Choosing a urethane casting service for prototyping needs careful thought. You should look at their skills, quality, material choices, support, and price. Make sure the provider can do what your project needs. Check if they fit your budget and timeline. Learn about mold life, picking materials, and how costs work. This helps you stop problems before they happen. Providers with a 99.96% quality success rate and ISO certifications give parts with almost no defects. MetricWhy It MattersQuality Success RateShows provider is reliableCustomer Satisfaction ScoreShows how good the service isISO CertificationsProves they follow strict rules Following steps and clear rules helps…

Polyurethane resin is a polyurethane resin strong and long-lasting material. It works well for many applications, handling heat up to 180 °C and pressure up to 350 bar. It resists damage from wear, scratches, chemicals, and weather. Even with 20% recycled material, it remains tough. Its flexibility and protective traits make it ideal for industrial, commercial, and DIY projects. Key Takeaways Polyurethane resin is tough and bendable, perfect for many uses like factory floors and protective layers. It handles heat and heavy weight, showing it lasts in tough places. Polyurethane resin fights damage from wear, chemicals, and sunlight, working well…

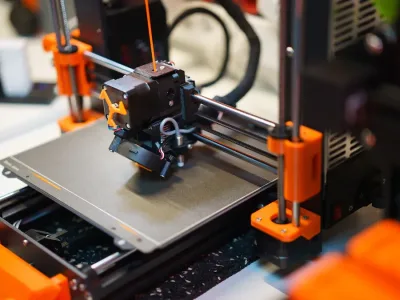

Vacuum casting uses silicone molds and vacuum chambers to make detailed parts. It is helpful for creating small batches that look like final products. This process makes prototypes very accurate and meets industry rules. The vacuum casting market is growing fast. It was worth $1.5 billion in 2022 and may grow 7.5% each year until 2030. Industries like cars, planes, and healthcare use vacuum casting to make high-quality parts. It works quickly and saves money, so manufacturers like it for making precise parts fast. Key Takeaways Vacuum casting is great for making detailed models and small amounts. It saves money…

Urethane rubber casting is an effective method for creating flexible molds. These durable molds are crafted using liquid urethane rubber casting, making them ideal for replicating intricate designs with precision. The process achieves size tolerances within ±0.010” to ±0.020”, which, while less precise than injection molding, still delivers reliable results. This technique is particularly beneficial for developing and testing new products. A single mold can produce 1–10 parts daily, depending on the type of urethane rubber casting used and the complexity of the part's design. The entire process, from start to finish, typically takes just a few weeks, making it…

Urethane and silicone casting involves using liquid urethane resin poured into silicone molds for creating parts or prototypes quickly and neatly. In contrast, silicone casting utilizes liquid silicone rubber to replicate objects or produce detailed components. Both urethane and silicone casting methods play a crucial role in modern manufacturing and prototyping. These techniques are increasingly valuable across various industries. For instance: The global urethane rubber market was valued at $1.5 billion in 2023 and is projected to grow to $2.6 billion by 2032. The rising demand for custom products has led to an increase in the use of urethane and…

Choosing the right method for manufacturing products is crucial. Polyurethane casting and injection molding differ in several aspects, such as production volume, cost, time, and materials. Polyurethane casting is ideal for small batches or prototype models, while injection molding is more suitable for large-scale production due to its lower cost per unit. Understanding these differences allows you to select the most effective approach for your project, ensuring optimal results. Key Takeaways Pick urethane casting for small jobs or test models. It is cheaper and helps test designs quickly. Use injection molding if you need many parts made. It costs less…

Polyurethane resin is a unique material created by combining specific chemicals. Renowned for its flexibility, durability, and longevity, polyurethane resin is widely utilized across various industries due to its versatility. It offers excellent adhesion, chemical resistance, and impact tolerance, making it essential in applications such as automotive, construction, and electronics. Advances in technology have further enhanced polyurethane resin, enabling it to withstand high temperatures. Its remarkable strength and adaptability solidify polyurethane resin as a cornerstone in contemporary products and designs. Key Takeaways Polyurethane resin is strong, bendable, and long-lasting. It works well in building, cars, and electronics. This material fights…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.