Global buyers often choose China for Wire EDM Machining Services. China offers very precise work and strong export skills. They also have strict rules to keep quality high. Chinese factories use smart machines and computers, which helps them work faster and make fewer mistakes. Wire EDM Machining Services in China are affordable and dependable. These services support many industries, including automotive and clean energy. They can produce just one part or many parts simultaneously.

Metric | Data/Trend |

|---|---|

Asia-Pacific market share (2023) | |

Expected CAGR | 7.5% growth is expected in the coming years |

China exports extensively and supports clients worldwide, making its Wire EDM Machining Services an excellent choice.

Key Takeaways

China is a leader in Wire EDM. They use advanced machines and skilled workers. These workers make very exact and smooth parts.

Chinese factories work with many metals and non-metals. They help industries like airplanes, cars, hospitals, and electronics. They make high-quality parts for these fields.

Factories can make one part or thousands fast. They keep strict quality checks and have important certificates.

China is great at sending parts to other countries. They ship fast and talk clearly with buyers. Their strong delivery systems help parts arrive on time everywhere.

Buyers trust Chinese Wire EDM services. They are accurate, fast, and have good prices. They also help with custom and big orders.

Why Pick China for Wire EDM Machining Services

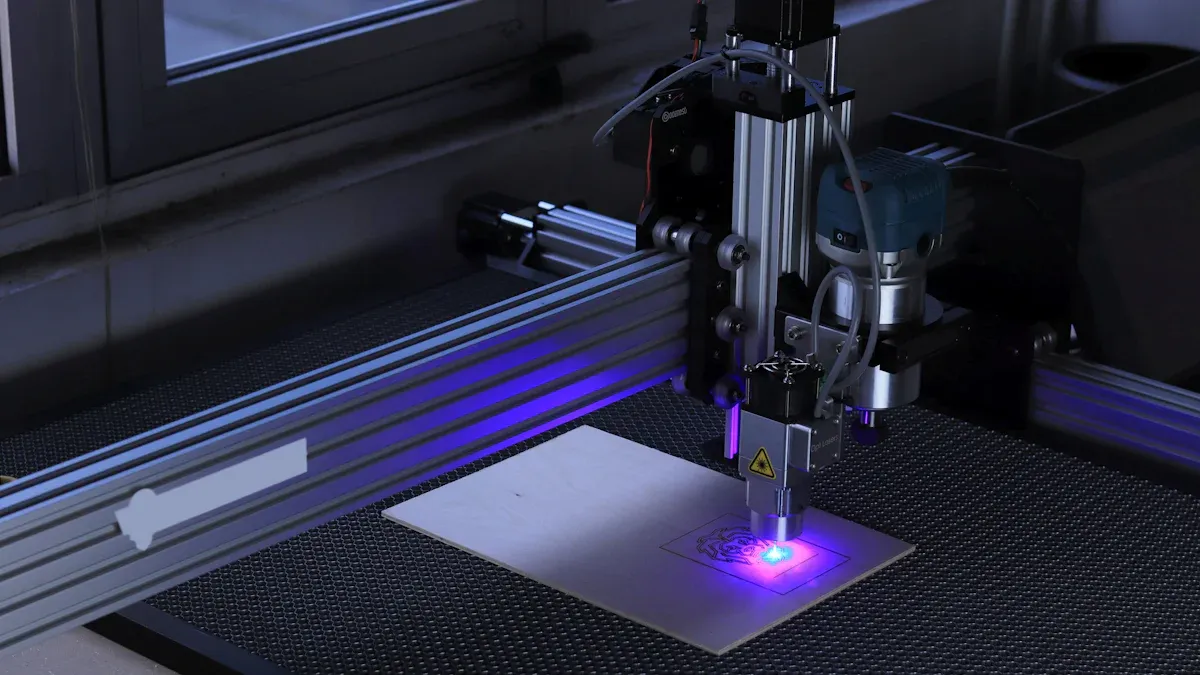

Advanced Technology

China is a leader in making things with new machines. The government spent about $200 billion to improve factories. They focus on making very exact machines like EDM. This helps factories grow fast and stay modern. Many places use special EDM machines and smart computers. These help make hard parts easily. Big industries like chips, medicine, and energy need these tools. For example, chip makers use EDM to make tiny parts. Some are smaller than a hair. Medical companies use EDM to make small metal cages and implants. These must be very smooth. These examples show China can do very careful work for people all over the world.

Skilled Workers

China’s workers are very skilled at EDM. Many have worked for over 15 years. They use special tools to check their work. Some tools are CMMs and optical comparators. They can make parts very close to the right size. The difference is less than a hair. Hard jobs like planes, cars, and electronics need this skill. Chinese workers use math to check every part. They make sure each one is just right. They can make one part or many parts. Their skills help them do both well.

Export Experience

China sends EDM parts to many countries. They work with big airplane companies. They are part of the world’s supply chains. Chinese factories make parts for jet engines and planes. This shows they meet world rules. There are over 8,000 metal shops in China. They sell about $23.5 billion each year. Many shops have hundreds of workers and new machines. People know Chinese shops for good work and fast delivery. Places like Shenzhen are extra helpful. They ship fast and help customers from other countries.

China is a top pick for EDM. They are careful, save money, and send parts worldwide.

Capabilities

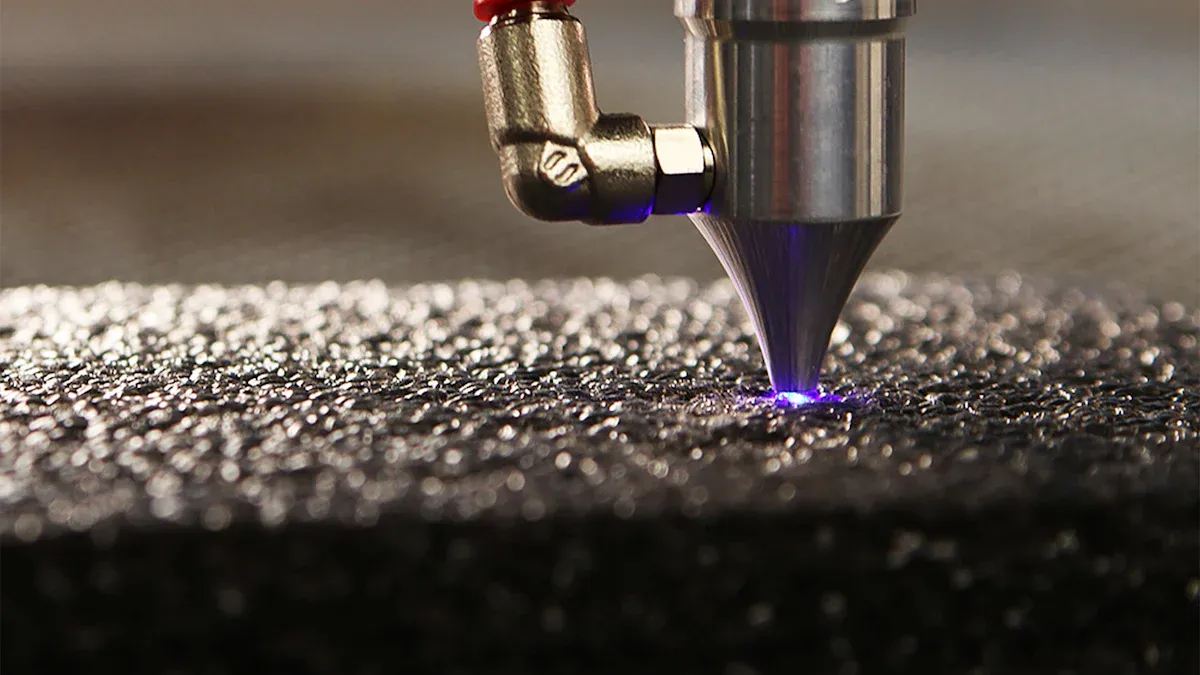

Precision & Tolerances

Chinese factories make very accurate parts with wire EDM. They can make parts almost perfect, with only tiny errors. The smallest error is about ±0.005 mm. This is very important for things like airplanes. Even a small mistake can be dangerous. For example, engine parts must fit just right to work safely. Tolerance means how much a part can be off from the perfect size. A smaller number means better accuracy. Chinese shops use special wire cutters to meet these rules. They also make sure parts are smooth. Smooth parts fit together well and last longer. Factories can make shapes with lots of details because of this control.

Note: Small errors and smooth parts help keep things safe and reduce waste.

Production Scale

Wire EDM in China can make one part or many. Factories can make a test part or thousands for big orders. They can switch between small and big jobs fast. This helps save time and money. Shops use wire EDM for easy and hard jobs. They can cut parts of many sizes and shapes. This is good for companies that need custom or many parts.

Prototype runs: Quick for new ideas

Medium batches: Good quality for growing companies

High-volume production: Steady parts for world markets

Equipment & Software

Chinese factories use new machines and smart software. They use computers to plan and control the work. For example, CAMWorks Wire EDM helps turn designs into machine steps fast. The software finds what to cut and makes paths for the tools. It can handle hard shapes and parts that are not flat. These tools make work faster and more exact.

Equipment/Software | Description |

|---|---|

Cuts many kinds of parts with smart CNC programs | |

CNC Guide | Software for planning and testing jobs on computers |

Smart Digital Twin Suite | Tools for testing, improving, and planning tool paths |

Chinese workers use these tools to make great parts. Their new machines help them meet tough rules and keep customers happy.

Materials & Industries

Metals & Alloys

Chinese wire EDM shops can cut many metals. They use smart ways to work with tough materials. Some metals they cut are titanium, stainless steel, tool steel, and aluminum. These metals are strong and do not rust easily. They are used when parts must be very exact.

Material / Alloy | Machining Technique | Key Findings / Applications |

|---|---|---|

Powder mixed Wire-EDM | Used in planes and medicine for strong, light parts | |

Al6061–7.5% SiC composite | Wire-EDM | Makes car and plane parts with great detail |

SS316L (Stainless steel) | Sinking EDM | Smooths out parts for medical use |

AISI D2 (Tool steel) | EDM | Fast cutting and smooth tools |

Tests show wire EDM makes smooth, exact metal parts. Titanium and nickel keep their shape after cutting. This is good for plane and medical parts.

EDM can cut super-strong metals and hard steels. These are needed for cars, food, and medical jobs.

Non-Metals

Wire EDM can also cut some non-metals. Shops use it for graphite, ceramics, and special mixes. These are used for molds and electronics. Carbide is very hard and breaks easily. Shops use gentle settings to stop cracks and get smooth sides.

Graphite: For making EDM tools and molds

Ceramics: Used in electronics and medical gear

Carbide: Needed for tough tools and dies

Industry Applications

Wire EDM helps many types of companies. Airplane makers use it for tricky parts. Car factories cut bumpers and fuel parts with it. Medical shops make bone plates and tools. Mold shops make dies for metal and plastic. Electronics companies make tiny parts with it.

Industry Sector | Example Application | Key Benefit |

|---|---|---|

Aerospace | Turbine blades, brackets | Very exact, stands up to heat |

Automotive | Custom metal parts, modules | Smooth cuts, no bending |

Medical | Bone plates, tools, implants | Safe and high quality |

Mold & Die Making | Aluminum dies | Strong, lasts a long time |

Electronics | Connectors, small parts | Tiny details, very exact |

Power Generation | Superalloy turbine blades | No rough edges, strong |

Cutting many parts at once | Saves time, less work needed |

Wire EDM can make one part or many at once. Robots and smart machines help make parts fast and the same every time. This is why buyers around the world trust Chinese shops.

Quality & Flexibility

Quality Control

Chinese wire EDM shops check quality at every step. They use special 5-axis machines for hard shapes. Workers use CMMs and testers to check each part. The surface is very smooth, between 0.1 and 0.8 micrometers. Parts can be made very exact, within ±0.0001 inches. Factories write down all checks and machine care. They watch the fluid and room temperature every day. Workers check parts during and after making them. Reports and photos are sent before shipping. These steps help make safe parts for planes, cars, and hospitals.

Note: Checking machines often keeps them working well and safe.

Certifications

Top Chinese shops have important world certificates. ISO 9001 means good quality rules. AS9100 is for airplane parts. ISO 13485 is for medical tools. Some also have ISO 14001 for the environment. ISO 45001 is for worker safety. Shops get checked often and train workers. Outside groups check their work too. First Article Inspections help prove they follow rules. These certificates help shops sell to more countries.

ISO 9001: Quality rules

AS9100: Airplane parts

ISO 13485: Medical tools

ISO 14001: Environment

ISO 45001: Worker safety

Custom CNC & Finishing

Chinese shops can make custom wire EDM parts. They help with one part or many. They use 3, 4, and 5-axis machines, plus turning and grinding. Many shops have over 50 machines. They also help with design and drawings. Shops offer finishes like anodizing, plating, and polishing. They can pack parts in special ways. Workers can make hard shapes and work fast. This helps many companies get the parts they want.

Help with one or many parts

Finishing and extra steps in one place

Fast work and easy to talk to

Tip: Ask for material papers and check reports for extra safety.

Global Export Capabilities

Export Logistics

China is number one for sending wire EDM parts worldwide. Their factories and shipping systems work fast and well. They team up with shipping companies to move parts quickly. Customs checks are smooth, so parts arrive on time. Many companies use tracking tools. Buyers can see where their packages are at any time. This helps buyers save money and get parts faster. China’s strong shipping network makes it a top choice for buyers everywhere.

Rank | Country | Export Shipments | Market Share (%) | Number of Top Suppliers |

|---|---|---|---|---|

1 | China | 54 | 334 | |

2 | Taiwan | 762 | 20 | 70 |

3 | India | 366 | 10 | N/A |

China ships the most wire EDM parts. They have many trusted suppliers.

The Logistics Performance Index (LPI) checks how well countries ship goods. China scores high, which means they send orders fast and safely.

Lead Times

Chinese factories work hard to ship orders quickly. They watch each step to stop delays. Most orders arrive on time because of good planning. They check:

How long each order takes

How fast customs checks are done

If papers are filled out right

How often customs is passed the first time

Factories use this info to get better and faster. These steps help China send wire EDM parts quickly and on time.

International Support

Chinese companies help buyers from all over the world. Many workers speak different languages. They know the rules for shipping to other countries. They help with customs forms and shipping choices. Buyers in the US, Europe, and Asia trust Chinese companies. They like the clear answers and fast help.

Buyers get quick replies and help at every step.

Chinese wire EDM shops do great work for many countries. Here are some main reasons to choose them:

Aspect | Key Benefit |

|---|---|

Makes very exact and tricky shapes | |

Materials | Cuts many metals, like titanium and steel |

Surface Finish | Parts are smooth, no extra work needed |

Efficiency | Can cut many parts at once, all look alike |

Equipment & Staff | New machines and workers who know their job |

Industries | Used for planes, cars, hospitals, and more |

Pricing | Good prices and quick work |

People around the world trust Chinese shops for good parts. You can talk to a shop now about your next job.

FAQ

What is the typical lead time for wire EDM parts from China?

Most shops in China send parts in 7 to 15 days. Big or tricky orders might need more time. If you need parts fast, you can pick express shipping.

Can Chinese wire EDM shops handle custom designs?

Yes, they can make custom parts. You can send your own drawings or 3D files. Engineers check each design and give advice. They help with one part or many parts.

Which industries benefit most from Chinese wire EDM services?

Many industries use these services. Airplane, car, medical, electronics, and mold companies all use wire EDM. They like the high accuracy and quick work.

How do Chinese suppliers ensure quality for export orders?

Shops check parts carefully and use special measuring tools. They have world certificates like ISO 9001. Before shipping, they send reports and photos to buyers.

What materials can Chinese wire EDM shops process?

Metal | Non-Metal |

|---|---|

Titanium | Graphite |

Stainless Steel | Ceramics |

Tool Steel | Carbide |

Aluminum | Composite |

Shops can cut many metals and some non-metals for special jobs.

Start your project with LKprototype

LKprototype company simplifies procurement for custom manufacturing, Suitable for making your products or prototypes with a variety of materials, such as metal or plastic, silicone rubber, from 3D Printing to CNC Machined Parts and Urethane Casting Service , with a focus on speed and efficiency. Our platform provides instant quotes. With LKprototype, You can connect with the team to communicate your project to ensure quality and on-time delivery.

Start with an instant quote and experience how our technology and expertise can make custom part procurement faster and easier.

LKprototype

LKprototype