CNC controllers are the main part of a CNC machine CNC system. They function like a brain, automating complex manufacturing tasks. These controllers convert designs into precise movements, enabling CNC machines to produce high-quality parts with minimal human intervention. This automation boosts speed and ensures consistent results every time.

CNC machine CNC technology is utilized across various industries. For example:

It integrates with IoT and data tools to enhance speed and accuracy.

CNC machines CNC now manufacture 50% of automotive parts.

In India, CNC machine CNC technology contributes to 18% of the industry's growth.

CNC machine CNC systems have revolutionized manufacturing, making it faster, more precise, and highly innovative.

Key Takeaways

CNC controllers handle tasks faster and more accurately, with fewer mistakes.

Learning G-code is important since it tells machines how to move.

CNC technology helps industries like cars and planes make better parts quickly.

Picking PC-based or PLC-based controllers depends on what your project needs.

CNC controllers give instant updates to keep quality high and avoid delays.

What Are CNC Machine Controllers?

Definition and Role in CNC Machines

A CNC controller is the main system of a CNC machine. It acts like the brain, turning digital designs into exact movements. It connects design software to machine parts by sending signals. This removes the need for manual controls, making automation key in manufacturing.

Here’s how CNC controllers work:

They read G-code, which tells the machine what to do.

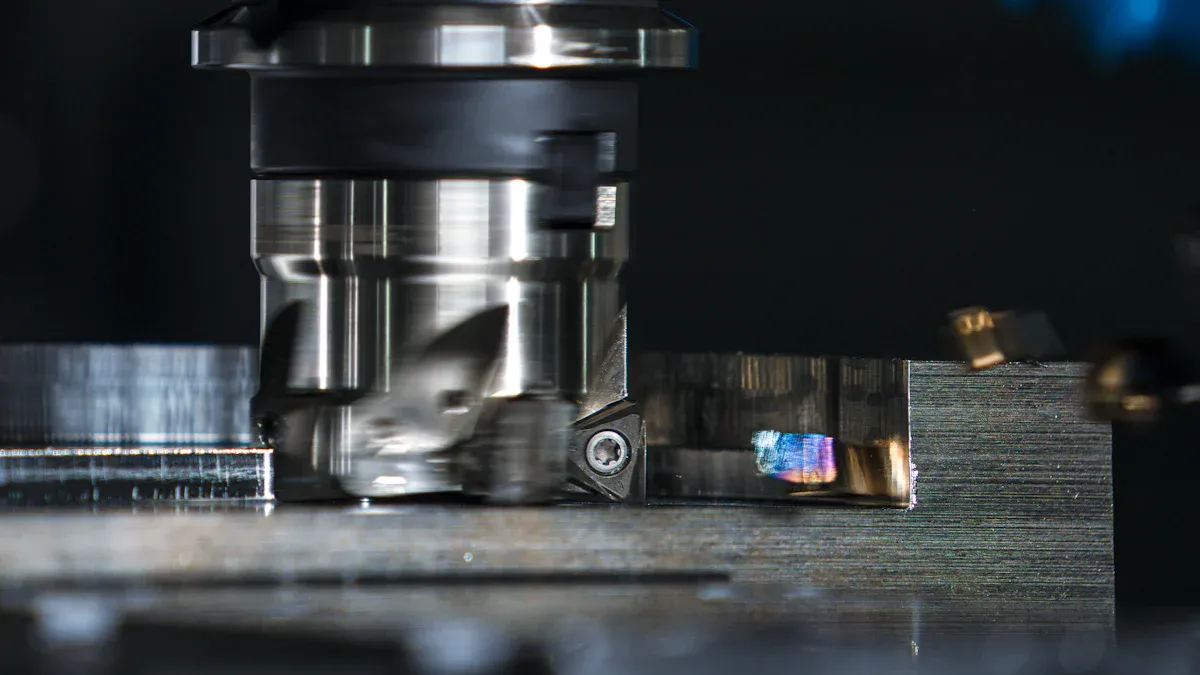

They control parts like motors and spindles for precise movements.

They automate machining, cutting down human effort and mistakes.

They use either a PC or PLC for computing, depending on needs.

By automating tasks, CNC controllers help make manufacturing accurate and consistent.

Importance in Modern Manufacturing

CNC controllers are crucial for today’s manufacturing. They help industries create high-quality parts quickly and accurately. With automation, complex designs and repeated tasks become easier. This technology has improved industries like cars, planes, and electronics by saving time and boosting efficiency.

Data shows the impact of CNC controllers:

They track tool wear and accuracy to keep quality high.

Real-time checks find problems early, keeping production steady.

Data-based changes improve processes over time.

These advancements make CNC technology essential for modern manufacturing.

Key Features of CNC Controllers

CNC controllers have features that make them useful and efficient. Some important features are:

Precision Control: They follow commands exactly for reliable results.

Real-Time Feedback: Sensors give instant updates on machine performance.

User-Friendly Interfaces: Touchscreens and simple software make them easy to use.

Integration with CAD/CAM Software: They connect smoothly with design tools for better workflows.

Scalability: They work for small projects or big industrial jobs.

These features make CNC controllers essential for innovation and efficiency in manufacturing.

Components of a CNC Controller

Hardware Parts in CNC Machines

The hardware in a CNC controller is its main structure. It includes motors, drives, and sensors that follow your commands. Motors, like stepper or servo motors, move the machine's parts. Drives send stronger signals to power these motors. Sensors check the process to keep it safe and accurate.

Modern CNC machines use advanced hardware for better performance. Real-time processing helps machines respond quickly to commands. Fast communication allows smooth data sharing between devices. These features make the hardware reliable and useful for many tasks.

Software and Firmware in CNC Systems

Software and firmware control how CNC machines work. The software reads your designs and turns them into G-code instructions. Firmware, inside the controller, helps the software and hardware work together smoothly.

CNC software has helpful features like CAD/CAM tools, which make programming easier and reduce mistakes. Real-time analytics let you watch machine performance and adjust as needed. Some systems even use AI to improve tasks and predict repairs. These tools make CNC controllers smarter and better for tough jobs.

Feature | What It Does |

|---|---|

Real-time Processing | Controls CNC tasks quickly and accurately. |

High-Speed Communication | Shares data easily with other devices. |

User-friendly Interfaces | Makes it simple for operators to learn and use. |

CAD/CAM Integration | Speeds up programming and lowers errors. |

Real-time Analytics | Lets you check machine performance live. |

Advanced Monitoring | Spots problems early to avoid bigger issues. |

Precision Upgrades | Keeps results accurate and reduces waste. |

AI Controls | Uses smart tech to improve tasks and plan maintenance. |

Input and Output Systems in CNC Controllers

Input and output systems help you communicate with the CNC machine. Input devices, like keyboards or USB ports, let you load designs and set options. Output systems, like screens, show real-time updates on the process.

These systems make CNC machines easier to use. Safety features protect workers, and simulation tools find mistakes before cutting starts. Tool management improves accuracy, helping you get good results with less waste.

How CNC Controllers Process G-Code and Work With CAD/CAM Software

What Is G-Code in CNC Machines?

G-Code is the set of instructions CNC machines follow. It tells the machine how to move, cut, or shape materials. Each line of G-Code gives details like tool position, speed, and cutting depth.

When you load G-Code into the CNC controller, it turns the code into exact movements. For example, if the code says to cut straight, the machine follows that path perfectly. This accuracy helps make parts the same every time.

Think of G-Code as a step-by-step guide. It removes guessing and ensures every action is repeatable. This makes CNC machines reliable and great for tricky tasks.

How CAD/CAM Software Helps CNC Machines

CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software are important tools for CNC machines. They let you design parts on a computer and turn those designs into G-Code.

Using CAD/CAM software with CNC controllers makes manufacturing easier:

You can program tool paths faster, saving time.

Simulations show how machines will work, reducing mistakes.

Better setups mean safer and more efficient processes.

This software simplifies programming and lowers errors. It also lets you see how the machine will work before starting. This helps industries make accurate parts quickly.

Real-Time Feedback and Actions in CNC Controllers

CNC controllers give real-time updates while the machine works. Sensors check how the machine is performing and send data back. This helps you fix problems right away.

For example, if a tool gets dull, the controller warns you. You can replace it before it ruins the part. This keeps production smooth and reduces delays.

CNC controllers also adjust movements as they process G-Code. This ensures every cut or drill matches the design perfectly.

These features make CNC machines more than just time-savers. They turn manufacturing into a precise and flexible process for modern needs.

PC-Based vs. PLC-Based CNC Controllers

Differences Between PC-Based and PLC-Based Systems

PC-based and PLC-based CNC controllers work differently. PC-based controllers use regular computers to run CNC machines. They are flexible and good for tasks needing detailed graphics or tough calculations. But they don’t have special systems for fast, real-time control. This can slow them down and make results less consistent.

PLC-based controllers are made for factories. They are strong and reliable, even if something goes wrong. Some newer PLCs work like PCs, making them more alike. Still, PLCs are better at handling big jobs and balancing cost with performance for manufacturing.

Pros and Cons of Each CNC Controller Type

Both types of CNC controllers have good and bad points.

PC-Based Controllers:

Pros: Easy to program, great visuals, and works with modern software.

Cons: Slower real-time control and less reliable during system problems.

PLC-Based Controllers:

Pros: Very reliable, tough design, and steady performance in hard conditions.

Cons: Not as good for tricky calculations or detailed graphics.

Picking the right controller depends on what your factory needs.

Applications in Modern Manufacturing

Both PC-based and PLC-based CNC controllers are important for manufacturing today. PC-based systems are best for industries like cars and planes. They handle hard designs and need high accuracy.

PLC-based controllers are used where strength and reliability matter most. Factories making heavy machines or energy equipment rely on them. They work well in tough places and keep things running smoothly.

Knowing what each system does well helps you choose the best controller. This improves your CNC machine and makes your factory work better.

Benefits and Applications of CNC Controllers

Precision and Consistency in CNC Machines

CNC controllers help machines work with great accuracy. They keep production steady, making high-quality parts every time. This is very important in fields like aerospace and medicine, where small mistakes can cause big problems.

CNC systems adjust for tool wear, heat, and vibrations. This keeps results precise and reliable.

Advanced controls reduce the need for people to operate machines. This ensures parts match designs exactly.

AI tools study machine data to improve performance and cut errors.

By keeping quality consistent, CNC machines help meet industry rules and cut waste. This makes them a key part of modern manufacturing.

Efficiency and Scalability in Modern Manufacturing

CNC machines make manufacturing faster and easier to scale. Multi-axis controllers are popular because they handle complex tasks well. These controllers move in many directions to create detailed parts with precision.

AI programs improve machining in real-time, saving materials and boosting efficiency.

CNC systems simplify processes, reducing setup time and using resources better.

Faster production and lower costs make CNC machines perfect for industries needing speed and accuracy, like cars and planes.

This flexibility lets you handle both small and large projects easily. It helps make your production more competitive.

Industry Applications of CNC Technology

CNC technology has changed many industries by improving precision and speed. In car-making, CNC machines create engine parts and detailed designs with great accuracy. Airplane makers use CNC systems to build strong, lightweight parts that meet strict safety rules.

In healthcare, CNC machines make surgical tools and prosthetics with high precision. Electronics and energy industries also use CNC systems to make circuit boards and heavy machine parts.

Using CNC technology in your work can boost productivity and meet modern manufacturing needs.

CNC controllers are important for modern manufacturing. They help make parts precise, save time, and encourage new ideas. They also reduce mistakes and waste, making production better. As industries grow, CNC technology keeps improving.

The CNC controller market is expected to grow from $2.96 billion in 2024 to $4.02 billion by 2029. This growth is due to high demand in industries like aerospace, cars, and medicine.

Future improvements include AI tools for better quality checks, eco-friendly machines, and using AR, VR, and digital twin technologies.

These changes will make manufacturing smarter, cleaner, and faster in the future.

FAQ

What does a CNC controller do?

A CNC controller runs CNC machines automatically. It changes digital designs into exact movements. This ensures accurate and steady manufacturing. It also removes the need for manual work, lowers mistakes, and speeds up production.

How is G-Code used in CNC machines?

G-Code gives CNC machines step-by-step instructions. It tells them how to move, cut, or shape materials. Each line includes details like tool position, speed, and depth. This makes actions precise and easy to repeat.

Can all software work with CNC controllers?

Most CNC controllers work with CAD/CAM software. These programs help design parts and create G-Code. But not all software fits every controller. Always check if they are compatible before using them.

Tip: Keep your software updated for better results and easier use.

Which industries use CNC technology the most?

CNC technology is common in aerospace, cars, healthcare, and electronics. It makes precise parts like engine pieces, surgical tools, and circuit boards. Its ability to handle tricky designs makes it very useful in these fields.

Should I choose PC-based or PLC-based controllers?

It depends on what you need. PC-based controllers are great for detailed designs and hard calculations. PLC-based controllers are stronger and better for tough jobs. Pick one based on your project’s needs and conditions.

Note: Think about your goals before making a choice.

LKprototype

LKprototype