You figure out cnc machining cost by looking at many things. These include material, machining time, complexity, and machine type. If you know about cnc costing, you can control your project’s budget. You can also avoid extra charges that you did not expect. Knowing each cost part helps you pick the best supplier. It also helps you plan production better. Cnc costs are different in each country:

Country | Average Hourly Cost |

|---|---|

USA | $75–$200 |

Canada | $70–$180 |

UK | $60–$150 |

Germany | $70–$160 |

China | $30–$90 |

You should always use a detailed cnc costing report or tool. This helps you keep cnc costing correct.

Key Takeaways

Learn what things change CNC machining costs, like the material you pick, how hard the part is to make, and what machine is used.

Look at cost details to plan your money well and stop surprise costs.

Buy more parts at once to make each part cheaper because setup and programming costs are shared.

Pick cheaper materials and design parts that are easy to make to save money on CNC machining.

Use online tools to get fast price guesses and always check with your supplier to make sure the price is right.

How Much Does CNC Machining Cost?

Typical CNC Machining Cost Per Hour

To guess cnc machining costs, you need to know machine hourly rates. These rates change in different places. They also change with machine type and how hard the project is. For example, cnc machining in China or India costs less than in the US or UK. The table below shows what you might pay per hour in each region:

Region | Notes | |

|---|---|---|

China | $10–30 (3-axis) | Costs are lower because of labor and machine type. |

$30–50 (multi-axis) | ||

India | Lower than US/Canada | Labor is cheap and there are fewer rules. |

US | High end ($100+) | Labor costs more and rules are strict, so prices go up. |

UK | Around $100 | High standards and special skills make it cost more, but it is still cheaper than the US. |

Malaysia | Around $80 | Prices are good, especially for plastic parts. |

Machine hourly rates can change your total cost a lot. Always ask your supplier what machines they use.

CNC Machining Cost Per Part Range

CNC machining costs for each part depend on many things. These include material, machine time, and how hard the part is to make. Simple plastic parts in big batches might cost $1 to $20 each. Hard metal parts can cost $100 or more for each one. The main things that change cnc machining costs are:

Cost Factor | Description |

|---|---|

Material Costs | What kind of material you use changes the price. |

Machine Setup | Getting machines ready and programming them adds to the starting cost. |

Hourly Rates | The type of machine and how hard the job is change the price. |

Labor and Overhead | Skilled workers, fixing machines, and running the shop all add to the final price. |

Always ask for a clear cnc costing breakdown. This helps you know what you pay for each part.

Prototype vs Production CNC Machining Cost

Making prototypes with cnc machining costs more for each part than making lots of parts. You pay more for setup and programming when you make just a few parts. In big production runs, these costs get split between many parts, so each part costs less. The table below shows the difference:

Cost factor | Prototype | Production |

|---|---|---|

Setup Costs | High for each part (few parts to split cost) | Low for each part (cost spread over many parts) |

Programming | Full cost for a few parts | Cost spread over all parts made |

Tooling | Special tools cost more for each part | Regular tools cost less for each part |

Material | Buying small amounts costs more, special materials may cost extra | Buying lots gets discounts, material use is better |

Machine Time | Takes longer (careful settings, lots of changes) | Faster (stronger settings, same process each time) |

Labor | Needs skilled workers, more checking and fixing | Trained workers, less checking, smoother work |

Inspection | Checks every part, detailed reports, may need fixing | Checks some parts, watches process, checks if process works well |

Overhead | All shop costs go into each part | Shop costs are lower for each part because of volume |

Tip: If you want to pay less for cnc machining, order more parts at once. This makes setup and programming costs smaller for each part.

You can use online cnc costing tools to quickly guess your project cost.

CNC Machining Cost Breakdown

When you know the cnc machining cost breakdown, you can plan better. This helps you not get surprised by extra costs. You should check each part of cnc costing to see where your money goes. Here are the main parts:

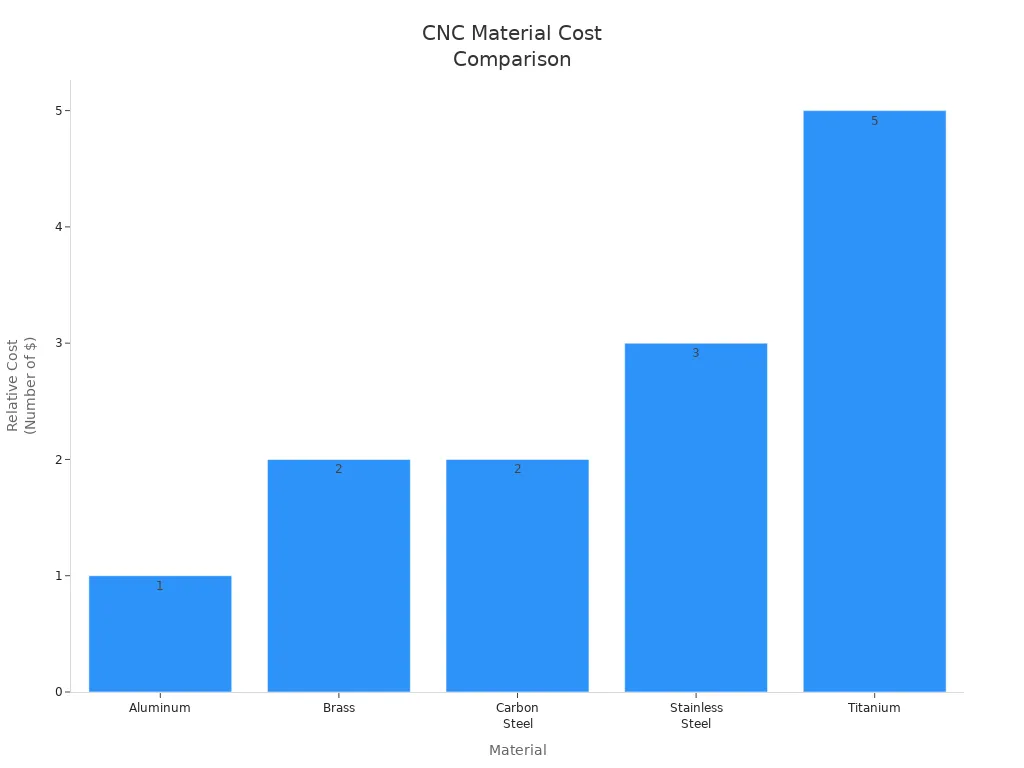

Material Costs

Material costs are a big part of cnc costing. The material you pick changes the price a lot. Aluminum is cheap and easy to use. Titanium costs much more and is hard to machine. The table below shows how different materials compare:

Material | Relative Cost | Machinability | Common Applications |

|---|---|---|---|

Aluminum | $ | Excellent | Prototypes, electronics enclosures, fixtures |

Brass | $$ | Very Good | Electrical components, decorative parts |

Carbon Steel | $$ | Good | Structural components, tooling |

Stainless Steel | $$$ | Moderate | Medical devices, food-grade equipment |

Titanium | $$$$$ | Poor | Aerospace components, medical implants |

Material prices can go up or down fast. This happens because of supply and demand. If you need special sizes or grades, you may pay more. For example, aircraft-grade aluminum costs more than normal aluminum.

Machining Time & Complexity

Machining time is a big part of cnc costing. Simple parts take less time to make. Complex parts need more steps and take longer. Some shapes need special machines, which cost more. More time on the machine means you pay more.

Complex parts need more setup and programming.

Small details need slower speeds and extra steps.

More machining time makes your total cost higher.

Setup & Tooling Costs

Setup and tooling costs matter, especially for small orders. You pay to get the machine ready and for special tools. If you order more parts, setup cost per part is lower. Tooling costs depend on how long tools last and how often you change them. Good design and smart choices can help lower these costs.

Labor & Overhead

Labor and overhead costs are what you pay workers and to run the shop. Skilled workers get paid more, so this affects cnc machining cost. Overhead also means things like rent, power, and insurance. These costs can be 30-40% of your total project cost.

Labor costs change with skill and where you are.

Overhead means rent, utilities, and office costs.

Checking quality and setup time add to labor and overhead.

Finishing & Secondary Operations

Finishing and extra steps add to your cnc costing. You might need grinding, painting, or heat treating. These steps make your part look better or stronger but cost more. Tight tolerances and smooth finishes take more time and special tools. Each extra step means more work and materials.

Note: Cleaning, deburring, and checking are common extra steps. These help make sure your parts are good quality.

If you know about each cost part, you can make better choices. This helps you control your cnc machining cost.

Key Factors That Affect CNC Machining Cost

When you start a CNC project, you should know what makes the price go up or down. Experts say these things matter most:

Material selection

Part complexity

Machining time

Quantity and volume

Machine type and accuracy

Surface preparation and post-processing

Part Geometry Complexity

The shape and details of your part can change the price a lot. If your part has tiny features or deep holes, it takes longer to make. The machine might need to stop and start again. You may need extra programming and special tools. Hard shapes often need more steps. This can make the cost two to ten times higher than for easy shapes.

Tolerance & Surface Finish Requirements

If you want your part to fit just right or look very smooth, it will cost more. The machine must go slower and change tools more often. Workers need to check the part more times. The table below shows how these needs change the price:

Cost Factor | Description |

|---|---|

Increased Machining Time | Tighter tolerances need slower speeds and more tool changes. |

Specialized Tooling and Equipment | High-precision tools cost more to buy and keep. |

Material Costs | Some materials for tight tolerances cost more. |

Increased Scrap and Rework | Less room for error means more scrap and fixing. |

Quality Control Expenses | More checks and inspections are needed. |

Design and Engineering Costs | More detailed design work is needed. |

Operational Efficiency Impact | Tighter tolerances can slow down production. |

Supply Chain Considerations | Suppliers may charge more for tight tolerances. |

Both surface finish and tolerance change how your part works. You need to find a good balance for the best part.

Batch Size & Order Quantity

How many parts you order changes the price for each one. If you order a lot, the setup and programming cost is shared. This makes each part cheaper. Prototypes cost the most because you pay for setup for just a few. Making lots of parts saves money and time.

Material Type

The material you pick changes the price and how long it takes to make your part. Some materials are easy to cut. Others are hard and slow down the machine. The table below shows how different materials compare:

Material Type | Machinability | Cost Implication |

|---|---|---|

Plastics | Moderate | Cutting too fast can give a poor finish |

Aluminum | Easier than plastics | Material cost may be higher |

Steels | Harder with carbon | Low carbon steel is easier to machine |

Brass | Highly machinable | Usually lower machining costs |

Machine Type (3-Axis vs 4-Axis vs 5-Axis)

The kind of CNC machine you use changes what you can make and how much you pay. Here is a quick look:

Machine Type | Capabilities | Advantages | Limitations | Cost Implications |

|---|---|---|---|---|

3-axis | Basic linear movement | Simple setup | Limited complexity | Lower initial cost |

4-axis | Multi-sided machining | Less setup time, better finish | Limited undercuts | Higher than 3-axis |

5-axis | Complex geometries | One setup, high accuracy | Higher cost, complex | Much higher than 3-axis and 4-axis |

Pick the right machine for your part to help control the price.

Lead Time (Standard vs Urgent)

Lead time means how long it takes to get your parts. Easy parts with normal materials can be ready in one to three weeks. If you need special materials or tight fits, it can take five to eight weeks or more. If you need parts fast, you may pay extra. Rush jobs use more time and people, so the price goes up. Always plan ahead to avoid paying more.

If you want to learn more or get a price, check out our CNC machining services or try our online quote page.

CNC Machining Cost by Material

Aluminum CNC Machining Cost

You will find that aluminum is one of the most popular choices for CNC projects. It is easy to machine and costs less than many metals. Here is what you should know:

The cost to machine aluminum parts ranges from $30 to $500 per part. The price depends on how complex your part is, the type of aluminum, and how many you order.

Setup expenses can range from $50 to $200 per hour. More complex parts need more setup time.

Machining charges usually fall between $30 and $150 per hour.

Aluminum material costs often range from $2 to $6 per pound. High-performance alloys cost more.

Aluminum gives you a good balance of price and performance for most projects.

Steel CNC Machining Cost

Steel is strong and used for many industrial parts. You will pay more for steel than for aluminum, but less than for titanium. The cost depends on the steel grade and how hard it is to cut. Simple steel parts cost less. Complex shapes or hard steels cost more because they wear out tools faster and take longer to machine.

Stainless Steel CNC Machining Cost

Stainless steel offers high durability and corrosion resistance. It is harder to machine than regular steel or aluminum. You will see higher cnc costing for stainless steel. The table below compares stainless steel to other metals:

Material | Cost Level | Machinability | Durability | Corrosion Resistance |

|---|---|---|---|---|

Stainless Steel | Medium-High | Low | High | High |

Aluminum | Low | High | Medium | Low |

Titanium | High | Medium | High | High |

Brass CNC Machining Cost

Brass is a costly material, but it is easy to machine. You will pay more for brass parts, especially if your design is complex or large. The type of brass you choose also affects the price. Brass is often used for electrical and decorative parts.

The cost of CNC machining brass changes with part size and complexity.

Brass machining usually costs more than aluminum or steel.

Titanium CNC Machining Cost

Titanium is strong and light, but it is expensive to machine. You will see higher cnc machining cost for titanium because of these reasons:

Factor | Explanation |

|---|---|

Material Cost | Titanium costs more to extract and process than aluminum or steel. |

Tooling and Equipment | You need special tools that wear out faster. |

Machining Speed | Machines must run slower, so jobs take longer. |

Coolant and Lubrication | More coolant is needed to keep tools cool. |

Post-Processing | Extra steps like heat treatment add to the cost. |

Plastic CNC Machining Cost

Plastic is a good choice for prototypes and light-duty parts. The cost depends on design complexity, machine tool type, and production volume. Here are some things that affect plastic cnc costing:

Complex designs need more programming and precision.

Machine tool costs change with the job.

Material prices vary by type.

Large orders lower the cost per part.

Finishing steps can add to the total cost.

You can get a fast quote for your material by using our online quote page or learn more about our CNC machining services.

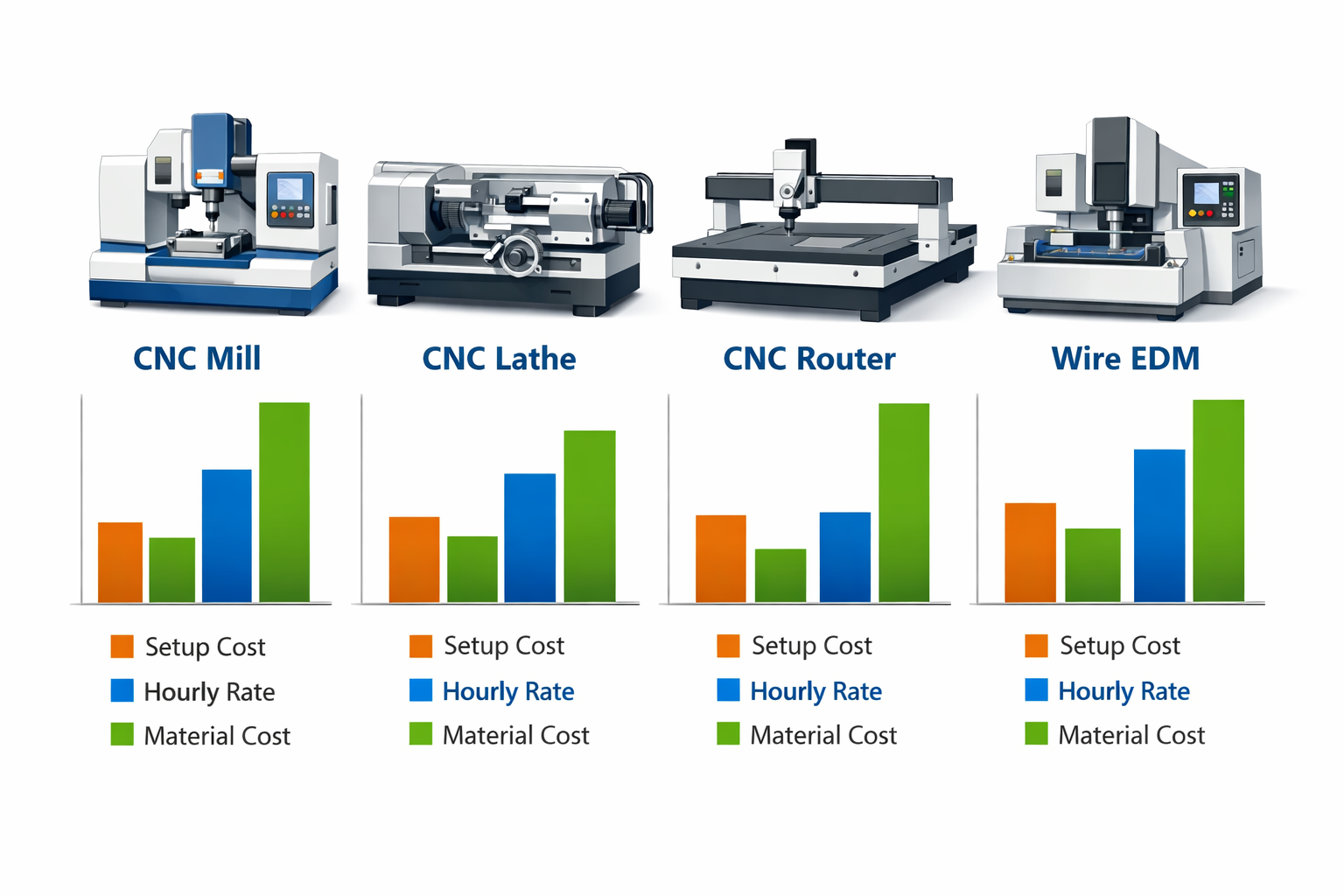

CNC Machining Cost by Machine Type

3-Axis CNC Machining Cost

You will see 3-axis CNC machines in many shops. These machines move in three directions: X, Y, and Z. They work well for simple parts. The cost per hour for a 3-axis CNC machine is about $40. You pay less for setup and programming. Most operators can learn to use these machines quickly. If you want to keep cnc costing low, 3-axis machines are a good choice for basic jobs.

Machine Type | Cost per Hour | Approximate Investment | Programming Complexity | Operator Skill Level |

|---|---|---|---|---|

3-axis | $40 | $50,000-150,000 | Moderate | Entry to intermediate |

Tip: If your part has features on many sides, you may need to move the part several times. This takes more time and can lead to mistakes.

4-Axis CNC Machining Cost

A 4-axis CNC machine adds one more movement. It can rotate the part, so you do not need to move it as much. The cost per hour is usually $45 to $50. You save time on setup, and you get better accuracy. If your part has holes or cuts on different sides, a 4-axis machine can help you finish faster. This keeps your cnc costing under control for medium-complexity parts.

5-Axis CNC Machining Cost

A 5-axis CNC machine can move in five directions. You can make very complex parts with just one setup. The cost per hour is higher, from $75 to $120. The machine itself costs more, and you need skilled workers. You pay more for programming and setup. If you need aerospace or medical parts, you may need a 5-axis machine. At PTSMAKE, we used to need five or six setups for some parts. Now, with 5-axis CNC, we do it in one setup. This saves time and reduces errors.

Machine Type | Cost per Hour | Approximate Investment | Programming Complexity | Operator Skill Level |

|---|---|---|---|---|

5-axis | $75-120 | $200,000-500,000+ | High | Intermediate to advanced |

CNC Turning Cost

CNC turning uses a lathe to make round parts. You can use this for shafts, bushings, and rings. The cost for CNC turning depends on part size and complexity. Simple turned parts cost less than milled parts. You pay less for setup and programming. If you want to lower your cnc costing, choose turning for round shapes.

Note: Each machine type changes your cnc machining cost. You should pick the right machine for your part to get the best value.

If you want to learn more about machine types or get a quote, you can visit our CNC machining services or try our online quote page.

How to Estimate CNC Machining Cost

Step-by-Step CNC Cost Estimation Process

You can estimate cnc machining cost by following a clear process. Each step helps you get accurate cnc costing for your project.

Choose Material and Quantity

Start by picking the right material for your part. You should know the grade and size. The number of parts you need also changes the cost. Large orders lower the price per part.

Estimate Machining Time

Next, look at how long it takes to make your part. Machining time estimation depends on part shape, size, and features. Complex parts take longer. You can ask your supplier or use a cnc costing calculator for help.

Add Setup and Tooling Cost

You must include the cost to set up the machine and buy special tools. Setup takes time, especially for new jobs. Tooling wears out and needs replacing. These costs spread out if you make many parts.

Include Finishing and Secondary Operations

Think about extra steps like coating, polishing, or heat treating. These finishing steps add to the total cost. Some parts need cleaning or inspection after machining.

Apply Overhead and Profit Margin

Add overhead costs like shop rent, power, and machine upkeep. You should also include a profit margin. This makes sure your cnc costing covers all expenses.

Tip: You can use our online quote page for fast and easy estimates.

Key Inputs Needed for Cost Estimation

You need the right data to get good estimates. Here are the main things you should prepare:

CAD Drawing or 3D Model

A clear CAD file or 3D model shows the part shape and size. Most shops use STEP or IGES files.

Material Specification

List the material type, grade, and hardness. This helps with cnc costing and picking the right tools.

Tolerance and Surface Finish

Tell your supplier how smooth and accurate you want your part. Tight tolerances and special finishes can raise the cost.

Order Quantity

Say how many parts you need. Making more parts lowers the cost per part.

You can learn more about our CNC machining services or get a quote online. Good cost estimation helps you plan your project and avoid surprises.

CNC Machining Cost Calculation Example

You can better understand cnc costing by looking at real examples. Here are two sample calculations. These show how you can estimate the cnc machining cost for both a prototype and a production run.

Prototype Part Cost Example

Suppose you need one aluminum bracket as a prototype. You choose 6061 aluminum. The part is small and simple. Here is how you might break down the costing:

Cost Item | Amount |

|---|---|

Material | $5 |

Machining Time | 1 hour @ $50 |

Setup & Tooling | $80 |

Finishing | $10 |

Overhead & Profit | $20 |

Total Cost | $165 |

You see that setup and programming make up a big part of the cost. This happens because you only make one part. If you want a quick estimate for your prototype, you can use our online quote page.

Production Part Cost Example

Now, imagine you order 100 of the same brackets. The material and machining time stay about the same for each part. The setup and tooling cost gets split across all 100 parts. Here is what the costing looks like per part:

Cost Item | Amount (per part) |

|---|---|

Material | $5 |

Machining Time | $50 / 100 = $0.50 |

Setup & Tooling | $80 / 100 = $0.80 |

Finishing | $10 |

Overhead & Profit | $5 |

Total Cost | $21.30 |

You can see that making more parts lowers the cnc costing for each one. If you want to learn more or get help with your project, visit our CNC machining services.

Tip: Always ask for a detailed cnc costing breakdown. This helps you plan your budget and avoid surprises.

CNC Machining Cost Calculator & Estimation Tools

When you want to plan your cnc project, you need to know the cost before you start. You can use different tools to help with cnc costing. These tools make it easier to get a fast and accurate estimate.

Online CNC Cost Calculators

You can find many online cnc costing calculators. These tools let you enter details like material, part size, and quantity. The calculator gives you a quick cost estimate. Some calculators also show you how changing the material or batch size affects the price. You can try our online quote page for a fast cnc costing estimate. Online calculators work well for simple parts and quick checks.

Tip: Always double-check the results from online calculators with your supplier. This helps you avoid surprises in your cnc machining cost.

CAD-Based Cost Estimation Tools

CAD-based tools use your 3D model or drawing to estimate cnc costing. You upload your CAD file, and the software looks at the shape, size, and features. The tool then gives you a detailed cost breakdown. These tools help you see which part features raise the cost. You can use this information to change your design and save money. CAD-based tools are great for complex parts or when you want to compare different designs.

Manual CNC Cost Estimation

You can also estimate cnc costing by hand. Start by listing all the steps in your process. Write down the time for each step, the material cost, and any extra finishing. Add up the numbers to get your total cost. Manual estimation takes more time, but it helps you understand where your money goes. You can use this method for special projects or when you want to check the numbers from a calculator.

If you want help with cnc costing, you can visit our CNC machining services page. You will find more tips and tools to help you plan your project.

How to Reduce CNC Machining Cost

You can take smart steps to reduce cnc machining price and keep your project on budget. Here are the best ways to lower cnc costing and get more value from your supplier.

Design for Manufacturability (DFM) Optimization

You should always design your part for easy manufacturing. Simple shapes and fewer features help reduce cnc machining price. If you avoid deep pockets or thin walls, you make the job easier for the cnc machine. You can ask your supplier for DFM advice. This helps you spot costly features before you start. For more tips, check out our CNC machining services.

Choose Cost-Effective Materials

Pick materials that are easy to machine and cost less. Aluminum and some plastics work well for most jobs. If you choose rare metals, you will see higher cnc costing. You can ask your supplier about cheaper options that still meet your needs. This step helps you reduce cnc machining price without losing quality.

Increase Batch Size

Making more parts at once spreads out setup and programming costs. You pay less for each part when you order in bulk. If you only need a few parts, try to combine orders with others. This method is one of the fastest ways to reduce cnc machining price.

Avoid Unnecessary Tight Tolerances

Tight tolerances make the cnc process slower and more expensive. You should only ask for tight fits where you really need them. Standard tolerances work for most parts. This choice helps you lower both cnc costing and total cost.

Combine Machining Operations

You can design your part so the cnc machine does more steps in one setup. This reduces handling and saves time. Fewer setups mean fewer mistakes and lower cost. You can talk to your supplier about combining operations for better cnc costing.

Tip: You can use our online quote page to see how design changes affect your cnc machining cost.

China vs USA vs Europe CNC Machining Cost Comparison

When you compare CNC machining cost around the world, you see big differences. You need to look at labor, machine prices, and how factories work in each region. This cost comparison helps you choose the best place for your project.

CNC Machining Cost in China

You find that China offers some of the lowest cnc prices in the world. Many factories use modern machines and skilled workers. Labor costs stay low, so you pay less for each part. You can get simple parts for $10 to $30 per hour. Complex parts cost more, but still less than in the USA or Europe. Many companies use China for large orders because the cost per part drops fast. You can try our online quote page to see how much you save with China cnc.

CNC Machining Cost in USA

In the USA, cnc machining cost is higher. You pay more for labor and strict safety rules. Machine shops use advanced equipment and offer high quality. The cost per hour often starts at $75 and can go over $200 for special jobs. You get fast service and strong support. If you need tight tolerances or special materials, the USA is a good choice. You can learn more about our CNC machining services in the USA.

CNC Machining Cost in Europe

Europe sits between China and the USA in this cost comparison. You see high standards and skilled workers. The cost per hour usually ranges from $60 to $160. Some countries, like Germany, focus on precision and quality. You pay more for complex parts, but you get strong engineering support. Europe works well for projects that need both quality and fair pricing.

Tip: Always do a cost comparison before you choose a supplier. This helps you find the best value for your cnc project.

If you want a detailed costing or a fast quote, visit our online quote page.

How to Get the Best Value from a CNC Machining Supplier

Compare CNC Machining Quotes

You should get quotes from a few cnc suppliers. This lets you see how much each one charges. Some quotes include setup, material, or finishing in the price. Other suppliers might list these as extra costs. You get the most for your money when you look at both price and what is included.

Tip: Ask for a full list of costs. This helps you find any hidden fees.

Check Supplier Certifications & Capabilities

Pick a supplier with the right skills and certificates. Certifications like ISO 9001 mean the shop follows strict rules for quality. Ask what machines they use. Some shops have special cnc machines for hard jobs. You get better value when your supplier can do the work you need every time.

Certification | What It Means |

|---|---|

ISO 9001 | Quality management |

AS9100 | Aerospace standards |

ISO 13485 | Medical devices |

Review Samples & Case Studies

Ask for samples or stories about past jobs. These show what the supplier can make. Look for parts that are like yours. Check if the finish and size are good. Good suppliers will show real examples. You get better value when you see proof of their work.

Clear Project Communication

You need to talk clearly with your supplier. Share your drawings, material needs, and when you need the parts. Ask questions if you are not sure about something. Good communication helps stop mistakes and saves money. You can also visit our CNC machining services page to learn more about supplier choices and help.

Note: You help your project succeed by picking the right supplier and staying involved.

Get an Accurate CNC Machining Quote

You want to know the exact cnc machining cost for your project. You can get a fast and accurate quote if you prepare the right information. Here is what you need to do.

What Information to Provide

You should collect these details before you ask for a cnc quote:

CAD drawing or 3D model of your part

Material type and grade

Quantity of parts you need

Tolerance and surface finish requirements

Any special finishing or secondary operations

You help your supplier give you a better price when you share clear and complete information. If you miss details, your quote may not match your real needs.

Typical Quotation Lead Time

Most cnc suppliers send you a quote in 24 to 48 hours. Some simple jobs get a price in just a few hours. Complex parts or large orders may take longer. You can speed up the process by sending all your files and details at the start.

Tip: If you need a quick answer, use our online quote page. You get a fast estimate for your cnc project.

Free DFM & Engineering Support

Many cnc shops offer free DFM (Design for Manufacturability) and engineering help. You can ask questions about your design or material choice. Experts will suggest ways to lower your cost or improve your part. This support helps you avoid mistakes and get the best value.

You should always use these free services. You save time and money when you work with skilled engineers.

You now know what affects cnc machining cost and how to estimate it. You can control cnc project cost by using clear steps and smart tips. Accurate cnc cost breakdown helps you plan and save money. Try our CNC machining services or use our online quote page to get started. Talk to cnc experts for more help.

FAQ

What is the main factor that affects CNC machining cost?

You see the biggest cost change from material choice and part complexity. Simple shapes and easy-to-machine materials cost less. For a quick estimate, try our online quote page.

How can you lower your CNC machining cost?

You can design simple parts, use standard materials, and order more pieces at once. Ask your supplier for DFM advice. Visit our CNC machining services for more tips.

How long does it take to get CNC machined parts?

Most shops finish simple parts in 1–3 weeks. Complex parts or special materials may take longer. You get faster service if you send clear drawings and details.

Do you need a CAD file for a CNC quote?

Yes, you need a CAD drawing or 3D model. This file shows the exact shape and size. It helps your supplier give you an accurate price.

Can you get just one CNC part made?

Yes, you can order a single prototype. The cost per part will be higher than for large orders. Use our online quote page to check the price for one piece.

LKprototype

LKprototype