Urethane casting prototype Selecting the right silicone rapid prototyping manufacturers is crucial for the success of your project. Reliable manufacturers not only save time and money but also ensure top-notch quality. For instance, rapid prototyping can complete tasks in just 6 hours compared to the 14 hours traditional methods might take. Additionally, it is more cost-effective, as older vacuum molds can be four times more expensive. Beyond cost savings, trusted silicone rapid prototyping manufacturers focus on accuracy and material strength by thoroughly measuring errors and testing durability. Choosing the right manufacturer is key to achieving your project's goals. Key Takeaways…

Selecting the right silicone rubber for mold-making is key to successful projects. Silicone rubber is flexible, durable, and easy to use, making it ideal for detailed molds. This guide details everything you need to know to make the best choice. Key Takeaways Selecting the right silicone rubber enhances mold quality. It emphasizes factors like flexibility, tear strength, and curing time for successful applications. A 1:1 mix ratio of silicone components simplifies the preparation process. It ensures consistent results while minimizing bubbles and imperfections. Fast-curing silicones facilitate quick production cycles. Their versatility allows for casting across various surfaces, making them essential…

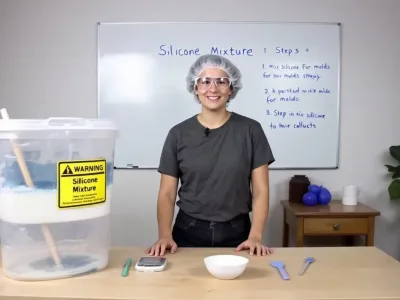

Looking to learn how to make silicone for molds at home? This guide will walk you through the necessary steps and materials, ensuring you can create high-quality molds easily. Key Takeaways Making silicone molds at home is cost-effective and allows for customization in crafting projects. Key materials for DIY silicone molds include silicone caulking, cornstarch, and mold release agents to ensure easy demolding. Curing time for molds varies, and safety precautions, like wearing gloves and ensuring good ventilation, are crucial during the process. Why Make Silicone Molds? Manufacturing silicone molds yourself can lead to significant savings over purchasing off-the-shelf options.…

Curious about how silicone prototypes can enhance your product development? Silicone prototypes provide a quick and precise way to test and refine designs. This article covers the main techniques for creating silicone prototypes and their benefits, helping you make informed decisions for your projects. Key Takeaways Silicone rapid prototyping accelerates product development, significantly reducing time to market with over 95% accuracy. Key techniques such as LSR molding, compression molding, and RTV silicone casting each offer unique advantages for various prototype needs. Selecting the appropriate silicone grade is essential for performance and safety, with factors like budget, application environment, and durability…

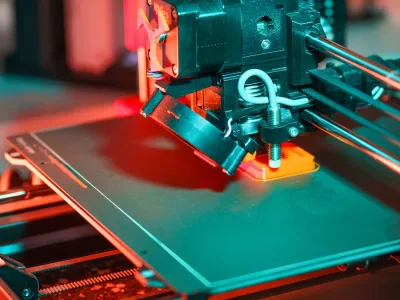

Vacuum casting is a process used to create precise prototypes and small-batch parts with silicone molds. It’s favored for its accuracy and speed, making it ideal for product development. This guide covers how vacuum casting works, the materials involved, and its benefits. Key Takeaways Vacuum casting is a precise manufacturing technique using silicone molds and vacuum environments to produce high-quality prototypes and small-batch parts. The process includes creating a master model, making silicone molds, mixing and pouring resins, and finishing the products, offering tolerances of ±0.1mm. Vacuum casting is cost-effective for low-volume production compared to injection molding and delivers superior…

Want to create detailed, custom molds for your projects? A silicone mold making kit is what you need. This article explains what these kits include, their benefits, and provides a step-by-step usage guide. Key Takeaways Silicone mold making kits include a silicone rubber base and catalyst, allowing for the creation of detailed and durable molds suitable for various crafting projects. Key quality features of silicone molds include high tear strength and low mixing viscosity, which contribute to the molds’ durability and ease of use. Using a vacuum chamber can enhance mold quality by removing air bubbles, while proper preparation and…

Injection moulding industries include automotive, medical, electronics, packaging, aerospace, and construction. This process produces precise, cost-effective parts crucial for each sector. This article explores how injection moulding enhances these industries and its key benefits. Key Takeaways Injection moulding is crucial across multiple industries such as automotive, medical, consumer electronics, packaging, aerospace, and construction, offering significant advantages like precision, cost efficiency, and customization. Emerging trends like automation, smart manufacturing, and sustainability practices are transforming injection moulding processes, enhancing productivity and reducing environmental impact. Choosing the right injection moulding company involves considering factors such as experience, technological capabilities, and customer support to…

Searching for the best silicone mold makers? In this article, we will guide you through the top companies and what sets their molds apart. Learn about their quality, range, and how they can help with your DIY projects. Key Takeaways LKprototype is a top silicone mold provider, known for their expertise and quality, delivering molds with a 99.96% quality rate. A new Spring 2023 collection of silicone molds offers whimsical designs, perfect for DIY projects such as garden decor and seasonal decorations. Custom silicone molds are versatile for various applications, enabling personalized creations in baking, crafting, and resin art, with…

Need to know how to cast silicone rubber? This guide explains every step, from gathering materials to curing the final mold. Avoid common mistakes and achieve a successful cast. Key Takeaways Gather all necessary materials, including safety gear and high-quality silicone, to ensure a smooth casting process. Properly prepare the master model and construct a sturdy, leak-proof mold box to achieve flawless silicone casts. Follow careful mixing, pouring, and de-molding techniques to minimize air bubbles and ensure a successful final product. Gather Your Materials and Equipment Before embarking on the process of silicone casting, ensure that you have all the…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.