Wondering whether brass vs stainless steel fittings are best for your project? This article breaks down durability, corrosion resistance, cost, and application suitability to help you decide. Key Takeaways Brass fittings are cost-effective and provide decent corrosion resistance, but they can suffer from dezincification in aggressive environments. Stainless steel fittings offer superior corrosion resistance and durability, making them suitable for high-pressure and extreme temperature applications, despite their higher initial cost. The choice between brass and stainless steel fittings should be based on factors such as budget, application environment, temperature tolerance, and pressure requirements. Understanding Brass Fittings Many homeowners favor brass…

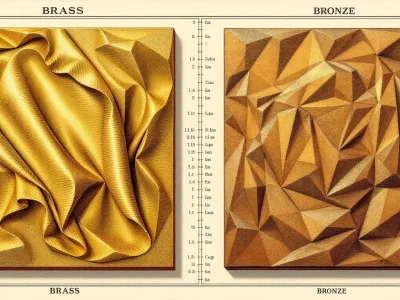

When deciding between brass vs bronze for a project, understanding their key differences is essential. Despite both being copper-based alloys, brass and bronze have distinct compositions and properties that make them suitable for different applications. This article will break down the composition, physical properties, mechanical properties, corrosion resistance, and common uses of brass vs bronze to help you make an informed choice. Key Takeaways Brass and bronze are distinct copper-based alloys, with brass being primarily composed of copper and zinc, while bronze consists mainly of copper and tin, leading to differing physical and mechanical properties. Brass is more malleable and…

Looking for ideas on what CNC machine products you can create and sell? The rise of affordable CNC machines has democratized the ability to produce custom items for small businesses and hobbyists. This article highlights the top 30 items, from custom signs and phone cases to jewelry and spare parts, showcasing the wide range of possibilities CNC technology offers. Key Takeaways CNC machining offers vast customization options for various products, such as custom signs, phone cases, and key holders, allowing businesses to cater to diverse customer preferences. High-quality materials and precise manufacturing enable CNC-created items like toys, jewelry, and lampshades…

Looking to understand molding polyurethane? This essential process transforms liquid polyurethane into durable, precision parts. We’ll explore different techniques like open cast, compression, and injection molding to help you find the best method for your needs, whether it’s for intricate designs or cost-effective production. Key Takeaways Polyurethane molding employs various techniques, including open cast, compression, and injection molding, to create precise parts suitable for diverse industries such as automotive and medical. Mold preparation is critical, involving sealing agents and releasing agents to ensure successful molding and avoid adhesion issues, with the technique chosen based on part complexity. Polyurethane’s physical properties,…

Facing a choice between alloy steel vs stainless steel? Understanding their differences in strength, corrosion resistance, cost, and applications will help you decide the best material for your project. Key Takeaways Alloy steel is versatile and primarily used for high strength and toughness applications, while stainless steel is known for its superior corrosion resistance and aesthetic appeal. The choice between alloy steel and stainless steel depends on factors like mechanical properties required, environmental conditions, and long-term cost considerations, with alloy steel being generally less expensive upfront but potentially requiring more maintenance. Understanding the specific applications of each type of steel—such…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.