A 4 axis CNC machine adds a rotational axis to the traditional three axes, allowing for more complex and precise machining. This additional axis enables the machine to access the workpiece from different angles, making it ideal for intricate designs and complex geometries. In this article, you’ll learn about the features, uses, and benefits of 4 axis CNC machines, helping you understand why they could be a valuable addition to your manufacturing process.

Key Takeaways

4-axis CNC machining offers enhanced precision and design flexibility by introducing an A-axis for rotational movement, crucial for complex components in industries such as aerospace and medical.

The main types of 4-axis CNC machines—milling machines, lathes, and routers—serve diverse applications, each tailored for specific tasks ranging from intricate part creation to large-scale production.

While 4-axis CNC machines improve efficiency and reduce production time, potential drawbacks include higher costs and the need for skilled operators, emphasizing the importance of regular maintenance for longevity.

Understanding 4 Axis CNC Machining

The process of 4-axis CNC machining marks an advanced level of manufacturing by integrating a rotational axis, which amplifies both the intricacy and precision in the fabrication of parts. In contrast to conventional 3-axis machinery that functions along X, Y, and Z axes, machines equipped with a 4th axis encompass an A-axis that revolves around the X-axis. The incorporation of this additional axis facilitates more complex designs and enables machining at diverse angles unavailable to traditional 3-axis devices.

With its ability to approach a workpiece from various perspectives, the A-axis significantly improves overall machining capabilities. This feature is particularly essential for creating components requiring angled incisions or specific characteristics found in sectors like aerospace or medical equipment production.

Employing 4-axis CNC technology promises enhanced precision and expedited production times when crafting intricate geometries. This advancement plays a vital role in augmenting design versatility within component manufacture.

The Mechanics of 4 Axis CNC Machines

The engineering behind 4 axis CNC machines is a testament to modern precision, encompassing the X, Y, Z, and A axes for exceptional accuracy and productivity. Movement along the linear axes (X, Y, and Z) combines with rotational motion around the X-axis via the A-axis. This synergistic movement pattern enables these machines to fabricate intricate geometries from various angles while minimizing time consumption and potential errors by negating repeated repositioning of the workpiece.

In terms of improving precision and enhancing product quality on multiple faces of a workpiece simultaneously, 4 axis CNC machinery proves invaluable. Industries that demand complex designs with stringent tolerances—like aerospace or medical device manufacturing—rely heavily on this advanced capability.

With such sophisticated control over both cutting tools and workpieces through two crucial axes—inclusive of rotation alongside linear motions—these machines consistently produce superior results when tackling elaborate machining tasks.

Types of 4 Axis CNC Machines

CNC machines with 4 axis functionality are available in several forms, catering to distinct uses and sectors. The principal varieties include 4 Axis CNC Milling Machines, Lathes with 4 Axis capabilities, and Routers operating on a 4 axis system. These machines each possess specialized features that make them adept at performing various operations, from fabricating complex components to precisely manipulating sizable materials across different industries.

4 Axis CNC Milling Machines

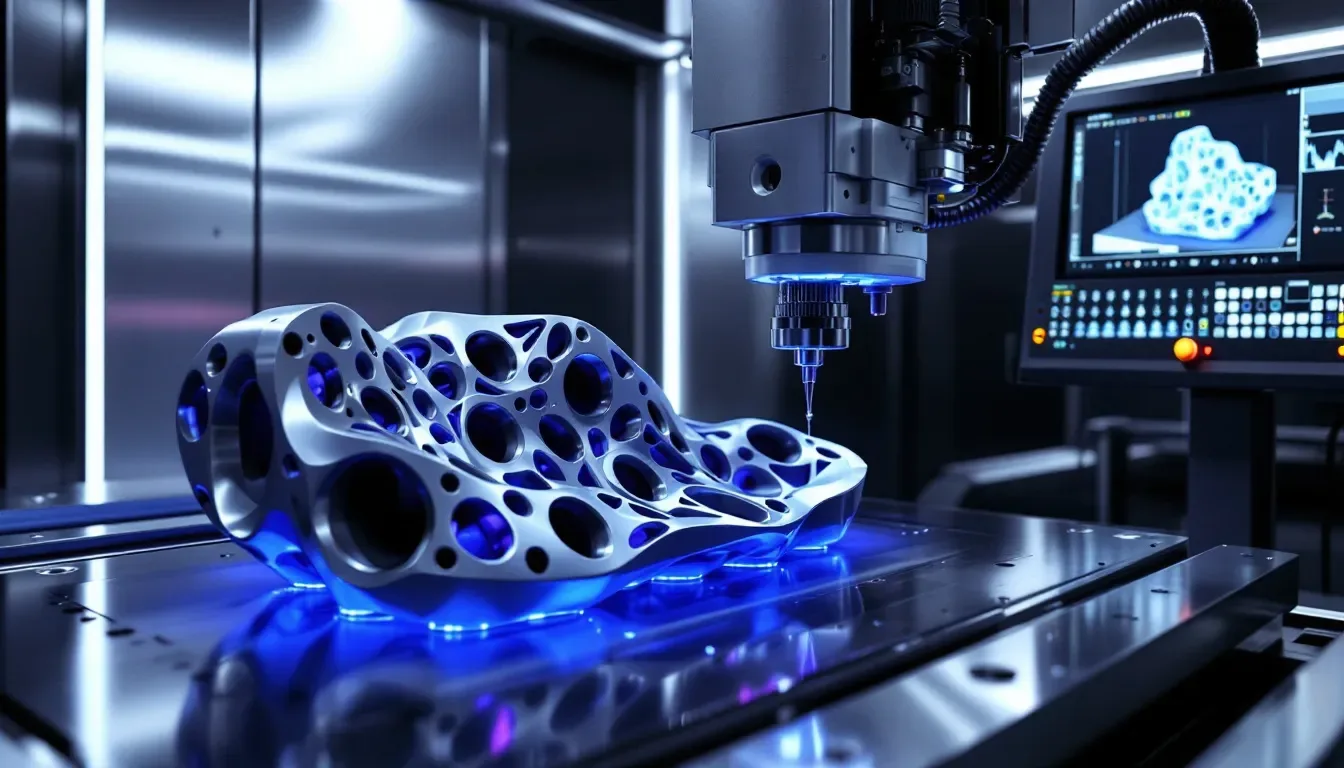

4-axis CNC milling machines serve as the backbone of contemporary manufacturing, excelling in generating intricate components that include angled features and perforations. The incorporation of an A-axis enhances the versatility of these machines by permitting cutting tools to engage with the workpiece from multiple angles, thereby facilitating the creation of complex shapes like cam lobes and turbine blades. Such capabilities are highly valued in sectors where precision and elaborate designs are critical, notably within aerospace and automotive production.

These versatile 4-axis CNC machines are capable of handling a diverse range of materials including metals and plastics, which positions them as essential tools for both prototyping phases and full-scale production lines. They enable manufacturers to swiftly develop prototypes for evaluation purposes, accelerating their time-to-market while also ensuring products adhere to exacting quality standards.

4 Axis CNC Lathes

CNC lathes with 4-axis capabilities play a crucial role in the production of parts that boast intricate geometries and demand rotational accuracy. Their proficiency in turning processes enables the manufacture of components with a high level of detail, adhering to precise requirements. Such precision and dependability are indispensable within industries such as aerospace and automotive, where these machines are highly valued for their manufacturing prowess.

4 Axis CNC Routers

CNC routers with a 4-axis configuration are highly favored within the woodworking sector, renowned for their precise cutting abilities and adeptness at managing sizeable components. Such routers are engineered to efficiently process extensive workpieces, rendering them perfectly suited for fabricating detailed wooden items like furniture, cabinetry, and intricate wood elements. The inclusion of an additional rotary axis facilitates complex designs and cuts that would otherwise be difficult to realize using conventional techniques.

The meticulous precision and efficiency exhibited by 4-axis CNC machines are not confined solely to woodworking. They also play a pivotal role in other sectors that demand intricate machining on a large scale. These versatile machines can manipulate various materials with ease, enabling producers across different industries to maintain consistent production of high-caliber components.

Key Applications of 4 Axis CNC Machines

CNC machines with 4-axis capabilities are integral to advancing production proficiency in various industries. Notably, they serve the aerospace industry by fabricating detailed parts like turbine blades with utmost precision and meeting stringent requirements. In automotive manufacturing, these machines contribute significantly to crafting intricate components accurately.

These versatile 4-axis CNC units enable machining of sophisticated geometries from numerous perspectives, making them essential for producing top-notch machined parts within the aerospace field.

Within the realm of automobile manufacturing, such machinery allows for efficient creation of complex elements including gearbox casings and motor pieces, enhancing both productivity and quality standards. The medical sector reaps similar advantages from 4-axis CNC technology’s ability to manufacture bespoke implants and surgical instruments that boast high accuracy levels as well as compatibility with living tissue – a crucial factor ensuring that medical devices fulfill strict safety protocols and functional criteria.

Advantages of Using 4 Axis CNC Machines

CNC machines with 4-axis capabilities markedly enhance the accuracy and productivity of manufacturing processes. The ability to machine from multiple angles without the necessity to reorient the workpiece streamlines operations, diminishing both time expenditure and potential inaccuracies—a key advantage when dealing with intricate shapes and complex designs.

The versatility of these 4-axis CNC machines extends across a broad range of materials, including metals and plastics, making them apt for a wide array of industrial applications. Their sturdy construction promotes consistent performance and longevity, positioning them as an asset worth acquiring for businesses aiming to bolster their production capacities.

Potential Drawbacks of 4 Axis CNC Machining

Potential users should be aware of the disadvantages that come with 4-axis CNC machines, despite their numerous benefits. The primary downside is the elevated price resulting from the intricate machinery and technology they use, which could pose a substantial financial burden, particularly for smaller enterprises. Running these complex machines demands operators who are highly skilled in managing and executing operations effectively.

To avoid expensive disruptions caused by machine failures, it’s essential to carry out consistent maintenance on CNC machines. Notably, unplanned malfunctions can incur greater costs compared to proactive maintenance efforts. Recognizing when to perform routine checks is vital for effective upkeep. Adhering to proper maintenance protocols can significantly increase a CNC machine’s operational lifespan up to two decades or more—highlighting just how critical regular care is for long-term functionality.

Selecting the Right 4 Axis CNC Machine

When choosing the ideal 4-axis CNC machine, it’s crucial to scrutinize several key aspects. Make sure the accuracy level meets your project demands for exact machining results. Evaluate both the size and weight of the machine, keeping in mind any space constraints within your work environment. Establish a budget that supports purchasing a machine with all necessary features without overextending financially.

Compatibility with your chosen CAD/CAM software is vital for streamlined design processes and operational efficiency. Investigate different spindle power and speed variations to ensure they can accommodate an assortment of materials effectively. Explore what rotational movements are possible by examining rotary axis capabilities, so you understand how it may affect machinable geometries.

Lastly, safety should never be overlooked when selecting a CNC machine. Look out for emergency stop mechanisms and protective guards or enclosures designed to safeguard operators from harm during usage.

4 Axis CNC Machining in Prototyping

CNC machining with 4-axis capabilities expedites the creation of prototypes, swiftly transforming design ideas into tangible samples. This method facilitates quick iteration and evaluation, permitting designers to polish their products effectively. The capacity to machine intricate geometries across various surfaces in one go renders 4-axis CNC machines perfectly suited for manufacturing components such as turbine blades, medical instruments, and molds used in injection molding.

This technology is cost-efficient by diminishing both the duration of production processes and excess use of materials, providing an economical option for crafting high-quality prototypes. Industries like aerospace, automotive, and healthcare reap significant rewards from 4-axis CNC machining due to its precision-driven approach tailored towards low-volume manufacturing demands.

Case Studies: Successful Implementation of 4 Axis CNC Machines

The adoption of 4-axis CNC machines within various industries has considerably influenced their manufacturing processes. Specifically, the aerospace industry leverages these machines to produce complex and highly efficient components that elevate both productivity and accuracy. The integration of cutting-edge technology in 4-axis CNC machinery represents a crucial evolution, facilitating more elaborate designs while reducing production time.

Manufactured goods derived from the use of 4-axis CNC machining exhibit enhanced precision and efficiency, highlighting their vital role in contemporary production practices. In terms of automotive applications, such machinery is instrumental in fabricating intricate engine parts with high detail. Meanwhile, in the medical industry, personalized implants are crafted thanks to the capabilities provided by 4-axis CNC technologies—illustrating its substantial benefits across diverse sectors like automotive and healthcare for precision machining tasks.

Maintenance Tips for 4 Axis CNC Machines

Essential maintenance for 4-axis CNC machines ensures longevity and optimal performance. Daily tasks include checking lubrication, coolant levels, and cleaning surfaces to avoid buildup. Maintaining coolant levels and concentration prevents overheating during machining. Regular lubrication of moving parts minimizes wear and ensures smooth operation.

Routine checks of hydraulic systems and filters are vital for maintaining optimal machine performance. Automated sensors help detect issues early, allowing timely maintenance and preventing costly breakdowns.

Real-time monitoring of CNC machines is increasingly critical, enabling companies to address potential issues proactively and maintain consistent quality.

Future Trends in 4 Axis CNC Machining

Advancements in technology and emerging trends are set to revolutionize the realm of 4-axis CNC machining. There is an anticipated rise in the utilization of multi-axis machining, which enables the crafting of intricate parts that conventional methods find challenging to produce with both efficiency and precision. As a result, industries increasingly dependent on sophisticated manufacturing techniques will witness significant improvements in production efficacy and accuracy through enhanced multi-axis machining capabilities.

The incorporation of these evolving trends promises to cultivate a more adaptive and efficient manufacturing environment. The ongoing progression in robotics integration and automation within CNC machining processes stands to boost productivity levels while minimizing manual errors, allowing machines greater autonomy during operation.

Such transformative developments indicate that 4-axis CNC machining is poised to become an indispensable pillar within contemporary industrial fabrication workflows, shaping how future manufacturing endeavors unfold.

Summary

Four-axis CNC machines have emerged as a significant innovation in the manufacturing sector, enhancing accuracy, efficiency, and adaptability. Their capacity to shape complex geometries from various perspectives renders them essential within multiple sectors including aerospace and medical. Despite facing issues like elevated costs and increased operational complexity, these challenges are dwarfed by the immense benefits they offer—positioning 4-axis machining as an asset worth acquiring for production facilities.

Looking ahead, it’s clear that the evolution of multi-axis CNC technologies will play a pivotal role in transforming how industries operate. Adoption of these cutting-edge advancements enables enterprises to boost productivity levels while minimizing mistakes and elevating product quality standards. With a promising future ahead for four-axis precision machining technology developments promise even greater innovations on the horizon for manufacturing processes.

Frequently Asked Questions

What is the difference between 3 axis and 4-axis machining?

The difference between 3-axis and 4-axis machining is that in 3-axis machining, the cutting tool moves along three fixed directions, whereas in 4-axis machining, the workpiece can also be rotated, allowing for more complex shapes and angles to be machined.

Consequently, 4-axis machining provides greater versatility and precision in fabrication.

Is a 4th axis worth it?

A 4th axis is indeed worth it as it allows for simultaneous motion, significantly reducing the number of setups and minimizing workholding challenges.

This enhancement can greatly improve productivity and accuracy in machining tasks.

What is the difference between 4 and 5-axis CNC?

The primary difference between 4-axis and 5-axis CNC machining lies in the number of rotational axes available; 4-axis machining incorporates one additional A-axis for rotation, while 5-axis machining includes two extra axes (A, B, or C), enhancing precision and complexity in machining operations.

Therefore, 5-axis CNC allows for more intricate designs and greater flexibility compared to 4-axis CNC.

What is the main advantage of 4-axis CNC machining over 3-axis machining?

The main advantage of 4-axis CNC machining over 3-axis machining is the capability to machine complex geometries from various angles, which minimizes workpiece repositioning and enhances both precision and efficiency.

How does 4-axis CNC machining benefit the aerospace industry?

The aerospace sector gains substantial advantages from 4-axis CNC machining, as it allows for the meticulous creation of complex parts like turbine blades, which must adhere to strict industry regulations.

Such proficiency boosts both the effectiveness and excellence of production processes within the manufacturing landscape of aerospace.

Still, need help? Contact Us: [email protected]

Need a PROTOTYPE or PARTS machining quote? Quote now

LKprototype

LKprototype