Wondering about CNC machine prices? They range from a few thousand to hundreds of thousands of dollars. This guide will help you understand the factors that impact CNC machine prices, and find the best deal available. Understanding the CNC machine price is essential for making an informed purchase.

Key Takeaways

CNC machine prices vary widely, influenced by factors such as size, material compatibility, and advanced features, with costs ranging from $2,000 to over $500,000.

Buyers should consider the total cost of ownership, including installation, maintenance, and tooling, alongside the initial purchase price for effective budgeting.

Researching and comparing various models, as well as timing purchases strategically, can help secure the best deals when buying CNC machines.

Understanding CNC Machine Prices

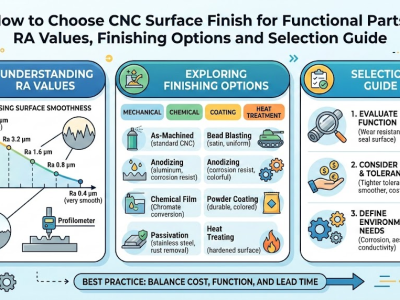

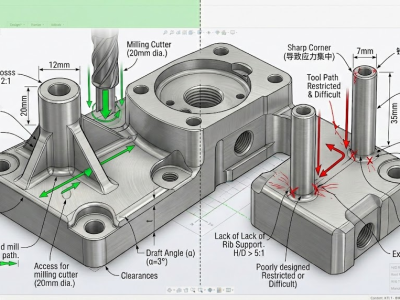

The cost of CNC machines is determined by a variety of factors. These can include the machine’s size, its power and cutting speed capabilities, level of precision it can achieve, compatibility with different materials, brand reputation, integrated software features and extra functionalities offered. Machines crafted for working on metal tend to be more expensive compared to those made for processing wood because they need to meet higher standards related to material handling and operational demands. Enhanced accuracy in these machines also comes at an additional expense due to stringent tolerance requirements and sophisticated calibration technologies.

Features such as intricate designs or built-in automation can escalate the price tags associated with CNC machinery significantly. As a result, prices span from several thousand dollars up into the high hundred thousand territory based on their performance characteristics and intended use cases. The average price range for new CNC equipment usually sits somewhere between $2,000 to $260k depending upon their design specs and functional breadth.

It’s critical when weighing out options for acquiring a CNC machine that you balance what your budget allows against what your operations necessitate. While premium models boast superior attributes and enhanced functionality which could benefit production quality or efficiency. These benefits might come at too steep a financial investment, especially if you’re managing within the tighter budgets typical of small-scale enterprises. Hence grasping how various elements influence cnc machine costs becomes essential in arriving at an informed purchasing decision.

Type of CNC Machine

Various types of CNC machines exist to cater to different tasks, including popular variants such as CNC routers, milling machines, and CNC mills. The cost of these tools can vary greatly depending on their functions and the level of precision they offer for particular applications. For instance, the price tag for a CNC router—often employed in woodworking where exactitude is key—can fluctuate based on its unique features and capabilities. It’s crucial to understand what each type of CNC machine tool offers in order to effectively compare them.

The nature of the task at hand and the materials involved play a pivotal role in determining how much you might pay for a CNC machine. Those designed with complex materials like metals in mind come at higher prices due to more demanding operational requirements necessary for compatibility with tougher substances. A comprehensive review of various models’ features will assist you in pinpointing which specific type aligns best with your operational objectives when choosing among different available options.

Machine Size and Capacity

The dimensions and capabilities of a CNC machine play a critical role in determining its cost. The larger the size of the machine, the more expensive it will be owing to greater material needs and increased complexity during construction. Larger machines often demand higher expenses because they use up more resources and entail intricate production procedures. Those machines that offer superior precision and enhanced cutting performance tend to carry a heftier price tag due to their advanced features.

It is crucial when choosing a CNC machine to take into account how much space you have at your disposal. Calculating both the area occupied by the actual machine as well as accounting for necessary storage for raw materials are vital steps in gauging how much room is needed for installation of one of these devices. The amount of available workspace dictates which machines can be considered viable options, ensuring that there’s adequate room within your working environment for operation.

For example, smaller desktop CNC models usually feature standard tabletop sizes like 2x4 feet configurations that fit comfortably within tighter spaces without compromising efficiency or functionality. These compact units provide an alternative solution tailored specifically towards locations where real estate comes at a premium.

Brand and Reputation

The reputation and brand of a CNC machine manufacturer can have a considerable effect on the cost of the equipment. Renowned brands often command higher prices. They compensate for this with superior customer support and more comprehensive warranty options, which may vindicate the elevated costs. These established companies produce dependable machines that are synonymous with quality—factors that are essential in maintaining seamless operations and reducing downtime.

Small businesses might be drawn to purchase less costly machines from lesser-known manufacturers due to budget constraints. Nevertheless, it is critical for them to assess whether the immediate savings outweighs the advantages offered by an acclaimed brand. The assurance provided through solid customer service and extensive warranties could translate into greater value over time, potentially rendering a steeper initial outlay as a sound investment.

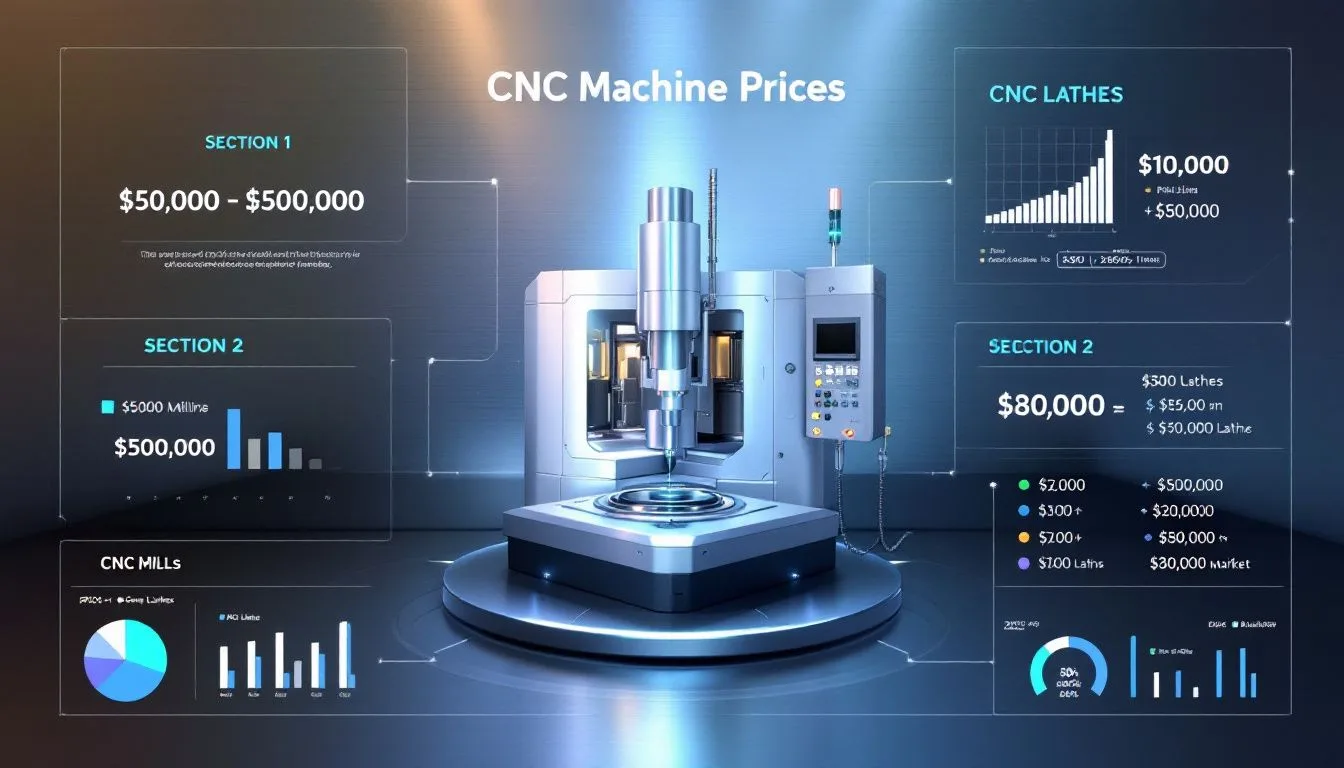

Average Price Ranges for Different CNC Machines

Prices for CNC machines can vary significantly, starting at a few thousand dollars and climbing to the several hundred thousand dollar range based on type and brand. The most expensive industrial-grade CNC machines reach up to $298,000, which reflects their sophisticated features and capabilities. It’s important to have an understanding of the common price brackets for various types of CNC machinery in order to make well-informed purchasing decisions that align with your financial constraints.

Among these machines are 5-axis models whose costs begin around $200,000 but can skyrocket beyond half a million dollars due to their exceptional precision and adaptability suited for intricate production processes.

Conversely, standard 3-axis machining centers fall within a more moderate price window ranging from $50,000 up to about $125,000. They strike an equilibrium between affordability and operational capacity. Both high-end versions of CNC lathe machines as well as those used for plasma cutting also come with steep prices – anywhere from roughly $100k-$500k is possible.

For newcomers or those seeking less costly alternatives without sacrificing quality too much: entry-level CNC lathes tend towards being reasonably priced between just over ten grand all the way through approaching the thirty grand mark. In sum, this means when diving into marketplace pricing fluctuations across different categories must be taken into account ensuring choice best suits one’s specific needs budget.

CNC Routers

CNC routers, which are essential for precision tasks in woodworking, can have a wide price range depending on their functionality. Prices of professional-grade CNC routers usually start around $5,000 and can go as high as $100,000. Some top-tier models may cost up to $150,000 due to their enhanced features and superior precision.

For small businesses looking for a more economical option that still delivers precise results in woodworking, entry-level CNC routers present an ideal choice. They offer the benefits of CNC technology without necessitating a significant investment.

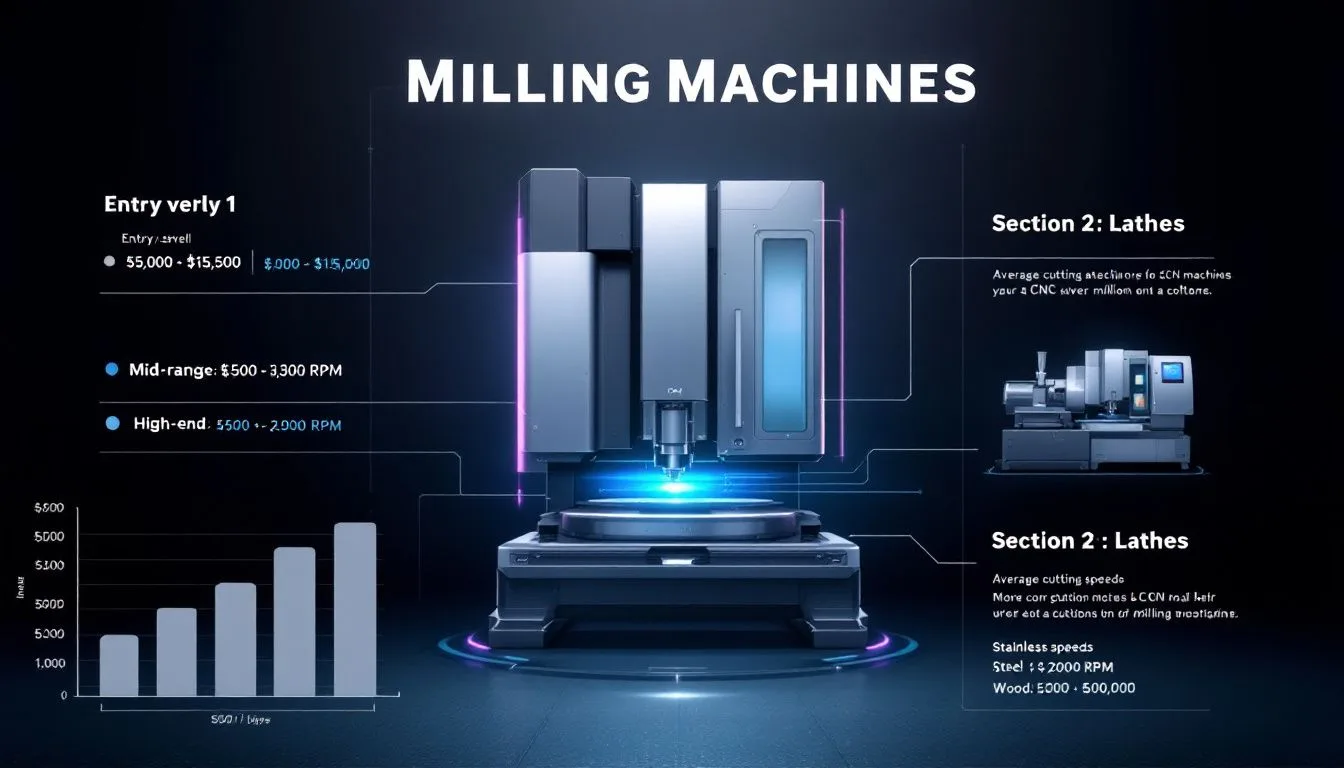

CNC Milling Machines

Computerized Numerical Control (CNC) milling machines come with a wide array of price points, catering to both enthusiasts with smaller budgets and industries requiring more sophisticated equipment. Hobbyist-level CNC milling apparatuses are priced within an approximate range of $3,000 to $120,000. Those seeking mid-tier CNC milling solutions can expect to find machines that combine affordability with practical features, typically costing between $30,000 and $100,000.

On the other hand, industrial-grade CNC mills present a notable jump in pricing due to their advanced capabilities. These robust machines have prices spanning from around $100,000 up to half a million dollars ($500k).

CNC Lathes

Manufacturing heavily relies on CNC lathes, with their cost differing greatly depending on their features and capabilities. For smaller operations looking to acquire these essential tools, entry-level CNC lathes are available at prices ranging from $10,000 to $30,000.

The price tag of top-tier models can rise with the addition of optional features. Extras such as automatic tool changers, coolant systems, and sophisticated software packages are among the elements that add to the higher expense associated with these advanced machines.

Additional Costs to Consider

When considering the acquisition of a CNC machine, it is imperative to assess the aggregate cost of ownership. This encompasses not only the initial outlay but also factors in expenses related to setup, supplementary components, operation and ongoing maintenance costs. For entities investing in manufacturing equipment like CNC machines, recognizing these extra expenditures is crucial for devising financial strategies and budget allocations.

Ensuring that new CNC machines are compatible with pre-existing CAD/CAM software should be factored into fiscal considerations as well. Assessing how user-friendly this software is and what training may be necessary can influence operational efficiency and output levels significantly. Specific metals require specialized metalworking CNC machines capable of achieving precise tolerances. Such specifications entail additional costs that underscore the importance of detailed planning when allocating funds for these purchases.

Tailoring a machine through customization has implications on its final price tag since meeting particular operating needs might necessitate unique features or enhanced capabilities within the machine’s design. As such, potential buyers need to meticulously analyze their operational demands while accounting for all ancillary charges involved with their investment to ensure they achieve an economical outcome from purchasing said machinery.

Software and Licensing

When budgeting for CNC operations, it is crucial to factor in the expense associated with software licenses. To guarantee efficient functioning and seamless integration with CNC machines, obtaining compatible computer aided design/CAM software is vital. Manufacturers often offer the option to incorporate additional expenses such as installation and training into financing arrangements, which simplifies handling the total investment.

Maintenance and Repairs

Regular upkeep of CNC machines, involving expenditure on lubricants and spare parts, contributes to the total cost of ownership. Pre-owned CNC machines might necessitate more regular repairs, thus elevating the long-term maintenance expenses. Ensuring that these machines receive routine maintenance is vital for their efficient operation and to avoid expensive malfunctions, which should be factored into budget considerations.

Accessories and Tooling

The upfront costs for tooling, including items like cutters and drills, can be significant. Over time, as machining requirements change, there might be a need to upgrade these tools, which could lead to extra expenses. Given that cutting tools and drills are crucial for efficient CNC (Computer Numerical Control) machining processes, it is important to allocate sufficient funds for these expenditures.

Buying New vs. Used CNC Machines

Choosing to invest in new or pre-owned CNC machines is a pivotal choice that influences both the expenditure and the productivity of operations. Utilizing the CNC Machine Price Guide as a tool can assist you in obtaining appraisals for second-hand CNC machinery, simplifying the process of comparing different alternatives.

Weighing up the advantages and disadvantages of each possibility is essential to ensure you make an informed decision that aligns with your specific requirements.

Benefits of New CNC Machines

CNC machines equipped with the most recent advancements carry several benefits that can compensate for their increased cost. They incorporate cutting-edge technology, which results in enhanced processing velocities and heightened efficiency during the machining process. A new CNC machine typically includes warranty coverage, providing safeguards against faults and mitigating the likelihood of unforeseen expenses on repairs. Such coverage is instrumental in preserving continuous operations and bolstering productivity.

Personalization features are often accessible with new CNC machines, allowing purchasers to modify these devices according to particular operational requirements—including incorporating a computer numerical (CNC) controller tailored specifically for their needs. This adaptability can improve compatibility with existing systems and streamline workflows more effectively, consequently amplifying overall performance and production outcomes.

Advantages of Used CNC Machines

Opting for pre-owned CNC machines can be a financially savvy choice, particularly for companies operating within a tight financial framework. These used pieces of equipment often come with much lower price tags compared to their brand-new counterparts, offering the possibility of securing premium industrial machinery without heavy initial expenditures and thus allowing funds to be allocated elsewhere in the business.

It’s imperative that any prospective buyers rigorously examine such machinery before committing to ensure they are not burdened with unforeseen flaws. It is essential to assess various aspects including how the machine sounds when at full speed, its operational hours recorded on the CNC control panel, any errors logged as stored alarms, and historical maintenance records.

Ensuring that thorough tests and evaluations are performed prior to acquisition will help confirm whether the machine aligns with your production needs while safeguarding against potential future expenses associated with maintaining it.

Financing Options for CNC Machines

Options for financing CNC machines typically encompass loans and leasing agreements provided by both manufacturers and financial institutions. These alternatives enable companies to distribute the expense over an extended duration, thus aiding in more efficient budget management. The terms of CNC machine loans can vary from 24 to 84 months, offering flexibility regarding repayments. Certain financing options may also offer up to a 90-day deferment on payments, which can assist in optimizing cash flow.

It is crucial for businesses acquiring CNC machines to consider these financing possibilities as they facilitate better fiscal planning. Customized arrangements made available by manufacturing firms and banks are designed to meet distinct business requirements, thereby simplifying the process of procuring necessary machinery without placing undue pressure on monetary assets.

Leasing vs. Buying

Acquiring CNC machines can be done through either leasing or purchasing, and each method offers distinct benefits and limitations. Opting to lease allows businesses to utilize the most current technology without a hefty initial outlay, aiding in maintaining liquidity. Leasing grants immediate access to essential machinery and may prove particularly beneficial for companies that frequently update their equipment.

Conversely, owning a CNC machine by outright purchase might lead to cost savings over an extended period due to the advantage of ownership. Despite requiring a considerable upfront financial commitment, buying the equipment provides long-term possession and the possibility of reduced expenses as time progresses. The decision between leasing and purchasing should ultimately be guided by specific business requirements and fiscal strategies.

Available Payment Plans

To cater to the diverse financial circumstances of purchasers, manufacturers typically offer a range of payment options. They frequently allow buyers to distribute their payments over time through flexible payment schedules, which helps lessen the monetary burden associated with acquiring CNC machines.

Certain manufacturers might provide financing that encompasses the entire project cost, including both equipment and ancillary expenditures. This provision affords businesses greater financial freedom and simplifies the process of investing in CNC machines.

Tips for Getting the Best Deal on a CNC Machine

Finding the best deal on a CNC machine requires understanding the market and negotiating effectively. Gathering multiple quotes from various dealers can help you find CNC machines at the best price and ensure you are not overcharged.

Practical buying tips include researching, comparing models, and timing purchases to take advantage of discounts and promotions.

Research and Compare

Thorough research and comparison of different CNC machine models and sellers are crucial for ensuring you find the best price. Investigating market prices and understanding the features and capabilities of various models can help you make an informed decision and avoid overpaying for a CNC machine.

Timing Your Purchase

Acquiring CNC machines strategically timed to coincide with certain periods can result in considerable cost reductions. Dealers are often motivated to offer more favorable deals towards the end of a year as they strive to achieve their sales objectives, making it an optimal time for buyers. Capitalizing on promotional holiday offers or annual clearance events is another effective way to reduce expenditure when investing in these machines.

Similarly, initiating purchases early within the year can be beneficial owing to typically reduced sales activity and vendors’ eagerness to meet fresh budget requirements.

Summary

In summary, grasping the intricacies of CNC machine pricing requires accounting for a multitude of elements such as the machine’s type, size, capacity, brand recognition and any ancillary expenses. Engaging in diligent research and model comparison along with exploring financing options and strategic timing can guide you to make a well-informed purchase that is both budget-friendly and meets your operational requirements. It’s crucial to analyze the advantages versus disadvantages when choosing between new or pre-owned CNC machines to ensure that your investment yields cost-effective results.

Equipped with this expertise, you now have an improved ability to traverse through the intricate marketplace of CNC machines. Leverage these insights strategically to secure optimal deals and invest in machinery that promises to boost your production efficiency while fostering growth within your business domain.

Frequently Asked Questions

Can a CNC machine cut metal?

Yes, a CNC machine can cut metal with high precision and accuracy, making it an effective tool for various metalworking applications.

The specific results depend on the type and hardness of the metal being processed.

Is a CNC business profitable?

Often outperforming many other small ventures in profitability, a CNC business can turn into a lucrative endeavor with proper skills and commitment.

What is the average cost of CNC?

The average cost of CNC machines varies widely, typically ranging from $10,000 to $100,000 depending on the model and capabilities. Entry-level options are suitable for small to medium-sized businesses, while mid-range machines provide enhanced precision.

What factors influence CNC machine prices?

CNC machine prices are primarily influenced by factors such as size, power, cutting speed, precision, materials, brand reputation, software capabilities, and additional features.

Understanding these elements can help you evaluate the right machine for your needs.

What is the price range for CNC routers?

CNC routers generally fall within the price range of $5,000 to $150,000, depending on the quality and features. Understanding your specific needs will help determine the best option for your budget.

Still, need help? Contact Us: [email protected]

Need a PROTOTYPE or PARTS machining quote? Quote now

LKprototype

LKprototype