Liquid silicone injection molding is a quick and accurate way to make parts from liquid silicone rubber. This process is special because it uses machines, gives smooth finishes, and makes parts that fit very well.

You get fast production and spend less money on workers than with hand molding.

Things like seals, medical tools, and electrical parts are made using this method.

The world market for liquid silicone injection molding is getting bigger, and it may be worth $3,700 million by 2035.

Key Takeaways

Liquid silicone injection molding works quickly and saves money. It is great for making many parts at once.

LSR is safe to use in medicine because it does not harm the body. It also does not get damaged by chemicals.

Using machines in the molding process helps work go faster. It also makes less waste and gives better parts.

Good design and tools are very important for good results. They also help stop mistakes from happening.

Liquid silicone rubber can be used again. This makes it a good choice for the environment when making things.

What Is Liquid Silicone Injection Molding (LSR Injection Molding)

Definition of Liquid Silicone Rubber (LSR)

Liquid silicone rubber is important in making many things. LSR starts as a liquid and has two main parts. You mix these parts together before using them. When the mixture goes into a mold, it turns solid very fast. This is called liquid silicone injection molding. People use this process because it is quick and saves money. LSR is also safe for nature and does not smell strong. It can handle bad weather and most chemicals do not affect it. LSR is used in things that need to be strong and bendy, like medical devices and seals.

Tip: LSR is picked by many industries because it works well and is dependable.

Core Materials & Properties of LSR

LSR has special features because of what it is made from. It has polysiloxane chains, treated silica, a platinum catalyst, and a cross-linker. These parts give LSR its unique qualities.

Here are some important properties:

Biocompatibility: LSR is safe for things that touch people, like medical tools.

Durability: LSR lasts long and does not get damaged by chemicals.

Wide Temperature Range: It works from -60°C to +250°C and keeps its shape.

Electrical Properties: LSR is great for electronics because it insulates well.

Aesthetic Flexibility: LSR can be clear or colored for different designs.

You can look at this table to see how LSR performs:

Key Performance Characteristic | Description |

|---|---|

High elasticity | Stretches and bends but does not break |

Low compression set | Keeps its shape after being squeezed |

Chemical resistance | Stays strong against many chemicals and oils |

High heat tolerance | Handles high heat without breaking down |

Biocompatibility | Safe for medical and food uses |

These features help LSR work well in tough places. That is why liquid silicone injection molding is used to make top-quality silicone parts.

Liquid Silicone Injection Molding Process Explained

Step-by-Step Process Flow

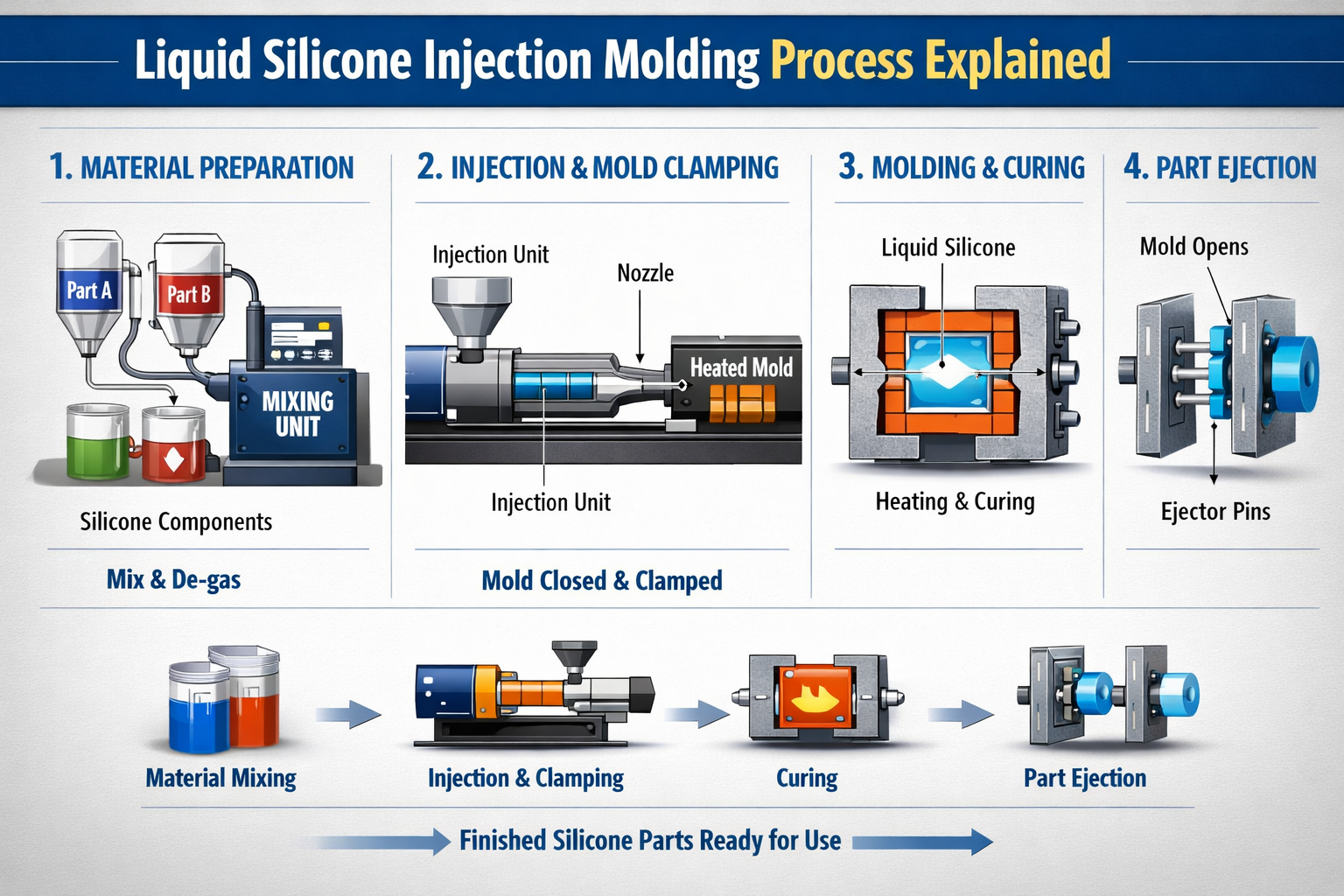

The liquid silicone injection molding process has four main steps. Each step is important to make sure parts are made right.

Step | Description |

|---|---|

1 | First, mix the two parts of liquid silicone. Make sure the temperature does not change. |

2 | Next, close the mold using a clamping machine. Then, start the injection. |

3 | After that, heat the mold to cure the silicone. This makes the part solid. |

4 | Last, let the part cool inside the mold. Take it out and let it cool in the air. |

Tip: If you control each step well, you can stop problems like warping or sink marks.

LSR Injection Molding Equipment

Special machines are needed for liquid silicone injection molding. Here is what you need:

Equipment Type | Specifications |

|---|---|

Liquid Silicone Molding Compounds | These come in two parts. You mix them in equal amounts. You can add color if you want. |

Mix Metering Units | These pump silicone from closed containers into the mold. |

Tooling Design | The molds are simple. They do not need to be shiny or have special angles. |

Shot Size | You can make big gaskets, up to 8 inches by 18 inches and over 300 grams. |

Cure Cycle | This step makes sure the silicone gets hard without tearing or changing shape. |

Automation & High-Volume Production

Automation helps make more parts faster and better. Here are some ways automation helps:

Fast cycles help you make more parts.

Using less material saves money.

Machines can make lots of parts for big orders.

Machines mix the materials in the right amounts every time.

Good control of heat and pressure keeps parts smooth and strong.

Mixing well and keeping the same conditions helps you get good parts every time.

Quality Control & Process Stability

You need to check your process to keep quality high. The best ways to do this are:

Quality Control Measure | Description |

|---|---|

Process Validation | Make sure your process always works right. Test and write down your settings. |

Material Testing | Check the silicone to see if it has the right properties. |

Compliance with Industry Standards | Follow rules like ISO 13485 and ASTM D1418 to keep things safe and good quality. |

Checking often helps you find problems early and keep your process steady.

Advantages & Limitations of Liquid Silicone Injection Molding

Key Advantages

Liquid silicone injection molding gives you many good things. It helps you work faster and makes less waste. You can make parts with small details and tight fits. Here are the main advantages:

Advantage | Description |

|---|---|

Shorter Cycle Time | Each cycle is done in seconds, not minutes. |

Contamination Prevention | Closed mixing keeps parts clean and safe. |

Ideal for Complex Parts | LSR flows well, so you make tiny, precise parts. |

Less Scrap | You use just enough material, so you waste less. |

Over-Molding Capability | You can mold LSR onto metals or thermoplastics. |

Note: Silicone comes from silicon, which is found in nature. Making silicone uses less energy than making plastics. It also makes fewer greenhouse gases. Silicone parts last long and do not break easily. They resist weather, heat, and chemicals. You do not need to replace them often, so you make less trash. LSR injection molding machines save energy and help lower carbon emissions.

Liquid silicone injection molding is good for the environment. You only use the silicone you need for each part. Silicone rubber can be recycled and used again. This means you do not need as much new material.

Limitations

There are some problems with this process. These can happen if you do not control your settings:

Parts can be too small if you set the temperature wrong.

Cycle times may change and cause defects or slow work.

LSR may not stick well to inserts, so over-molded parts can have issues.

Mold flashing can happen if shot sizes change or molds do not close tight.

Bubbles, burn marks, or whitening can show up if air or water gets in.

Flow lines or weld lines can appear if you use the wrong speed or temperature.

Scorching can happen if silicone cures too soon during injection.

Pot life problems may come up if material cures inside the machine after breaks.

Tip: You can stop most problems by checking your settings and keeping equipment clean.

Liquid Silicone Injection Molding Applications by Industry

Medical Devices

Liquid silicone injection molding is used for many medical devices. This process makes safe and clean parts for hospitals. In 2024, healthcare uses over 38.3% of the world’s liquid silicone rubber. Silicone is found in things that touch or go inside the body. Some examples are implantable devices, diagnostic tools, and patient-worn sensors. These products are trusted because silicone does not react with skin. It stays strong and flexible after many uses. Parts also resist germs and chemicals, so patients stay safe.

Automotive Components

Liquid silicone injection molding is used in cars and trucks. This process makes parts that last long and work well. Silicone can handle heat, cold, and oil. You find it in seals and gaskets, keypads and buttons, and connectors. Seals and gaskets stop leaks and keep out dirt. Keypads and buttons help you control car features. Connectors protect wires and electronics. Parts have smooth finishes and tight fits, so they work every time. Car makers use silicone to make vehicles safer and better.

Electronics & Consumer Products

You use electronics and home items every day. Liquid silicone injection molding helps make products that look good and last long. Silicone keeps water and dust out of gadgets. It is used in smartphone cases, wearable bands, kitchen tools, and remote control covers. You get soft grips and bright colors. Silicone does not break down when used often. You get safe and strong products for your home and office.

Tip: Silicone is a good choice for parts that bend, stretch, or need to stay clean. This process helps many industries get great results.

Design Considerations for LSR Injection Molding

Part Design Guidelines

You get better results if you follow good design rules. First, pick the best material for your part. Choose sizes and tolerances that fit your needs. Small and medium parts can have tolerances from ±0.05 mm to ±0.1 mm. Bigger parts usually have tolerances from ±0.1 mm to ±0.2 mm. Think about the shape of your part. Simple shapes are easier to make. Try to keep the walls the same thickness. Avoid deep undercuts so you can remove the part easily. Use a runner system that does not waste much material. Pick gates that help the silicone move smoothly.

Description | |

|---|---|

Material Selection | Pick the right material for good parts and easy molding. |

Dimensioning and Tolerances | Use the right sizes so parts fit and work well. |

Part Geometry | Simple shapes make molding and tooling easier. |

Demolding Design | No deep undercuts and even walls help with removal. |

Runner System Selection | Choose a system that saves material and works well. |

Gate Selection | Use gates that help silicone flow and make better parts. |

Tip: If you plan your design early, you will not need to make expensive changes later.

Tooling & Mold Design

You must pay attention to your tooling and mold design. Keep parting lines short and simple. This helps you get cleaner parts and faster cycles. LSR shrinks at about 0.025 in./in., so plan for this in your mold. Watch for flash if the mold does not close tight. You can use undercuts, but you may need special tools or extra steps to get the part out. Make your mold so the part stays in one half for easy removal. Air can help push the part out.

Consideration | Description |

|---|---|

Parting Lines | Simple lines give you cleaner parts and faster work. |

Shrink and Flash | Plan for shrinkage and check for flash at the mold edges. |

Undercuts | Use undercuts if needed, but plan for extra steps to remove parts. |

Part Ejection | Make parts stay in one mold half and use air to help remove them. |

Cost Factors in LSR Injection Molding

You can save money if you know what makes costs go up. Complex shapes take more time and skill, so they cost more. High-quality tool steel is more expensive than regular steel. Molds with one cavity cost less than molds with many cavities. If you need lots of parts, you need molds that last longer and are more exact. Smooth finishes and tight tolerances also cost more. Machine costs depend on the type, how much energy it uses, and how fast it works. The price of raw materials can change. Skilled workers and extra steps like trimming or painting add to the price. Rent and utilities also affect the total cost.

Description | |

|---|---|

Design Complexity | Harder shapes need more work and time. |

Tool Material | Better tool steel costs more money. |

Cavity Number | More cavities mean higher mold costs. |

Production Requirements | High-volume molds must be stronger and more exact. |

Surface Finish and Tolerances | Smoother finishes and tighter tolerances cost more. |

Machine Operation | Costs depend on machine type, energy use, and speed. |

Raw Material Costs | Prices change with the market and material type. |

Labor Costs | Skilled workers and checks add to the price. |

Post-Processing | Extra steps like trimming or painting cost more. |

Overhead Expenses | Rent and utilities add to the total cost. |

Note: You can spend less if you keep your design simple and plan your production early.

Liquid Silicone Injection Molding vs Other Molding Methods

LSR vs Compression Molding

You might wonder how liquid silicone injection molding is different from compression molding. The biggest differences are in how the process works, how you handle the material, and what kinds of parts you can make. Check out this table:

Aspect | Compression Molding | |

|---|---|---|

Process | Automated, involves mixing and injecting liquid silicone into a mold | Manual placement of solid silicone into a mold |

Efficiency | High efficiency with shorter cycle times | Slower, more traditional method |

Material Handling | Liquid form, no manual mixing required | Solid form, requires manual weighing and placement |

End-Use Applications | Ideal for intricate designs and high-volume production | Suitable for thicker profiles and less detailed designs |

LSR uses liquid silicone, so machines mix and cure it exactly right.

Compression molding uses solid silicone, so people must weigh and put it in the mold by hand.

LSR helps you make thin and detailed parts.

LSR is better when you need parts that are safe for people or can handle tough places. Compression molding is good for simple shapes that are thick and solid.

LSR vs Thermoplastic Injection Molding

You can also compare LSR to thermoplastic injection molding. Both use machines, but the materials and results are not the same. Here is a table to help you see the differences:

Aspect | Thermoplastic Injection Molding | |

|---|---|---|

Cycle Time | Moderate (depends on part complexity) | Faster, especially for simple designs |

Durability | Excellent flexibility, high-temperature resistance, and chemical stability | Varies by type, generally cost-effective for high-volume production |

LSR makes parts that stay bendy and strong, even in heat or with harsh chemicals. Thermoplastics work for many things, but they might not last as long in really hard conditions.

Tip: Pick LSR if you need parts that bend, stretch, or get very hot.

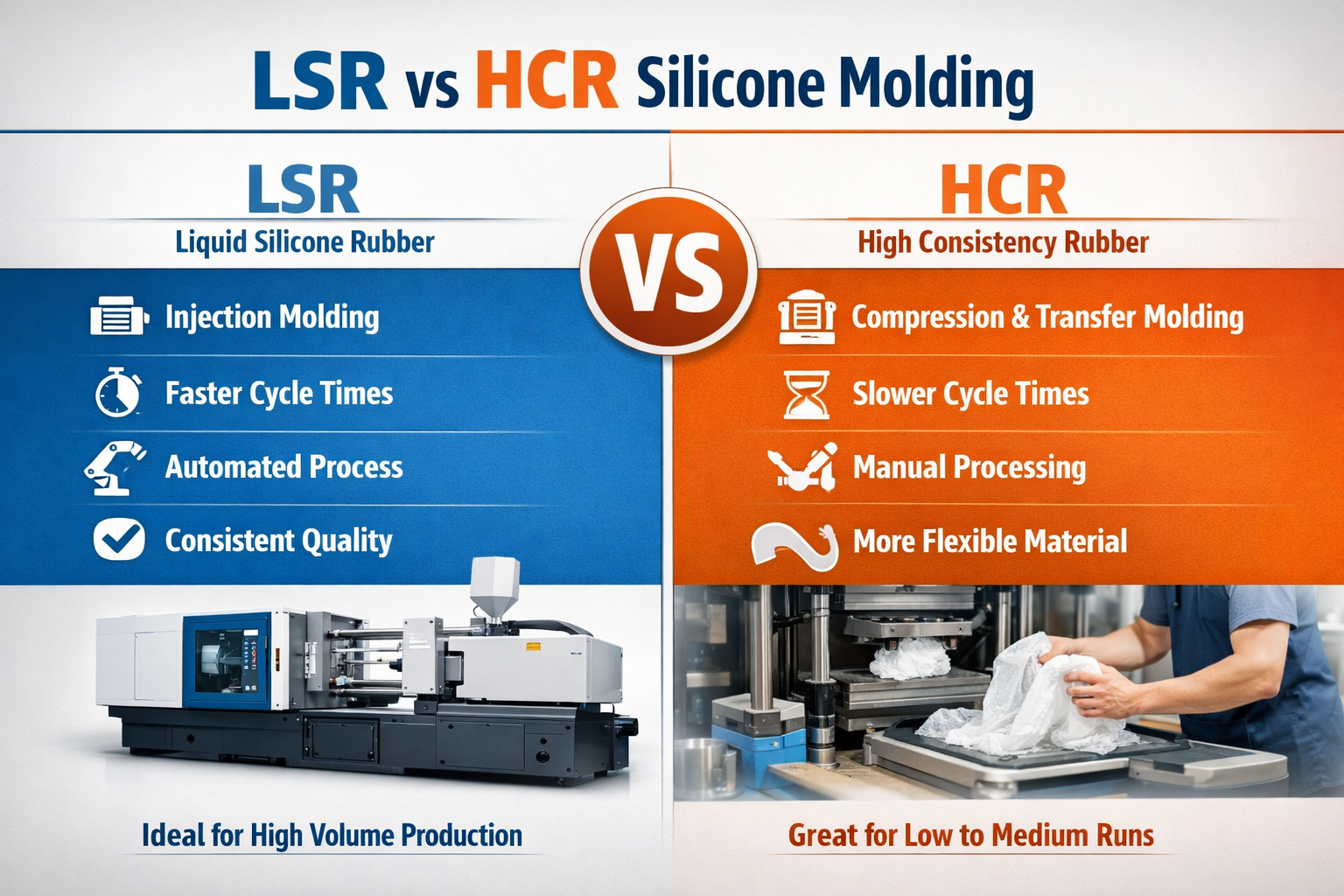

LSR vs HCR Silicone Molding

You might hear about HCR, which means high consistency rubber, for some silicone parts. LSR is thinner, so it flows into small spaces and fills tricky molds. You use injection molding for LSR, so you can make lots of parts fast. HCR feels sticky and needs more work because you use compression or transfer molding. This makes HCR slower and costs more.

HCR is good for some jobs, but you may need extra steps like post-curing, especially for medical parts. LSR usually does not need this, so you save time and money. LSR is a great pick for medical devices because it is flexible and saves money.

Note: LSR and HCR both use silicone, but they flow and cure in different ways, so each is best for certain jobs.

Some questions about liquid silicone injection molding

You may have questions before you start using liquid silicone injection molding. Here are answers to some of the most common questions manufacturers ask:

How can you mold complex LSR parts with undercuts and no draft angles in the cavity?

Why do you not use ejector pins and slides in LSR tooling designs?

Can you convert a thermoplastic rubber mold into an LSR mold?

What type of surface finish should you specify for a molded LSR part?

What tolerances can you hold in rubber molding? Is LSR molding more precise?

Why do you avoid aluminum molds for prototypes?

Is moisture a concern during the LSR curing process?

Tip: You can mold very complex shapes with LSR. The material flows easily and fills small spaces, so you do not always need draft angles or slides.

Many people believe some things about liquid silicone injection molding that are not true. Here are some common misconceptions and the facts:

LSR is only for simple parts. In fact, you can make very detailed and complex shapes.

LSR is not durable. LSR is strong and can handle heat, cold, and chemicals.

LSR is hard to process. It is actually easy to mold and works well for high-volume production.

Liquid injection is expensive. This process can save you money, especially when you need many parts.

Injection molding has design limits. LSR is flexible and lets you add custom features.

Gumstock is better. Gumstock takes more work and does not allow for as many design options.

You may also wonder about precision. LSR molding can hold tight tolerances, often better than other rubber molding methods. You get clean, repeatable results.

If you have more questions, talk to your supplier or mold designer. They can help you choose the best process for your project.

You can count on liquid silicone injection molding to make parts that are strong, safe, and bendy. This process uses less energy and makes less trash, so it is better for the earth. You get good parts without spending a lot of money or needing many workers. Many businesses use this method for things like medical tools, car pieces, and electronics.

Makes parts quickly and saves money

Gives you parts that work well every time

Used for many different things in many fields

If you want a smart and earth-friendly way to make parts, you should think about using this process for your next project.

FAQ

What makes liquid silicone injection molding better for medical parts?

You get clean, safe parts with this process. Machines keep germs out. Silicone does not react with skin. You can trust these parts for medical use.

Can you recycle liquid silicone rubber parts?

Yes, you can recycle silicone rubber. You can grind old parts and mix them with new material. This helps you save resources and protect the environment.

How do you avoid defects in LSR molded parts?

You should check your machine settings often. Keep molds clean. Control temperature and pressure. Good mixing and careful monitoring help you get strong, smooth parts.

Is liquid silicone injection molding good for making small, detailed parts?

You can make tiny, complex shapes with this process. Liquid silicone flows into small spaces. You get sharp details and tight fits every time.

LKprototype

LKprototype