Additive manufacturing process involves creating objects by adding layers based on digital plans. Today, companies use this additive manufacturing process to produce car parts and medical tools. Imagine a designer with a new product idea—this additive manufacturing process allows them to quickly test models. They can begin mass production much sooner than before.

Nearly 70% lower prototyping costs help companies save money.

Lead times shrink from weeks to days, enabling faster responses.

Up to 90% less wasted material benefits the environment.

Every step in the additive manufacturing process is crucial. Designers select the best materials and settings to ensure parts are strong and suitable for each industry. The additive manufacturing process is rapidly growing, transforming how products are made and distributed.

Key Takeaways

Additive manufacturing makes things by adding layers from digital designs. This saves time and cuts down on waste compared to old ways.

Picking the right materials and watching the process closely makes strong, good parts. Many industries like aerospace and healthcare use these parts.

This process helps companies go from prototypes to mass production fast. It also saves money and lets them change designs easily.

There are problems like slow speed and rough surfaces. But new technology and teamwork are helping fix these issues.

The future of additive manufacturing looks good. Machines are getting faster, software is getting smarter, and more industries are using it around the world.

Additive Manufacturing Overview

What Is Additive Manufacturing?

Additive manufacturing makes things by adding layers of material. Machines use digital designs to build parts from the bottom up. Many industries like this process because it is fast and does not waste much. It works with many materials, like metals and plastics. ASTM F3049-14(2021) is a standard that helps keep metal powders high quality. ASTM D4673-16 is a rule for plastics like ABS. ISO/TC 261 sets rules for words, steps, and quality. This helps companies use the same ways and terms.

Material Type | Standard or Description | Notes |

|---|---|---|

Metal Powders | ASTM F3049-14(2021) – Guide for Characterizing Properties of Metal Powders | Covers metal powders used in AM processes |

Nickel Alloy (UNS N07718) | ASTM F3055-14a(2021) – Specification for Powder Bed Fusion | Specific to nickel alloy powder bed fusion |

Polylactic Acid (PLA) | Biodegradable thermoplastic from renewable resources | Used in medical suturing and implants; body-compatible |

Acrylonitrile Butadiene Styrene (ABS) | ASTM D4673-16 – Classification for ABS plastics and alloys | Low cost, easy to fabricate, used in food processing and prototyping |

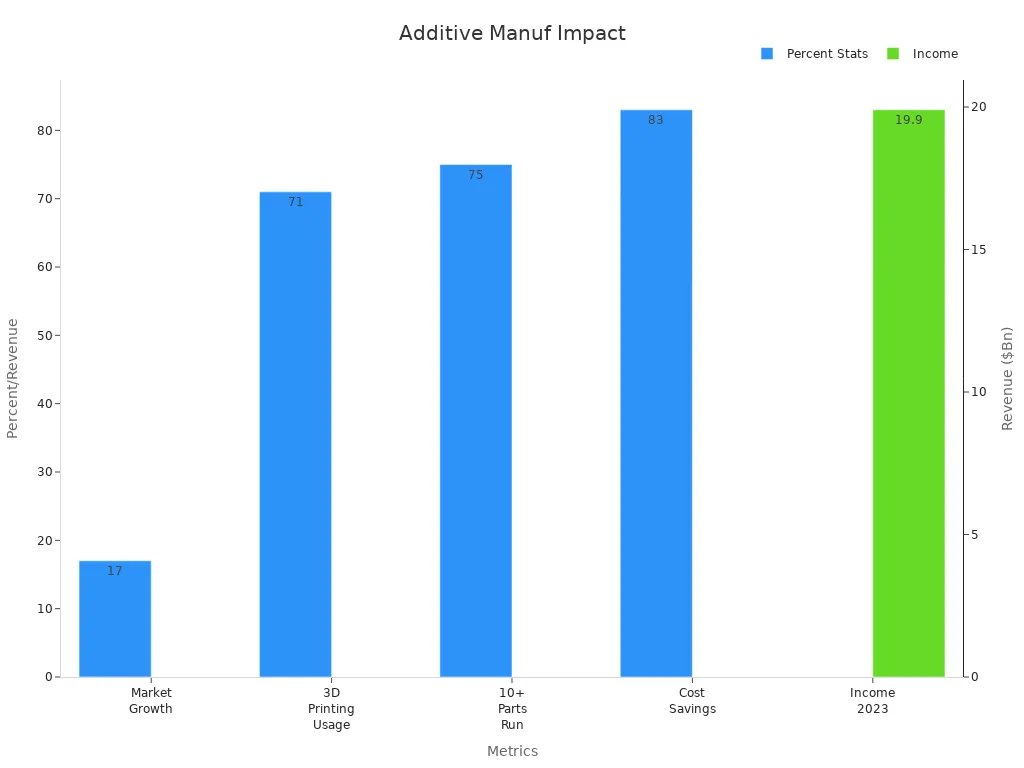

Additive manufacturing is growing very quickly. The market was $22.4 billion in 2024. It might reach $158.3 billion by 2034. North America has the biggest share at 38.6%. Most people use it for prototyping, which is more than half of all uses.

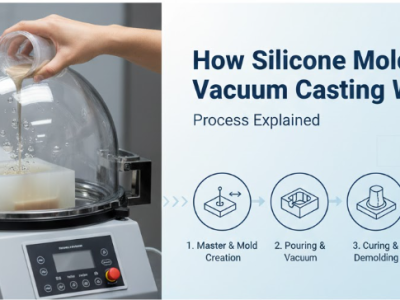

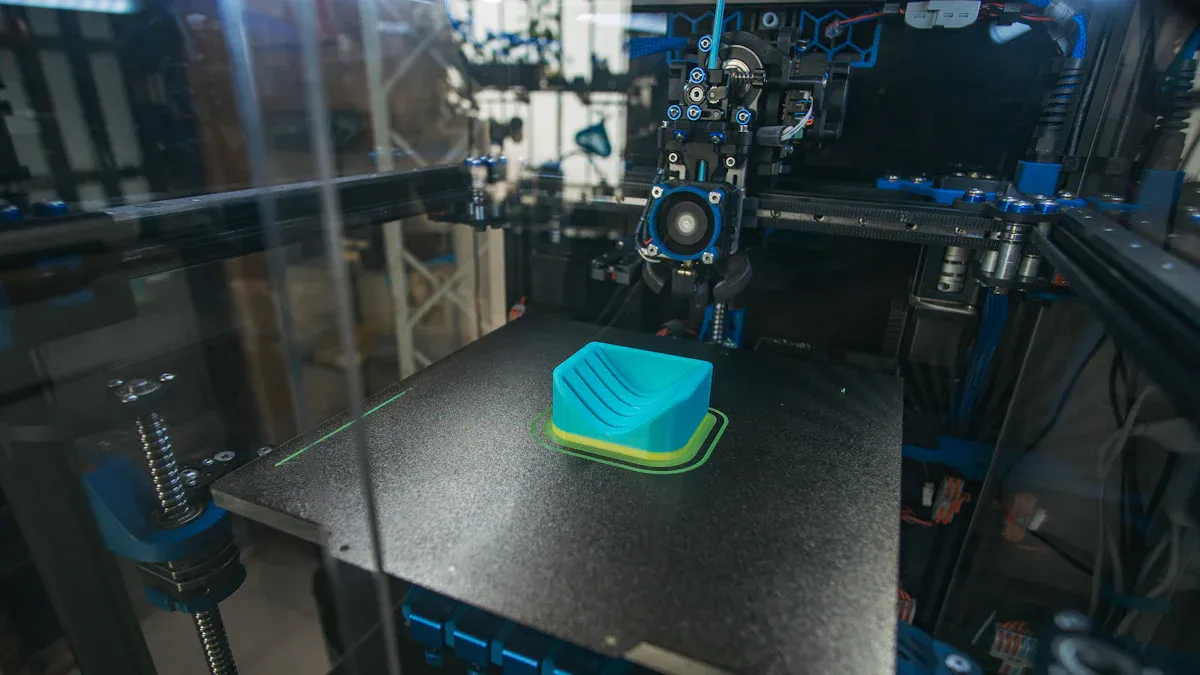

3D Printing Basics

3d printing is the most popular type of additive manufacturing. Machines follow digital plans to build objects one layer at a time. It starts with a design made on a computer using CAD software. The software cuts the design into thin layers. The 3d printer puts down material, like PLA or ABS, layer by layer. It keeps going until the object is finished.

Make a digital design with CAD software.

Cut the model into thin, flat layers.

The 3d printer reads these layers and adds material one by one.

Materials like plastic or metal are melted or joined to make each layer.

Layers are stacked to form the final object.

3d printing can make tricky shapes and lets you change things fast. It also saves material because it only uses what is needed.

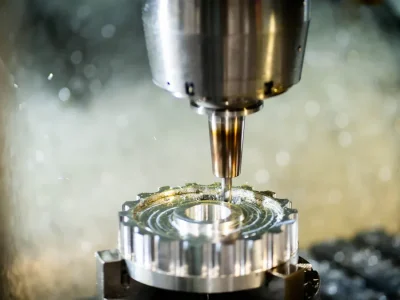

Additive Manufacturing vs. Traditional Methods

Additive manufacturing and traditional manufacturing are different in many ways. Traditional methods, like injection molding or CNC machining, are best for making lots of parts. They use molds or cut away extra material, which can waste resources. Additive manufacturing builds parts straight from digital files. This makes it easy to change designs and make small amounts.

Feature | Additive Manufacturing | Traditional Manufacturing |

|---|---|---|

Geometry | Enables complex, intricate internal structures and organic shapes | Limited by traditional tooling and processes |

Customization | Easily tailored to specific requirements without extra tooling costs | Limited customization, suited for mass production |

Waste Reduction | Minimal waste, uses only necessary material, reducing cost and environmental impact | Generates byproducts and waste materials |

Tip: Additive manufacturing works best for prototypes and custom parts. Traditional methods are better for making lots of the same thing.

Additive Manufacturing Process

Digital Design

The additive manufacturing process starts with a digital design. Designers use CAD software to make a 3D model. They check the model in many steps to make sure it works. The steps are:

Make the first design in CAD.

Use databases and tools like FEA to test the part.

Use topology optimization to make the part lighter and stronger.

Print test parts with the same materials and methods as the final part.

Test these parts in real life to see how they bend or break.

Compare test results with digital predictions using special tools.

Change the design based on test results to fix mistakes early.

Write down every step and make sure all software works together.

Designers also use generative design. This lets artificial intelligence suggest new shapes that fit the rules. It helps make tricky shapes that are hard with old methods. The digital design phase helps move from computer models to real parts easily.

Material Selection

Picking the right material is very important. Designers must think about quality, strength, cost, and how easy it is to use. There are over 1,500 metal materials for additive manufacturing. Each one has good and bad points. This makes picking hard, especially when materials are alike or do not mix well.

Mechanical properties like tensile strength, compressive strength, and impact resistance matter for strong parts.

Thermal properties like melting point and heat resistance are important for hot or cold places.

Chemical resistance helps parts last longer in tough places.

Cost and availability can decide if a project can happen.

New materials, like advanced composites and biocompatible metals, help make new things for medicine and electronics.

Many companies use special databases and software to pick the best material. These tools show data on strength, heat, and how long a part will last. This cuts down on guessing and makes things faster. Experts and industry rules also help pick materials for the additive manufacturing process.

Additive Manufacturing Processes

The additive manufacturing process has many steps to turn a digital design into a real thing. Here is how it works:

Designers make a 3D model with CAD software.

The model turns into an STL file, which slices it into thin layers.

Operators set up the machine, load the material, and adjust settings like layer thickness and temperature.

The machine builds the part layer by layer, following the plan.

Workers take the finished part out of the machine.

Post-processing makes the part smoother and stronger.

Quality control and testing make sure the part is good.

There are seven main types of additive manufacturing processes:

Category | Description |

|---|---|

Material Extrusion | Material pushed through a nozzle to form layers (e.g., FDM 3D printing). |

Vat Photopolymerization | Liquid resin cured by light to form solid layers (e.g., SLA, DLP). |

Powder Bed Fusion | Laser or electron beam fuses powder particles (e.g., SLS, SLM, EBM). |

Binder Jetting | Liquid binder glues powder particles together layer by layer. |

Material Jetting | Droplets of material deposited and cured to build parts. |

Sheet Lamination | Sheets of material cut and bonded to form objects. |

Directed Energy Deposition | Focused energy melts material as it is put down (often for metals). |

Each method works with different materials and can make tricky shapes. The choice depends on what the part needs and what it should do.

Post-Processing

Post-processing is a key step in the additive manufacturing process. Even with good machine settings, parts often need more work to be just right. Post-processing means removing supports, smoothing surfaces, and heat treating parts to make them stronger and look better.

The detailed steps show that post-processing can fix rough spots, small holes, or uneven shapes. These fixes help parts meet strict rules for things like planes and medical tools. Post-processing also lets companies add special finishes, like metal coatings or better heat resistance.

Companies must plan post-processing early. This makes sure the final part works well and keeps costs low. New machines and technology keep making post-processing faster and better.

Quality Control

Quality control and testing are very important for every additive manufacturing process. Companies use many ways to make sure each part is safe and meets the design.

Regular machine checks keep production accurate.

Materials come from trusted suppliers, and each batch is tested.

Real-time monitoring uses sensors and cameras to find problems during printing.

Post-processing steps, like smoothing and heat treatment, make parts better.

Inspections use 3D scanning and non-destructive testing to check size and strength.

Detailed records track every part from start to finish.

Certifications like ISO 9001 show high standards.

Traceability links each part to where it came from, which is important for planes and medicine. Real-time checks of powder properties, like flow and density, help fix problems fast. This lowers mistakes and keeps results the same. Data analytics and machine learning help find problems and make the process better over time. Companies use key performance indicators, like OEE, to measure and improve production.

Tip: Companies can control parameters influencing additive manufacturing processes by using advanced sensors, regular machine checks, and data analysis. This helps answer how these parameters can be controlled for optimal results and ensures every part meets strict standards.

Scaling Up Production

From Prototype to Mass Production

Moving from one prototype to making many products takes planning. Companies first make a prototype to test ideas and get feedback. They use the additive manufacturing process to change designs quickly. When the prototype works well, they start thinking about making more.

A good switch to mass production needs several steps. The table below lists important steps and what companies look for:

Workflow Stage / Aspect | Key Elements / Metrics | Industry Benchmarks / Outcomes |

|---|---|---|

Testing Phases | User Testing, Performance Testing, Market Testing | Design refinement, Quality assurance, Product positioning |

Manufacturing Readiness Factors | Product design optimization, Material availability and quality, Process validation | Component standardization, CAD verification, Supply stability |

Cost Analysis | Material costs at volume, Labor requirements, Equipment investment, Overhead | Economic feasibility, Profit margins, Setup and operational costs |

Quality Assurance | Functionality testing, Durability, Safety verification, Statistical process control | Consistent output, Defect rate reduction, Compliance adherence |

Strategic Scale-Up Planning | Production capacity, Workforce planning, Supply chain management, Quality control | Skilled labor training, Supplier reliability, Quality system implementation |

Lean Manufacturing & Efficiency | Waste elimination, Just-in-time production, Six Sigma, 5S workplace organization | 20-30% cycle time reduction, 10-15% material cost savings, Near-zero defect rates |

Success Metrics | Production yield rates, Quality control alignment, Cost parameters, Timeline accuracy | Meeting efficiency thresholds, Budget adherence, Realistic timelines |

The additive manufacturing process helps companies go from a few parts to thousands. They work on making production faster and keeping costs low. They also build a strong supply chain for bigger orders. Six Sigma process mapping helps compare small and large production steps. This makes sure teams use resources well and are ready for more work.

Other methods like injection molding and CNC machining help too. These methods cut down waste and make things run better. Quality control systems keep products good as numbers go up. Companies use demand forecasting to avoid making too many or too few parts. The additive manufacturing process lets companies make 1,000 or even 100,000 parts a month using the same steps.

Note: It is very important to test prototypes for how they work, how long they last, safety, and rules before making lots of them.

Challenges and Solutions

Making more products with the additive manufacturing process brings problems. Sometimes, machines cannot make enough parts fast. Parts may not always be the same. Changes in heat during printing can make parts different inside. Heat treatments made for old methods can give odd results.

Other problems are:

High process variability

Low part accuracy and surface quality

Inconsistent material properties

Lack of qualification and certification methods

Complexity in process physics, especially for metal-based additive manufacturing

Closed, proprietary machine systems that limit integration and control

To fix these problems, experts have found some answers:

The AM Bench initiative gives tests and problems to check computer models.

Working together worldwide helps make rules and ways to measure.

In situ measurements, like melt pool length and cooling rate, help control the additive manufacturing process.

Measurement science methods help check parts and materials better.

Example datasets and databases help design and approve new parts faster.

Process metrology, sensing, and control methods improve quality and speed.

Test methods and reference data lower the cost and time for approval.

Groups like America Makes and ASTM AM Center of Excellence help with research and rules.

NIST is a trusted group that gives science, rules, and data.

Sharing data and working together helps everyone learn more.

These solutions help companies make better parts, save time, and make custom products when needed.

Case Studies

Aerospace and automotive companies are leaders in using the additive manufacturing process. In aerospace, companies join many parts into one piece. This makes things lighter and cheaper. GE Aviation’s LEAP engine jet nozzle is a famous example. The nozzle has fewer parts, weighs less, and costs less to make. Boeing uses selective laser sintering (SLS) to make parts for planes. These examples show how aerospace uses additive manufacturing for new materials, accuracy, and quick production.

Car companies also use the additive manufacturing process. One company made more spare parts by using two steps. They made parts in local centers or used service providers, depending on how hard the part was to make. This helped with costs and getting approval. It also made it easier to make spare parts when needed, helping the supply chain.

Both industries have problems like getting approval, checking quality, and making enough parts. They solve these with digital tools, strong quality systems, and always trying to get better. These stories show that the additive manufacturing process can help make lots of products, custom items, and respond quickly to what people want.

Benefits and Limitations

Advantages of Additive Manufacturing

Additive manufacturing has many good points for companies. It lets people make shapes that are hard to build with old ways. This process uses only the material needed for each part, so there is less waste. Companies do not have to buy costly molds or tools. They can start making things fast, which helps them get prototypes and custom parts sooner.

The table below shows how traditional and additive manufacturing are different:

Aspect | Traditional Manufacturing | Additive Manufacturing |

|---|---|---|

Design Freedom | Tooling and machines limit design choices | Can make very complex shapes easily |

Material Efficiency | Wastes a lot of material | Uses much less material (35-80% less) |

Cost Efficiency | Cheaper for making lots of the same thing | Cheaper for small batches and tricky parts |

Performance | Has normal properties | Can change properties for each part |

Surface Finish | Parts look smooth | Needs extra work to look smooth |

Production Speed | Makes many parts quickly | Slower if making lots of parts |

Equipment Cost | Costs less at the start | Costs more at the start |

Sustainability | Uses more energy and makes more waste | Better for the planet, less waste |

Common Limitations

Additive manufacturing also has some problems. It is slow when making many parts, so old methods are better for big orders. Parts often need extra work to look and feel right. Machines cost a lot, and each part can use more energy. There are not as many materials to pick from, and post-processing is needed. Sometimes, using this technology makes supply chains harder, not easier. These problems can make it take longer for companies to use additive manufacturing everywhere.

Note: Supply chains can get more or less complex depending on many things. It does not always make things simpler.

Overcoming Challenges

People have found ways to fix these problems in additive manufacturing. Using two print heads or new printers can make things up to 20 times faster. Robots and machines help finish parts, so workers do not have to do as much. Special computer programs help plan work and check if parts will print well. Sensors watch the process and help keep quality high. More materials are being added, so companies have more choices. Groups like ISO and ASTM make rules so everyone follows the same steps. Training helps workers learn new skills faster. These ideas help more companies use additive manufacturing in their work.

Future of Additive Manufacturing

Emerging Trends

Additive manufacturing is changing fast. Many companies use 3d printing to make things quicker and cheaper. New methods like Continuous Liquid Interface Production and metal binder jetting help save money and time. Companies also use materials that are better for the planet.

Manufacturers mix 3d printing with artificial intelligence, the Internet of Things, and augmented reality. These tools help watch machines, find problems early, and make better designs. People can now order products made just for them. This is growing in stores and online shopping.

Experts think the market will grow a lot. It could go from $21 billion in 2023 to $119.39 billion by 2032. That is a growth rate of 21.3% each year. The main reasons are more digital tools, faster testing, and less waste.

Metric | Details |

|---|---|

Market Size (2023) | USD 21.0 billion |

Market Size (2032 forecast) | USD 119.39 billion |

CAGR (2025-2032) | 21.3% |

Key Growth Drivers | Digitization, rapid prototyping, design flexibility, waste reduction |

Innovation Trends | Multi-material printing, large-scale solutions, AI and IoT integration, sustainable materials |

Industry Adoption

Many industries use 3d printing for more than just test models. Aerospace, car, and healthcare companies make strong, light parts for planes, cars, and medical tools. Metal printing is now used more than plastic for tough parts.

Companies use 3d printing to make supply chains simpler and keep less stock. They can react fast to what customers want. Making small batches helps them change plans quickly.

Governments help with money and special programs. Both new and big companies make new products and get investments. North America uses 3d printing the most because of good technology and strong systems.

Reasons for using it are better products, saving money, and faster making.

Problems are high machine prices and slow speed.

Good things are easy custom orders, less waste, and faster delivery.

Additive manufacturing will keep changing how companies design, make, and send out products.

The steps from making a prototype to mass production need good planning. Designers must pick the right materials and check their work often. They also need to control the process and test quality. Companies can make many different designs and waste less material. They can also make custom products for each customer. But there are problems too. It can be hard to get smooth surfaces and perfect shapes. There are not as many materials to choose from.

Method | Strengths | Weaknesses |

|---|---|---|

VPP | Makes parts with fine detail and smooth finish | Costs more and has fewer material options |

PBF | Works with many materials and is cheaper | Parts can feel rough and are not always even |

MEX | Is flexible and does not cost much | Not as exact and has fewer material choices |

New machines and direct digital manufacturing will help more companies use these methods. Companies should think about both the good and bad sides as they grow.

FAQ

What materials can companies use in additive manufacturing?

Companies can pick from plastics, metals, ceramics, and some composites. Each one is good for different things. Plastics are great for making test models. Metals like titanium and steel are used for strong parts in cars and planes.

How does additive manufacturing help the environment?

Additive manufacturing only uses the material it needs. This means there is less waste. Many companies recycle leftover powder or plastic. Some printers use materials that break down naturally. These actions help keep the planet safe.

Can additive manufacturing make large products?

Yes, some machines can make big parts. Big printers can build car frames or airplane pieces. Most small printers make little things. Industrial printers can make much larger items.

Is additive manufacturing safe for making medical devices?

Doctors and engineers follow strict rules to keep medical devices safe. They test every part to make sure it fits and is strong. Many hospitals use 3D-printed tools and implants. The FDA checks and approves these before doctors use them.

LKprototype

LKprototype