Urethane casting prototype Choosing the best vacuum casting factory is crucial for creating high-quality prototypes and parts for your project. A reliable factory equipped with advanced tools and experienced professionals ensures precise and consistent results. Their efficient processes save both time and money while offering custom solutions tailored to your specific needs. Selecting the right vacuum casting factory simplifies the process of transforming your ideas into tangible products. Key Takeaways Look up different vacuum casting companies. Check reviews and their work to ensure they are good and trustworthy. Pick a factory with trained workers and modern tools. This helps make…

Urethane casting prototype Vacuum casting silicone mold is a meticulous process that ensures the creation of high-quality silicone molds. This technique utilizes reduced air pressure to eliminate bubbles, resulting in a smooth finish. It is particularly effective for testing ideas and producing small batches, as it captures intricate details with remarkable accuracy. The process involves placing mixed silicone in a vacuum chamber to remove air bubbles, which leads to a flawless surface. The steps include preparing materials, mixing and pouring the silicone, eliminating air bubbles, and allowing the mold to harden. This method enables you to produce vacuum casting silicone…

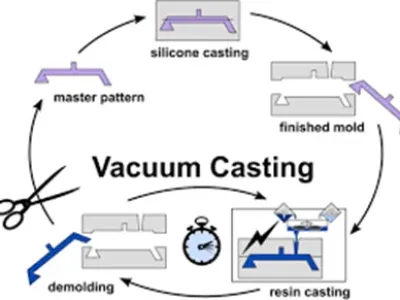

Vacuum casting is a process used to create precise prototypes and small-batch parts with silicone molds. It’s favored for its accuracy and speed, making it ideal for product development. This guide covers how vacuum casting works, the materials involved, and its benefits. Key Takeaways Vacuum casting is a precise manufacturing technique using silicone molds and vacuum environments to produce high-quality prototypes and small-batch parts. The process includes creating a master model, making silicone molds, mixing and pouring resins, and finishing the products, offering tolerances of ±0.1mm. Vacuum casting is cost-effective for low-volume production compared to injection molding and delivers superior…

Vacuum Casting Services are extensively applied to short-time producing processes and designing trial production. Polyurethane vacuum casting is a specific technique used in these services, known for producing high-quality prototypes and small to medium production runs. This process results in parts with good detail and surface finish and with considerably less tool wear. It is effective in prototyping new designs, making fully functional prototypes and for developing relatively small numbers of components. What is Vacuum Casting? Vacuum casting is one in which the silicone rubber molds are made under a vacuum. These molds are then used to pour parts of…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.