Yield strength vs tensile strength are critical material properties that reveal how materials respond to stress. Yield strength refers to the point at which a material begins to deform permanently, while tensile strength is the maximum stress a material can endure before it fractures. These properties play a vital role in science and engineering, as they help us understand how materials perform under heavy loads or extreme forces. For instance, a 2018 study demonstrated that recycling AlSi10Mg improved tensile strength by 10% but had minimal impact on yield strength. Another study observed a 3-4% reduction in both yield strength vs…

Picking the right stainless welding rod is very important. It helps make strong and long-lasting welds. The correct rod works well with the base metal. It lowers the chance of cracks and makes better welds. For example, a 309L rod joins carbon steel to stainless steel. It gives a ferrite content of 14-16 FN, stopping weld problems. High-carbon steel might need a 312 rod. This rod gives ferrite levels of 70-90 FN, which stops cracks. Also, hydrogen moves slower in stainless welds than in carbon steel. So, choosing the right rod avoids mistakes. Here are five reliable brands for stainless…

Titanium does not rust like steel or iron, leading many to wonder, "can titanium rust?" The answer is that it does not rust because it contains no iron, which is the primary cause of rust. Instead, titanium forms a thin oxide layer for protection, typically measuring 3–7 nanometers in thickness. This protective layer can become stronger with special treatments, such as heating. Studies indicate that longer heating times enhance its toughness and longevity. However, it is important to note that titanium can corrode under certain conditions, including exposure to acids, salt, or extremely high heat. Despite this, titanium’s rust resistance…

You might wonder, is bronze magnetic? Generally, bronze, along with brass and copper, is not magnetic. These metals don’t exhibit a strong pull or push on magnets. However, certain bronze alloys containing iron can be slightly magnetic. Similarly, metals like aluminum, titanium, and brass are also not magnetic. Key Takeaways Bronze, brass, and copper are not magnetic. This makes them great for tools and art. Some bronze and brass alloys may be slightly magnetic. This happens if they have iron or nickel, but it is uncommon. Knowing what these metals are made of helps pick the right one. This is…

In this article, we explore how the density of stainless steel—which typically falls between 7.5 and 8.0 grams per cubic centimeter—affects its performance and utility in various industries such as construction, aerospace, and marine sectors. We will examine the influence that different alloy compositions and manufacturing techniques have on the density of stainless steel and consequent implications for its application. Key Takeaways Stainless steel contains at least 10.5% chromium and is manufactured in various grades tailored for specific applications, providing durability and corrosion resistance. The density of stainless steel ranges from 7.5 to 8.0 g/cm³, influencing its strength and suitability…

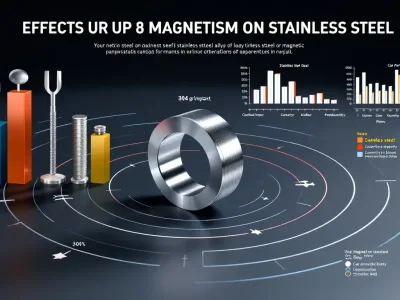

Is stainless magnetic? It can be, but it depends on the type. In this article, you’ll learn why some stainless steels are magnetic and others aren’t, and how this affects their uses. Key Takeaways Stainless steel’s magnetic properties are influenced by its crystal structure and chemical composition, with martensitic and ferritic types being magnetic, while austenitic types are typically non-magnetic. Understanding the magnetic characteristics of different stainless steel types—like austenitic, ferritic, martensitic, and duplex—is crucial for selecting the right material for specific applications such as manufacturing and food processing. Testing for magnetism using a simple magnet can indicate magnetic properties,…

Wondering whether brass vs stainless steel fittings are best for your project? This article breaks down durability, corrosion resistance, cost, and application suitability to help you decide. Key Takeaways Brass fittings are cost-effective and provide decent corrosion resistance, but they can suffer from dezincification in aggressive environments. Stainless steel fittings offer superior corrosion resistance and durability, making them suitable for high-pressure and extreme temperature applications, despite their higher initial cost. The choice between brass and stainless steel fittings should be based on factors such as budget, application environment, temperature tolerance, and pressure requirements. Understanding Brass Fittings Many homeowners favor brass…

Facing a choice between alloy steel vs stainless steel? Understanding their differences in strength, corrosion resistance, cost, and applications will help you decide the best material for your project. Key Takeaways Alloy steel is versatile and primarily used for high strength and toughness applications, while stainless steel is known for its superior corrosion resistance and aesthetic appeal. The choice between alloy steel and stainless steel depends on factors like mechanical properties required, environmental conditions, and long-term cost considerations, with alloy steel being generally less expensive upfront but potentially requiring more maintenance. Understanding the specific applications of each type of steel—such…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.