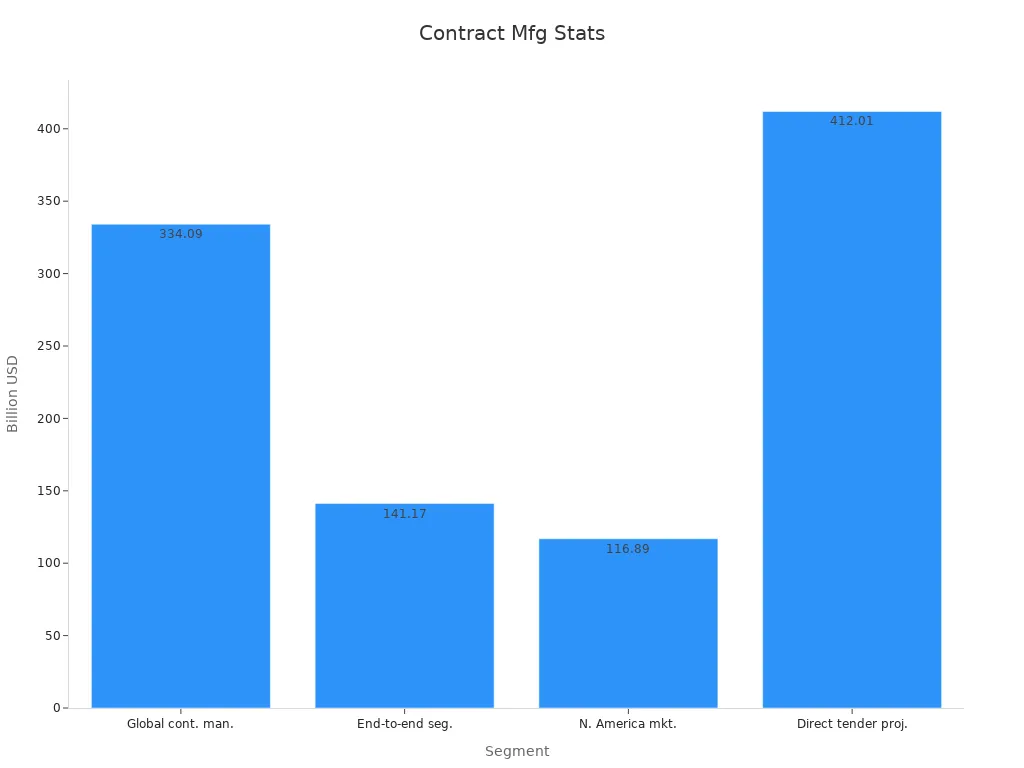

You need to understand the contract manufacturing process to see how it works. Contract manufacturing is when you allow another company to produce your product. You provide your product design and requirements to the contract manufacturing company, and they handle the production for you. This contract manufacturing process helps many businesses save money and operate more efficiently. The table below shows that contract manufacturing is expanding worldwide.

Metric/Segment | Value (2023/2024) | Projected Growth/Notes |

|---|---|---|

Global contract manufacturing market | USD 334.09 billion (2023) | CAGR 9.32% (2024-2031), projected USD 676.76 billion |

Pharmaceuticals & biopharmaceuticals | 32.35% market share (2023) | Expected USD 225.24 billion by 2031 |

End-to-end manufacturing segment | USD 141.17 billion (2023) | Highlights efficiency via integrated services |

Key Takeaways

Contract manufacturing means you pay another company to make your products. This helps you save money and time.

You need to talk clearly with the manufacturer. Picking the right manufacturer is important for good quality. It also helps your products arrive on time.

Testing prototypes early can help you find problems. This makes your product better before you make a lot of them.

Using data and checking quality often keeps things running well. It also makes sure your products work as they should.

There are different types of contract manufacturing. These types let you choose what fits your business and helps you grow.

Contract Manufacturing Process Steps

Identifying Needs

You begin by figuring out what you need to make. This is the first step and it is very important. You decide what product you want, how many you need, and what quality you expect. If you explain your needs clearly, you lower the chance of mistakes. This helps your products stay safe and high quality.

Work with your contract manufacturer to make a testing plan. The plan might have stability, microbial, and compatibility tests.

Make a checklist for GMP, labeling, safety, and rules.

Write down all testing and compliance steps. This helps you track and check everything.

Pick a contract manufacturer who knows about testing and compliance. They can help you meet safety and quality rules.

Tip: Get ready for audits by looking at your documents and old audit reports. Audits help you find problems and make your process better.

Selecting a Contract Manufacturer

After you know your needs, you pick a contract manufacturer. This choice changes your product’s quality, speed, and cost. You should look at both money and non-money factors.

Money factors are return on assets (ROA), return on equity (ROE), and net present value (NPV).

Non-money factors are speed, quality, and yield.

Most buyers care about part quality, speed, and price. You usually have to pick two out of three.

Other things to think about are moving fixed costs to variable, sharing risks, and using new technology.

Ask for quotes from different contract manufacturers. Compare their win rates and why they lose deals.

You also need to choose between full and partial outsourcing. Full outsourcing means the contract manufacturer does everything. Partial outsourcing means you only give them some parts or steps.

Agreement and Purchase Order

When you pick a contract manufacturer, you need an agreement and a purchase order (PO). These papers set the rules for working together.

A good PO process stops mistakes, delays, and money problems. It also makes your relationship with the supplier stronger. Clear agreements show what you need and what the supplier must do. They help you plan your budget and follow the rules.

KPI Name | Description and Impact on Production Success |

|---|---|

PO and Invoice Accuracy | High accuracy means fewer mistakes and saves money. |

Supplier Defect Rate | Checks for bad products and helps improve quality. |

Compliance Rate | Shows if you follow the rules and lowers risks. |

Supplier Lead Time | Measures how fast suppliers fill orders; faster is better. |

Procurement ROI | Shows savings and benefits from clear agreements and POs. |

Note: Talking clearly and having detailed agreements are very important for contract manufacturing.

Prototyping and Approval

Before making lots of products, you and your contract manufacturer make prototypes. This step helps you find problems early.

Check prototypes for mistakes or problems.

Write down any issues you see.

Find out if the problem is from design or making the product.

Fix the problem so it does not happen again.

Only approve parts that pass the checks.

Keep talking with your contract manufacturer to make things better.

Work with design teams and suppliers to make sure everything is right.

Finding problems early saves money later.

Testing and feedback make the product better.

Fast prototyping like 3D printing lets you change things quickly.

Real prototypes help everyone understand the product.

Prototyping helps you find design and safety problems before making a lot. This step makes sure your product is good and safe.

Production and Assembly

After you approve the prototype, the contract manufacturer starts making the product. This is where full production happens and being efficient is important.

KPI Name | Description | Efficiency Aspect Measured |

|---|---|---|

Overall Equipment Effectiveness (OEE) | Checks if machines work well and make good products. | Machine use and quality |

Throughput | Shows how much and how fast you make products. | Output and speed |

Downtime | Tracks when machines are not working. | Lost time |

Manufacturing Cycle Efficiency | Compares useful time to total time. | Speed and less waste |

Asset Utilization | Shows how well you use your equipment. | Use of capacity |

Capacity Utilization | Checks how much of your production space you use. | Efficiency |

First Pass Yield | Counts products made right the first time. | Less waste |

Production Attainment | Checks if you meet your production goals. | Staying on schedule |

Cycle Time | Time to finish one product cycle. | Speed and efficiency |

Unit Costs | Average cost to make one product, not counting materials. | Cost efficiency |

You and your contract manufacturer should watch these numbers to keep production running well. OEMs use real-time data to make machines work better and cut down on lost time.

Quality Control

Quality control is needed in every step of contract manufacturing. You and your contract manufacturer must use strong quality checks to make sure products work well.

Statistical Process Control (SPC) looks at data to find problems early.

Hypothesis testing checks if changes make products better.

Design of Experiments (DOE) tests different ways to improve quality.

Control charts show if things are working right or need fixing.

KPIs like defect rates, on-time delivery, and complaints show how you are doing.

Checking quality during and after making products helps you catch problems fast. Keeping records helps you see trends and fix issues, so you keep getting better.

Tip: Use real-time data and regular checks to keep quality high.

Delivery and Logistics

The last step is delivery and logistics. Good delivery makes sure your products get to customers on time and in good shape.

Talk with suppliers and cut down order wait times.

Plan and schedule production to stop delays.

Use lean methods to remove waste.

Automate and use digital tools for faster work.

Use real-time tracking to watch shipments and avoid delays.

Companies that use supply chain tracking get better on-time delivery. For example, Smithfield raised its on-time delivery from 87% to 94% by working with trucking companies. Kraft Heinz got 5% better in one year by picking good carriers and using tracking tools.

Good delivery and logistics help you plan with stores and change delivery times if needed. This step finishes the production cycle and keeps customers happy.

Types of Contract Manufacturing

Full Production Outsourcing

Full production outsourcing means contract manufacturers do every step for you. You give them your product design and what you need. They find materials, make the product, put it together, and pack it. Sometimes, they even ship it for you. This is good if you want to spend time on marketing or new ideas instead of running a factory.

Full outsourcing can make things faster and cost less to manage. Many contract manufacturers use new technology and strong quality checks. You get to use their skills and tools. Reports from BCC Research say full outsourcing is common in electronics and pharmaceuticals. It gives you more choices and lets you use global supply chains.

Tip: Full production outsourcing helps you grow fast, but always check the contract manufacturer’s history.

Component or Subcontract Manufacturing

Component or subcontract manufacturing lets you keep some control. You might make the main product yourself and let others make certain parts. This way, you can watch quality and costs better.

Here is a table that shows how making parts yourself compares to full outsourcing:

Metric / Outcome | Component Remanufacturing In-House (RIS) | Remanufacturing Outsourcing (ROS) | Additional Insights on Partial Outsourcing and Related Factors |

|---|---|---|---|

Peak Capacity Cost | Lower | Higher | N/A |

Inventory Holding Cost | Lower | Higher | N/A |

Backlog Cost | Lower | Higher | N/A |

Bullwhip Effect | Less | More | N/A |

Manufacturing Production Duration | Longer (may increase costs) | Shorter | N/A |

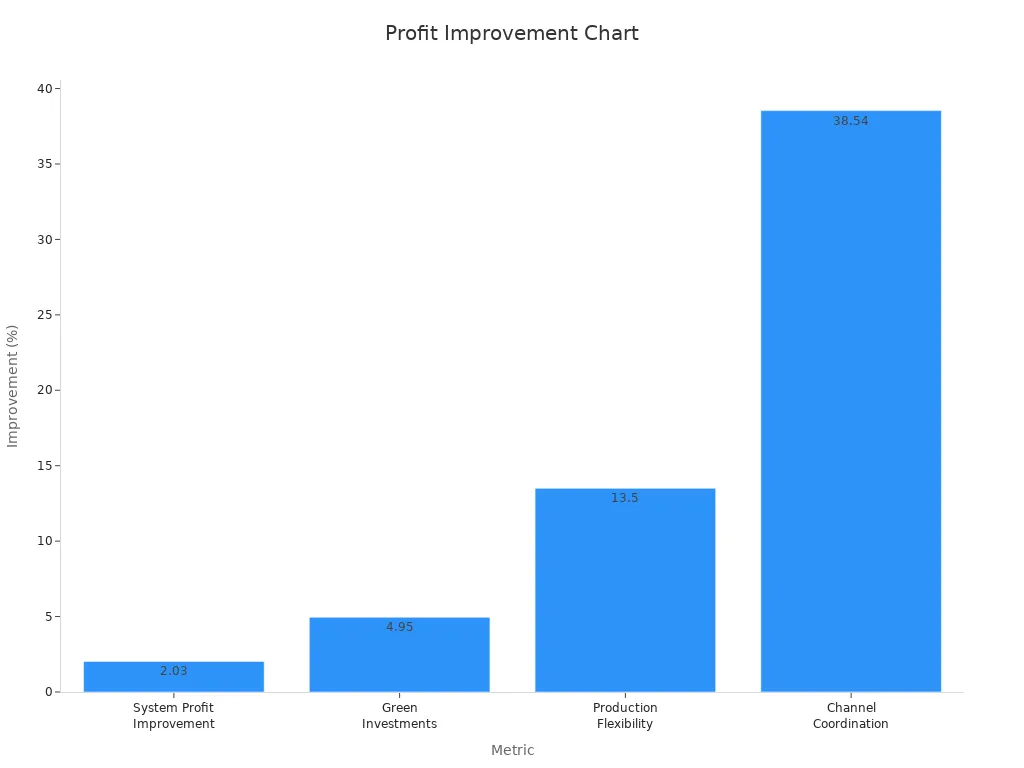

System Profit Improvement (Partial Outsourcing) | N/A | N/A | +2.03% |

Profit Improvement (Green Investments) | N/A | N/A | +4.95% |

Profit Improvement (Production Flexibility) | N/A | N/A | +13.50% |

Profit Improvement (Channel Coordination) | N/A | N/A | +38.54% |

You can see that partial outsourcing can help you earn more money. This is true if you spend on flexibility and work well with others. This model is good if you want some control and also want the good things from outsourcing.

Private Label Manufacturing

Private label manufacturing is when contract manufacturers make products for your brand. You do not have to design or create the product yourself. You pick from products they already make and sell them with your brand name.

This type of contract manufacturing is growing fast. Studies show that most people in the U.S. buy private label products. They think these are as good as or better than big brands. Private labels made almost $199 billion in sales in 2021. Sales grew by 5-6.2% in recent years. You can often sell these products for 20-30% less than big brands because you save money on ads and middlemen.

Evidence Aspect | Description & Supportive Details |

|---|---|

Market Size & Growth | Private Label Manufacturers Association says U.S. store brand sales went up 11.3% in 2022, reaching $228 billion. |

Competitive Advantage | Private labels help stores stand out and get more customers by meeting special needs. |

Risk Considerations | Private label sellers have risks like product problems, so they must manage these risks. |

Private label manufacturing helps you be different and make customers loyal. You still need to watch for risks and check quality, just like with other contract manufacturing types.

Pros and Cons of Contract Manufacturing

Advantages

There are many good things about using contract manufacturing. It helps you save money and lets you focus on your main work. Here are some important benefits:

You do not need to buy costly machines or pay for repairs and workers.

Lower costs mean you can spend more on research, ads, or helping customers.

Contract manufacturers can change how much they make for you. This helps you meet what the market wants.

You get to use new technology and skilled people. This helps you make better products.

You can grow your business without building new places or hiring more people.

Contract manufacturing changes fixed costs into costs that change. This gives you more ways to use your money.

Many contract manufacturers help with design and engineering. This makes your product better and faster to sell.

You can move where you make things if there are problems. This keeps your business strong.

Tip: With contract manufacturing, you can work on your brand. Experts will take care of making and checking your products.

A survey of 275 companies found that by 2010, 29% of what they made would be outsourced. Most companies pick contract manufacturing to save money. They also care about quality, being on time, and having good partners.

Risks and Disadvantages

You should know the bad sides of contract manufacturing too. Some problems can hurt your business if you do not watch out.

A study of 473 U.S. industries showed that contract manufacturing can make owning things cost more. You might spend less on new ideas and sometimes see lower product quality. Strong contract manufacturers could even become your rivals. These problems can take away the good parts of contract manufacturing if you do not check quality well.

In food and drinks, companies have problems with quality, being on time, and making products the same way each time. If your contract manufacturer does not do a good job, customers may stop trusting you. You also need to look for special needs, like certain certificates or help with new products.

Aspect | Advantages | Limitations / Challenges |

|---|---|---|

Cost Savings | Lower operating and capital costs | May ignore supplier ability and long-term costs |

Quality Products | Access to expertise and advanced technology | Product quality may drop without strong checks |

Flexibility | Easy to scale production | Problems with sharing data and keeping good relationships |

Strategic Alignment | Focus on core business | Needs big changes in how you manage things |

Note: Always check if your contract manufacturer can make good products and finish on time. Talking clearly and having good deals help you avoid most problems with contract manufacturing.

Success Tips for Contract Manufacturing

Choosing a Contract Manufacturer

Picking the right contract manufacturer is very important. First, write down what your product needs. This includes materials, how it should work, and what it must do. Find a contract manufacturer with a good history and strong quality checks. Make sure they follow the rules for your industry. Ask if they know how to move technology from one place to another. Check how they get their supplies and what they do if problems happen.

Tip: Always keep your ideas safe with clear contracts and rules about secrets.

A good contract manufacturer will explain their quality checks. They will show you how they finish work on time. You should also decide who does what. This stops confusion and keeps your project moving.

Managing the Process

You can manage contract manufacturing better with real-time data and machines. Many companies use sensors and cloud tools to watch shipments and how suppliers do. AI helps plan orders, pick suppliers, and find the best ways to deliver. Dashboards let you see your whole supply chain. This helps you act fast if something goes wrong.

Use automatic inventory tools to stop running out or having too much.

Meet often with your contract manufacturer to fix problems quickly.

Set clear goals for delivery, quality, and how well things work.

Using data helps you save money and waste less. It also helps you make better choices. Train your team and use data in your work to get the best results.

Avoiding Common Pitfalls

Many problems happen because people do not talk enough or check quality well. You can stop these problems by talking often and checking quality at every step. Use audits and reports to find problems early.

Pick a contract manufacturer with strong quality checks.

Do not make them use your own quality system, as this can cause fights.

Use clear numbers and scorecards to see how things are going.

Use risk tools to find and fix problems before they get big.

Note: Talking often and having clear deals help stop mix-ups and keep your production working well.

You can do well with contract manufacturing if you follow simple steps and make good choices. First, know what you need. Next, pick a partner you can trust. Make sure you both agree on the rules.

You spend less money because you make more at once.

You can work on your main business while others make your products.

You get better products and they arrive faster.

Strategic Benefit | Explanation |

|---|---|

Scalability and Flexibility | Change how much you make to fit what people want and help your business grow. |

Quality Assurance | Keep your products good and make them better as time goes on. |

Look at your goals and check out different partners before you choose. Talking often and having clear rules helps you stop problems and helps your business get bigger.

FAQ

What is the difference between contract manufacturing and outsourcing?

A contract manufacturer makes your product for you. Outsourcing means hiring another company to do any job, not just making things. Contract manufacturing is a kind of outsourcing, but it only covers making products.

How do you protect your product idea with a contract manufacturer?

You sign a non-disclosure agreement (NDA) before you share your design. This paper is a legal promise to keep your ideas safe. Always make sure your contract manufacturer follows the rules and respects your rights.

Can you change your order after production starts?

You can ask to change your order, but it might cost more or take longer. Tell your contract manufacturer right away if you want changes. Acting fast helps stop bigger problems.

What should you look for in a good contract manufacturer?

You should look for:

Strong quality checks

Good reviews from other customers

Clear and easy communication

Experience in your type of business

Can finish work on time

LKprototype

LKprototype