CNC machinists operate computer-controlled machines to produce precision parts and components. This crucial role involves programming and maintaining equipment to meet detailed design specifications. As technology advances, the demand for skilled CNC machinists is rising, making this a promising career path. This article will outline the duties of the CNC machinist, required skills, and career opportunities. Key Takeaways CNC machinists are essential in modern manufacturing, requiring a mix of technical skills, attention to detail, and strong problem-solving abilities to ensure precision in high-quality component production. The career path for CNC machinists is promising, offering opportunities for advancement into specialized roles,…

Understanding the right CNC file format is crucial for precision machining. Key formats like G-code, STEP, and DXF ensure your CNC projects run smoothly and accurately. This article will guide you through these essential formats and their roles in CNC machining. Key Takeaways The essential CNC file formats for precision machining include G-code, STEP, and DXF, each serving unique roles in maintaining accuracy and compatibility. Conversion of CAD files into CNC-compatible formats through CAM software is crucial for precise machining instructions and reduces the risk of errors. Effective communication with CNC technicians and detailed preparation of CAD files are vital…

4 axis CNC machines add a rotational axis to traditional CNC machining, making them capable of complex and precise parts. Industries like aerospace and medical devices rely on them for their versatility. This article covers how 4 axis CNC works, its benefits, and comparisons with 3 and 5 axis machines. Key Takeaways 4-axis CNC machining enhances precision and efficiency by incorporating an additional rotational axis, allowing for complex geometries to be produced without repositioning the workpiece. Compared to 3-axis and 5-axis machines, 4-axis CNC machines provide a balanced option for intricate part production that requires both versatility and cost-efficiency. Regular…

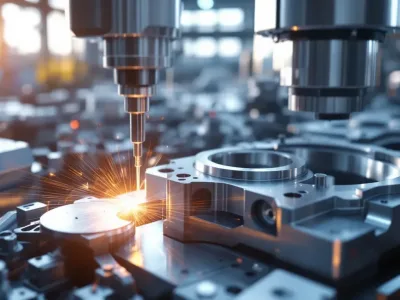

CNC precision machining is the method of using computer-controlled machinery to create parts with extreme accuracy. It’s crucial for industries where tight tolerances and high-quality standards are non-negotiable, such as aerospace, medical, and automotive. In this article, we delve into the processes, advantages, and wide-ranging applications of CNC precision machining. Key Takeaways CNC precision machining is a computer-controlled process that significantly enhances manufacturing efficiency and accuracy by automating material removal and minimizing human error. Achieving tight tolerances is essential in CNC machining, particularly in industries such as aerospace and medical, where precision directly impacts safety and performance. Recent innovations such…

An 8 axis CNC machine lets manufacturers achieve high precision and create intricate designs. It operates on multiple dimensions, making it versatile for complex tasks. In this guide, we’ll look at the key features, benefits, and applications of 8 axis CNC machines. Key Takeaways The i2r 8 Axis CNC machine enables high-precision machining through multi-axis movement and advanced software integration. Skilled operators are required to utilize its full potential. Key features include a high-speed spindle operating up to 24,000 RPM and a Y-axis travel distance of 48 inches. It also includes the ability for single setup machining, enhancing versatility and…

Looking for the price of a 5-axis CNC machine? You’ll find options between $10,000 and $500,000 for a 5-axis CNC machine price. This guide explains the factors impacting costs and offers tips for finding the best deals within your budget. Key Takeaways 5-axis CNC machine prices range from $10,000 to $500,000, influenced by factors like complexity, speed, brand reputation, and machine features. Choosing between new and used machines is crucial, as new models offer the latest technology, while used options can provide significant cost savings. Maximizing ROI involves regular maintenance, skilled operator training, and efficient production processes to enhance productivity…

Automotive CNC machines are vital for modern vehicle manufacturing, providing the precision needed for components like engines and transmissions. Discover how automotive CNC machine technology enhances quality and efficiency across the automotive industry. Key Takeaways CNC machining enhances precision, speed, and efficiency in automotive manufacturing, crucial for producing complex components while meeting stringent safety standards. Key applications of CNC machining in the automotive industry include the production of engine components, transmission systems, and interior/exterior panels, all requiring high precision for optimal performance. Emerging trends in CNC machining, such as the integration of AI and the use of advanced materials, are…

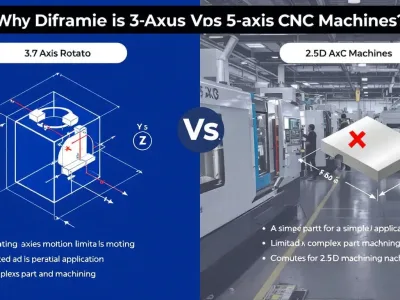

Choosing between a 3 Axis CNC and a 5 Axis CNC machine depends on your project’s complexity and precision needs. In this article, we will explore the key differences, benefits, and drawbacks of 3 axis CNC vs 5 axis machines to help you decide which is right for you. Key Takeaways 3-axis CNC machines are cost-effective and suitable for simpler tasks, but they struggle with complex geometries and require multiple setups for intricate designs. 5-axis CNC machines excel in precision and efficiency, capable of machining complex shapes with fewer setups, making them ideal for industries demanding high accuracy like aerospace…

Looking for the top CNC equipment manufacturers? This article covers the leading companies, their specialties, and why they stand out in the industry. Key Takeaways CNC machines enhance precision and efficiency in manufacturing by automating processes and executing tasks directly from CAD files. Leading CNC equipment manufacturers such as Yamazaki Mazak, Trumpf, and DMG MORI are recognized for their innovative technologies and quality machinery, catering to various industries. Automation in CNC machining, including robotic systems and automated tool changers, significantly improves productivity and reduces manual labor, though challenges like initial investment remain. Understanding CNC Equipment A CNC machine is a…

A 4 axis CNC machine adds a rotational axis to the traditional three axes, allowing for more complex and precise machining. This additional axis enables the machine to access the workpiece from different angles, making it ideal for intricate designs and complex geometries. In this article, you’ll learn about the features, uses, and benefits of 4 axis CNC machines, helping you understand why they could be a valuable addition to your manufacturing process. Key Takeaways 4-axis CNC machining offers enhanced precision and design flexibility by introducing an A-axis for rotational movement, crucial for complex components in industries such as aerospace…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.