CNC polycarbonate changes manufacturing by using smart machining and strong materials. It combines tough polycarbonate with advanced tools for better results.

Clear polycarbonate is very strong and lasts a long time.

It has low haze and no distortion, improving visibility for things like security windows.

Its clear look and fire resistance make it great for military and safety gear.

This flexibility helps make things faster, wastes less, and saves money over time.

Key Takeaways

CNC polycarbonate is tough and lasts long, great for safety tools.

CNC machining works fast and cuts waste, saving time and cash.

Polycarbonate is light but strong, lowering costs in cars and planes.

CNC polycarbonate makes exact designs, so parts fit and work well.

Picking CNC polycarbonate means less fixing and replacing, saving money later.

Efficiency of CNC Machining for Polycarbonate

CNC machining has changed how we work with polycarbonate. It uses smart machines and strong materials to make parts faster. This process also reduces waste and improves accuracy. Let’s see why it works so well.

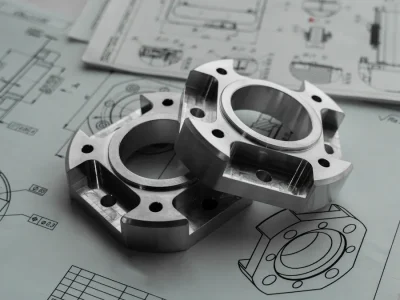

Precision and Accuracy in Machining Polycarbonate

Making precise parts from polycarbonate is very important. CNC machines can make parts accurate to ± 0.005 inches (0.127 mm). This ensures every piece fits perfectly, even in tricky designs. CNC machines can handle tiny details, like 0.50 mm features and 0.75 mm walls.

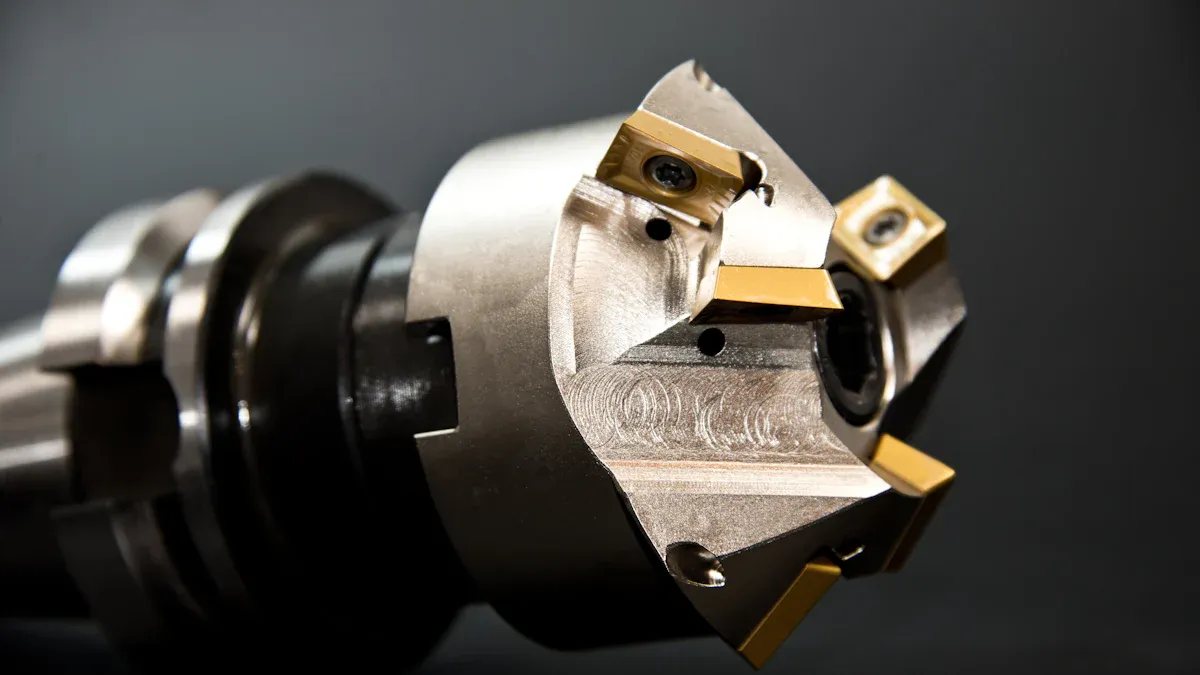

Special tools help keep this precision. Carbide or diamond tools stop melting and reduce friction. Single-flute end mills remove chips quickly to avoid heat. Jigs and fixtures hold the material steady for clean cuts and exact sizes.

Measurement Type | Value |

|---|---|

Tolerances | ± 0.005 inches (0.127 mm) |

Minimum Feature Size | Φ 0.50 mm |

Wall Thickness | 0.75 mm |

These features make CNC machining great for things like medical tools or optical parts where precision is key.

Faster Production with CNC Automation

CNC machines make parts much faster than manual methods. They run nonstop, cutting downtime and increasing output. Switching between designs is quick with pre-set tools.

Digital tools make the process even faster. CAD files go straight into the CNC system, turning designs into parts in just one day. High-speed machines and automated checks ensure fast, high-quality results.

Automation removes the need for manual work.

Quick setup saves time when switching designs.

CAD files speed up the move from design to product.

This speed is perfect for industries like aerospace and automotive, where time matters.

Minimizing Waste Through Optimized Processes

CNC machining cuts waste by using smart cutting paths. Software plans the best way to cut, saving material and money.

Polycarbonate’s strength and heat resistance also help reduce waste. It can handle tough cutting without breaking. Water-based coolants keep it clear, so even small scraps can be reused.

Tool Type | Purpose |

|---|---|

Carbide or Diamond Cutting Tools | Reduce friction and stop melting. |

Single-Flute End Mills | Remove chips fast to avoid heat. |

Water-Soluble, Non-Aromatic Coolants | Keep the surface smooth and clear. |

Jigs and Fixtures | Hold material steady for clean, accurate cuts. |

By saving material and cutting costs, CNC machining is good for both the planet and your wallet.

Material Properties of Polycarbonate That Enhance CNC Machining

High Impact Resistance and Durability

Polycarbonate is very strong and hard to break. It can handle heavy hits without cracking or shattering. This makes it great for safety gear and protective items. Certifications like UL Standard 752, NIJ 0108.01, and ASTM F1233 prove it can resist bullets and forced impacts. These tests show polycarbonate meets strict safety rules. It works well for bulletproof windows, shields, and barriers.

Its toughness means fewer replacements are needed. This saves time and money. Whether used for airplane parts or security tools, polycarbonate lasts a long time.

Lightweight and Strong Characteristics

Polycarbonate is strong but much lighter than steel. A 0.5-inch sheet weighs about 3 pounds per square foot. Steel of the same size weighs around 10 pounds per square foot. In big panels, polycarbonate can be over 100 pounds lighter. Even though it's light, it’s 30 times stronger than acrylic. This makes it perfect for tough jobs.

Property | Polycarbonate Value | Comparison with Steel |

|---|---|---|

Heat Resistance | Handles high temperatures | N/A |

Long-term Use Temperature | Up to 130 °C (266 °F) | N/A |

Heat Deflection Temperature | 279 °F (137 °C) at 0.45 MPa | N/A |

Thermal Conductivity | 0.19 W/(m.k) | N/A |

Weight (0.5” sheet) | About 3 lb/SF | 0.25” steel weighs about 10 lb/SF |

Weight Difference (4’x4’ panel) | Nearly 112 lbs lighter than steel | N/A |

Impact Resistance | 30 times stronger than acrylic | N/A |

Its light weight and strength make it ideal for cars and planes. These industries need materials that reduce weight.

Easy Machinability for Complex Designs

Polycarbonate is easy to shape into detailed designs. It doesn’t crack during cutting and stays clear and flexible. Machine-grade polycarbonate, like PC 1000, is even stronger and handles heat well. This makes it good for tricky designs in tough conditions.

Property | Description |

|---|---|

Impact Resistance | Polycarbonate doesn’t shatter and is stronger than glass. |

Clarity | Lets more light through than glass, great for clear items. |

Ease of Machining | Simple to mold and shape without breaking. |

Cost-Effectiveness | Works for many uses, making it affordable for designs. |

Polycarbonate is great for things like clear windows, sight glasses, and detailed prototypes. Its easy machining allows complex designs without losing quality or strength.

Cost Advantages of CNC Polycarbonate

Lower Labor Costs with CNC Automation

CNC machines cut labor costs by working on their own. Unlike manual work, CNC systems need little human help. This reduces the need for skilled workers to do repeated tasks. Workers can focus on more important jobs while CNC handles the details.

Buying CNC machines costs a lot at first. But over time, the savings are worth it. These machines work faster and waste less material, saving money. Here’s a simple breakdown:

Factor | Description |

|---|---|

Initial Investment | |

Labor Cost Reduction | Automation lowers labor costs by reducing manual work. |

Production Speed | Faster production helps save money overall. |

Material Waste Minimization | CNC precision reduces waste, making it more cost-effective. |

Using CNC polycarbonate speeds up production and cuts labor costs. It’s a smart choice for industries that want to save money.

Long-Term Savings with Durable Material

Polycarbonate lasts a long time, saving money in the future. Its strength means parts don’t break easily, even in tough conditions. CNC polycarbonate is great for making items that resist wear and tear, so replacements are needed less often.

This material doesn’t crack or shatter, making it reliable. Whether for airplane parts or safety shields, its durability means fewer problems and lower costs. Choosing CNC polycarbonate gives you a strong material that saves money on replacements.

Fewer Repairs and Replacements Needed

CNC polycarbonate needs less fixing because it’s so tough. You won’t have to replace parts often, saving time and money. Some CNC machines even track damage in real-time, stopping big problems before they happen.

Polycarbonate is also lightweight, making it easier to move and install. This lowers labor and equipment costs compared to heavier materials like steel. Picking CNC polycarbonate means fewer repairs and long-term savings for your business.

Tip: Choose CNC polycarbonate for less maintenance and longer-lasting products. Its strength and easy machining make it a smart, cost-saving option.

Applications of CNC Polycarbonate in Various Industries

CNC polycarbonate is used in many industries because it is strong and flexible. Its special features make it great for making high-quality parts that fit specific needs. Let’s look at some important uses.

Prototyping and Product Development

Using CNC polycarbonate for prototypes has many advantages. Designs can be made quickly, tested accurately, and changed without spending too much. The material’s flexibility lets you try different shapes and uses while keeping quality high.

Accurate testing ensures designs work well.

Flexible material fits many different needs.

Affordable changes lower total costs.

Polycarbonate’s strength and heat resistance make it perfect for prototypes. Projects often finish early, and parts perform better than expected. This makes CNC polycarbonate a top choice for creating new products.

Aerospace and Automotive Components

In planes and cars, lighter parts are very important. Polycarbonate is light but strong, making it ideal for these industries. A 0.5-inch sheet of polycarbonate weighs much less than steel, helping reduce the weight of vehicles and aircraft.

Polycarbonate is tough and handles extreme conditions well. It can take high heat and hard impacts, so it works for windows, windshields, and covers. CNC machining allows detailed designs that meet strict industry rules.

Note: Using CNC polycarbonate in planes and cars saves fuel and lowers repair costs.

Medical and Optical Equipment

Medical and optical tools need to be clear and precise. Polycarbonate is perfect because it is strong and see-through. CNC machining ensures exact sizes for medical devices and lenses.

Polycarbonate lets more light through than glass, making it great for clear shields and sight glasses. Its toughness keeps people safe in medical settings. The material is also easy to shape into detailed designs for advanced tools.

By choosing CNC polycarbonate, you can make strong, reliable parts for important medical and optical uses.

Comparing CNC Polycarbonate to Other Materials

Benefits Over Acrylic and Glass

Polycarbonate has many advantages over acrylic and glass. It is stronger, clearer, and lasts longer. These features make it better for many uses.

Clarity: Polycarbonate lets light pass through like glass. It works well for clear items.

Strength and Impact Resistance: It is much tougher than glass or acrylic. This makes it great for safety gear and bulletproof windows.

Dimensional Stability: Polycarbonate keeps its shape in different conditions. It doesn’t shrink much.

Environmental Resistance: It handles UV rays and temperature changes. This makes it good for outdoor use.

Property | Polycarbonate | Acrylic | Glass |

|---|---|---|---|

Impact Resistance | Higher | Lower | Moderate |

Thermal Stability | Superior | Moderate | Moderate |

Electrical Insulation | Excellent | Good | N/A |

Flame Retardancy | More | Less | N/A |

Dimensional Stability | Better | Good | N/A |

Polycarbonate is the best choice when you need strength, clarity, and durability.

Cost and Performance Comparison with Metals

Polycarbonate is better than metals in cost and machining speed. Metals like titanium are expensive and take longer to machine. Polycarbonate is cheaper and easier to work with.

Material Costs: Polycarbonate costs less than most metals. It’s a smart choice for saving money.

Machining Times: Polycarbonate machines faster than metals. Metals need slower cutting and stronger tools.

Durability: Metals are strong, but polycarbonate absorbs shocks better. It’s ideal for items needing impact resistance.

Using polycarbonate saves time and money while keeping high performance.

Environmental Advantages of Polycarbonate

Polycarbonate is good for the planet and works well. Its toughness means fewer replacements, which reduces waste. It can also be recycled, making it eco-friendly.

Reduced Waste: Polycarbonate lasts longer, so fewer parts are thrown away.

Recyclability: Unlike some metals, polycarbonate can be recycled easily.

Energy Efficiency: Its light weight lowers shipping costs and energy use.

Choosing polycarbonate helps the environment and saves money. It’s a smart and green option.

CNC polycarbonate offers great efficiency and saves money. It’s changing how products are made. It helps make parts faster, wastes less material, and ensures high-quality results.

Testing and prototyping during design improve products and lower risks.

Polycarbonate is strong, easy to machine, and affordable for production.

Using CNC polycarbonate gives better performance and saves money over time. Its flexibility and eco-friendly features make it perfect for industries wanting to stay ahead and help the planet.

Tip: Use CNC polycarbonate in your work to get the best results for your business.

FAQ

What is CNC polycarbonate?

CNC polycarbonate is polycarbonate shaped with CNC machines. These machines use computers to cut and shape the material. The process makes strong, clear, and precise parts. It’s great for industries needing tough and detailed components.

Why is polycarbonate better than acrylic for CNC machining?

Polycarbonate is tougher and doesn’t break like acrylic. It stays strong during cutting, even with tricky designs. It also handles heat better, making cuts smoother. These features make polycarbonate a better choice for CNC machining.

Can CNC polycarbonate be recycled?

Yes, polycarbonate can be recycled. Leftover pieces from machining can be reused, reducing waste. Recycling helps the environment and supports green manufacturing. Its strength also means fewer replacements, which saves resources.

How does CNC polycarbonate save money?

CNC polycarbonate saves money by wasting less material and cutting labor costs. Its durability means fewer replacements are needed. CNC machines also work faster, lowering production costs. This makes it an affordable option for manufacturing.

What industries benefit most from CNC polycarbonate?

Industries like aerospace, cars, medical tools, and product design benefit a lot. Polycarbonate is strong, clear, and easy to shape. It’s perfect for lightweight parts, medical devices, and prototypes. Its versatility works well for precise and durable applications.

Tip: Use CNC polycarbonate for projects that need strength and save money.

Start your project with LKprototype

LKprototype company simplifies procurement for custom manufacturing, Suitable for making your products or prototypes with a variety of materials, such as metal or plastic, silicone rubber, from 3D Printing to CNC Machined Parts and Vacuum Casting , with a focus on speed and efficiency. Our platform provides instant quotes. With LKprototype, You can connect with the team to communicate your project to ensure quality and on-time delivery.

Start with an instant quote and experience how our technology and expertise can make custom part procurement faster and easier.

LKprototype

LKprototype