Resin art is all about creating shiny, beautiful items with liquid resin. You can make coasters, jewelry, or unique trays. It’s a blend of crafting and science! If you’re just starting out, silicone molds are incredibly useful. They are flexible, reusable, and shape resin perfectly. Consider them essential tools for beginners to learn the craft. They’re user-friendly, ensuring your projects turn out beautifully. For newcomers, using silicone molds is the simplest way to dive into resin art without any stress. Key Takeaways Silicone molds are great for beginners in resin art. They bend easily, can be reused, and are simple…

Choosing a weed grinder as a beginner can feel tricky. However, it can significantly enhance your experience. A good grinder provides an even herb texture, making your sessions easier and more enjoyable. Now, consider adding your own style to it with personalised weed grinders. You could incorporate a design, your name, or a humorous quote. Personalised grinders not only look fantastic; they also reflect your personality. They make using them feel unique. Whether it’s for yourself or as a gift, select one that functions well and showcases your style. Key Takeaways Pick a basic grinder if you're new. A 2-piece…

Image Source: pexels ABS plastic prototypes and regular ABS have different uses in making things. Prototypes made from ABS-like materials act like regular ABS. They are strong, resist impacts, and handle heat well. These are great for testing designs before making many copies. Regular ABS, however, is used in finished products because it is tough and flexible. The differences between them decide how they are used. For example: ABS-M30, a prototype material, is 70% stronger than regular ABS. This makes it good for testing strong structures. ABS-CF10, mixed with carbon fiber, is 50% stiffer than regular ABS. It works better…

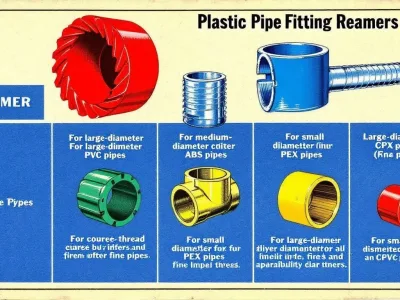

A plastic pipe reamer is a tool used to remove old fittings from plastic pipes, ensuring a clean surface for new connections. It’s essential for plumbing repairs and installations. In this article, we’ll explore how plastic pipe reamers work, different types available, key features to look for, and maintenance tips. Key Takeaways Plastic pipe reamers are essential for removing fittings and preparing pipes for new installations, enhancing efficiency in plumbing tasks.The Clean Ream Extreme® reamer is notable for its ability to clean and reuse fittings, which minimizes material costs and waste.High-quality reamers feature durable designs with carbide cutting inserts and…

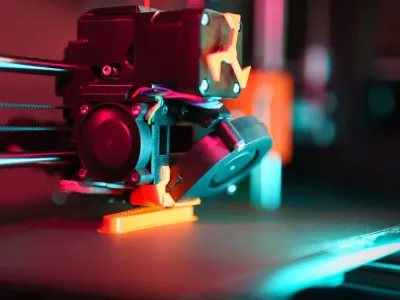

Choosing the right prototype tooling plastics is essential for efficient and cost-effective prototype production. This guide covers the top methods and materials to help you create high-quality prototypes quickly, including 3D printing, CNC machining, and injection molding. Key Takeaways Prototype tooling plastics enable rapid and cost-effective production of prototypes, facilitating early design validation and testing.Key methods for creating prototype tooling include 3D printing, CNC machining, and injection molding, each offering unique benefits for different prototyping needs.The benefits of using prototype tooling plastics include faster time to market, significant cost savings, and improved design validation, making them essential in various industries.…

Selecting the right silicone rubber for mold-making is key to successful projects. Silicone rubber is flexible, durable, and easy to use, making it ideal for detailed molds. This guide details everything you need to know to make the best choice. Key Takeaways Selecting the right silicone rubber enhances mold quality. It emphasizes factors like flexibility, tear strength, and curing time for successful applications. A 1:1 mix ratio of silicone components simplifies the preparation process. It ensures consistent results while minimizing bubbles and imperfections. Fast-curing silicones facilitate quick production cycles. Their versatility allows for casting across various surfaces, making them essential…

Plastic weld adhesives create strong bonds between plastic materials by chemically fusing them. This article explains how they work, reviews the best options, and provides usage tips. Key Takeaways Plastic weld adhesives create strong molecular bonds between plastics, making them ideal for durable repairs on various thermoplastics like PVC and acrylic. The effectiveness of these adhesives relies on proper surface preparation, capillary action, and quick setting times, often curing within minutes. Safety precautions, including protective eyewear and ventilation, are essential when using plastic weld adhesives to prevent injuries and ensure a safe working environment. Understanding Plastic Weld Adhesives Adhesives known…

The manufacturing process does affect the cost factors, time, quality, and size. Both cast urethane and injection molding are common techniques utilized in the making of parts for the automotive, aerospace, and consumer goods industries. They get to know the best method to use depending on their manufacturing, designing, and engineering requirements. What is Injection Molding: A Comparison with Cast Urethane? Cast Urethane is a casting process in which a liquid polymer is delivered in molds to form parts. It is often used for low production volume and initial part making because of the lower manufacturing cost, type of material,…

Vacuum casting is a process used to create precise prototypes and small-batch parts with silicone molds. It’s favored for its accuracy and speed, making it ideal for product development. This guide covers how vacuum casting works, the materials involved, and its benefits. Key Takeaways Vacuum casting is a precise manufacturing technique using silicone molds and vacuum environments to produce high-quality prototypes and small-batch parts. The process includes creating a master model, making silicone molds, mixing and pouring resins, and finishing the products, offering tolerances of ±0.1mm. Vacuum casting is cost-effective for low-volume production compared to injection molding and delivers superior…

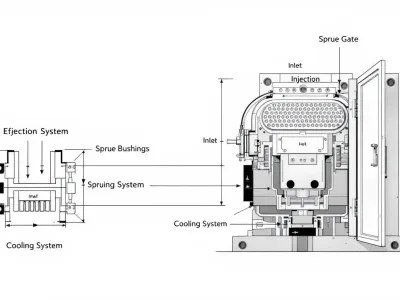

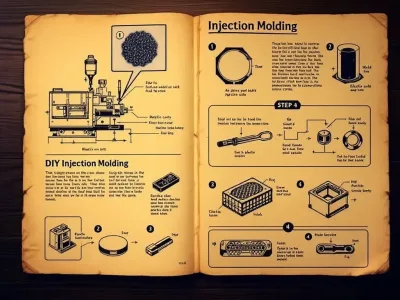

If you’re looking to learn how to make an injection mold, understanding the steps is crucial. The process includes designing the mold, prototyping, machining, and assembling. This guide will walk you through each stage, helping you create a functional injection mold. Key Takeaways Injection molding is a crucial manufacturing technique that involves injecting molten plastic into metal molds to produce high-quality parts efficiently. Key factors in mold design include the choice of materials, cooling channel optimization, and detailed design features such as draft angles and parting lines, all of which ensure product quality and production efficiency. Proper maintenance and care…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.