Plastic molders are essential for creating precise, high-quality plastic parts. In this article, you’ll learn about the advanced methods plastic molders use and the benefits of partnering with a top-tier plastic molder like LKprototype Plastic Molders. Discover how they can help turn your concepts into reliable, market-ready products.

Key Takeaways

LKprototype Plastic Molders specializes in high-quality plastic manufacturing with over 15 years of experience, offering personalized customer service for both small and large orders.

The company utilizes advanced plastic injection molding techniques, including Water-Assisted and Microcellular Injection Molding, to enhance product quality and reduce production times.

Their comprehensive design and engineering support, along with custom mold-making capabilities, ensure tailored solutions that meet the specific needs of clients across diverse industries.

LKprototype Plastic Molders: Your Go-To Manufacturing Partner

What distinguishes LKprototype from its competitors is their commitment to providing customized client service. They uphold the philosophy that every customer should receive equal consideration and meticulous attention to detail, regardless of order size. This focus on prioritizing customers guarantees that each project receives exacting care, leading to outcomes that not only meet but surpass expectations.

Advanced Plastic Injection Molding Techniques

LKprototype Plastic Molders utilizes state-of-the-art plastic injection molding processes to elevate product excellence, accelerate production timelines, and guarantee consistent dimensional accuracy. The implementation of advanced techniques such as Water-Assisted Injection Molding (WAIM) and Gas-Assisted Injection Molding (GAIM) is key in the creation of products that are both light in weight and uniform.

Incorporating Microcellular Injection Molding (MIM), LKprototype has harnessed a technology capable of producing structures permeated with minuscule bubbles, which not only diminishes material consumption but also augments strength and endurance in finished components. These outcomes are refined through variable mold temperature technologies that offer on-the-fly adjustments throughout the molding procedure for heightened productivity.

LKprototype stands out particularly for its expertise in Microinjection Molding (IM), an indispensable process for fabricating ultra-precise microcomponents vital to sectors like medical device manufacturing. Alongside rapid thermal cycling molding and multicomponent injection molding techniques, these specialized approaches reflect the commitment to superior quality products with design versatility at LKprototype Plastic Molders. Their engineering team showcases their proficiency through certifications in scientific molding—an acknowledgment of their adeptness at these forefront technological methodologies within injection molding.

Comprehensive Product Design & Development

At LKprototype Plastic Molders, they provide extensive assistance in transforming your ideas into finished products ready for the market. Their product design proficiency spans the full spectrum of development, from the initial concept stage through to completion of production, guaranteeing both innovative and dependable results. Whether you aim to create a brand-new item or enhance an existing one, Premier is equipped with the necessary skills and assets to realize your objectives.

The methodology employed by Premier in product design and advancement is founded on collaborative efforts and perpetual enhancement. By maintaining close interactions with clients, Premier ensures that each product undergoes meticulous refinement for optimal functionality and ease of manufacturing. This systematic process benefits greatly from their deep-rooted engineering knowledge coupled with cutting-edge machinery at their disposal.

Collaborative Design Process

LKprototype Plastic Molders prioritize a joint design process that is crucial in crafting products of exceptional quality. This involves an intensive partnership with clients to perpetually improve the designs of products, guaranteeing they are not only top-performing but also viable for manufacturing. Such collaboration permits continual input and assessment of market trends, significantly contributing to the improvement of product functionality.

The company offers substantial engineering support, encompassing choices related to materials, refinement of production procedures, and mold tooling strategies to assure adherence to precise technical standards. This proactive assistance is instrumental in identifying and addressing potential issues with mold designs prior to initiating production—this foresight saves both time and resources effectively.

Engineering Support

LKprototype Plastic Molders is adept at offering comprehensive engineering assistance during both the design and development stages, guaranteeing technical precision and conformity with project requirements. They utilize sophisticated plastic injection molding methods that integrate state-of-the-art technology to improve quality and productivity within the manufacturing process.

LKprototype, their dedicated team pledges exceptional engineering support aimed at fulfilling projects according to outlined specifications while increasing client satisfaction. Their cooperative design approach promotes continuous dialogue with clients, enabling them to perfect product designs for maximum efficiency.

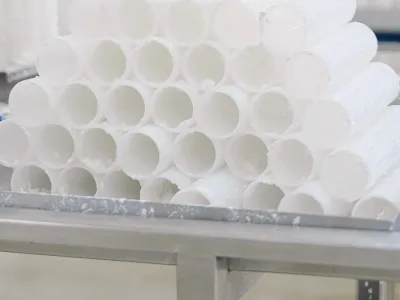

Custom Mold Making Capabilities

LKprototype Plastic Molders specializes in creating bespoke molds that are meticulously crafted to suit the specific requirements of each customer. They employ aluminum molds without heating or cooling channels, which could extend the cycle duration. This strategy guarantees accuracy and excellence throughout the molding procedure. By doing so, they can fabricate intricate and detailed mold designs that augment both functionality and dependability in end products.

Their emphasis on methodical precision and efficacy within their molding practices confirms that every custom-designed mold upholds supreme standards of quality. These individualized molds are adeptly engineered for a multitude of uses across various sectors, demonstrating LKprototype’s adaptability as well as their unwavering dedication to delivering outstanding services.

Quality Assurance & Certifications

At LKprototype Plastic Molders, the essence of their operations revolves around quality. They proudly hold ISO 9001:2015 and ISO/TS 16949 certifications, which attest to their adherence to strict quality management protocols. These accreditations serve as prominent signals of their dedication to upholding superior quality norms.

LKprototype has incorporated automated inline CMM technology along with robotic systems for quality control in order to achieve precise dimensional accuracy and reduce instances of product rejection. Their steadfast commitment towards ensuring top-quality assurance is fueled by an unwavering focus on customer satisfaction, making certain that each item delivered not only meets but potentially surpasses client expectations.

Efficient Production & Logistics Management

LKprototype Plastic Molders has refined their manufacturing process through the application of scientific molding methods, which guarantee regular output of high-quality parts. The use of robotic automation significantly contributes to boosting production velocity, resulting in reduced cycle times and greater throughput. These automated systems can be scaled up or down to align with fluctuations in market demand.

Incorporating robots into the workflow not only leads to substantial cuts in labor expenses and material waste, but also enhances resource efficiency overall. Premier’s skilled professionals are committed to providing precise and adept services that promote swift completion times while managing inventory programs tailored to customer requirements.

Ensuring a well-managed logistics operation is key for sustaining an uninterrupted production timetable and driving business performance forward. Through strategic optimization of logistical processes, Premier is capable of slashing supply chain expenditures by as much as 15% while simultaneously elevating customer satisfaction levels. Their dependable supply chains alongside streamlined operations play a vital role in amplifying productivity and reducing costs related to running their facilities.

Diverse Industry Applications

LKprototype Plastic Molders offers their services to a wide array of sectors, illustrating their adaptability and commitment to high-quality workmanship. Their certification under IATF 16949:2016 is an indication of their unwavering dedication to maintaining quality management within the realm of automotive production, with a focus on consistent enhancement. They specialize in crafting lightweight plastic parts for automobiles that comply with safety standards while promoting efficient manufacturing processes.

LKprototype exhibits proficiency in producing medical devices, backed by ISO 13485:2016 certification and MedAccred Plastics accreditation, which underscore strict adherence to exacting quality management protocols. The company also caters to needs across other industries such as pharmaceuticals, telecommunications, electronics, construction, food and beverage services, plus packaging solutions—each time delivering customized molded components designed to satisfy specific regulatory demands as well as performance criteria.

Advanced Automation & Equipment

LKprototype Plastic Molders significantly benefits from the integration of sophisticated automation, which bolsters both efficiency in production and adherence to superior quality benchmarks. The company has implemented leading-edge automated technologies, such as high-level robotics and intelligent manufacturing systems, which serve to refine their production operations while minimizing potential errors.

They utilize top-tier machinery equipped with precision injection molding capabilities that elevate product quality and uniformity. Premier’s commitment to investing in contemporary equipment provides them with enhanced versatility allowing for tailored solutions that cater to a wide array of client requirements across multiple industries.

To guarantee that every item meets exacting quality criteria prior to distribution, Premier employs automated quality control mechanisms throughout their manufacturing process.

Dedicated Team & Customer Focus

At the heart of LKprototype Plastic Molders’ achievements lies outstanding customer service. The team, committed to excellence, concentrates on providing bespoke support designed to meet the individual needs of each client’s project. This dedication to ensuring client satisfaction propels their promise to supply superior quality goods and services.

The process of interacting with customers is highly efficient, offering them direct communication channels with those in charge. Such a method guarantees that clients are provided with prompt updates and assistance at each stage of their project’s progression, which cultivates robust and enduring partnerships.

Case Studies & Success Stories

LKprototype Plastic Molders excels in delivering top-tier plastic injection molding services, offering bespoke solutions across multiple industries. A key endeavor included fabricating tailor-made components for a client within the automotive sector, demonstrating their proficiency in creating custom molds and meticulousness. The triumph of this undertaking resulted in enhanced performance of the client’s assembly operations, markedly boosting production efficacy while minimizing excess material.

This fruitful engagement led to LKprototype securing an ongoing partnership with this automotive firm, paving the way for collaborative ventures and consistent shared expansion. The heightened satisfaction of the client along with the persistent achievement of these initiatives reaffirms LKprototype’s status as a trusted partner in manufacturing.

Summary

LKprototype Plastic Molders distinguishes itself as a top-tier entity within the realm of plastic manufacturing, providing sophisticated injection molding processes along with exhaustive services in product design and development, bolstered by their specialized abilities in crafting custom molds. Their allegiance to ensuring high-quality output, streamlining production and logistics operations, and catering to an extensive array of industries underscores their adaptability and unyielding pursuit of superiority.

Employing cutting-edge automation technologies paired with modern equipment, LKprototype’s committed workforce prioritizes client satisfaction, which guarantees that each project is conducted according to the most stringent criteria. Their track record replete with success narratives and sustained collaborations reflects their aptitude for delivering outstanding results while propelling growth. When you select LKprototype Plastic Molders for your upcoming venture, prepare to witness how superior artisanship melded with innovative practices can culminate in a transformative impact.

Frequently Asked Questions

What is moldable plastic called?

Thermoplastic, also known as thermosoftening plastic, is a type of moldable material that becomes flexible when heated and then hardens when cooled down.

Due to this characteristic, it can be repeatedly reshaped and remolded for diverse uses.

Are plastic molds expensive?

Yes, plastic molds can be expensive, with costs ranging from $1,000 to over $100,000 depending on complexity and size.

It’s essential to assess your project requirements to determine the appropriate budget.

What do plastic molders do?

Plastic molders manufacture custom plastic parts by injecting molten plastic into a metal mold under high pressure, allowing it to cool and solidify before removing the finished piece.

This process is essential for producing a wide range of plastic components used in various industries.

What industries does Premier Plastic Molders serve?

LKprototype Plastic Molders caters to a diverse range of sectors, such as automotive, medical devices, pharmaceuticals, telecommunications, electronics, construction, food and beverage industries along with packaging.

Their broad engagement across these areas demonstrates their adaptability and proficiency in addressing the requirements of different industry segments.

What certifications does LKprototype Plastic Molders hold?

LKprototype Plastic Molders is committed to maintaining high standards of quality management and conforming to industry norms, as evidenced by their possession of ISO 9001:2015, ISO/TS 16949, ISO 13485:2016 certifications along with MedAccred Plastics certification.

Still, need help? Contact Us: [email protected]

Need a PROTOTYPE or PARTS machining quote? Quote now

LKprototype

LKprototype