Choosing a good CNC machining service is very important, especially when it comes to specialized kovar machining services. Kovar has unique traits like heat sensitivity and hardening when worked on, which require careful handling and skill. Small mistakes can lead to significant issues, particularly in critical fields like space, electronics, and healthcare. A subpar provider may deliver poor quality, take too long, or charge excessively, jeopardizing your project. It’s essential to select skilled providers with advanced tools and certifications in kovar machining services. This ensures accurate work, fast production, and reliable results.

Key Takeaways

Pick companies with lots of experience in Kovar machining for good results.

Find providers with great reviews and past projects to check their reputation.

Compare price and quality; don’t pick the cheapest if it lowers standards.

Look for certifications like ISO 9001 to prove they focus on quality.

Request detailed quotes listing all costs to avoid hidden charges.

Choose vendors who reply fast and clearly to keep your project running smoothly.

Work with trusted providers long-term for better results in future projects.

Key Factors in Choosing a Machining Vendor

Check Their Skills and Experience

Years of experience in Kovar machining services

Pick vendors with lots of experience in Kovar machining services. Those with many years of practice know how to handle Kovar well. They understand its special traits, like low heat expansion and strong stability. Experienced vendors have a history of doing great work. This lowers risks and helps your project succeed.

Special knowledge of Kovar's unique traits

Working with Kovar needs special skills because it is tricky. For example, Kovar gets harder as you machine it, making cuts tougher. Heat from machining can also change its properties. Skilled providers use advanced tools to solve these problems. Their expertise ensures accurate and dependable results, which are vital for industries like space and electronics.

Evidence | Description |

|---|---|

Unique Traits | Kovar has low heat expansion and strong stability, needing expert handling. |

Machining Problems | Tool choice and quality checks need careful planning and skill. |

Heat Control | Proper methods stop heat from changing Kovar's properties. |

Hardening Issues | Experts know how to manage hardening that makes cutting harder. |

Reputation and Customer Opinions

Why customer reviews and examples matter

A vendor’s reputation shows how trustworthy they are. Reviews and project examples give useful details about their work. Look for successful projects, especially with Kovar machining services. These show if they can meet your needs. Happy customers mean the vendor values quality and satisfaction.

Reading online reviews and industry feedback

Online reviews and industry opinions are also key. Sites like Google Reviews or forums can show how vendors perform in real jobs. Check comments about their skills, delivery times, and service. A vendor with good reviews is more likely to do a great job.

Tip: Always check reviews from different places. This helps you get a clear idea of the vendor’s abilities.

Cost and Value

Finding the right balance between price and quality

Price matters, but don’t pick cheap over good quality. A good vendor offers fair prices without lowering standards. They give clear quotes with all costs explained. This avoids surprises and ensures you get good value for your money.

Watching out for hidden charges

Hidden costs can mess up your budget. Ask vendors for a full list of their prices. This should include materials, labor, and extra fees. Clear pricing shows the vendor is professional and honest.

Factor | Description |

|---|---|

Pricing | Fair prices, discounts for big orders, and no hidden fees. |

Quality | Reliable results that meet standards with strong quality checks. |

Delivery | On-time delivery and ability to handle changes in demand. |

Customer Service | Quick responses and services tailored to your needs. |

Financial Stability | Ability to keep long-term partnerships and handle challenges. |

A vendor’s reliability affects your project’s success. Late deliveries can ruin schedules, and bad quality causes faulty parts. Choose a vendor focused on quality and honesty to avoid problems and ensure success.

Turnaround Time and Reliability

Why meeting deadlines matters for your project

Finishing on time is very important for your project. If a CNC machining service is late, it can mess up your schedule. This is especially bad for industries like space, healthcare, and electronics. These fields need things done on time and with care. A good provider delivers parts when promised. This helps you reach your goals without extra stress.

Fast turnaround shows the provider runs things well. Companies that keep machines working smoothly do better. They avoid mistakes and delays by fixing problems early. This makes production faster and improves product quality. Picking a provider known for on-time work lowers risks. It also keeps your project moving forward.

Tip: Ask providers about their usual turnaround time. Check how they handle tight deadlines to see if they are reliable.

Checking if the provider can handle urgent needs

Sometimes, you might need parts quickly because of sudden changes. In these cases, the provider must handle rush orders well. A trustworthy provider can prioritize your job without lowering quality. This needs good tools and a skilled team used to tight schedules.

Choose providers with modern CNC machines and smart workflows. These help them adjust to quick demands while staying accurate. Also, ask how they communicate updates. Providers who keep you informed are more likely to deliver on time. Clear updates help you plan better, even when time is short.

Note: Providers with strong planning and customer care handle rush jobs better. Look for these traits when choosing a provider.

Quality Assurance and Certifications

Why Quality Control Matters

Strong quality checks are essential

Always check how a provider ensures quality. Good quality control means the final product is safe, works well, and lasts long. It’s not just about checking the finished item. It includes careful checks during every step of making it.

Consistent methods make sure parts are accurate and reliable.

Careful checks at each step catch problems early, saving money later.

When a provider focuses on quality, you can trust their work. This is very important for fields like healthcare and aerospace, where reliability is key.

How quality checks improve product dependability

Good quality control makes products more dependable. Providers with strong systems deliver parts that meet your needs every time. For example, regular checks during production keep things precise and error-free. This attention ensures parts work as they should. Choosing a provider with proven quality control lowers the chance of getting bad parts.

Important Certifications to Look For

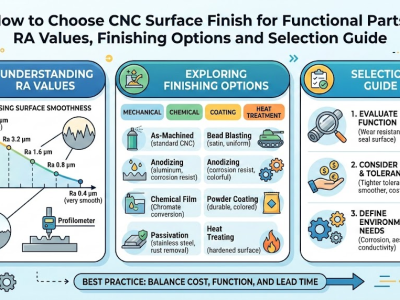

Certifications like ISO 9001 and AS9100D

Certifications show a provider cares about quality. ISO 9001 (Click to view) ensures they follow good processes to make high-quality items. AS9100D is for aerospace and focuses on safety and dependability.

Certified companies meet strict rules. For example, LKprototype earned ISO 9001(Click to view), which helped We reduce mistakes and improve quality. LKprototype also used ISO 9001 to improve Our systems, leading to better teamwork and fewer risks.

Why certifications prove quality commitment

Certifications mean the company works hard to meet high standards. They invest in training and systems to make better products. When picking a provider, choose one with these certifications. It shows they can deliver reliable and top-quality parts.

Checking Customer References

Ask for past client references

Ask providers for contact details of past clients. A good provider will share this information. Talking to these clients helps you learn about the provider’s quality, delivery, and reliability.

Use references to confirm claims

When speaking to references, ask clear questions. Did the provider deliver on time? Were the parts made as promised? How did they fix any problems? These answers help you decide if the provider is trustworthy and fits your needs. Checking references helps you avoid issues and pick the right provider.

Equipment and Technology for Kovar Machining Services

Advanced CNC Machinery

Why modern equipment is important

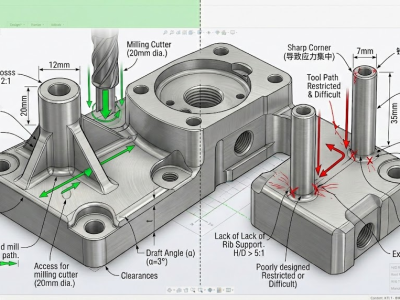

Using the right tools is key for Kovar machining services. Modern CNC machines are built to handle Kovar's challenges, like hardening during cutting. These machines make sure every cut is exact and steady. This is very important for industries like healthcare and aerospace. Old machines may not meet the strict needs of Kovar parts. This can cause mistakes and delays. Advanced tools help ensure accuracy and keep your product reliable.

How new machines improve work

New CNC machines have changed how machining works. CAD/CAM software helps move designs into production easily. Multi-axis machines allow more flexibility and fewer setups, reducing mistakes. Smart factory tools use real-time data to improve production. AI helps with tool paths and checks quality. These updates make work faster and more accurate, keeping your project on track.

Technology Type | What It Does |

|---|---|

CAD/CAM Software | Makes it easy to go from design to production for complex shapes. |

Multi-Axis Machines | Adds flexibility and cuts down on errors by reducing setups. |

IoT and Smart Factory Tools | Tracks data in real-time to improve production and fix problems early. |

Artificial Intelligence | Optimizes cutting paths and improves quality checks during production. |

3D Printing with CNC | Combines printing and machining for faster, more precise results. |

Customization and Flexibility

Making custom parts

Good Kovar machining services can create parts to fit your needs. Advanced CNC machines can make items like custom hydraulic manifolds or engine parts. These machines ensure the parts are made exactly as needed. This helps them work well in their specific jobs.

Adjusting to special projects

Flexibility is also very important. Skilled teams with modern tools can handle unique projects. They can make things like structural attachments or special fittings. This flexibility ensures the final product matches your needs. Providers who can adapt are great for both simple and complex designs.

Custom Hydraulic Manifolds: Made to fit machines perfectly for better performance.

Engine Components: Built with exact measurements to improve how engines work.

Structural Attachments and Fittings: Designed to make machines more useful with special mounts.

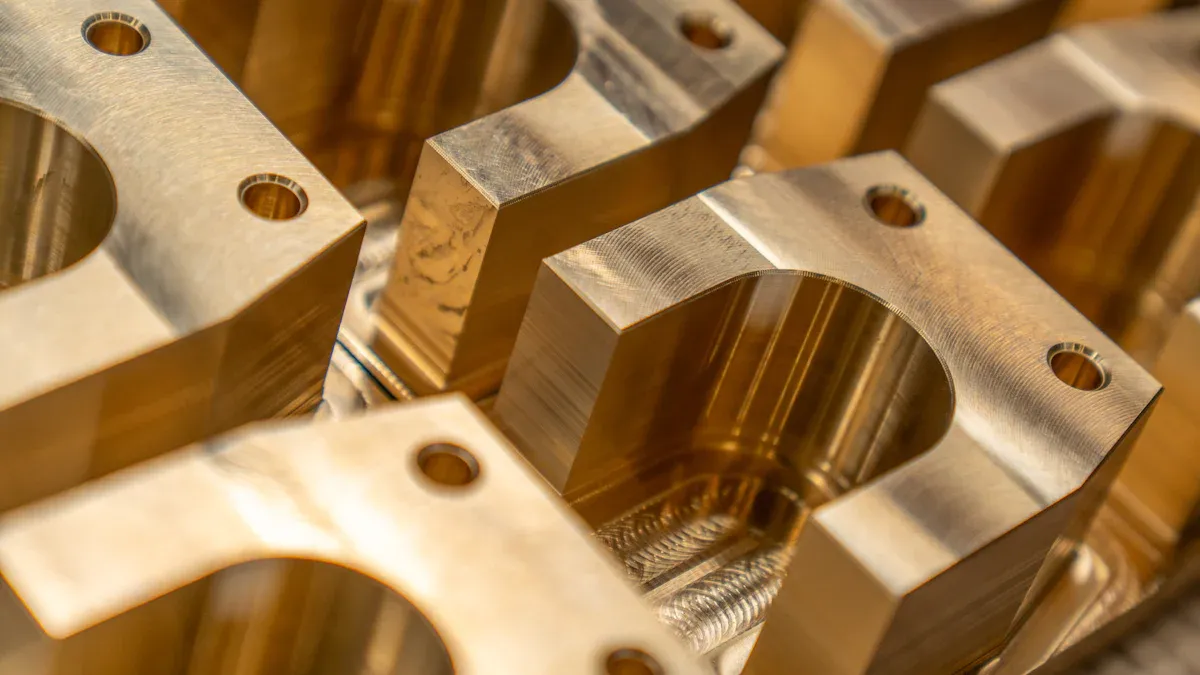

Material Expertise in Kovar

Knowing Kovar’s special traits

Working with Kovar needs a deep understanding of its properties. Its low heat expansion and strong stability make it great for precise jobs. But these same traits also make it hard to machine. Kovar gets tougher as you cut it. Experts know how to handle these issues to meet your needs.

Skilled with similar materials

Providers who work with Kovar often know other similar materials too. This makes them better at handling different projects. Picking a provider with lots of experience ensures your project benefits from their skills and knowledge.

Tip: Choose providers with advanced tools and material knowledge for the best results.

Customer Support and Communication

Responsiveness and Transparency

Why quick replies are important

Fast replies are key to keeping projects on track. When you contact a CNC machining provider, quick answers show they care about your needs. Slow responses can cause confusion or missed deadlines, delaying your project. A good provider answers quickly, making you feel valued and supported.

Clear communication also helps explain your needs early. Providers who reply fast can better understand your goals and challenges. This lowers mistakes and ensures the final product meets your expectations. Choosing a provider who values quick replies helps avoid delays and keeps your project moving smoothly.

Explaining costs, timelines, and steps clearly

Being clear about costs and timelines builds trust. A reliable provider explains everything upfront. They should give a detailed cost list, including materials, labor, and extra fees. This helps you plan your budget and avoid surprises.

Realistic timelines are just as important. Providers who share clear deadlines help you stay organized. They also update you on progress, so you know about any changes. Clear steps show how the project will go, making teamwork easier and goals achievable.

Solving concerns fast makes customers happier.

Good communication builds trust and shows project reliability.

Long-Term Support and Collaboration

Helping after the project ends

A good CNC provider doesn’t stop helping after delivery. They stay available to fix issues, make changes, or give advice. This shows they care about your success even after the project is done.

Post-project help is very important in fields like healthcare or aerospace. If changes are needed, a dependable provider can handle them quickly without lowering quality. This ensures your project works well even after it’s finished.

Building strong partnerships for the future

Working with the same provider long-term has many benefits. A provider who knows your business can deliver better results over time. They learn your preferences, making future projects easier and faster.

Long-term partnerships also build trust. When you stick with one provider, you know their work is reliable. This saves time finding new vendors and ensures your projects are in good hands. By checking customer support, you can find providers who want to build lasting relationships.

Tip: Choose providers who focus on teamwork and care about your future success.

Steps to Pick the Best CNC Machining Provider

Asking for Detailed Quotes

What to include in your quote request

When asking for a quote, share all project details. This helps the provider understand your needs and give an accurate price. Mention the material, like Kovar, along with sizes and tolerances. Include any special finishes or treatments required. Let them know how many parts you need and when you need them. Clear details help avoid confusion and ensure the provider knows the project’s scope.

A detailed request also shows how professional the provider is. Providers who send clear and complete quotes show they care about quality. This step is important for finding the right CNC machining provider for your project.

Comparing quotes for value and honesty

After getting quotes, compare them carefully. Don’t just look at the price. A low price might mean lower quality or hidden fees. Check if the quote covers everything, like materials, labor, and extra costs. Honest pricing shows the provider is trustworthy and professional.

Buyers often trust facts and examples when choosing providers. For instance:

49% rely on examples or reviews to decide.

67% want proof of good results before picking a service.

Case studies can show how a provider solved problems for others. These examples help you see their skills and make a smart choice.

Visiting the Facility and Checking Operations

Looking at equipment and processes

Visiting the provider’s facility lets you see how they work. Check their machines, especially CNC ones. Modern machines are needed for materials like Kovar, which need precision. Old machines might cause mistakes or delays. Look for advanced tools like multi-axis CNC machines or CAD/CAM software. These tools improve accuracy and save time.

Ask about how they maintain their machines. Well-kept equipment shows they care about quality. Providers who invest in their tools are more likely to deliver great results.

Checking cleanliness and organization

A clean and tidy workspace shows the provider pays attention to details. Organized spaces reduce mistakes and keep things running smoothly. Look for clear workflows and safety rules. Providers with high standards in their workspace are likely to do the same for your project.

Also, notice how the staff treats you. Friendly and skilled workers show the provider values customers. This gives confidence that they will meet your needs.

Judging Flexibility and Problem-Solving

Seeing if they can adjust to your needs

Good providers can adapt to changes in your project. Sometimes, designs change or deadlines get tighter. Flexible providers can handle these changes without lowering quality. Ask how they manage custom designs or urgent jobs. Providers who adjust well are better at ensuring your project succeeds.

Why problem-solving matters

Problem-solving is key for handling challenges during projects. Providers who work well in teams often find better solutions. For example:

Focus Area | Key Takeaway |

|---|---|

Flexible Design Changes | Adapting to changes leads to better results. |

Teamwork and Collaboration | Working together creates smarter solutions. |

Learning and Improving | Learning from issues improves future work. |

Flexible providers can fix problems quickly and keep your project on track. Those who focus on improving are more likely to deliver great results.

Tip: Pick a provider who is flexible and solves problems well. This ensures they can handle challenges and deliver top-quality work.

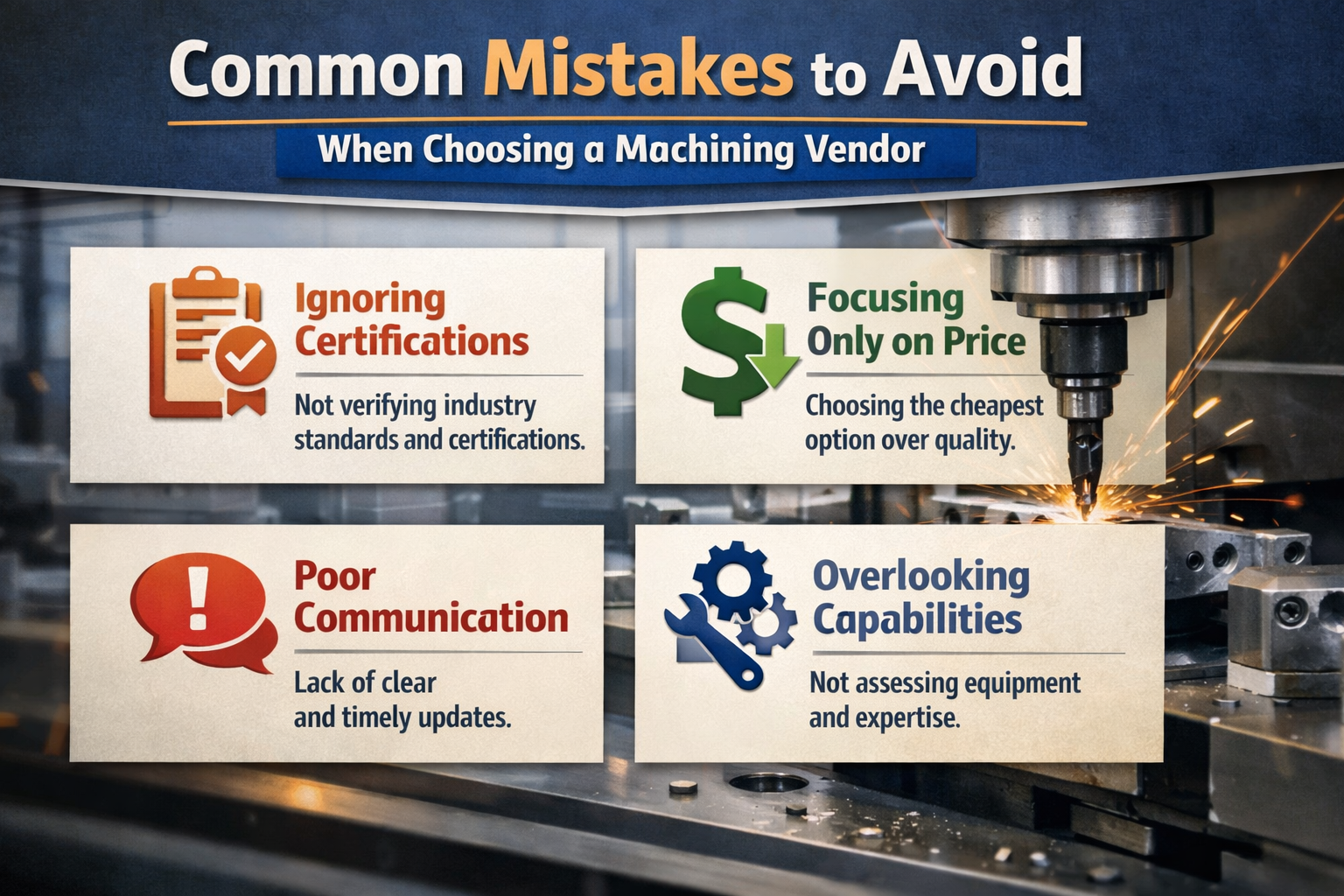

Common Mistakes to Avoid When Choosing a Machining Vendor

Picking Price Over Quality

Problems with choosing the cheapest vendor

Going for the lowest price may seem smart, but it’s risky. Cheap vendors might skip steps, leading to bad-quality parts. These parts may not work well or meet your needs. This can cause delays, extra costs, or even ruin your project. For instance, a low-cost vendor might use old machines or skip important checks. These shortcuts can make your final product unreliable.

Tip: The cheapest choice isn’t always the best. Bad parts can cost more later.

Finding a balance between cost and quality

To balance cost and quality, check vendors carefully. Pick one with fair prices and good work. Ask for detailed quotes to see what you’re paying for. A trustworthy vendor will explain their prices and how they keep quality high. Focus on value, not just cost, to avoid risks and keep your project on track.

Skipping Certifications and References

Why certifications and references matter

Certifications and references prove a vendor’s skills. Certifications like ISO 9001 or AS9100D show they follow strict rules for quality. These ensure the vendor can deliver good results every time. References from past clients show how well they’ve done before. They help you see if the vendor meets deadlines and handles tough jobs.

Note: Vendors with certifications and good references are more dependable.

Checking if claims are real

To check certifications, ask for proof and confirm with the issuer. For references, talk to past clients and ask clear questions. Did the vendor finish on time? Were the parts made correctly? How did they fix problems? These steps help you trust the vendor and avoid issues.

Ignoring Communication and Support

Problems caused by poor communication

Bad communication can lead to mistakes and delays. If a vendor doesn’t reply quickly or give updates, it’s hard to track progress. This can mess up your schedule and cause stress. For example, unclear messages or missed updates might lead to wrong parts being made.

Tip: Pick a vendor who communicates well and keeps you updated.

Ensuring good communication

To check communication, see how the vendor talks to you early on. Do they answer your questions fast? Do they explain costs, timelines, and steps clearly? A good vendor keeps you informed and solves problems quickly. Clear communication builds trust and helps your project succeed.

Picking the best Kovar machining provider needs careful thought. Look for skills, certifications, and modern tools to succeed. Providers with good quality checks and new machines give better results. Their knowledge and safety focus ensure accuracy and trust.

Certifications like ISO 9001 show they care about quality.

New machines work faster and save money.

Ongoing help builds strong partnerships.

Check vendors closely before choosing. Focus on trust and value, not just low prices. This way, you find a reliable partner for future projects.

FAQ

1. What is Kovar, and why is it hard to machine?

Kovar is a nickel-cobalt metal with low heat expansion. It’s great for precise industries like aerospace and electronics. But, it gets harder when cut, making machining tough. Skilled providers use special tools to handle these problems well.

2. How can I check if a provider is good at Kovar machining?

Look for certifications like ISO 9001 or AS9100D. Ask for examples of past work or client references. Choose providers with lots of experience and knowledge about Kovar’s tricky traits, like heat sensitivity and hardening.

3. Why do certifications matter when picking a machining vendor?

Certifications show the provider follows strict quality rules. ISO 9001 ensures good processes, and AS9100D focuses on aerospace safety. Certified vendors train their teams and use systems to deliver high-quality results.

4. What details should I include in a quote request for Kovar machining?

List the material (Kovar), sizes, and any special finishes needed. Share the number of parts and when you need them. Clear details help providers give accurate prices without hidden costs.

5. How do modern CNC machines help with Kovar machining?

New CNC machines make work faster and more precise. Multi-axis machines reduce mistakes by needing fewer setups. CAD/CAM software makes it easy to turn designs into finished parts. These tools handle Kovar’s challenges, like hardening, better.

6. Can I trust online reviews when choosing a machining provider?

Online reviews can show how reliable a provider is. Look for comments about quality, delivery times, and service. Combine reviews with certifications and references to get a full picture of their skills.

7. What should I check during a visit to a provider’s facility?

Look for modern machines, like multi-axis CNC tools. Check if the workspace is clean and organized, as this shows care. Talk to the staff to see if they are professional and helpful. A tidy facility shows they focus on quality.

8. Why is good communication important in machining projects?

Clear communication helps providers understand your needs better. Quick replies and clear timelines build trust. Regular updates keep your project on track and prevent mistakes or delays.

Start your project with LKprototype

LKprototype company simplifies procurement for custom manufacturing, Suitable for making your products or prototypes with a variety of materials, such as metal or plastic, silicone rubber, from 3D Printing to CNC Machined Parts and Vacuum Casting , with a focus on speed and efficiency. Our platform provides instant quotes. With LKprototype, You can connect with the team to communicate your project to ensure quality and on-time delivery.

Start with an instant quote and experience how our technology and expertise can make custom part procurement faster and easier.

LKprototype

LKprototype