CNC machinists are essential in manufacturing and operating CNC machines to produce precision parts. This article explains the key CNC machinist duties and the skills needed for the job.

Key Takeaways

CNC machinists operate, program, and maintain CNC machines to produce precise metal or plastic parts, requiring a blend of technical expertise and hands-on skills.

Effective communication and collaboration with engineers and designers are essential for CNC machinists to ensure project specifications and enhance production efficiency.

Continuous learning and obtaining certifications are important for career advancement in CNC machining, as they help machinists stay competitive and adapt to technological advancements.

Key Responsibilities of CNC Machinists

CNC machinists serve as a critical pillar within the manufacturing sector, tasked with the management of CNC machines to manufacture, alter, and repair items. They are pivotal in guaranteeing that these machines function efficiently and output components adhere to exact standards. This encompasses inserting raw materials into the machine, configuring tools appropriately, and supervising machine operations—a process greatly optimized by computer aided manufacturing.

These professionals do more than simply handle machinery. They collaborate closely with engineers and fellow team members to ensure that manufacturing processes correspond seamlessly with project demands. Possessing substantial knowledge in both maneuvering and programming machine tools is essential for CNC operators when it comes to fabricating parts made of metal or plastic with high precision.

Operating CNC Machines

CNC machinists shoulder the crucial task of managing CNC machines, such as mills, routers, grinders and lathes that sculpt various materials like metals, wood and plastics. The machining process kicks off with loading the raw materials into the machine and fitting cutting tools in place. Following this setup stage is programming codes input to dictate cnc machine settings which may include operating CNC mills.

It’s essential for skilled CNC machinists to accurately interpret technical specifications and blueprints for proper cnc machine configuration and operation. They must be well-versed in IT and mathematics to decode designs effectively ensuring parts are crafted correctly according to precise standards.

To ensure a smooth manufacturing process, successful CNC machinists maintain vigilant oversight over their cnc machines during operations—ready to fine-tune settings or address potential issues promptly. This requires not only an eye for detail but also extensive practical skills on top of technological proficiency. Thus positioning these specialized CNC machine operators as indispensable components within the manufacturing sector.

Programming CNC Machinery

The task of programming CNC machinery necessitates proficiency in G-code and M-code, the critical languages for computer numerical control procedures. Implementing these codes allows one to input specific commands that dictate the path, velocity, and feed rate at which the machine cuts materials. For parts to be crafted with requisite accuracy and excellence, a deep understanding of CNC programming is vital.

Courses designed for educating CNC machinists typically encompass an extensive curriculum covering topics such as CNC programming, interpreting blueprints, and managing machine operation. Possessing this level of technical expertise equips machinists with not only the capability to operate cnc machinery efficiently, but also empowers them to diagnose issues within machining processes and enhance their performance.

Ensuring Precision and Quality

A CNC machinist’s primary responsibility is to ensure that precision and quality are maintained throughout machine operations. By supervising the machining process, they make necessary adjustments for optimized production efficiency. To verify parts’ accuracy and adherence to specifications, they use precision measuring instruments.

It’s critical in CNC machining to follow inspection guidelines diligently and identify any deviations promptly to uphold product integrity. Choosing the correct tools and calibrating them properly plays a significant role in securing the high level of exactness needed for final products, which must satisfy the strict standards set by diverse sectors.

Daily Tasks in CNC Machining

CNC machinists are tasked with a variety of responsibilities on a daily basis, necessitating the ability to manage multiple machines and processes during their shifts. Precision is paramount in this role as they must maintain acute attention to detail to avoid errors that can be expensive for operations. They are also expected to collaborate effectively with colleagues, contributing towards improved productivity—a common aspect found within the job description for a CNC machinist.

The capacity for clear communication stands as a crucial component in the realm of CNC machining, ensuring tasks are carried out correctly and missteps are minimized. Those who work as CNC machinists should be flexible enough to handle an array of duties while possessing the aptitude for teamwork required to meet production objectives successfully.

Reading Technical Drawings

For CNC machinists, the ability to read and decipher technical drawings is essential in order to manufacture parts that meet precise specifications. They convert these blueprints into programmable instructions for production, as they scrutinize and interpret both blueprints and sketches during their preparation procedures.

Tool Setup and Calibration

CNC machinists are tasked with the crucial role of selecting the right tools and calibrating them accurately, essential for achieving precision in machining operations. They must evaluate the specifications of the job at hand, taking into account both material types and the intended finish.

Ensuring dimensional accuracy before inserting cutting tools into a CNC machine is fundamental. Machinists employ precise measuring devices to check that completed components match their specifications, confirming that all final products adhere to established quality criteria.

Routine Maintenance Tasks

Performing routine maintenance tasks is essential to ensure that CNC machines function properly and prevent potential malfunctions. These tasks, which include cleaning, lubricating, and calibrating machine components, are a regular part of the duties carried out by CNC machinists.

By routinely inspecting machine components for issues, machinists help avert malfunctions that could disrupt operations. This ongoing maintenance not only keeps the machines running efficiently, but also enhances their durability and dependability.

Collaboration and Communication

CNC machinists typically operate within a collaborative setting, highlighting the significance of transparent dialogue to guarantee the accomplishment of projects. It is crucial for team players to communicate effectively in order to grasp project specifications and resolve any problems that may occur.

Joint endeavors involving CNC machinists, designers, and engineers contribute to enhanced productivity and excellence in manufacturing. Such teamwork plays a vital role in adhering to production timelines and confirming that completed goods align with stipulated standards.

Working with Engineers and Designers

Technical drawings are an essential medium of communication between engineers and machinists, facilitating the creation of parts with exact precision. For CNC machinists, grasping blueprint details is imperative for the correct interpretation of specifications and measurements necessary to machine components accurately.

In many cases, CNC machinists collaborate closely with engineers in order to evaluate design practicality and solve problems that may surface. They typically communicate with engineers to understand design requirements thoroughly and tackle any technical difficulties that occur throughout the manufacturing process.

Reporting and Documentation

It is vital for the operational efficiency of CNC machining to meticulously maintain records concerning machine settings and production logs. Conducting inspections at routine intervals plays a key role in pinpointing possible complications, as well as guaranteeing precise documentation of machinery performance.

For CNC machinists, possessing adept troubleshooting abilities is paramount since it enables them to solve problems effectively. This problem-solving capability is instrumental in preserving the integrity of record-keeping.

Skills and Competencies Required

Precision, adeptness with technology, the capacity to resolve issues, and effective management of one’s time are essential competencies for a CNC machinist. The ability to troubleshoot and possess technical know-how is imperative for excelling in CNC machining.

To embark on a career as a CNC machinist, possession of at least a high school diploma or its equivalent is typically necessary. Those who aim to enter this field should contemplate engaging in specialized training programs or courses offered by vocational schools or community colleges after completing high school. The specific credentials required may vary according to each employer’s expectations of their CNC machinists. Instruction in these educational programs often encompasses topics such as interpreting blueprints, computer-aided design (CAD), and operating CNC machines.

Technical Expertise

Effective CNC machinists are adept in both the fundamental principles of machining and the intricacies of CNC programming. Their proficiency in CNC programming is essential for carrying out detailed machining operations with accuracy.

For successful CNC machinists, acquiring hands-on experience through operating CNC machines forms an integral part of their training. The blend of comprehensive theoretical understanding and practical skills equips them to manage intricate machining assignments meticulously.

Problem-Solving Abilities

The ability of CNC machinists to solve problems effectively is greatly improved by their experience. These problem-solving skills are crucial for detecting and fixing any complications that may occur throughout the machining process.

Physical Stamina and Dexterity

The occupation of a CNC machinist necessitates considerable physical endurance due to the long durations spent standing while carrying out tasks. They routinely engage in strenuous activities that demand both power and agility.

In this position, individuals are tasked with managing weighty materials and undertaking labor-intensive duties over the course of their shifts.

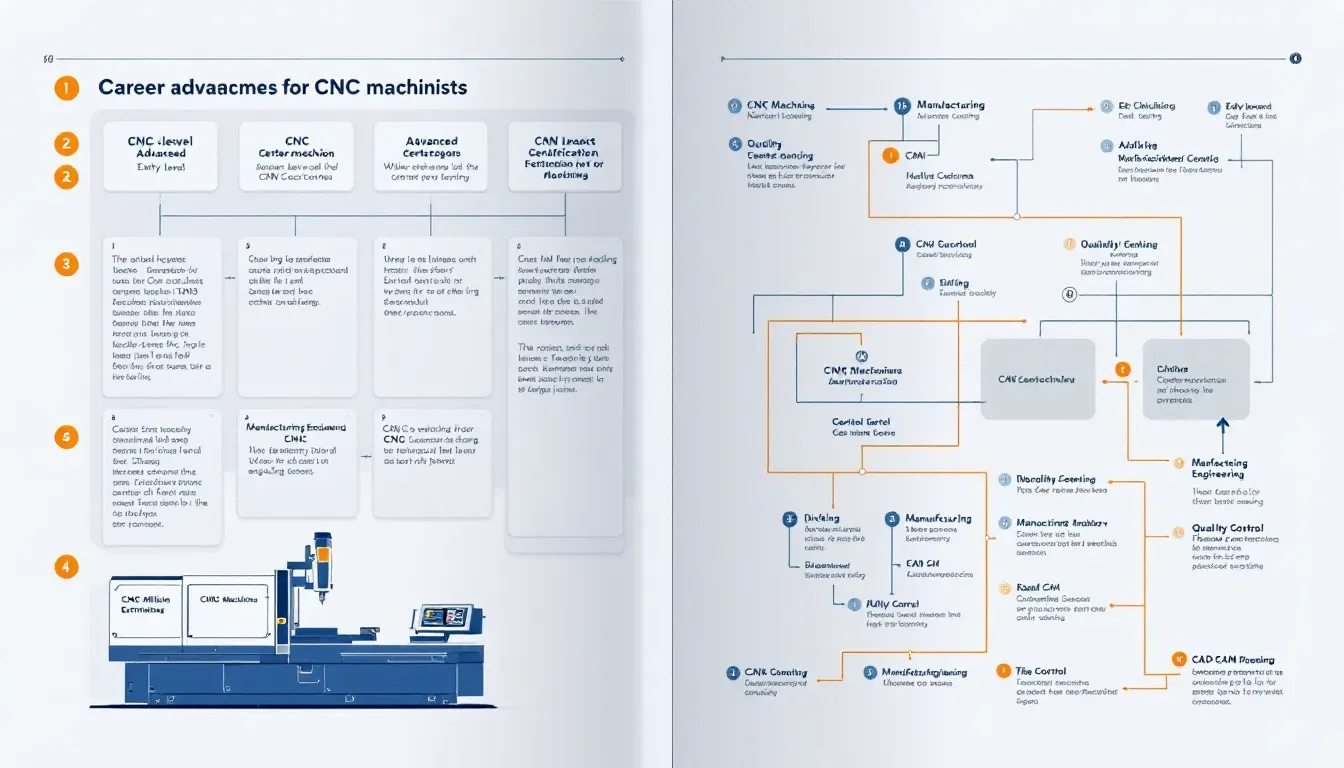

Career Path and Advancement

The domain of CNC machining is expected to experience a substantial number of job opportunities due to the combination of an expanding industry and the retirement of current professionals. Those skilled as CNC machinists have a variety of career paths available, including roles in metrology, quality control, programming, maintenance, and even management positions. In order to improve their capabilities and remain relevant within the field—especially when considering potential earnings—it’s vital for these specialists to commit themselves to ongoing learning.

Maintaining an up-to-date skillset through continued education is essential for those in CNC machining careers as it not only bolsters their abilities but also broadens employment prospects. Achieving certain certifications can be particularly advantageous since many employers look favorably upon them when hiring within this sector. These qualifications serve both as a testament to a machinist’s dedication and proficiency. They may facilitate access to better-compensated roles that reward advanced expertise in the trade.

Entry-Level Positions

For those starting out in the field of CNC machining, entry-level roles offer critical employment opportunities that serve as a career base. Typical positions for newcomers include CNC operator and apprentice machinist titles. These roles are instrumental in imparting essential skills pertinent to the manufacturing sector. One significant advantage of commencing at an entry-level position within CNC machining is the acquisition of practical expertise under the guidance of experienced practitioners.

In order to achieve proficiency as a competent CNC machinist, individuals have options such as enrolling in community college programs or engaging in apprenticeship schemes.

Advanced Roles

Mastering CNC programming equips individuals to handle more complex machining assignments while delivering heightened accuracy. Such expertise paves the way for professional advancement and additional accountability in the realm of CNC machining.

Taking on advanced positions such as lead machinist, supervisor, or CNC programmer marks a significant progression from beginner roles. These elevated roles not only present challenges that develop a machinist’s skill set, but also contribute positively to their career path within the manufacturing sector.

Continuous Learning and Certification

NASCAR’s UTI’s. Tech campus in Mooresville, North Carolina offers training programs for CNC machinists. It is essential that CNC machinists engage in continuous education to stay abreast of technological developments and refine their abilities.

The acquisition of certifications can improve employment opportunities for a machinist by confirming their proficiency and understanding. For the professional development and upward career mobility of CNC machinists, ongoing learning and certification are extremely important.

Staying Updated with Industry Trends

Keeping up with industry trends is vital for adapting to advancements in technology and manufacturing processes. CNC machinists can stay updated on industry advancements by networking and engaging with peers. They can also attend industry events and pursue continuous learning opportunities.

CNC machinists should continuously refine their technical and soft skills, including problem-solving and communication.

Obtaining Certifications

Having a certification serves as an endorsement of the expertise and capabilities in CNC machining. The National Institute for Metalworking Skills (NIMS) stands out as an esteemed entity that provides certifications specifically for CNC machinists. When bringing on new machinists, many employers give preference to those who hold certifications from this notable institution.

Though not invariably required, possessing professional certification can be greatly beneficial for CNC machinists aiming to progress in their careers. Such credentials are instrumental because they bolster a machinist’s qualifications and broaden employment opportunities within the field.

Summary

Summarize the key points covered in the blog post. Highlight the essential responsibilities, daily tasks, collaboration, required skills, career paths, and the importance of continuous learning and certification. End with an inspiring note encouraging readers to pursue a career in CNC machining.

Frequently Asked Questions

What are the primary responsibilities of a CNC machinist?

A CNC machinist is tasked with the operation of CNC machines in order to produce and alter items, as well as programming these machines. They must also maintain quality control by conducting accurate measurements.

They work alongside engineers to ensure that manufacturing processes meet the exact requirements laid out for specific projects.

What skills are essential for a CNC machinist?

A CNC machinist must possess technical expertise in CNC programming, problem-solving abilities, physical stamina, and a keen attention to detail to excel in their role.

These skills are vital for ensuring precision and efficiency in machining operations.

How can one become a CNC machinist?

To become a CNC machinist, you should obtain a high school diploma or equivalent, and then pursue vocational training or community college courses.

Gaining experience through entry-level positions, such as a CNC operator or apprentice machinist, is a common pathway to advance in this career.

What are the career advancement opportunities for CNC machinists?

CNC machinists have the opportunity to progress into roles like lead machinist, supervisor, or even a CNC programmer.

Engaging in ongoing education and obtaining certifications can greatly improve their career prospects and open doors to better-compensated positions.

Why is continuous learning important in CNC machining?

In the realm of CNC machining, it is crucial to engage in ongoing education to stay abreast of technological developments and refine one’s skills. This not only boosts employment opportunities but also increases an individual’s appeal in the job market. Earning certifications from reputable institutions serves as a testament to a machinist’s proficiency, securing their competitive edge within the industry.

Still, need help? Contact Us: [email protected]

Need a PROTOTYPE or PARTS machining quote? Quote now

LKprototype

LKprototype