Employees are operating machine tools in the processing workshop of CNC machine tool parts manufacturer Choosing the right machine parts manufacturer is crucial. It ensures your machines operate at their best. A reliable machine parts manufacturer provides genuine, precise parts, which enhances quality and builds trust. Your decision directly impacts the efficiency and growth of your business. If you require custom or original parts, the machine parts manufacturer must understand your specific needs. Their expertise in producing parts and offering warranties ensures your machines perform optimally and last longer. Partnering with the right machine parts manufacturer means collaborating with someone…

Training CNC machine skills is crucial for success in today's manufacturing landscape. Many industries require skilled workers to operate CNC machines and produce precise parts. The CNC machine market is projected to expand by 44%, reaching $35 billion by 2026. Despite this growth, companies face challenges in finding trained workers. For instance, Connecticut has between 8,000 to 10,000 open machining positions. Additionally, 40% of companies report difficulties in locating workers with the necessary skills. Engaging in training for CNC machines helps bridge this skills gap. It also equips you with the expertise needed to fulfill industry demands. By mastering CNC…

Introduction Bronze is one of the oldest metal alloys, yet it remains highly relevant in modern manufacturing. This copper-based alloy (typically copper mixed with tin, aluminum, silicon, or other elements) offers a blend of strength, corrosion resistance, and machinability that make it popular for precision components (A Guide to Different Types of Bronze Alloys - MetalTek). In CNC machining, working with bronze can be rewarding for beginners if they understand its basic properties and how to address common challenges. This blog post provides an accessible overview of bronze alloys, the challenges of machining them, effective CNC techniques, key industrial applications,…

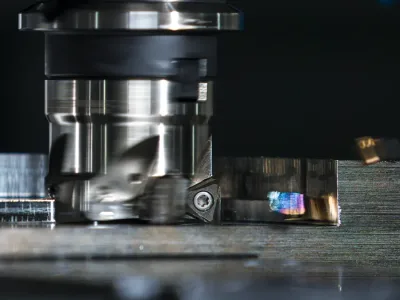

Imagine a CNC machine metal device that turns raw metal into precise parts. That’s what CNC machines do. They change manufacturing by using automation and programming to make perfect results every time. CNC machines have changed industries by working faster, wasting less, and repeating tasks perfectly. Here’s how they’ve made a difference: Valve factories using CNC machine metal technology cut setup time a lot between 1997 and 2002. Companies using CNCs needed more workers with engineering skills (from 52% to 72%) and programming skills (from 14% to 43%). CNC machines run fast all the time, saving time and keeping products…

CNC polycarbonate changes manufacturing by using smart machining and strong materials. It combines tough polycarbonate with advanced tools for better results. Clear polycarbonate is very strong and lasts a long time. It has low haze and no distortion, improving visibility for things like security windows. Its clear look and fire resistance make it great for military and safety gear. This flexibility helps make things faster, wastes less, and saves money over time. Key Takeaways CNC polycarbonate is tough and lasts long, great for safety tools. CNC machining works fast and cuts waste, saving time and cash. Polycarbonate is light but…

Acrylic CNC service uses computer-run machines to cut or shape acrylic. These machines can also engrave designs with great accuracy. This method makes sure the work is neat and allows for detailed designs. Many industries, like signage and manufacturing, use this service because it is fast and flexible. The world market for acrylic edge bending machines was worth USD 723 million in 2023. It might grow to USD 1,012 million by 2032. More need for accurate manufacturing and better automation tools are causing this growth. Companies in the signage business buy these machines to make top-quality ads. This rising use…

Acrylic is a great material for acrylic CNC machining. It is affordable and can be used in many ways. It is easy to work with and looks clear and shiny, making it perfect for industries that require precise work. Acrylic is a good choice when you need a strong, see-through material at a low cost. Accuracy and speed are very important when performing acrylic CNC machining. Its density is 1.18 g/cm³, and its strength is 70 MPa. These features help you achieve excellent results without damaging the material. Acrylic also allows 92% of light to pass through, making it ideal…

Yield strength vs tensile strength are critical material properties that reveal how materials respond to stress. Yield strength refers to the point at which a material begins to deform permanently, while tensile strength is the maximum stress a material can endure before it fractures. These properties play a vital role in science and engineering, as they help us understand how materials perform under heavy loads or extreme forces. For instance, a 2018 study demonstrated that recycling AlSi10Mg improved tensile strength by 10% but had minimal impact on yield strength. Another study observed a 3-4% reduction in both yield strength vs…

Choosing a weed grinder as a beginner can feel tricky. However, it can significantly enhance your experience. A good grinder provides an even herb texture, making your sessions easier and more enjoyable. Now, consider adding your own style to it with personalised weed grinders. You could incorporate a design, your name, or a humorous quote. Personalised grinders not only look fantastic; they also reflect your personality. They make using them feel unique. Whether it’s for yourself or as a gift, select one that functions well and showcases your style. Key Takeaways Pick a basic grinder if you're new. A 2-piece…

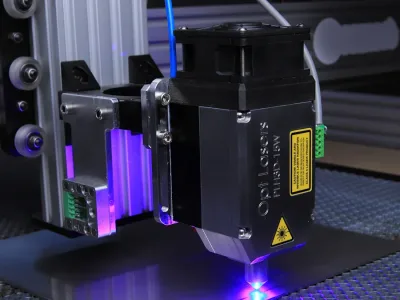

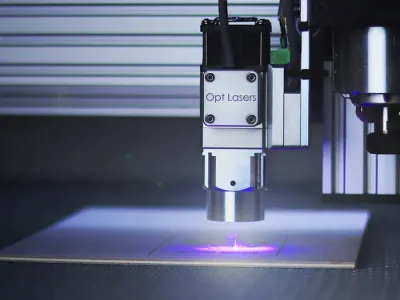

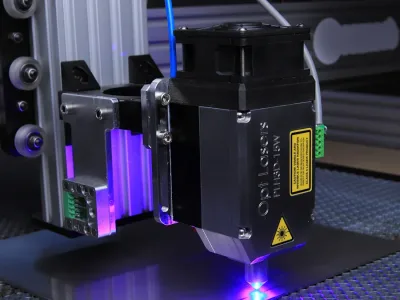

A CNC router, or to answer the question "what is a CNC router," is a machine operated by a computer that cuts and shapes materials with exceptional precision. It automates tasks that would otherwise require manual effort, making the process both faster and more accurate. Unlike traditional tools, CNC routers optimise material usage, helping to minimise waste and reduce costs. They ensure that every product is consistent in appearance and of high quality. Additionally, CNC routers significantly cut down production time, enabling quicker delivery and the effortless creation of intricate designs. These versatile machines can be used on materials such…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.