yes, CNC machines can shape plastics, wood, and composites too. These materials are used in things like electronics and lightweight products. CNC machines are flexible and work for many industries.

How do CNC machines help reduce waste?

CNC machines cut only what’s needed by following exact plans. This wastes less material compared to doing it by hand. Smart programming also saves resources, making the process better for the environment.

Are CNC machines good for small projects?

Yes, CNC machines are good for both small and big jobs. For small projects, they save money by needing less labor and being very accurate. This means fewer mistakes and less time fixing errors.

Which industries use CNC machining the most?

Industries like airplanes, cars, healthcare, and electronics use CNC machines a lot. They make exact parts for planes, cars, medical tools, and gadgets. CNC machines are great for making detailed designs in modern factories.

Start your project with LKprototype

LKprototype company simplifies procurement for custom manufacturing, Suitable for making your products or prototypes with a variety of materials, such as metal or plastic, silicone rubber, from 3D Printing to CNC Machined Parts and Vacuum Casting , with a focus on speed and efficiency. Our platform provides instant quotes. With LKprototype, You can connect with the team to communicate your project to ensure quality and on-time delivery.

Start with an instant quote and experience how our technology and expertise can make custom part procurement faster and easier.

LKprototype

LKprototype