In this article, we explore how the density of stainless steel—which typically falls between 7.5 and 8.0 grams per cubic centimeter—affects its performance and utility in various industries such as construction, aerospace, and marine sectors. We will examine the influence that different alloy compositions and manufacturing techniques have on the density of stainless steel and consequent implications for its application.

Key Takeaways

Stainless steel contains at least 10.5% chromium and is manufactured in various grades tailored for specific applications, providing durability and corrosion resistance.

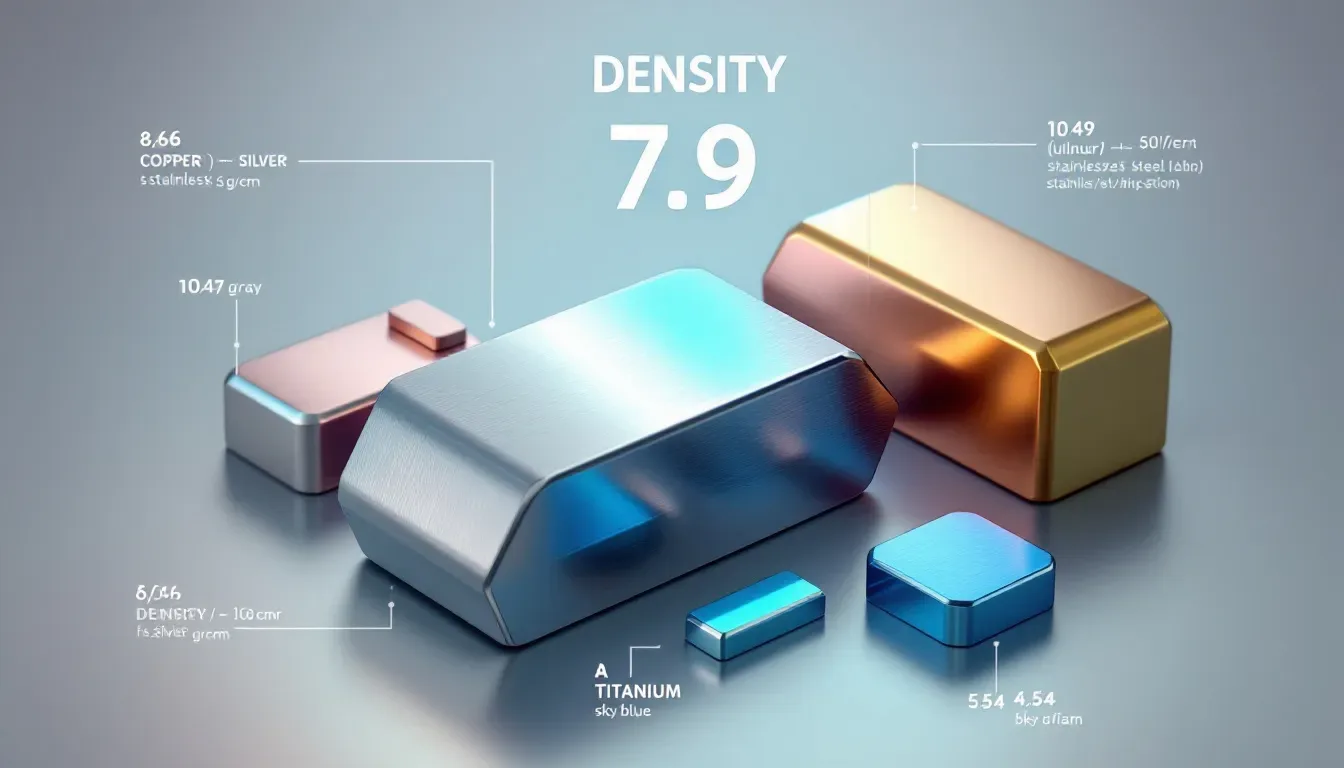

The density of stainless steel ranges from 7.5 to 8.0 g/cm³, influencing its strength and suitability for different industrial uses, with specific grades varying in density based on composition.

Understanding density is essential for material selection in engineering, impacting performance, weight considerations, and applications in industries like aerospace, marine, and medical.

Understanding Stainless Steel

Stainless steel is characterized by its minimum 10.5% chromium content, which gives rise to an oxide layer that safeguards against corrosion. Its suitability for use in environments where resistance to rust and stains is crucial stems from this feature.

Incorporating nickel into stainless steel enhances its corrosion resistance. Molybdenum contributes additional strength, while titanium ensures stability under high temperatures. This combination results in a resilient and adaptable material appropriate for myriad uses.

The extensive selection of over 60 different grades of stainless steel allows it to be customized based on specific attributes and intended applications. Certain grades are designed to withstand extreme temperatures, while others offer robust defenses against harsh chemicals, providing industries the flexibility to select the most fitting variant according to their requirements.

The production process for stainless steel commences with purifying raw materials within electric arc or blast furnaces. It proceeds through casting and molding stages, culminating in a product that conforms precisely with standards for strength, endurance, and capacity for resisting corrosion.

What is Density?

Density is the measure of how much mass is contained within a unit volume, which does not change regardless of the quantity present. This property, crucial for both scientists and engineers, can be quantified in kilograms per cubic meter (kg/m3) or grams per cubic centimeter (g/cm3).

In terms of its impact on material behavior under different circumstances, density plays a pivotal role. It’s essential when determining if an object will either float or sink in fluid environments – critical to selecting appropriate materials for specific applications. The principle that explains why dense substances like pebbles submerge in water while less dense ones like logs remain afloat demonstrates the influence of density on buoyancy.

Comprehending the density values for materials including stainless steel is vital for optimizing cost-efficiency alongside performance criteria across various sectors. High-density materials offer greater strength and longevity suited to strenuous tasks whereas low-density counterparts are favored where minimizing weight is paramount — exemplified by their application within aerospace engineering fields.

Density of Stainless Steel

The density of stainless steel is typically within the range of 7.5 to 8.0 grams per cubic centimeter, characterizing it as a material with high density that lends itself well to numerous uses. Its considerable strength and durability are largely due to this property, making it an ideal choice for various applications.

Stainless steel’s density can differ slightly between grades owing to their distinct compositions. For instance, Grade 304 stainless steel possesses a density approximately equaling 7930 kilograms per cubic meter while the addition of more molybdenum in Stainless Steel Grade 316 results in a marginally higher density of around 7980 kg/m3. Conversely, Stainless Steel Grade 430 exhibits a lesser density at about 7750 kg/m3 because its composition varies.

The manufacturing process has an influence on stainless steel’s final measured density, including factors like exact alloy mixture and specific production techniques which might introduce minor discrepancies in densities from one batch or product to another. These variations underscore why accurate measuring and stringent quality control protocols are crucial for upholding necessary industry standards regarding stainless steel properties.

Factors Affecting Density

The density of stainless steel can be affected by several elements, with temperature being one of the most significant. When the temperature increases, the material typically experiences a reduction in density as thermal expansion causes its atoms to become more widely spaced. This phenomenon is particularly important in applications involving high temperatures because it can impact both performance and structural stability.

In contrast, while pressure does have an effect on materials’ densities, its influence on stainless steel is relatively negligible under standard engineering circumstances. As a result, changes in pressure do not usually alter the density of stainless steel significantly, allowing for consistent performance expectations.

Another essential factor determining stainless steel’s density is its alloy composition. The inclusion of elements such as chromium, nickel and molybdenum can markedly affect this characteristic of the metal. Impurities and variations that may occur during production contribute to differences in densities across various grades of stainless steel. Emphasizing why precision selection and handling of raw materials are crucial throughout manufacturing processes.

Comparing Stainless Steel Grades

The density of various stainless steel grades can differ notably. Take grade 316, for instance. It has a density that measures at approximately 7980 kg/m3. Its chemical composition includes 16-18% chromium, alongside other elements like nickel (10-14%) and molybdenum (2-3%), as well as trace quantities of carbon, manganese, phosphorus, sulfur, silicon and nitrogen.

Notably recognized for its formidable resistance to both corrosion and oxidation is grade 316 stainless steel. It has exceptional strength and resilience coupled with an impressive capacity to withstand high temperatures. These characteristics make it the material of choice in severe conditions demanding robust performance.

In selecting suitable stainless steel materials for specific uses – whether they be within construction sectors or marine environments all the way through to medical equipment manufacturing, industries examine variations in densities along with their respective chemical compositions across different grades. An informed comprehension of each grade’s distinctive attributes ensures not only outstanding functionality but also enduring service life wherever implemented.

Importance of Density in Applications

Density measurement is vital for quality control in industries. It helps identify material purity and ensures stainless steel meets required specifications. Understanding its density aids in predicting performance related to strength and thermal conductivity.

In engineering projects, density is crucial for weight considerations and strength-to-weight ratios. In aerospace engineering, selecting materials with the right density enhances fuel efficiency and performance. In industrial design, density influences material selection for weight-critical applications like airplanes.

Density is critical in specific applications like the marine and food service industries. Grade 316 stainless steel is widely used in the marine sector for its superior resistance to saltwater corrosion. In the food service industry, it’s favored for equipment requiring high hygiene standards and corrosion resistance.

High Temperature Resistance and Thermal Expansion

Stainless steels with high chromium content exhibit strong resistance to oxidation and high-temperature strength. This makes them suitable for applications involving elevated temperatures, such as power plants and industrial furnaces.

316 stainless steel has excellent corrosion resistance, but its protective qualities may diminish under high temperatures or acidic conditions. Its coefficient of linear thermal expansion ranges from approximately 16.0 10-6 K-1 at 20°C to 18.0 10-6 K-1 at 500°C. These properties are crucial for applications with significant temperature range variations.

Despite changes in thermal expansion, stainless steel maintains good mechanical properties at standard room temperature. For example, the modulus of elasticity decreases from 200 kN/mm2 at room temperature to 165 kN/mm2 at 500°C, ensuring the material remains stable and reliable under various conditions.

Corrosion and Oxidation Resistance

Stainless steel’s ability to resist corrosion is essential for its use in the marine and chemical industries. Notably, 316 stainless steel boasts remarkable resistance to both corrosion and oxidation.

Incorporating molybdenum and nickel, the composition of 316 stainless steel significantly bolsters its durability against corrosive conditions, rendering it highly suitable for tasks involving exposure to harsh chemicals or seawater. Its properties are particularly advantageous for applications within marine environments and chemical processing sectors.

The formation of a protective oxide layer on stainless steel plays a pivotal role in safeguarding it from Oxidative damage and corrosion. This passive layer acts as a barrier. When contaminants penetrate this defense, they can initiate localized forms of corrosion such as crevice corrosion.

Mechanical Properties and Stress

The mechanical properties of stainless steel 316 are noteworthy, with tensile strength ranging from 620 to 795 MPa. This range indicates the material’s ability to endure significant mechanical stress without altering its shape.

With a yield strength around 206 MPa and an elongation at break close to 30%, stainless steel 316 exhibits respectable ductility. These characteristics render it an ideal option for uses that necessitate both flexibility and fracture resistance.

Featuring a Brinell hardness score of approximately146, along with an approximate modulus of elasticity standing at164 GPa, stainless steel 316 demonstrates considerable reliability in applications such as structural supports due to these inherent mechanical properties combined with its density.

It is essential to acknowledge that the density and resultant attributes of stainless steel can be affected by mechanical stress. This underscores the criticality of understanding these elements when selecting materials.

Practical Applications

Stainless steel’s sustainability is a significant factor in its use, as its capacity for recycling and enduring nature promotes environmentally sound practices. Utilizing high-density stainless steel bolsters structural strength, which is critical for construction projects such as erecting building frames and crafting bridges.

In the realm of aerospace engineering, there is a preference for stainless steels with lower densities to diminish aircraft weight, thereby improving fuel efficiency—an essential aspect of both performance and safety within the field.

For endeavors involving marine environments, 316-grade stainless steel stands out due to its exceptional resistance to corrosion from saltwater. Similarly, this grade of steel sees frequent employment in pharmaceutical manufacturing equipment because it resists degradation by strong cleaning agents effectively.

The medical sector favors 316-grade stainless steel when creating medical devices on account of its compatibility with biological tissues combined with notable corrosion-resistant properties. This same resistance makes it an advantageous choice for equipment used in chemical processing industries where exposure to potent chemicals is common.

Summary

Grasping the significance of stainless steel’s density is essential for its deployment in a multitude of industrial uses. Stainless steel stands out as an integral substance for various sectors, owing to key features such as substantial density, exceptional corrosion resistance, and formidable mechanical robustness - qualities that render it vital in realms like construction, maritime activities, healthcare services, among others.

Acknowledgement of elements influencing density—including temperature fluctuations and alloy mixture—plays a pivotal role when choosing the appropriate stainless steel variant tailored to particular applications. Understanding these details enables engineers and creators to make educated choices that improve both efficacy and durability in their ventures.

Frequently Asked Questions

What is the typical density range of stainless steel?

The typical density range of stainless steel is between 7.5 to 8.0 g/cm3, making it a dense and sturdy material for various applications.

Why is density important in material selection?

Density is vital in material selection as it influences strength, durability, and overall performance, thus allowing for effective quality control and accurate predictions of material behavior.

How does temperature affect the density of stainless steel?

Temperature decreases the density of stainless steel, as rising temperatures lead to thermal expansion and the spreading apart of atoms.

Therefore, higher temperatures result in lower density.

What makes 316 stainless steel suitable for marine applications?

Due to its outstanding ability to withstand saltwater corrosion, 316 stainless steel is especially appropriate for use in marine settings. This feature ensures that it remains durable and lasts a long time, even under the severe conditions of marine environments.

How does the composition of stainless steel impact its density?

The density of stainless steel is directly influenced by the specific amounts of elements such as chromium, nickel, and molybdenum in its composition.

Therefore, variations in these alloying elements can result in significant differences in density.

Start Your Next Project with LKprototype

LKprototype simplifies procurement for custom manufacturing, Suitable for making your products or prototypes with a variety of materials, such as metal or plastic, silicone rubber, from 3D Printing to CNC Machined Parts and Vacuum Casting , with a focus on speed and efficiency. Our platform provides instant quotes. With LKprototype, You can connect with the team to communicate your project to ensure quality and on-time delivery.

Start with an instant quote and experience how our technology and expertise can make custom part procurement faster and easier.

LKprototype

LKprototype