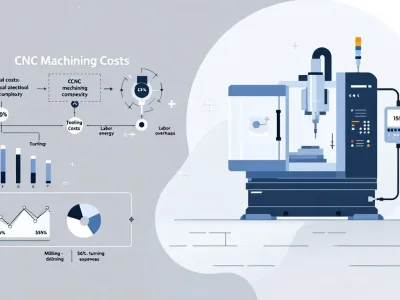

Looking to cut down costs on your CNC machining projects while maintaining top-notch quality? Low cost CNC machining is achievable with practical strategies like optimizing material selection, simplifying part designs, and leveraging online CNC services. This article dives into proven methods to help you get the best value for your investment without compromising on precision or quality. Key Takeaways CNC machining combines precision and versatility, making it essential in industries like aerospace and automotive, while online platforms offer cost-effective access to these services. Costs in CNC machining are influenced by material selection, design complexity, and machine setup efficiency, with strategies…

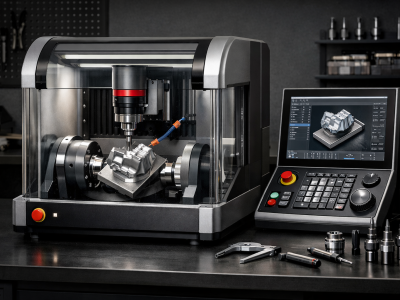

Looking to achieve high precision in a small workspace? A 5 axis desktop CNC machine provides advanced capabilities needed for complex designs. They are perfect for industries like aerospace, medical devices, and jewelry. In this article, we review the top 5-axis desktop CNC machines available today. Key Takeaways 5-axis desktop CNC machines offer advanced machining capabilities from multiple angles, maintaining high precision suitable for various industries such as aerospace and medical device manufacturing. Compact designs of these machines significantly save floor space while delivering high performance, making them ideal for workshops with limited space. With integrated software solutions and user-friendly…

Wondering about CNC machine prices? They range from a few thousand to hundreds of thousands of dollars. This guide will help you understand the factors that impact CNC machine prices, and find the best deal available. Understanding the CNC machine price is essential for making an informed purchase. Key Takeaways CNC machine prices vary widely, influenced by factors such as size, material compatibility, and advanced features, with costs ranging from $2,000 to over $500,000. Buyers should consider the total cost of ownership, including installation, maintenance, and tooling, alongside the initial purchase price for effective budgeting. Researching and comparing various models,…

Are you looking to achieve low cost CNC machining without sacrificing quality? This guide offers valuable insights into reducing CNC machining expenses. You’ll learn about factors that impact costs, tips for cutting down expenses, and affordable CNC machine options for small businesses. Dive in to discover strategies that can optimize your CNC machining processes efficiently. Key Takeaways CNC machining costs are influenced by material selection, design complexity, machine setup time, and production volume. Key strategies to reduce CNC machining costs include optimizing material usage, simplifying designs, bulk ordering, and minimizing finishing operations. Low-cost CNC machining provides significant advantages like cost…

Understanding Prototypes and Their Importance A prototype is a model or early version of your invention that helps you test and refine your idea. Creating basic prototypes using everyday materials is an essential step in refining designs before moving into mass production. Prototypes are essential for identifying and fixing design flaws, understanding user needs, and gathering feedback. The prototype development process can save time and money in the long run by ironing out production issues and rectifying problems before mass production. Creating a proof of concept can further validate the feasibility of your invention before moving to more advanced prototyping…

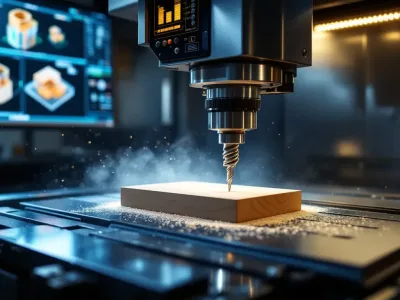

CNC machining prototypes utilize advanced computer-controlled machines to create precise prototypes rapidly, showcasing their versatility and precision across various industries, including military, medical, automotive, aerospace, oil, and energy. This process is crucial in product development, offering advantages like speed, accuracy, and material versatility. Read on to explore the benefits and applications of CNC prototyping in various industries. Key Takeaways CNC prototype machining accelerates product development by enabling rapid iterations and precise prototypes that closely match final product specifications. The versatility of CNC machining allows for the use of various materials like metals, plastics, and composites, making it adaptable to diverse…

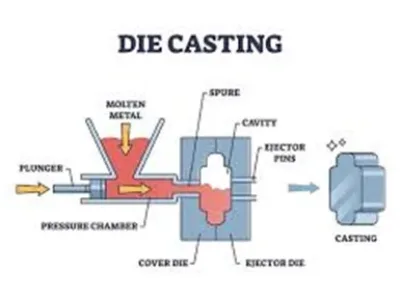

Molding manufacturing is a very common technique in operations such as that of automotive and even consumer goods. It consists of forming materials by introducing them into molds. What Is Molding Manufacturing? The Molding manufacturing process is the inverse of sheet metalworking in that it involves heating and pressuring a material into a molding cavity so as to achieve the desired shape. When cooled, the material sets in the shape of the cavity. Different Types of Molding Processes The term molding manufacturing includes a number of processes all aimed at working with different materials and responding to diverse product needs.…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.