Urethane casting prototype Selecting the right silicone rapid prototyping manufacturers is crucial for the success of your project. Reliable manufacturers not only save time and money but also ensure top-notch quality. For instance, rapid prototyping can complete tasks in just 6 hours compared to the 14 hours traditional methods might take. Additionally, it is more cost-effective, as older vacuum molds can be four times more expensive. Beyond cost savings, trusted silicone rapid prototyping manufacturers focus on accuracy and material strength by thoroughly measuring errors and testing durability. Choosing the right manufacturer is key to achieving your project's goals. Key Takeaways…

Image Source: pexels Product design and prototyping mean making and improving a product. Prototyping is very important in this process. It helps test ideas, check if things work, and make sure the product is easy to use. This happens before making the product fully. It helps find problems early, saving time and money. Prototyping makes products much better. Look at these facts: Repeating design steps makes product launches 75% more successful. Starting prototyping early cuts product failures by 75%. Using user feedback during prototyping makes products 50% more successful. By using prototyping, you can avoid risks, test ideas, and make…

If you’re navigating the world of product development, understanding the various rapid prototyping types is essential. From proof-of-concept and low-fidelity to high-fidelity, looks-like, and works-like prototypes, each type serves a unique function in design and testing. This article breaks down these types and shows you when and how to use them effectively. Key Takeaways Rapid prototyping is essential in product development, enabling quick iterations and varying levels of fidelity to validate design and functionality effectively. Different types of prototypes, including low-fidelity, high-fidelity, works-like, and looks-like, serve specific purposes in the development process, from concept validation to final testing. Material selection…

Selecting the right silicone rubber for mold-making is key to successful projects. Silicone rubber is flexible, durable, and easy to use, making it ideal for detailed molds. This guide details everything you need to know to make the best choice. Key Takeaways Selecting the right silicone rubber enhances mold quality. It emphasizes factors like flexibility, tear strength, and curing time for successful applications. A 1:1 mix ratio of silicone components simplifies the preparation process. It ensures consistent results while minimizing bubbles and imperfections. Fast-curing silicones facilitate quick production cycles. Their versatility allows for casting across various surfaces, making them essential…

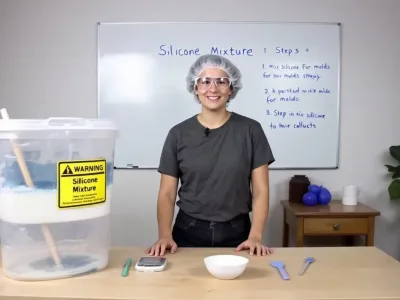

Looking to learn how to make silicone for molds at home? This guide will walk you through the necessary steps and materials, ensuring you can create high-quality molds easily. Key Takeaways Making silicone molds at home is cost-effective and allows for customization in crafting projects. Key materials for DIY silicone molds include silicone caulking, cornstarch, and mold release agents to ensure easy demolding. Curing time for molds varies, and safety precautions, like wearing gloves and ensuring good ventilation, are crucial during the process. Why Make Silicone Molds? Manufacturing silicone molds yourself can lead to significant savings over purchasing off-the-shelf options.…

Medical device prototyping involves creating early models of medical devices to test, refine, and perfect designs before mass production. By quickly identifying and resolving design flaws, prototyping ensures that the final product is safe, effective, and meets regulatory standards. In this article, we will explore the key stages and advanced techniques of medical device prototyping, offering insights for anyone involved in the development of innovative medical technologies. Key Takeaways Medical device prototyping is essential for transforming concepts into functional products, allowing for early design validation and risk reduction.The prototyping process involves key stages such as conceptualization, material selection, and iterative…

Before electronic devices enter mass production, innovators develop prototypes as initial models to examine and improve their concepts. This crucial stage allows for the testing and perfecting of design details. It helps to confirm functionality, reduce potential risks, and certify that product standards are met. By having the devices prototyped, it becomes possible to determine cost-efficiency and identify potential defects early. Consequently, this helps prevent higher expenses during manufacturing. We will delve into the fundamental phases of electronic prototyping in this article and provide valuable advice for efficiently advancing your projects. Key Takeaways Electronic prototyping validates design and functionality, minimizing…

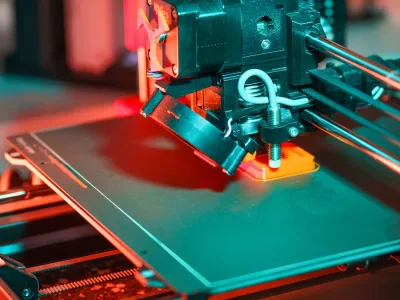

Prototyping manufacturing helps you develop products efficiently. You create early test versions to spot and fix issues, saving time and money before mass production. This article explores best practices and techniques in prototyping manufacturing. Key Takeaways Prototyping manufacturing is essential for identifying design flaws early, reducing risks, and accelerating product development. The selection of the right prototyping method and materials significantly impacts the functionality, cost, speed of the product development process. Emerging trends, including advanced materials and automation, are enhancing prototyping efficiency and enabling the development of complex, high-quality prototypes. What is Prototypeing Manufacturing? Manufacturing prototypes involves the creation of…

Curious about how silicone prototypes can enhance your product development? Silicone prototypes provide a quick and precise way to test and refine designs. This article covers the main techniques for creating silicone prototypes and their benefits, helping you make informed decisions for your projects. Key Takeaways Silicone rapid prototyping accelerates product development, significantly reducing time to market with over 95% accuracy. Key techniques such as LSR molding, compression molding, and RTV silicone casting each offer unique advantages for various prototype needs. Selecting the appropriate silicone grade is essential for performance and safety, with factors like budget, application environment, and durability…

Curious about how iPhone prototypes shape the final product? This article gives you an exclusive look at rare iPhone prototypes, revealing how Apple’s secretive testing processes influence the features and design of their iconic devices, including the iPhone prototype. Key Takeaways Apple’s iPhone prototypes have evolved significantly, reflecting a continuous pursuit of innovation that shapes the design and functionality of final products. The prototyping process involves meticulous stages of design, including the use of silicone molds and CNC technology, which ensure high precision and quality. Recent trends in iPhone prototyping include the use of advanced materials and the integration of…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.