When you want custom CNC parts, it's essential to consider quality, cost, and time. Many engineers face challenges with how to choose a CNC machining service, especially when it comes to early communication, collaborating on design, and selecting materials. Steel CNC machining can be particularly difficult because strong cutting and heat can lead to mistakes. Before you choose a CNC machining service, make sure you understand your project's needs and set clear goals.

Early communication is crucial

Material characteristics can affect results

Establishing tolerance is very important

Selecting the right partner helps prevent issues

Key Takeaways

Talk early and clearly with your CNC partner. This helps stop confusion and makes your project work well. - Pick materials carefully for your part’s job and where it will be used. This can make your part work better and cost less. - Know what tolerances and precision your part needs. This helps your parts fit right and stops expensive errors. - Check CNC shops for what they can do, their certificates, and their past work. This helps you get good quality and trust. - Do not just look at price when you get quotes. Think about quality, service, and how good the value is over time.

Understand Your Project Requirements First

Define Part Function and End-Use Application

You should know what your part will do. Think about where you will use the part. Ask yourself what forces the part will face. Also, think about the place where the part will work.

Mechanical Loads and Working Environment

Check if your part needs to hold heavy weight or last a long time. Some materials are strong and can bend without breaking. These are good for tough jobs. If your part will get wet, hot, or touch chemicals, pick materials that can handle these things. The strength compared to weight is important for cars and planes.

Custom dies and molds make special shapes for products.

Rapid prototyping helps you test ideas fast when you need quick results.

Industry-Specific Requirements

Some jobs have strict rules. Medical, aerospace, and car parts need special papers and must be made very carefully. Make sure your CNC partner knows these rules.

Select Suitable Materials and Specifications

Picking the right material changes how much you pay and how well your part works. You can choose metals, plastics, or other strong materials for your project.

Metals vs Plastics vs Engineering Materials

Criteria | Description |

|---|---|

Material Properties | Physical and mechanical traits like strength and ductility. |

Machining Needs | How well the material works with CNC machines. |

Finishing Requirements | Surface finish and post-processing needs. |

Cost Factors | Price of material and processing. |

Material Availability and Cost Impact

Aluminum and plastics are cheaper and easier to cut. Titanium and tool steel cost more but are stronger. If you need parts fast, use materials that are easy to machine. Strong materials last longer and need less fixing later.

Determine Tolerance, Precision, and Surface Finish

Standard Tolerances vs Tight Tolerances

Different machines can make parts with different accuracy. For example:

Machine Type | Typical Tolerance | Notes |

|---|---|---|

3-Axis CNC Mill | ±0.05 mm | Good for most parts |

5-Axis CNC Mill | ±0.01–0.02 mm | Best for tricky shapes |

CNC Lathe | ±0.01 mm | Great for round parts |

Swiss Lathe | ±0.005 mm | Used for small or medical parts |

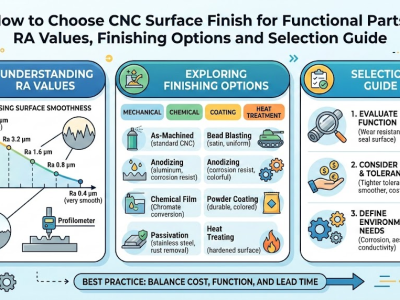

Surface Roughness and Finishing Options

You can pick finishes like anodizing, electropolishing, or powder coating. The right finish makes your part look better and last longer.

Estimate Order Volume and Production Stage

Prototype vs Low-Volume vs Mass Production

How many parts you need changes the price and how they are made.

Production Volume | Cost Implications | Strategies to Optimize |

|---|---|---|

High Volume | Lower per-unit cost | Use high-capacity machines |

Medium Volume | Moderate per-unit cost | Combine orders |

Low Volume | Higher per-unit cost | Use standard tooling |

Prototype/One-Off | Very high per-unit cost | Try 3D printing for prototypes |

Future Scalability Considerations

Think about growing in the future. If you will need more parts later, pick a CNC partner who can make more when you need them. This helps you avoid waiting and paying extra money later.

Tip: Write down what you need before you talk to CNC shops. This helps you compare choices and get the right prices.

Key Capabilities to Look for in a CNC Machining Service

When you pick a CNC machining service, check what machines they have. Also look at the skills of their workers. The right machines and skills help you get parts that fit your project.

Available CNC Machine Types

3-Axis CNC Machining

3-axis CNC mills are good for simple jobs. These machines move up, down, left, right, and forward. They make basic shapes, slots, and holes. If your part is not complex, use a 3-axis machine.

4-Axis and 5-Axis CNC Machining

Some parts need more advanced machines. 4-axis CNC mills can spin the part. This lets you cut on more sides without moving it. 5-axis CNC mills move in five ways. They make tricky shapes and finish parts faster. You get better accuracy and need fewer setups.

Tip: Ask your CNC partner about their machines. More axes give you more choices for your design.

You may see other machines in a shop:

CNC Lathes spin the part and use a tool to shape it. They work best for round or tube-shaped parts.

CNC Routers cut softer materials like wood or plastic. They make detailed shapes and patterns.

Electrical Discharge Machines (EDM) use electricity to cut hard metals. They make complex shapes.

Supported Machining Processes

CNC Milling and Turning

CNC shops use different ways to make your parts. Milling uses spinning tools to cut away material. Turning spins the part and shapes it with a tool. Both help you get the right size and shape.

Drilling, Tapping, and Multi-Process Integration

You may need holes, threads, or special finishes. Drilling makes holes with high accuracy. Tapping adds threads for screws. Some shops can do many processes in one setup. This saves you time.

Machining Process | Description | Applications |

|---|---|---|

CNC Milling | Uses spinning cutting tools to remove material. | Gears, engine parts, medical devices |

CNC Turning | Uses a single cutting tool on a spinning part. | Fast production, cars, planes |

CNC Drilling | Makes holes in a part with high accuracy. | PCBs, engine blocks, tools |

CNC Grinding | Uses rough wheels for smooth finishes and exact cuts. | Cutting tools, car parts, planes |

CNC Swiss Machining | Makes small, exact parts with a sliding head. | Medical devices, watches, electronics |

Engineering and DFM Support

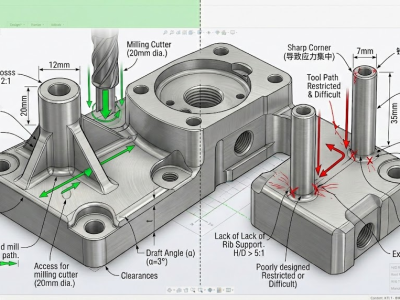

Design for Manufacturability Review

Good engineering support helps your part work and cost less. Design for manufacturability (DFM) means your design matches what machines can do. Shops with DFM help you change your design so it is easier and cheaper to make. This support helps you avoid mistakes and get better parts.

Impact Area | Description |

|---|---|

Cost | Smart designs lower how much you pay. |

Accuracy | Good design makes sure parts are exact. |

Lead Time | Smart designs help you get parts faster. |

Overall Performance | Good DFM makes your product work better. |

Note: DFM support helps you balance your ideas with what is possible. You get parts that work well and cost less.

Drawing and File Format Support

You need to send drawings and files to your CNC shop. Good shops accept many file types, like STEP, IGES, or DXF. They help you check your files and make sure everything matches your needs. This makes things easier and helps you avoid delays.

Experience with Similar Parts and Industries

Prototype Manufacturing Experience

If you need a prototype, choose a shop that has made similar parts before. Shops with experience fix problems fast. They help you test ideas and make changes quickly.

Production Machining Experience

For big orders, pick a shop that knows how to make many parts at once. Experienced shops waste less material and finish jobs faster. They know the rules for your industry, so you get parts that meet all standards.

You get better quality and fewer mistakes.

You save time because the shop works faster.

You avoid wasting materials and money.

Tip: Ask for examples of parts the shop has made before. This helps you see if they can handle your project.

How to Evaluate Quality and Reliability

In-House Quality Control System

You should see if the CNC shop checks quality well. This helps you get good parts every time. Shops use many steps to keep quality high.

Incoming, In-Process, and Final Inspection

Shops check materials when they come in. Workers look at parts while making them. Before shipping, they check finished parts again. These steps catch mistakes early. This helps you avoid problems later.

Traceability and Documentation

Good shops keep records for each part. You can ask for papers that show how workers made and checked your parts. Traceability helps you find out what went wrong. Documentation proves the shop did what you asked.

Component | Description |

|---|---|

Certifications | ISO 9001 means the shop follows strict quality rules. |

Continuous Improvement | Shops track mistakes and fix them to get better. |

Metrology | Good measurements help keep quality high at every step. |

Tip: Ask your CNC partner for sample inspection reports. These reports show how they check quality.

Certifications and Compliance Standards

You should look for shops with the right certificates. These show the shop cares about quality and follows the rules.

ISO 9001

ISO 9001 is a common certificate. It means the shop checks quality for many types of work.

ISO 13485 and AS9100 (When Applicable)

If you need medical or airplane parts, check for ISO 13485 or AS9100. These show the shop meets strict rules for those jobs.

Certification | Description |

|---|---|

ISO 9001 | Quality system for many types of work. |

AS9100 | Extra rules for airplane parts. |

ISO 13485 | Quality rules for medical device parts. |

ITAR | Defense rules for special parts. |

Inspection Equipment and Measurement Capability

You should ask what tools the shop uses to check parts. Good tools help keep quality high.

CMM and Optical Measurement

Shops use CMMs to check part size very closely. Optical scanners and microscopes help check surfaces and shapes. These tools find tiny mistakes that simple tools miss.

Equipment Type | Purpose |

|---|---|

CMM | Checks part size and shape. |

GOM 3D-Scanner | Checks quality with 3D scans. |

Optical microscope | Looks at surface quality. |

Laser Inspection | Measures part size. |

CMMs can measure hard shapes very exactly, up to ±0.001 mm. This helps you trust the results.

Part Samples and Case Studies

You should ask for part samples and stories about past jobs. These show how the shop checks quality in real work.

Sample Evaluation

Look at sample parts to see the finish, size, and quality. You can tell if the shop meets your needs.

Customer Success Stories

Read stories from other customers. These show how the shop fixed problems and made good parts.

Note: Looking at samples and customer stories helps you feel sure about the shop’s quality.

Cost vs Value – How to Compare CNC Machining Quotes

When you compare CNC machining quotes, you need to look beyond the price. You should understand what affects the cost and how to get the best value for your project.

Main Factors That Affect CNC Machining Cost

Many things change the price of CNC machining. You can see the main factors in the list below:

Part Complexity and Geometry: Simple shapes cost less. Complex designs need more time and special programming.

Material Selection: Some materials, like aluminum, are easy to machine and cost less. Harder materials, such as titanium, cost more and take longer to cut.

Tolerances and Precision: Tight tolerances mean the shop must work more carefully. This increases the cost.

Order Quantity (Volume): Large orders lower the price for each part. Small orders cost more per part.

Surface Finish: Special finishes, like anodizing or polishing, add extra steps and raise the price.

Programming Effort: Advanced designs need more time for CAD/CAM programming.

Custom Tooling: Unique shapes may need special tools, which cost extra.

Error Risk: Complex parts can lead to more mistakes. Fixing errors adds to the cost.

Material Cost

You pay more for rare or hard-to-machine materials. Aluminum and plastics are cheaper. Titanium and tool steel cost more because they are tough and need special tools. The material you choose changes the price and how fast you get your parts.

Machining Time and Complexity

Parts with many details take longer to make. Shops need more time to set up machines and program them for tricky shapes. If your part needs tight tolerances or special finishes, the shop must work slower and check quality more often. This adds to the cost.

Tip: Ask your CNC shop to explain how your design affects the price. You can change your design to save money.

Why the Lowest Price Is Not Always the Best Choice

You may want to pick the cheapest quote, but this can lead to problems. You should look at the value, not just the price.

Quality Risks

Low prices often mean the shop uses cheaper materials or skips quality checks. You may get parts that do not fit or break easily. Poor quality can cause delays and cost you more in the long run.

Hidden Costs

Some quotes look cheap but hide extra fees. You may pay more for shipping, rush orders, or fixing mistakes. If the shop does not follow your specifications, you may need to redo the job.

Risk Type | Description | Impact on Project |

|---|---|---|

Poor Quality | Parts may not meet your standards | Delays, extra expenses |

Extra Charges | Fees for changes or rush orders | Higher total cost |

Missed Specs | Wrong materials or tolerances | Rework, wasted time |

Note: Always check what is included in the quote. Ask for a cost breakdown to avoid surprises.

How to Request an Accurate Quote

You get better quotes when you give clear information. Shops need details to understand your project and price it right.

Provide Complete Drawings

Send drawings that show every detail. Use both STEP files and PDFs for clarity. Include measurements, tolerances, and finishes. Clear drawings help the shop see what you need and avoid mistakes.

Specify Quantity and Lead Time

Tell the shop how many parts you need. The quantity changes the price and how fast they can finish the job. Share your timeline so the shop knows when you need the parts. If you need parts for testing or production, explain how you will use them. This helps the shop suggest the best process.

Checklist for Accurate Quotes:

Describe your project, including material and complexity.

Attach drawings and specifications.

List all measurements and tolerances.

State the number of parts you need.

Share your deadline for delivery.

Explain how you will use the parts.

Tip: The more details you give, the better the quote you get. Good communication helps you avoid delays and extra costs.

By looking at cost and value together, you make smarter choices for your CNC machining project. You get quality parts, fair prices, and on-time delivery.

Lead Time, Capacity, and Scalability

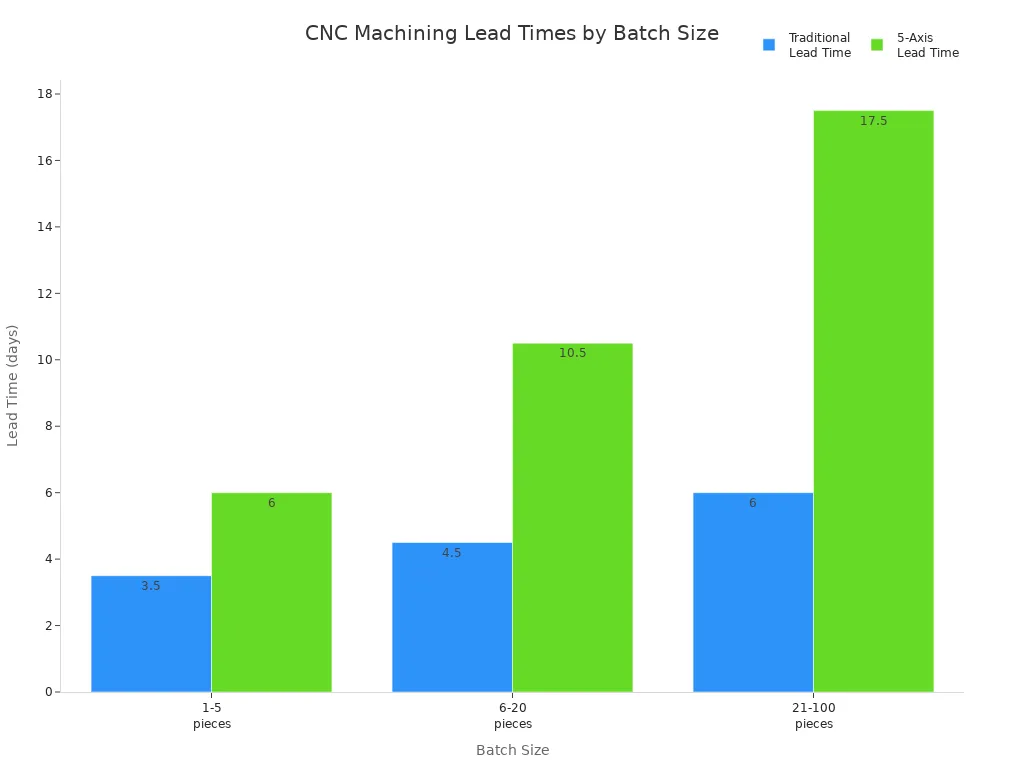

Typical CNC Machining Lead Times

It is important to know how long parts will take. Lead time means the time from order to delivery. The time depends on how hard the part is to make and how many you need. Prototypes usually take about 1 or 2 weeks. If you need a lot of parts, it can take 3 or 4 weeks. Some machines, like 5-axis CNC, can make parts much faster.

Batch Size | Traditional Lead Time | 5-Axis Lead Time | Reduction |

|---|---|---|---|

1-5 pieces | 3-4 weeks | 5-7 days | ~75% |

6-20 pieces | 4-5 weeks | 1-2 weeks | ~65% |

21-100 pieces | 5-7 weeks | 2-3 weeks | ~60% |

Prototype Lead Time

You can get prototype parts in about 1 or 2 weeks. Some shops with better machines can finish even faster. Sometimes, you get parts in less than a week.

Production Lead Time

Making lots of parts takes longer. Most production orders need 3 or 4 weeks. If you want a big batch or a tricky part, it might take more time.

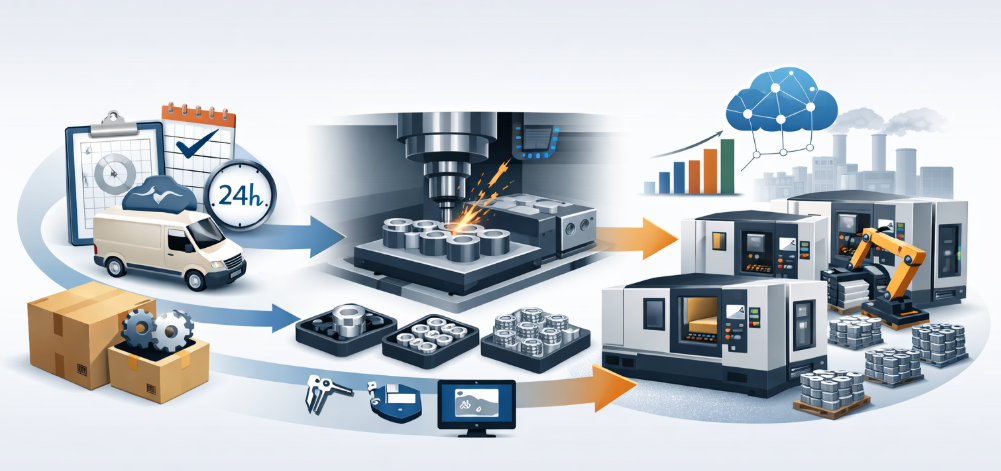

Manufacturing Capacity and Scheduling

You should see if your CNC shop has enough machines. Good planning helps you get parts on time. Most delays happen because of bad planning, not machine problems.

60% of late orders are from wrong guesses about capacity.

70% of lead time comes from planning and setup.

Machine Quantity

If a shop has more machines, they can make parts faster. Ask how many CNC machines the shop uses.

Shift System and Throughput

Shops that work in shifts can finish jobs quicker. High throughput means they can make lots of parts at once.

Ability to Scale from Prototype to Production

You want a shop that can grow with you. Good shops use smart ways to make more parts when you need them.

Lean manufacturing helps save time and materials.

Good suppliers keep materials coming without stopping.

Data analytics help shops plan for busy times.

New technology helps make more parts with fewer mistakes.

Pilot Runs

Pilot runs are small tests before making lots of parts. You can find and fix problems early.

Long-Term Production Planning

Good shops plan for the future. They help you stay on schedule and avoid delays.

Rush Orders and Emergency Support

Sometimes you need parts very fast. CNC shops can help with special rush services.

Service Type | Delivery Time | Description |

|---|---|---|

Fast Track Service | 1-2 Days | Quick delivery for emergencies and urgent projects. |

Rush Service | 3-6 Days | Fast delivery for rush orders. |

Standard Service | 7-10 Days | Regular delivery for standard projects. |

Shops use advanced machines and skilled teams to finish rush jobs fast. Many customers get emergency parts in less than one day.

Fast-Track Manufacturing

Fast-track service means you get parts in 1 or 2 days. This is for emergencies.

Priority Scheduling

Priority scheduling puts your order first. You get updates and fast delivery.

Communication, Service, and Project Management

Responsiveness and Technical Communication

You need your CNC machining partner to talk clearly and quickly. Good shops answer questions fast and give helpful advice. When you send a design, engineers should check it and suggest ways to make it better. Fast answers help you fix problems before they get bigger.

Engineering Feedback

Engineers should look at your drawings and tell you if something is wrong. They might suggest changes to make your part easier or cheaper to make. You get better parts when the shop shares ideas and helps you avoid mistakes.

Response Time

Quick replies show the shop cares about your project. You should get answers to technical questions in one business day. Fast quotes help you plan your money and schedule. The table below shows what good technical communication looks like:

Metric | Description |

|---|---|

Initial quote turnaround time | How fast you get a price estimate. |

Technical inquiry response speed | How quickly you get answers to questions. |

Project update frequency | How often you get updates on your order. |

Communication clarity and thoroughness | How clear and detailed the messages are. |

Availability of technical staff | If you can talk to technical experts. |

Willingness to accommodate design changes | If the shop can change your design if needed. |

Order Tracking and Progress Updates

You want to know where your order is at every step. Good CNC shops use technology to keep you updated.

Project Manager Assignment

A project manager helps you track your order. This person answers your questions and sends updates. You always know who to talk to.

Status Reporting

Shops use dashboards and alerts to show how your job is going. You may get messages about delays or machine problems. Workers use tablets to record quality checks and track downtime. Reports show how machines are working and help you see your order’s progress.

Feature | Description |

|---|---|

Real-Time Dashboards | Show how your job is doing right now. |

Alerts and Notifications | Tell you about delays or machine problems. |

Quality Tracking and Reporting | Give you data about part quality as it happens. |

Machine Utilization Reporting | Show how much the machines are being used. |

Job Setup/Changeover Tracking | Track setup times and lost production time. |

After-Sales Support and Revisions

Support does not stop when you get your parts. You need help if something goes wrong or if you want to make changes.

Rework Handling

Shops offer help and troubleshooting if you have problems. You can talk to experts any time for support. If a part breaks, warranty rules cover replacements. You get clear rules for fixing mistakes and quick solutions.

Continuous Improvement

Shops check in with you to see how your parts work. They ask for feedback and use it to get better. You get help with design changes and inspection reports. This keeps your parts good and helps you get better results over time.

Tip: Pick a CNC partner who talks with you and helps you before, during, and after making your parts.

Common Mistakes to Avoid When Choosing a CNC Machining Service

Choosing Based Only on Price

Some people pick a CNC machining service just because it is cheap. They think this will save money, but it can cause problems later. Low prices often mean the shop uses bad materials or skips important steps. Your parts might not last long or work well.

Short-Term Savings vs Long-Term Cost

You should look at more than just the price. If you only care about cost, you might have these problems:

Bad materials can make your parts weak or break.

You might pay more later to fix or replace parts.

Cheap parts can make your project cost more in the end.

Picking a good shop helps you save money over time.

Tip: Always ask about the materials and how the shop makes your parts, not just the price.

Ignoring Certifications and Quality Systems

You need to check if the CNC shop has the right certificates. These show the shop follows rules and cares about quality. Certificates like ISO 9001 help shops do better work and keep customers happy.

Compliance Risks

If you skip this step, you might get parts that do not work for you. Here is why certificates are important:

Certificates make sure the shop follows safety and quality rules.

They help the shop make fewer mistakes and better parts.

Certified shops use systems to keep parts very exact, like ±0.01 mm.

You get parts that meet or are better than what you want.

Certified shops waste less and work faster.

Note: Always ask to see certificates before you pick a CNC shop.

Not Verifying Machining Capability

You should always check what machines and materials the shop can use. Some shops cannot make hard shapes or work with special materials.

Machine Limitations

If you do not check the machines, you might get parts that do not fit your design. Some machines cannot make small corners or tiny details.

Material Restrictions

Not all shops can cut every material. If you need titanium or special plastics, make sure the shop has done this before. Ask to see examples of their work.

Remember: The right CNC shop has the machines and skills for your project.

Checklist – How to Choose a CNC Machining Service

Picking the best CNC machining shop can seem hard. This checklist helps you compare shops and make a good choice.

Technical Capability Checklist

Machine Types

See if the shop has machines for your parts.

Ask if they use 3-axis, 4-axis, or 5-axis CNC machines.

Check if they have CNC lathes, routers, or EDM for your design.

Tip: More machine types let you make harder shapes.

Supported Materials

Make sure the shop can use your material.

Ask if they have worked with metals, plastics, or engineering materials.

Ask to see parts made from your material.

Quality and Certification Checklist

Certifications

Certification | Why It Matters |

|---|---|

ISO 9001 | Shows the shop checks quality. |

AS9100 | Needed for airplane parts. |

ISO 13485 | Needed for medical parts. |

Ask to see certificates before you order anything.

Certified shops follow important rules.

Inspection Equipment

Check if the shop uses CMMs, scanners, or microscopes.

Ask for sample reports that show how they check parts.

Good tools help find mistakes early.

Commercial and Service Checklist

Pricing Transparency

Ask for a price list that shows all costs.

Ask if there are extra fees for fast work or changes.

Make sure the price matches your drawings and needs.

Lead Time and Support

Ask how long it takes to get prototypes and finished parts.

See if the shop can do rush jobs.

Find out if you get a project manager or updates.

Note: A good CNC shop gives clear answers and helps you before and after you get your parts.

Why Choose a Professional CNC Machining Partner

Consistent Quality and Precision

You want your custom parts to fit and work well. Professional CNC machining partners use advanced machines. Skilled technicians check every detail. They follow strict rules for making parts. You get parts that match your drawings. The shop uses tight tolerances and repeatable steps. This means fewer mistakes and less waste. Your project stays on track.

Tip: Good quality helps you avoid fixing mistakes and waiting longer.

Here is how a professional partner helps you:

Advanced CNC machines make parts faster and better.

Skilled technicians make sure every part is made right.

Benefit | Description |

|---|---|

Precision | CNC machining gives very accurate parts that match your needs. |

Efficiency | Smart techniques help finish jobs quickly and save materials. |

Quality Control | High standards mean fewer errors and broken parts. |

Cost-Effective Manufacturing

You save money with a professional CNC shop. These shops use smart ways and new machines. You do not need to buy tools or hire more workers. The shop does all the work for you. Fast production means you get parts quickly and pay less.

Benefit | Description |

|---|---|

Reduced Costs | Outsourcing CNC machining saves money on tools and workers. |

Improved Production | Smart steps help make more parts and meet demand. |

You do not get surprise fees or hidden costs.

You get clear prices and on-time delivery.

Reliable Long-Term Partnership

A professional CNC partner helps as your business grows. You get support for new designs and changes. The shop keeps your records and knows your standards. You build trust and work together on new projects. Good communication makes every order easier.

Note: A strong partnership means you always have help and get good parts.

You can pick the best CNC machining service by thinking about quality, price, and how long it takes. Make a checklist to help you look at different shops. Ask each shop about their machines, materials, and certificates. Talking clearly with the shop helps you stop mistakes and get good parts.

Look at what your project needs

Check what each shop can do

Ask questions before you choose

Use these steps for your next CNC parts job to get great results.

FAQ

What information do you need to get an accurate CNC machining quote?

You need to send drawings that show your part. Tell the shop what material you want. Say how many parts you need. Share when you want your parts delivered.

Tip: Clear drawings and notes help the shop know what you want and stop mistakes.

How do you check the quality of CNC machined parts?

You can ask for reports that show measurements. You can ask for a sample part to see how it looks. You can ask for certificates that prove the shop follows rules.

Quality Check | What You Get |

|---|---|

Inspection Report | Shows measurements |

Sample Part | See the real part |

Certification | Proves standards |

Can you request rush orders for CNC parts?

Yes, most shops can make parts fast if you need them quickly. Ask about fast-track choices and extra costs.

Fast delivery: 1-2 days

Standard delivery: 7-10 days

What should you do if a CNC part does not meet your specifications?

Contact the shop as soon as you find a problem. Most shops will fix or replace the part.

Note: Keep all your papers and reports to help solve problems fast.

LKprototype

LKprototype