CNC grinders have revolutionized manufacturing processes by delivering exceptional accuracy and consistent results. These advanced machines are designed to produce smooth surfaces with minimal errors. Industries such as aerospace, automotive, and medical equipment heavily rely on CNC grinders for their ability to handle complex designs and a variety of materials. Operating automatically, CNC grinders ensure uniform outcomes with every use. Their remarkable precision, with errors as small as ±0.001 inches, makes them ideal for creating intricate components that are critical for safety and performance in demanding environments.

Key Takeaways

CNC grinders are very accurate. They make parts with tiny errors, as small as ±0.001 inches. This makes them important for industries like airplanes and cars.

Learning about parts like diamond wheels and strong frames helps us understand how CNC grinders work so well.

Taking care of CNC grinders is important. Check coolants and wheels often to keep them working properly and making good parts.

Smart software and machines make CNC grinding faster and better. This helps make more parts with fewer mistakes, which is important for good manufacturing.

CNC grinding makes surfaces smooth. This helps parts last longer, lowers friction, and stops damage. It’s very important for safety in tough jobs.

Understanding CNC Grinders

What Is a CNC Grinder?

A CNC grinder is a machine that shapes materials precisely. It uses computer controls to automate grinding, making results consistent. Think of it as a computer-guided grinding tool. This lets it create detailed designs and smooth finishes on many materials.

These machines are vital in industries needing exact measurements. They make parts with tight tolerances for aerospace, cars, and medical tools. CNC grinders can remove extra material, polish surfaces, and shape complex designs. Whether working with metal, ceramics, or composites, they ensure every detail is perfect.

Modern CNC grinders have features to improve performance. Cooling systems help manage heat during grinding. Flood coolants use lots of liquid to keep parts cool. Mist coolants use less liquid but still control heat for smaller jobs. Some machines even grind without liquids, using advanced systems to handle heat. These features make CNC grinders flexible and efficient.

Other upgrades, like automation and smart programming, boost efficiency. Automated systems use robots and tool changers to reduce manual work. CAD/CAM software helps plan tool paths for better results. Regular maintenance, like checking coolant and wheels, keeps them running well. Energy-saving parts, like efficient pumps, also make them eco-friendly.

Key Components of CNC Grinders

CNC grinders rely on key parts to work well. Each part helps the machine stay precise and efficient. Here’s a list of important components and what they do:

Component | How It Helps |

|---|---|

Rigidity | Reduces vibration, keeping accuracy high during long jobs. |

Horsepower Driving the Spindle | Handles tough materials while staying precise. |

More Axes for Better Geometries | Makes complex shapes with great accuracy. |

Diamond Grinding Wheels | Perfect for hard materials, giving smooth finishes easily. |

CBN Wheels | Great for tough metals, staying stable under high heat. |

Resin Bond | Flexible and good for smooth finishes with less heat. |

Hybrid Bond | Strong and sharp, balancing cutting speed and finish quality. |

These parts work together to make CNC grinders reliable and precise. For example, rigidity stops vibrations, keeping accuracy during long jobs. Powerful spindles let you grind tough materials without losing precision. Special wheels, like diamond and CBN, handle demanding tasks with ease.

By knowing these parts, you’ll see how CNC grinders achieve such precision. Whether making airplane parts or medical tools, these machines deliver the results you need.

The CNC Grinding Process

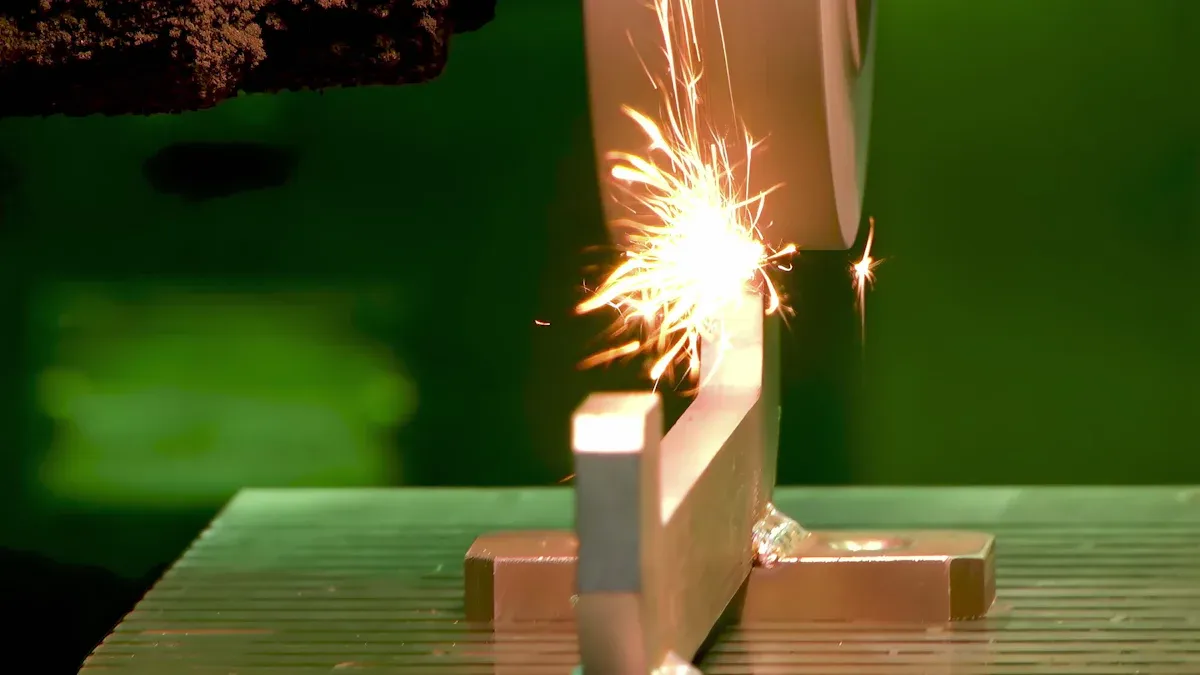

How CNC Grinding Works

CNC grinding turns raw materials into finished parts. It starts with a CAD file that shows the part's exact design. This file is loaded into the CNC grinder, which uses software to plan the best tool paths. The machine follows these steps, grinding the material layer by layer to create the right shape and smooth surface.

Many factors affect how well CNC grinding works. Picking the right grinding wheel is very important. The wheel must match the material's hardness. Adjusting feed rate and speed helps avoid tool damage and overheating. Coolants and lubricants make tools last longer and improve surface quality. Regular maintenance keeps the machine in good condition. Simplifying designs can also make the process faster.

The size of the grinding tool matters too. Bigger tools are sturdier, while smaller ones are better for detailed work. Shorter tools vibrate less, making them more stable. Changing the depth of the cut helps balance tool pressure and surface finish. This ensures both efficiency and quality.

Technologies Enabling Precision

Modern CNC grinders use advanced technology for high accuracy. Sensors and monitoring systems check every part of the process. Adaptive controls adjust settings automatically if materials or conditions change.

Better software and grinding wheels have made CNC grinding faster. Automated systems clean and reshape wheels, saving time and keeping temperatures steady. Continuous dress creep feed (CDCF) grinding reduces wear, allowing longer cuts and shorter cycles.

Automation and smart technology have improved CNC grinding even more. Machines with AI can adjust processes on their own, cutting down mistakes and increasing productivity. These innovations make CNC grinders essential for industries needing detailed designs and exact measurements.

Importance of Precision Surface Finishing

Why Surface Finishing Matters

Precision surface finishing is key to making parts last longer. A smooth surface helps parts work better and stay strong. For example, smoother parts reduce friction, making machines run easier. This also means less wear and tear over time. In industries like cars and planes, even tiny flaws can cause big problems.

Surface grinding protects parts from damage by the environment. A smooth finish stops rust and keeps out moisture and chemicals. This protection helps parts last longer and work better. For instance, car parts with smooth finishes handle heat and dirt better than rough ones.

Different industries show how important surface finishing is. In engines, smoother cylinder bores and piston rings mean fewer repairs. This also makes oil changes needed less often. In tires, smooth finishes stop clumps, making them last longer and work better.

Industry | Example |

|---|---|

Engine Manufacturing | Smoother cylinder bores and piston rings reduce repairs and make oil changes less frequent. |

Tire Industry | Smooth finishes stop clumps in materials, improving tire life and performance. |

Achieving Tight Tolerances with CNC Grinding

CNC grinding is great for making exact parts. It removes material very precisely, so every part fits perfectly. This is important for things like medical tools and airplane parts, where mistakes can’t happen.

Smooth surfaces from CNC grinding stop parts from breaking under stress. For example, gaskets and O-rings seal better with smooth finishes, stopping leaks. Less friction also means machines use less energy and last longer.

CNC grinding also helps parts last a long time. Smooth surfaces wear out slower than rough ones. This keeps parts working well, even in tough conditions. By reducing flaws, parts stay reliable and strong.

New technology makes CNC grinding even better. Smart systems adjust settings automatically to keep results consistent. These tools make CNC grinding a must-have for making high-quality, precise parts.

Applications of CNC Grinding

Industries Using CNC Grinding

CNC grinding is important for industries needing exact and reliable parts. These machines are used where high-quality results are a must. They make parts with tight tolerances and consistent finishes.

Aerospace: Turbine blades and engine parts need perfect shapes. These parts face tough conditions and must work without problems.

Automotive: Pistons and cylinders need smooth surfaces to reduce friction. This helps engines run better and last longer.

Medical Devices: Surgical tools and implants need precise sizes and finishes. This ensures they are safe and work properly.

Energy Sector: Alumina spacers in nuclear plants must be the right size. These spacers keep control rods working safely.

CNC grinders help these industries by working nonstop. This reduces delays and speeds up production. Automation makes work faster and more efficient. Laser systems check parts for accuracy, ensuring high-quality results. These machines can also quickly switch designs when needed.

Examples of Detailed Parts

CNC grinders are great at making detailed parts for advanced uses. Here are some examples of what they can do:

Industry | Example of CNC Grinding Application |

|---|---|

Aerospace | Turbine blades and engine parts for jets needing exact shapes. |

Automotive | Pistons and cylinders for engines to improve performance. |

Medical Devices | Surgical tools and implants with precise sizes and finishes. |

Nuclear Power Plant | Alumina spacers for control rods, keeping them safe and accurate. |

Medical Device | Parts for powered shavers with tight spaces for smooth operation. |

These examples show how CNC grinders handle complex tasks. They make identical parts every time, ensuring reliability. Industries like aerospace and medicine depend on this precision to avoid problems.

CNC grinders also make work safer. Automated systems lower mistakes and improve accuracy. They can shape different materials and designs, making them essential for modern manufacturing.

Advantages of CNC Grinding Machines

Accuracy and Consistency

CNC grinding machines are great at being precise and reliable. They use smart tools like 3D models to find and fix mistakes. This makes sure every part is made exactly right. For example, laser sensors help robots polish parts perfectly. These robots work well even in tough factory conditions, like heat or humidity.

Improvement Type | Description |

|---|---|

Better Accuracy | |

Faster Work | Real-time comparisons make the process quicker and more efficient. |

Works in Tough Places | Laser sensors keep robots accurate in hard factory conditions. |

These tools help make every project super accurate. That’s why CNC grinding machines are so important for jobs needing exact measurements.

Efficiency and Productivity

CNC grinding machines help you get more done in less time. They let you switch tasks quickly, saving hours of work. Their accuracy means fewer mistakes, so you don’t have to redo parts. Easy controls make them simple to use, even for beginners.

Accurate results mean less rework and smoother workflows.

Easy controls make them user-friendly for everyone.

These features help you finish projects faster without losing quality. CNC grinding machines are a must-have for efficient manufacturing.

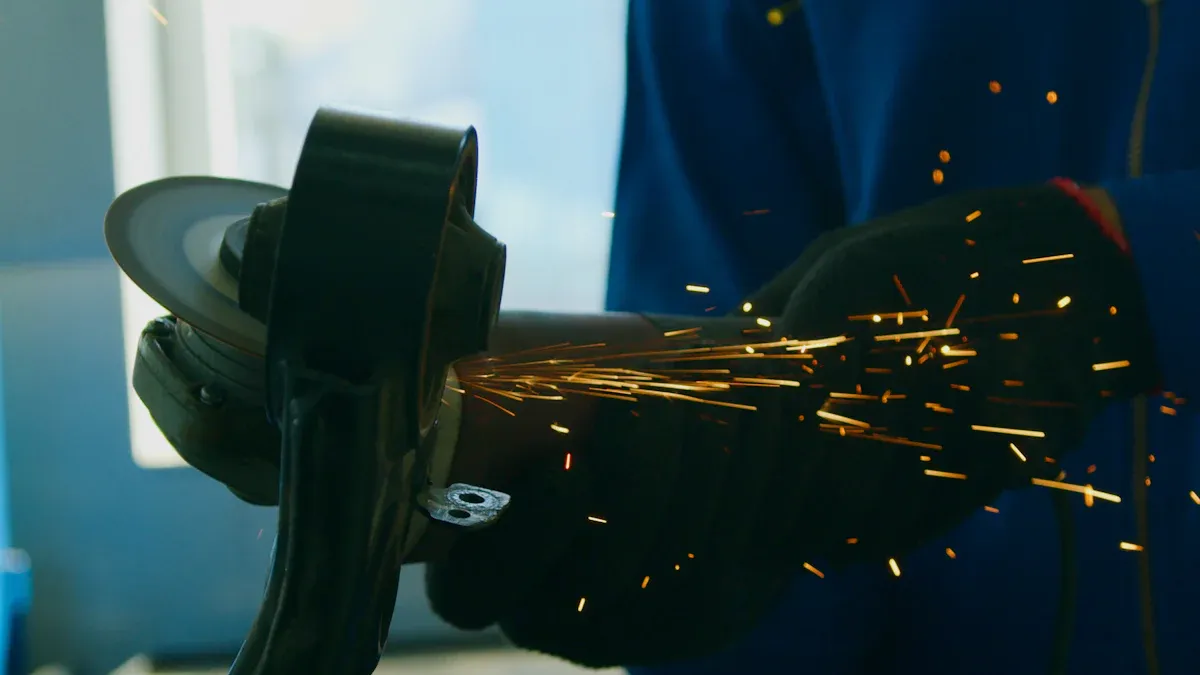

Versatility in Materials and Designs

CNC grinding machines can handle many materials and designs. They work with metals, ceramics, and even soft materials like aluminum. These machines are perfect for making detailed shapes and smooth finishes.

For example, they can polish hard metals like titanium or softer ones like aluminum. This makes them useful for industries like aerospace, cars, and medical tools. No matter the material or design, CNC grinders deliver great results every time.

CNC grinding machines are key tools in today's manufacturing. They help make complex parts with great accuracy and speed. Industries like aerospace and cars depend on them for precise work. By 2033, the market for these machines may grow to $2.1 billion, with a 6.2% yearly growth rate.

Year | Market Value (USD) | Growth Rate (%) |

|---|---|---|

2024 | 1.3 billion | N/A |

2033 | 2.1 billion | 6.2 |

New features like automated grinding and robot systems will improve production. As factories change, CNC grinders will stay important for making top-quality parts.

FAQ

What materials can CNC grinding machines handle?

CNC grinders work with metals like steel, titanium, and aluminum. They also shape ceramics, composites, and softer materials. This makes them useful for aerospace, car, and medical industries.

How do CNC grinders achieve such high precision?

CNC grinders use computers to follow exact designs. Sensors and controls check the process as it happens. These tools ensure accurate results, even for tricky shapes.

Are CNC grinding machines eco-friendly?

Yes, many CNC grinders save energy with special pumps and coolers. These features lower waste and energy use, helping the environment.

Can CNC grinders handle custom designs?

Yes! CNC grinders use software to plan custom shapes. This lets them make unique designs with great accuracy for any project.

How often should CNC grinders be maintained?

Regular care is important. Check wheels, coolants, and lubricants often. Cleaning and inspecting the machine keeps it working well for a long time.

LKprototype

LKprototype