Imagine changing a plain piece of wood into art easily. That’s the power of CNC machine woodworking. Whether you’re new or experienced, this tool helps you. It allows for accuracy and creativity that old methods can’t do. The facts are clear: CNC wood lathes sales may grow from $1.2 billion in 2024 to $1.8 billion by 2033. The global CNC market might reach $150 billion by 2032. These numbers show how CNC is changing woodworking. It gives you tools to make amazing projects simply.

Key Takeaways

CNC woodworking uses machines to make exact cuts and cool designs. It removes the guessing from old methods.

New users should try easy projects first, like coasters or name signs. This helps them learn and feel more confident before harder tasks.

Take care of your CNC machine. Clean it often and tighten loose parts. This keeps it working well and avoids big repairs.

Pick the right wood. Softwoods like pine are good for beginners. Hardwoods like oak are strong and better for tough projects.

Safety is very important. Wear safety gear and keep your area neat. This helps prevent accidents when using CNC machines.

Understanding CNC Machine Woodworking

What is CNC woodworking?

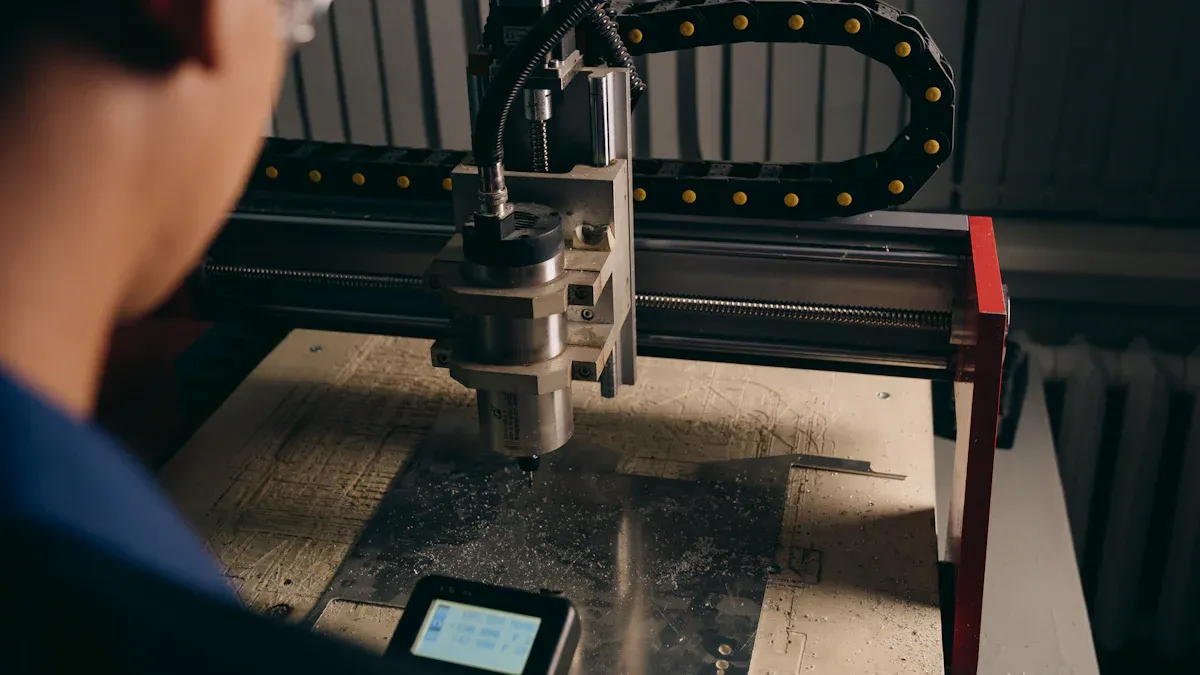

CNC woodworking uses computers to guide machines in shaping wood. CNC means "Computer Numerical Control," where software gives the machine commands. You don’t need to use hand tools or guess measurements. It helps you make detailed designs, smooth edges, and perfect cuts easily. Whether making furniture or decorations, CNC woodworking lets you be creative without limits.

Benefits of using a CNC machine for woodworking

CNC machines have many benefits for woodworking. Here’s why they’re loved:

Precision and consistency: Every cut is exact, and pieces fit perfectly.

Efficiency: CNC machines are faster than old methods, saving time.

Reduced waste: They use materials wisely, cutting down on scraps.

Flexibility: You can change designs quickly without switching tools.

More people want custom furniture and décor, so CNC machines are in demand. Furniture makers use them to create unique designs that customers love. If you want to make special items, CNC woodworking is a great choice.

CNC woodworking vs. traditional woodworking methods

CNC woodworking has big advantages over older methods. CNC machines save time and lower labor costs compared to hand tools. You don’t need hours to adjust tools or measure by hand. Instead, you can program the machine for new designs in minutes.

Traditional woodworking depends on skilled workers, which takes time and costs more. CNC machines automate tasks while staying accurate and consistent. They’re perfect for big projects or detailed designs. Whether you’re a beginner or expert, CNC woodworking makes work easier and results better.

Essential CNC Tips for Beginners

How to operate a CNC machine

Using a CNC machine might feel hard at first. But with practice, it gets easier. Begin by learning the machine’s buttons and software. Most CNC machines use CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) programs. Spend time understanding these tools—they are key to CNC woodworking.

Here are some simple tips for beginners to use a CNC machine well:

Know your materials: Different woods act differently. Pick wood with even thickness that fits your project.

Pick the right tools: Use sharp, clean bits for neat cuts. Dull tools can mess up your work and waste wood.

Check your machine: Calibrate often for better accuracy. Make sure your wood is tightly secured before starting.

Learn the software: Plan your tool paths carefully to save time and avoid mistakes.

Be safe: Wear safety gear and follow rules. Dust can be harmful, so get a good dust collector.

Making mistakes is normal when learning. Try new things and learn from errors. Joining CNC groups can also give you helpful advice from skilled users.

Pro Tip: Write down your settings and results in a notebook. This will help you save time on future projects.

Setting up a workspace for CNC woodworking

A tidy workspace is important for CNC woodworking success. Pick a spot with enough space for your machine and wood. Make sure it’s bright and has good airflow.

Here’s how to create a good workspace:

Plan ahead: Use software to map out steps before cutting. This keeps you organized and reduces errors.

Reduce waste: Cut carefully and save leftover wood for small projects.

Control dust: Use a dust collector to keep your area clean and safe. This also helps your machine last longer.

Organize tools: Keep bits, clamps, and other items in labeled boxes for easy use.

A clean workspace makes your work better and more fun.

Note: Check your CNC machine often for damage. Fixing small issues early can prevent expensive repairs later.

Beginner-friendly CNC woodworking projects

If you’re new, start with easy projects to build skills. Here are some ideas for beginners:

Name plaques: Make wooden name signs with simple CNC techniques.

Coasters: Cut custom coasters from scrap wood. Try different shapes and designs.

Key holders: Create a key holder with hooks that’s both useful and decorative.

Wall art: Carve simple patterns or quotes into wood panels.

These projects are fun and useful. They help you practice cutting, engraving, and finishing.

DIY Tip: Use softwoods like pine or cedar. They are easier to cut and won’t harm your tools.

As you improve, try harder projects. Each project helps you learn and get better at CNC woodworking.

Avoiding Common Beginner Mistakes

Starting with CNC machines is exciting but can be tricky. Mistakes happen, but don’t worry—they’re part of learning. With some planning, you can avoid most problems. Let’s explore common errors and how to prevent them.

1. Skipping the Basics

Jumping into hard projects too soon can be frustrating. Learn how your CNC machine works first. Understand the software, tools, and settings. Begin with simple projects like coasters or name signs to gain confidence.

Tip: Watch beginner videos or join online CNC groups. They offer helpful advice and guides.

2. Ignoring Material Properties

Different woods behave differently. Softwoods like pine are easy to cut, but hardwoods like oak need more care. Using wrong settings can damage tools or ruin your work. Always research your wood type and adjust your machine.

3. Overlooking Machine Maintenance

A dirty or loose machine can cause bad cuts or break. Check for loose screws, dull bits, or dust often. Clean and oil your machine to keep it running well.

Pro Tip: Make a checklist for maintenance. It saves time and money.

4. Rushing Through Setup

Hurrying during setup can lead to mistakes. If the wood isn’t secure, it might move and ruin your design. Always double-check clamps and alignment before starting.

5. Neglecting Safety Measures

Safety is very important. Dust can harm your lungs, and sharp tools can hurt you. Wear goggles, gloves, and a dust mask. Keep your workspace clean to avoid accidents.

6. Forgetting to Test Designs

Skipping test cuts can waste wood or damage your machine. Always try your design on scrap wood first. This helps you catch mistakes early.

Note: Testing may take extra time, but it prevents big problems later.

7. Mismanaging Tool Paths

Bad tool paths can cause uneven cuts or wasted wood. Plan your tool paths carefully in the software. Make sure the machine moves in a smart order.

8. Using Dull or Incorrect Bits

Dull or wrong bits can ruin your cuts. Check your bits before starting. Replace worn ones and pick the right bit for your project.

Avoiding these mistakes saves time and reduces stress. Remember, even experts started as beginners. Take it slow, and you’ll improve with every project.

Advanced CNC Techniques for Experts

Choosing the Best Materials for CNC Woodworking

Picking the right materials is key to great CNC projects. Not all materials work the same with a CNC wood router. Some are simple to cut, while others need extra care. Let’s look at some top materials and their features.

Material | Features | Uses |

|---|---|---|

Aluminum | Light, strong, easy to machine | General CNC projects |

Stainless Steel | Tough, resists rust | Durable parts |

Brass | Strong, easy to machine, resists rust, conducts electricity | Plumbing, electrical, artistic uses |

Titanium | Strong but light, resists rust | Aerospace, medical uses |

Bronze | Easy to machine, resists rust | Marine uses |

For wood, softwoods like pine are easy for beginners. Hardwoods like oak are tougher but look better. For detailed designs, try brass or aluminum since they’re easier to shape.

Pro Tip: Test your material first. This shows how it cuts and engraves, helping you get better results.

Maintaining and Upgrading Your Wood CNC Machine

Keeping your CNC machine in good shape is very important. Skipping maintenance can cause bad cuts and expensive repairs. Follow this simple schedule:

How Often | Tasks | Why It’s Important |

|---|---|---|

Daily | Clean surfaces, check for debris, inspect visually | Prevents buildup and keeps it running smoothly |

Weekly | Deep clean, oil moving parts, check dust filters | Keeps it efficient and working well |

Monthly | Replace worn parts, adjust settings, test safety | Ensures accuracy and safety |

Quarterly/Yearly | Full cleaning, inspect system, get professional help | Extends machine life |

Upgrades can make your CNC machine even better. Add features like air-cooled spindles. These stop wood from warping, need less maintenance, and save energy.

Note: Write down every fix or change you make. This helps you track problems and improve performance.

Using Advanced CNC Software for Intricate Designs

Advanced software lets you create amazing, detailed designs. Tools like Fusion 360 and VCarve Pro help with 3D carvings and patterns. They also have smooth filters to improve accuracy by reducing jerky movements.

Here’s how advanced software helps:

Better Accuracy: Smooth filters make precise cuts for tricky designs.

Less Vibration: They stop shaking that could ruin your cuts.

Longer Tool Life: Smooth movements reduce wear on your CNC machine.

For detailed projects, use slower speeds and feed rates. This improves the finish and protects your tools.

DIY Tip: Try different software settings to see what works best. Save your favorite settings to make future projects easier.

Improving Accuracy and Speed in CNC Projects

In CNC projects, being accurate and fast is very important. Whether you're making detailed designs or big items, improving these can save time, reduce waste, and give better results. Here are some easy ways to improve your CNC woodworking skills.

1. Try New Tools and Methods

Modern CNC machines have great tools to make work easier. For example:

High-speed cutting helps you finish projects quickly without losing quality.

Multi-axis cutting uses less material and makes exact shapes. This is great for tricky designs.

Adaptive cutting changes settings as needed. It lowers mistakes and keeps your work consistent.

Using these methods can make your projects more accurate and faster.

Pro Tip: Test different woods like softwoods or hardwoods. Each type works differently, so testing helps you pick the best one.

2. Make Better CNC Programs

Good programming makes CNC work smoother and faster. Spend time fixing your CAD and CAM files for better tool paths. This avoids extra moves and saves time. Here’s how to improve your programming:

Plan cuts in order to avoid moving the wood too much.

Use software to test your design before cutting.

Change speeds based on the type of wood you’re using.

These small changes can improve your project quality a lot.

3. Get the Right Tools

Upgrading your CNC machine or adding new parts can help. For example, advanced milling machines save time by cutting without needing to move the wood. This means faster and more accurate work.

Also, advanced tools like focused ion beam masking can help with very detailed designs.

Note: Keep your machine clean and check for damage often. This helps it last longer and work better.

4. Save Materials and Time

Being efficient isn’t just about speed. It’s also about using materials wisely. Multi-axis cutting and adaptive methods help reduce waste while keeping quality high. High-speed cutting also helps you finish projects faster.

DIY Tip: Keep leftover wood from old projects. Use scraps for small items like coasters or key holders.

5. Use Advanced Software for Better Accuracy

Advanced CNC programs like Fusion 360 or VCarve Pro can improve your designs. These tools have features like smooth filters to reduce shaking and make cuts more accurate. They also protect your tools by making smoother movements.

For detailed designs, slow down the machine’s speed. This gives it more time to cut neatly and leaves a cleaner finish.

Pro Tip: Save your favorite software settings. This saves time and keeps your projects consistent.

By following these tips, you’ll make your CNC projects more accurate and faster. Plus, you’ll enjoy creating unique and amazing designs.

Creative CNC Project Ideas for All Skill Levels

Easy CNC Projects for Beginners

Starting with easy CNC projects helps you learn and gain confidence. These projects are simple, fun, and useful for practice.

Coasters: Add names or patterns to make them personal.

Name signs: Create wooden signs for desks or doors.

Keychains: Make small, unique shapes for key holders.

Puzzles: Cut simple pieces that fit together for fun.

Phone stands: Design a stand that holds your phone perfectly.

These projects teach basic CNC skills like cutting and engraving. Softwoods, such as pine, are great because they’re easy to cut and gentle on tools.

Tip: Test your design on scrap wood first. This avoids wasting materials and time.

Medium-Level CNC Woodworking Projects

After learning the basics, try medium-level projects. These need more detail and creativity but are still doable with practice.

Here are some ideas:

Jewelry boxes: Add pretty patterns for a special keepsake.

Wall clocks: Make custom shapes and engrave numbers or designs.

Cutting boards: Use different woods for a unique style.

Trays: Mix function with artistic designs.

Picture frames: Carve borders to make photos look amazing.

These projects let you try harder designs and use stronger materials. Hardwoods like oak or walnut are great for their strength and smooth finish.

Pro Tip: Use advanced software like VCarve Pro for detailed designs and tool paths.

Advanced CNC Projects for Experts

If you’re experienced, advanced projects let you show off your skills. These often include detailed designs and techniques like 3D carving.

Here’s what you can make:

Furniture: Create tables, chairs, or shelves with unique carvings.

Models: Build accurate scale models for architects or designers.

Sculptures: Carve amazing 3D art pieces with your CNC machine.

Large-scale items: Save materials by planning cuts for big projects.

Advanced projects improve your skills and can grow your business. For example:

Offer package deals to keep clients coming back.

Sell design subscriptions for steady income.

Partner with interior designers to find new customers.

Buying materials in bulk can save up to 15% per item. Good supplier relationships also help you get better prices, boosting profits.

Note: Keep your CNC machine in top shape. Regular maintenance ensures accuracy and smooth operation for professional results.

Customizing CNC projects for unique designs

Making your CNC projects unique is where creativity shines. It’s a chance to create something special that shows your style. Whether it’s a gift, decoration, or useful item, adding personal touches makes it better.

Try using different materials to make your projects stand out. Wood is common, but you can mix it with acrylic, metal, or leather for a modern look. For example, wood and acrylic together can make cool layered designs. Always test materials first to see how they work with your CNC machine.

Get creative with your designs. Use advanced CNC software to add patterns, textures, or even 3D details. You can also make items personal by engraving names, quotes, or logos. These small details make your projects more special and memorable.

Don’t forget about finishes. A good finish can turn plain wood into something amazing. Try staining, painting, or burning designs onto the surface. You can also layer finishes to add depth and texture.

Think about how useful your project will be. Customizing isn’t just about looks—it’s also about making things practical. Add hooks, compartments, or other features to make your creations helpful in daily life.

Pro Tip: Keep a notebook or digital file for your ideas. This keeps you organized and gives you inspiration for future projects.

By customizing your CNC projects, you’re not just making things—you’re creating art with meaning. Let your imagination guide you and see what you can create!

Learning CNC woodworking lets you create with accuracy and imagination. Whether you're just starting or already skilled, always stay curious and aim to improve. Following clear steps, like choosing the right materials and checking your work, helps you make high-quality pieces. This combines old woodworking skills with new technology.

Trying out different woods and designs can inspire fresh ideas. For example, using softwoods for easy cutting and hardwoods for strength can make beautiful projects. The need for precise and fast furniture-making shows how important CNC skills are today.

Pro Tip: Plan your workspace to reduce extra movement. This saves time and makes work faster.

Now is a great time to start your next project. Whether it’s a simple sign or a detailed carving, let your creativity lead the way. With the right tools and practice, you can make something amazing.

FAQ

What type of wood works best for CNC woodworking?

Softwoods like pine are ideal for beginners. They are easy to cut and won’t damage tools. For tougher projects, hardwoods like oak or walnut are better. They are strong and look polished. Always test your wood first to see how it works with your machine.

Tip: Practice on scrap wood to save money and materials.

How do I pick the right CNC machine?

Think about what you want to make and your budget. Small desktop machines are good for hobbies. Bigger machines are better for heavy-duty work. Look at features like spindle power and software options before buying.

Pro Tip: Read reviews and join forums to learn from others.

How can I make my CNC projects more accurate?

Check your machine’s settings and secure your wood tightly. Plan your tool paths carefully to avoid extra movements. Use sharp bits and slow down the speed for better precision.

Note: Regular cleaning and maintenance keep your machine working well.

Is CNC woodworking safe for beginners?

Yes, but you must follow safety rules. Wear goggles, gloves, and a dust mask. Keep your workspace clean and organized. Always check your setup before starting the machine to avoid accidents.

Reminder: Never leave your CNC machine running without supervision.

Can CNC machines cut non-wood materials?

Yes! CNC machines can cut things like acrylic, aluminum, and leather. You’ll need the right tools and settings for each material. Check your machine’s manual to make sure it can handle the material.

DIY Tip: Try mixing materials for creative and unique designs.

LKprototype

LKprototype