You pick the best CNC machining material by matching it to your project. Think about what your part needs to do. Does it need to stand up to heat? Does it need to resist chemicals? Does it need to look a certain way? When considering CNC machining material selection, check the main things to think about:

Criteria | Description |

|---|---|

Environmental | Stands up to heat, fire, or chemicals. |

Electrical | Carries or blocks electricity. |

Mechanical | Is strong, tough, or hard to wear out. |

Cosmetic | Gives color, see-through look, or feel. |

Size | Fits the size of the material you have. |

Cost | Makes sure price and quality are balanced. |

Ask experts for help if you are not sure. Picking the right CNC machining material selection helps you get great results.

Key Takeaways

Pick a CNC material that fits your project. Think about strength, heat resistance, and how it looks. This helps your project work well.

Check if the material is easy to machine. This can save time and money. Aluminum and brass are easier to machine. They also help tools last longer.

Make sure the cost and quality are balanced. Pick materials that fit your budget. They should also work well for your project. This gives you better value.

Ask experts if you are not sure. Get advice for hard projects or special materials. This can help you avoid expensive mistakes.

Use a checklist to pick your material. Write down what you need. Look at your choices. Make smart choices to help your project succeed.

CNC Machining Material Selection Factors

When you start picking a cnc machining material, you need to think about a few important things. Each thing changes how your part works and how much it costs. Let’s look at the main things you should think about.

Mechanical Properties

Mechanical properties show how a material acts when you push, heat, or bend it. You need to match these properties to what your project needs. Here are five mechanical properties you should check:

Mechanical Property | Description |

|---|---|

Strength | The ability to withstand force without breaking. |

Wear resistance vs Machinability | Balances durability with how easy the material is to machine. |

Strength to weight ratio | Shows how strong a material is compared to its weight. |

Elasticity | The ability to return to its original shape after bending or stretching. |

Elongation | How much a material can stretch before it breaks. |

Steel is strong and does not wear out fast. You use steel for tough parts that need to last. Some metals, like maraging steel, are very strong and hard. Plastics are not as strong or hard. They are good for lighter jobs and are easy to machine.

Tip: Always check if your part needs to hold heavy things or if it will wear out fast. This helps you pick steel or a lighter material.

Machinability

Machinability means how easy it is to cut or shape a material with cnc. Good machinability saves time and money. Some materials, like free-cutting brass and aluminum 6061-T6, are easy to machine. You can make parts fast and your tools last longer.

Material | Machinability Rating | Key Features |

|---|---|---|

Free-Cutting Brass | 100% | Easy to cut, low tool wear, smooth finish |

Aluminum (6061-T6) | 90-95% | Fast machining, minimal tool wear, smooth surfaces |

If you pick a material that is hard to machine, like some steel, you may need to change tools more. This can slow you down and cost more. If you cut faster, you can finish quicker, but your tools may wear out faster.

Cutting faster by 15% can help you remove more material by 18%.

The same speed can make tools wear out 30% faster if you use machines a lot.

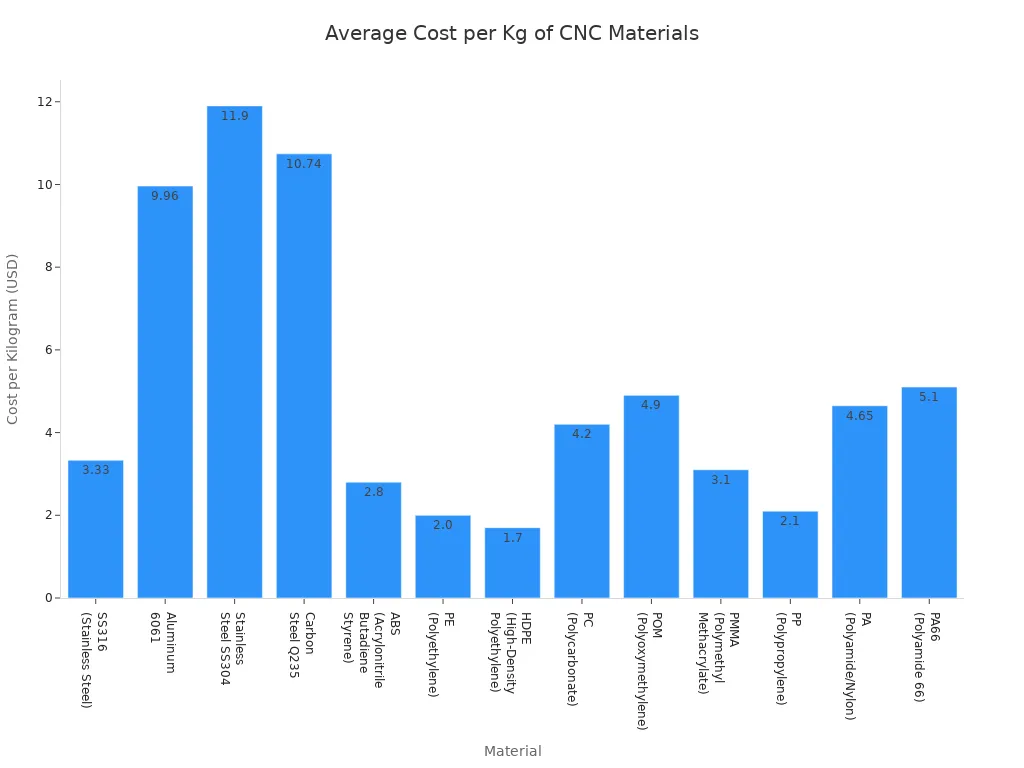

Cost

Cost is a big part of cnc machining material selection. You want to get good value for your money. Some materials, like stainless steel and titanium, cost more. Plastics like ABS and PE are cheaper and work for many jobs.

Material | Cost per Kilogram (USD) |

|---|---|

SS316 (Stainless Steel) | $3.33 |

Aluminum 6061 | $9.96 |

Stainless Steel SS304 | $11.90 |

Carbon Steel Q235 | $10.74 |

ABS (Acrylonitrile Butadiene Styrene) | $2.80 |

PE (Polyethylene) | $2.00 |

HDPE (High-Density Polyethylene) | $1.70 |

PC (Polycarbonate) | $4.20 |

POM (Polyoxymethylene) | $4.90 |

PMMA (Polymethyl Methacrylate) | $3.10 |

PP (Polypropylene) | $2.10 |

PA (Polyamide/Nylon) | $4.65 |

PA66 (Polyamide 66) | $5.10 |

The material you pick changes the cost for each part. Hard materials like steel and titanium cost more to buy and machine. Machinability also changes tool wear, which can add to your costs. Prices can change, so always check before you buy.

Application Needs

You need to think about what your part will do and where it will go. Application needs help you pick the right cnc machining material. Some jobs need materials that can handle heat, chemicals, or rust. Other jobs need parts that meet special rules.

Factor | Description |

|---|---|

Machinability | Affects machining speed, tool changes, and surface finish, impacting overall costs. |

Cost Implications | High-performance materials like titanium and PEEK are expensive; balancing cost with properties is key. |

Material Certification | Ensures compliance with standards, crucial for quality assurance in regulated industries. |

The environment matters too. High heat, chemicals, and coatings can change what you pick. For example, steel is good for tough places, but you may need a coating to stop rust.

The place your part works, like heat and chemicals, changes how long it lasts.

If parts get hot, they can move or break.

Coatings can help parts last longer.

Surface Finish

Surface finish is how smooth or rough your part feels and looks. Some materials, like aluminum and brass, are smooth after machining. Softer materials look good without extra work. Harder materials, like steel, may need more finishing.

Aluminum is good for anodizing, which makes it smoother and adds color.

Titanium is also good for anodizing.

Hard materials may need polishing or other steps to look nice.

A good surface finish can help your part work better. It can make parts stronger, help them last longer, and stop rust.

Performance Metric | Impact of Surface Finish |

|---|---|

Fatigue Strength | Rough surfaces lead to stress concentration, reducing strength. |

Wear Resistance | Higher surface finish improves wear resistance; rough surfaces increase friction. |

Corrosion Resistance | Smooth surfaces resist corrosion better than rough ones. |

Stability of Fit | Rough surfaces can compromise fit stability, affecting accuracy. |

Note: Always match the surface finish to your part’s job. A smooth finish can help your part work better and look nicer.

When you follow these cnc machining material selection factors, you make better choices for your project. You get parts that work well, last longer, and fit your budget.

Common CNC Metals

CNC machining uses many metals to make strong parts. These parts are also very exact. You need to know how these metals are different. This helps you pick the best one for your project. The most common metals for cnc are aluminum, brass, bronze, copper, nickel alloys, stainless steel, and titanium.

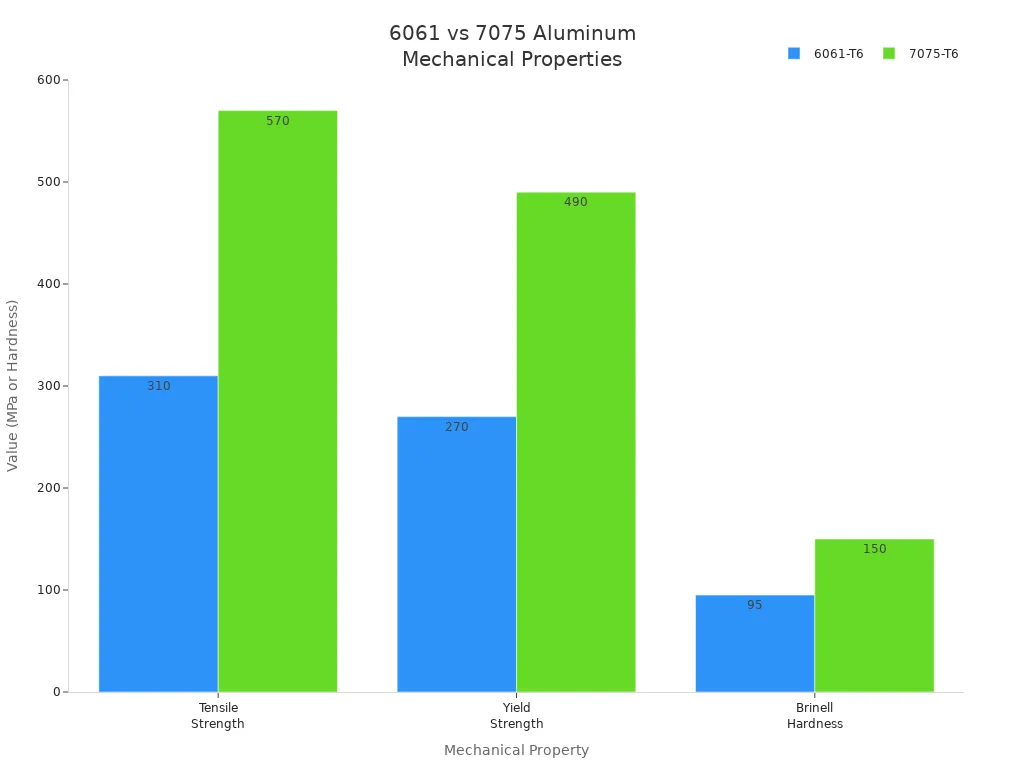

Aluminum Overview

Aluminum is a popular material for cnc. It is light and strong. It is also easy to machine. Many industries use aluminum. Two types are 6061 and 7075. 6061 aluminum is easy to weld and machine. 7075 aluminum is much stronger and harder. But you cannot weld 7075 because it cracks. 6061 is good for general parts. 7075 is used for strong parts like airplane frames.

Property | 6061-T6 | 7075-T6 | Notes |

|---|---|---|---|

Tensile Strength (MPa) | 310 | 570 | 7075 is nearly 84% stronger |

Yield Strength (MPa) | 270 | 490 | 7075 is 81% stronger |

Hardness (Brinell) | 95 | 150 | 7075 is 58% harder |

Fatigue Resistance | Moderate | Good | 7075 offers better resistance |

Impact Resistance | Moderate | Good | 7075 absorbs more impact |

Aluminum gives you a good mix of price, strength, and machinability. You can use it for cars, planes, and everyday products.

Steel Overview

Steel is a strong and tough metal for cnc. You use steel when you need parts that last long. Steel does not wear out fast. It is very strong and durable. But steel can be hard to machine. It can make tools wear out faster. Steel is used in building, cars, and big machines.

Advantages | Disadvantages |

|---|---|

Strength | Work hardening during machining |

Durability | Increased tool wear |

Corrosion resistance | Lower thermal conductivity |

Potential for intergranular corrosion | |

Risk of stress corrosion cracking |

Steel is best for parts that must hold heavy things or work in rough places.

Stainless Steel Overview

Stainless steel is a special kind of steel. It does not rust or corrode easily. You use stainless steel where parts must stay clean and strong. It is used in medicine, food, planes, and cars. Stainless steel is harder to machine than normal steel. But it lasts longer and looks nice.

Aeronautics and flight

Gunsmithing and arms

Construction

Automotive

Mining

Medical industry

Consumer products

Robotics

Food and beverage industry

Aerospace

Marine

Military

Oil & Gas

Stainless steel is great for parts that must not rust and must keep their shape in tough places.

Brass Overview

Brass is easy to machine and has a shiny gold color. You use brass for parts that need to look nice and last long. Brass does not rust and is easy to shape. It works well for electric parts, valves, and decorations.

Highly machinable

Corrosion resistance

Plasticity for complex shapes

Strength and hardness

Aesthetic appeal

Brass is a good choice for cnc if you want fast machining and a nice look.

Copper Overview

Copper is known for carrying electricity and heat very well. You use copper for cnc parts that need to move electricity or heat. Copper is soft and easy to machine. But it can cost more than other metals.

Excellent electrical conductivity for connectors

High thermal conductivity for heat sinks

Precise machining for complex shapes

Copper is best for electric and heat-moving jobs.

Titanium Overview

Titanium is strong, light, and does not rust. You use titanium for cnc parts in planes, medicine, and high-tech jobs. Machining titanium is hard. It keeps heat near the cutting edge and reacts with tools. It can also get harder as you cut it.

Challenge | Description |

|---|---|

Low Thermal Conductivity | Heat builds up during machining. |

High Chemical Reactivity | Titanium reacts with tools and can damage them. |

Work Hardening | Cutting makes titanium harder and tougher to machine. |

Chip Evacuation Issues | Chips can clog and break tools. |

Titanium is the best for parts that need to be strong and light. But you need special tools and skills to machine it.

Popular CNC Plastics

When you pick plastics for cnc, you have many choices. Each plastic has special features for different jobs. These materials make parts that are light, strong, and not expensive.

ABS Overview

ABS is tough and can take hits without breaking. It works well for parts that need to handle bumps. The butadiene in ABS helps absorb shocks. This keeps your parts strong when they get stressed. ABS stays tough even when it is cold. It gives steady strength. People use ABS for test models, covers, and things people buy.

ABS is simple to machine and lasts a long time. You get good results for most cnc uses.

Polycarbonate Overview

Polycarbonate is very strong against impacts. You can use it for parts that face stress or rubbing. Polycarbonate is stronger than acrylic. It lasts longer than many other plastics. You see polycarbonate in safety shields, machine guards, and clear covers.

Very strong against hits

Lets light pass through well

Good for hard cnc jobs

Nylon Overview

Nylon is liked for cnc because it is light and strong. It can make its own slippery surface, so it slides easily. Nylon is good for gears, bushings, and bearings. It does not wear out fast and does not rust. But nylon takes in water and gets bigger when hot.

Advantages of Nylon | Limitations of Nylon |

|---|---|

Wears out slowly | Takes in water |

Easy to machine | Gets bigger with heat |

Light weight | Not good with sunlight |

Nylon does not cost much and you can recycle it. You can use it for strong parts that need to slide.

PEEK Overview

PEEK is a top plastic for cnc. It is tough, handles high heat, and does not break down with chemicals. PEEK is used in medicine, planes, and cars. It stays strong up to 260°C. It does not get ruined by acids or solvents.

Property/Application | Description |

|---|---|

Handles high heat | Stays strong up to 260°C |

Fights chemicals | Does not break down easily |

Safe for bodies | Used for medical parts |

Wears out slowly | Slides easily for bearings |

Stops electricity | Good for connectors |

You use PEEK for seals, bushings, and brackets.

It works for medical and electric parts.

PEEK is best for tough places.

Delrin Overview

Delrin, also called acetal, is strong and exact for cnc. It can hold heavy loads and is very stiff. Delrin does not wear out fast and can take hits. It keeps tight sizes and needs little fixing after machining.

Property | Description |

|---|---|

Holds heavy loads | Can take a lot of weight |

Wears out slowly | Good for moving parts |

Takes hits well | Does not crack easily |

Keeps size close | Machined to ±0.001 inches |

Stops electricity | Good for electric parts |

Delrin is great for gears, rollers, and electric insulators.

PTFE Overview

PTFE, called Teflon, fights chemicals better than other plastics. You can use it for cnc parts in tough places. PTFE does not get ruined by acids, bases, or solvents. It stays strong and steady in hard jobs.

PTFE is best for valves, seals, and clean jobs.

You get strong parts and low friction for big cnc projects.

PTFE is the right pick when you need parts that do not break down in harsh places.

If you want to see these plastics, you can show pictures of cnc machined ABS, polycarbonate, nylon, PEEK, Delrin, and PTFE parts to compare how they look and feel.

Material Selection Guide for CNC Projects

Decision Checklist

Picking the right material for your cnc project needs a good plan. You should use a checklist to help your part work and save money. Here is a simple checklist you can follow:

Define Your Requirements

Write down what your part must do. Think about how strong it should be. Think about if it needs to handle heat. Think about how it should look and how much it costs. Decide if you need things like corrosion resistance or electrical properties.Identify Candidate Materials

Look for materials that match most of your needs. Compare choices like steel, aluminum, brass, and plastics. Check if each material can do the job you want.Balance Performance and Cost

Pick the material that gives you good performance and price. Make sure you can get it and that it works with your cnc process.

Tip: Always ask your supplier if they can send the material on time. If they are late, your cnc project can slow down.

Matching Materials to Needs

You need to match your project needs to what different materials can do. This helps you get the best results from cnc machining. Follow these steps to make a smart choice:

Define Design and Environmental Needs

Decide how your part will work. Write down its size and shape. Write down how strong it needs to be. Think about where it will be used, like hot or wet places.Evaluate Material Performance

Check things like tensile strength and hardness. Steel is very strong and lasts long. Aluminum is light and easy to machine. Plastics like ABS and nylon are good for light jobs and simple shapes.Assess Machinability and Efficiency

Find out how easy it is to machine each material. Steel is hard to cut and can wear out tools fast. Brass and aluminum are easier to machine and give smooth finishes.Determine Cost and Availability

Compare prices for each material. Steel and titanium cost more than plastics. Make sure you can buy the material from a trusted supplier.Make a Final Decision

Think about all the things above. Choose the material that fits your needs, budget, and cnc process.

Step | What to Check | Example Material |

|---|---|---|

Design Needs | Size, strength, environment | Steel |

Performance | Tensile strength, hardness | Aluminum |

Machinability | Tool wear, cutting speed | Brass |

Cost | Price per kilogram, supplier reliability | Nylon |

Final Decision | Balance all factors | ABS |

Note: If your part needs to last in tough places, steel is often best. If you want fast machining and a smooth finish, aluminum or brass may be better.

Consulting CNC Experts

Sometimes you need help to pick the best material. You should talk to experts if your project is hard or needs high performance. Here are times when you should ask for advice:

You need to use advanced materials like titanium or PEEK.

Your part must meet strict rules or certifications.

You want to make machining faster or reduce tool wear.

You are not sure which material fits your design.

You can talk to cnc machining partners, material suppliers, or engineers. Working together early helps you pick the right material and avoid mistakes. Experts can share tips about steel grades, machining methods, and ways to save money.

Callout: Working with experts can help you avoid big mistakes and get better results from your cnc project.Contact Us

If you follow this guide, you will make smarter choices for your cnc machining projects. You will get parts that work well, last longer, and fit your budget.

Choosing the right material for your cnc project means looking at strength, cost, and how your part will be used. You should always match your material to your project’s needs. Use the checklist and talk to experts if you feel unsure. The table below shows key points to remember:

Takeaway | Description |

|---|---|

Align Material Choice | Pick materials that fit your project’s stress and environment for better results. |

Short-term vs Long-term Goals | Think about both today’s needs and future repairs or upgrades. |

Durability and Maintenance | Strong materials can save money on repairs over time. |

Make smart choices and you will get parts that last and perform well.

FAQ

What is the best cnc material for beginners?

You should start with aluminum. It is easy to machine and gives good results. Many beginners use aluminum for cnc projects because it does not wear out tools quickly. You can make strong parts and learn basic cnc skills.

How do you choose between steel and stainless for cnc machining?

You need to look at your project needs. Steel works well for strong parts. Stainless resists rust and lasts longer in wet places. If you want a part that stays clean and does not corrode, pick stainless. For heavy-duty jobs, steel is a good choice.

Can you use plastics in cnc machining?

You can use plastics for many cnc projects. ABS, nylon, and polycarbonate work well. These materials are light and easy to machine. You can make test models, covers, and gears. Plastics cost less than metals and help you save money.

Why do people use aluminum so much in cnc?

Aluminum is popular because it is light and strong. You can machine aluminum quickly. It gives a smooth finish and does not rust. Many industries use aluminum for cnc parts in cars, planes, and electronics. You get good value and fast results.

What makes stainless better than regular steel for cnc parts?

Stainless resists rust and stains. You can use stainless for parts that need to stay clean. Stainless lasts longer in tough places. Regular steel is strong but can rust. If you want a part that looks good and lasts, choose stainless for your cnc project.

LKprototype

LKprototype