Want to build a CNC machine? This guide to CNC DIY parts covers everything you need, including mechanical components, electronic systems, and more. Find out how to choose the best parts for a reliable and precise machine.

Key Takeaways

Mechanical components, including frames, axis drives, and ways, are essential for building a reliable and efficient CNC machine.

The integration of electronic systems, such as CNC controllers and microcontrollers, is crucial for ensuring precise machine operation and performance.

DIY CNC kits vary in complexity and customization, providing options for all skill levels, from beginners to experienced enthusiasts.

need help? Contact Us: [email protected] Need a PROTOTYPE or PARTS machining quote? Quote now

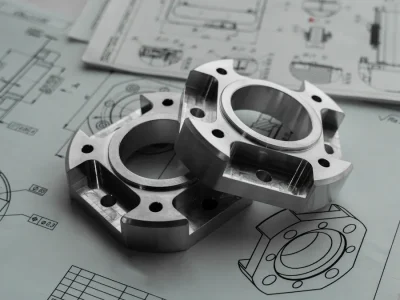

Essential Mechanical Components

The mechanical parts form the crucial support system for a CNC machine, offering the necessary structure, movement capabilities, and precision for precise machining operations. For those embarking on a DIY CNC project, an essential first step is acquiring a comprehensive mechanical kit. These kits typically encompass fundamental components such as the frame of the machine and systems responsible for axis control and guidance.

Choosing suitable mechanical elements can significantly affect your CNC machine’s effectiveness and longevity. Every part contributes distinctly by ensuring stability or enabling fluid and accurate motion throughout its operation.

Outlined below are key mechanical components required to assemble a reliable and high-performing CNC machine.

Frames

The foundation of every CNC machine is its frame, which ensures the necessary stability to resist cutting forces while preserving precision.

The typical materials employed for constructing CNC frames are:

Aluminum extrusions

Aluminum plates

Steel weldments

Wood

Aluminum extrusion stands out as a preferred choice owing to its excellent combination of lightweight properties, versatility, and structural strength. For top-tier performance and robustness in high-end CNC machines, materials such as aluminum and steel are often selected.

The selection of material for a frame hinges on specific requirements. Wooden frames may encounter issues with maintaining accuracy due to potential moisture-induced expansion. In contrast, frames made from aluminum or steel provide enhanced durability and overall superior functionality.

Rigidity within the frame plays an essential role in safeguarding precision during CNC machining processes since any bending could result in errors. Making an investment into a premier-quality frame assures peak performance outcomes.

Axis Drives

The function of axis drives is to transform the rotational movement generated by motors into the necessary linear motion to operate the machine’s axes. There are various types of drive systems such as Rack and Pinion, Ball Screws, C-Beam Actuators, and Leadscrews. Each offers its unique benefits: for instance, Leadscrews provide highly accurate linear motion while Belt and Pulley systems excel in achieving greater speeds.

Selecting an appropriate axis drive system has a significant effect on both the precision and velocity at which a machine operates. Belt-driven mechanisms can reach up to twice the speed that Leadscrew setups can manage, but may sacrifice a bit of accuracy in comparison. To accomplish precise and reliable movements within these systems, stepper motors or servo motors are frequently utilized.

Understanding what each type of drive system brings to the table helps you choose wisely for your CNC endeavor. Recognizing their respective strengths alongside potential drawbacks guides you towards selecting one most suitable for your project’s requirements.

Ways

V-Grooves play a vital role in CNC machines by facilitating the necessary motion and ensuring stability for tasks requiring high precision. These grooves provide an economical sliding mechanism, perfect for smoothly directing movable parts on a CNC machine with straightforward alignment. Round shafts crafted from robust hardened steel offer a slick, enduring surface that boosts the accuracy of CNC machines.

For more challenging applications within CNC operations, linear slides are recognized for their ability to bear substantial loads while maintaining exceptional precision. The implementation of sliding ways is crucial as it permits the movement of the CNC machine with minimal resistance, which results in improved speed and pinpoint machining processes. Choosing appropriate types of ways is essential to greatly enhancing both performance and exactitude in your CNC equipment’s operation.

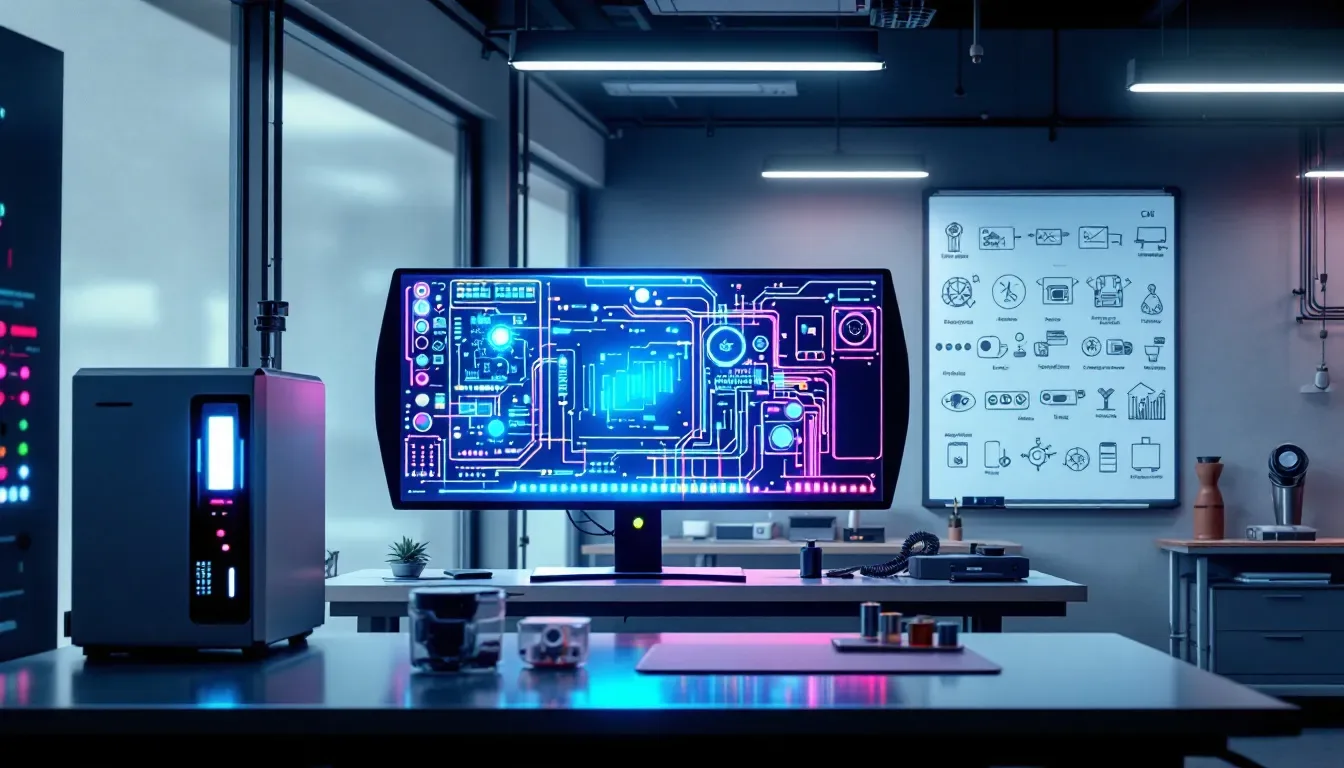

Electronic Systems and Controllers

Incorporating an electronic system into CNC machines is essential for their meticulous functioning. This system orchestrates the various movements and activities of the machine, guaranteeing both precision and productivity during machining processes. The selection of these electronic systems greatly affects how effectively a CNC machine can be controlled as well as its ultimate performance.

To achieve peak performance, it’s important to seamlessly combine electronic systems with the mechanical parts of a CNC machine. Every part, from the CNC controllers down to the microcontrollers and even how wiring is managed, contributes significantly to the operation. Here are those key components described more thoroughly.

CNC Controllers

CNC controllers serve as the central intelligence of CNC machines, guiding their movements and functions according to preset commands. Tormach’s PathPilot is favored by many in the CNC community for its accessible interface that simplifies machine control. GRBL has gained traction as an open-source platform commonly employed by hobbyists and those with small-scale commercial projects.

The xPRO V5 caters to novices due to its straightforward design, running on a robust 32-bit architecture. Alternatives like UCCNC and Mach3 are also noteworthy for offering a comprehensive environment tailored for controlling CNC machines.

Choosing an appropriate CNC controller that aligns with one’s individual requirements and skill level is crucial for achieving efficient operations of the machinery.

Microcontrollers

Microcontrollers are essential for governing the functions of a CNC machine. Kits featuring AVR microcontrollers serve as a welcoming gateway for individuals with foundational programming knowledge, making them particularly suitable for beginners in CNC control. Conversely, ARM microcontroller kits attract those who demand superior features and performance, appealing more to seasoned users.

Selecting an appropriate microcontroller kit can greatly influence both user-friendliness and the capabilities of your CNC device. Microcontroller solutions are available that cater to various degrees of proficiency and requirements, whether one is just starting out or has advanced experience in using CNC machines.

Wiring and Cable Management

Maintaining an organized arrangement of cables within CNC machines is crucial to avert damage and keep the cables orderly. Implementing cable drag chains can efficiently organize the wires, significantly reducing the likelihood of them becoming tangled while the machine is in use. By adhering to effective cable management methods, you can prolong the operational life of electrical components found in these CNC machines.

Ensuring that DC power supply units are installed correctly and that cables are neatly arranged enhances both safety and productivity for your CNC machine. Adequate cable management helps avoid possible complications and guarantees seamless operations for the machinery.

Spindles and Cutting Tools

At the core of CNC machines lies the critical combination of spindles and cutting tools, which perform essential machining and cutting functions. The main role of a spindle is to spin the cutting tool at significant velocity, enabling it to shape material with accuracy. Given their enhanced capabilities over routers and trimmers, spindles are often favored for a multitude of CNC tasks.

The selection process for an appropriate spindle and corresponding cutting tool is pivotal in achieving the required level of precision and surface quality in your workpiece. There’s a spectrum from high-frequency spindles down to conventional routers available on the market. Your choice should be informed by what exactly suits your specific operational demands and types of projects you undertake.

Types of Spindles

Spindles that operate at high frequencies offer improved efficiency and produce less noise than conventional routers, making them well-suited for a wide range of CNC applications. These spindles are capable of sustaining their torque even at reduced RPMs, which is particularly advantageous for heavy-duty operations, ensuring enhanced performance during strenuous tasks.

Superior-grade spindles deliver more robust performance along with sophisticated capabilities that enhance the efficacy and accuracy of a CNC machine. Understanding the various spindle types available and their respective advantages is crucial when selecting the most appropriate one for your specific project needs.

Router Options

In the realm of woodworking, it is advisable to employ a standard CNC endmill when operating with CNC routers. It’s essential to assess various router choices for these machines by considering both their price and power specifications.

Understanding the assortment of available routers and their specific uses can assist in choosing wisely. There are suitable alternatives tailored for either intricate engraving or robust cutting tasks, depending on your requirements.

Hold Down Clamps

Clamping devices for holding down are indispensable in the realm of CNC routing, serving to secure workpieces steadfastly as they undergo the machining operation. By solidifying materials firmly, these clamps not only advance precision but also fortify safety by mitigating the potential for shifts that could cause deviations from accuracy. Within this context, limit switches are pivotal, offering crucial positional feedback regarding the placement of these clamps.

The use and integration of superior hold-down clamps can markedly elevate both performance levels and safety measures on a CNC machine. These essential components play a key role in realizing precise outcomes consistently across various CNC machining endeavors.

Workholding Solutions

Securing the workpiece is vital during CNC machining to ensure stability and precision. Tables for CNC routers are constructed from a range of materials, such as aluminum, MDF, steel, wood, and phenolic. For increased stability, premium CNC router tables often utilize sturdy materials like aluminum, steel or phenolic.

Choosing an appropriate workholding solution is essential for maintaining accuracy while the machine operates. The selection includes diverse options like T-Tracks, vacuum tables and spoil boards to match your particular requirements and uses within various applications.

T-Tracks

T-Tracks play a pivotal role in CNC router tables as they provide the necessary means to firmly hold different workpieces in place while being machined. The 500mm T-Track, specifically, delivers an array of options for affixing hold-down clamps which are vital for maintaining the stability of workpieces throughout the machining process.

Incorporating top-notch T-Tracks into your CNC machine significantly boosts both its accuracy and adaptability. These tracks are instrumental in obtaining precise and uniform outcomes across various machining projects.

Vacuum Tables

Vacuum tables serve as a reliable method for firmly securing flat sheet materials in place while performing CNC tasks. They employ a vacuum to keep workpieces steady, which facilitates the machining of intricate designs and slender materials with efficiency.

Especially advantageous for thin or non-standard shaped materials, these tables are designed to prevent any shifting during the milling process. Utilizing a top-tier vacuum table can substantially enhance both the precision and overall performance of your CNC machine.

Spoil Boards

Protecting the table surface of a CNC router from harm is achieved through the use of spoil boards, which also serve to stabilize the workpiece. Consistency in results is maintained by frequently leveling and flattening these spoil boards to preserve an even cutting area.

To secure optimal performance and extended lifespan for your CNC machine, it’s vital to choose and uphold proper care for suitable spoil boards. These elements are essential for achieving accuracy and uniformity across machining tasks.

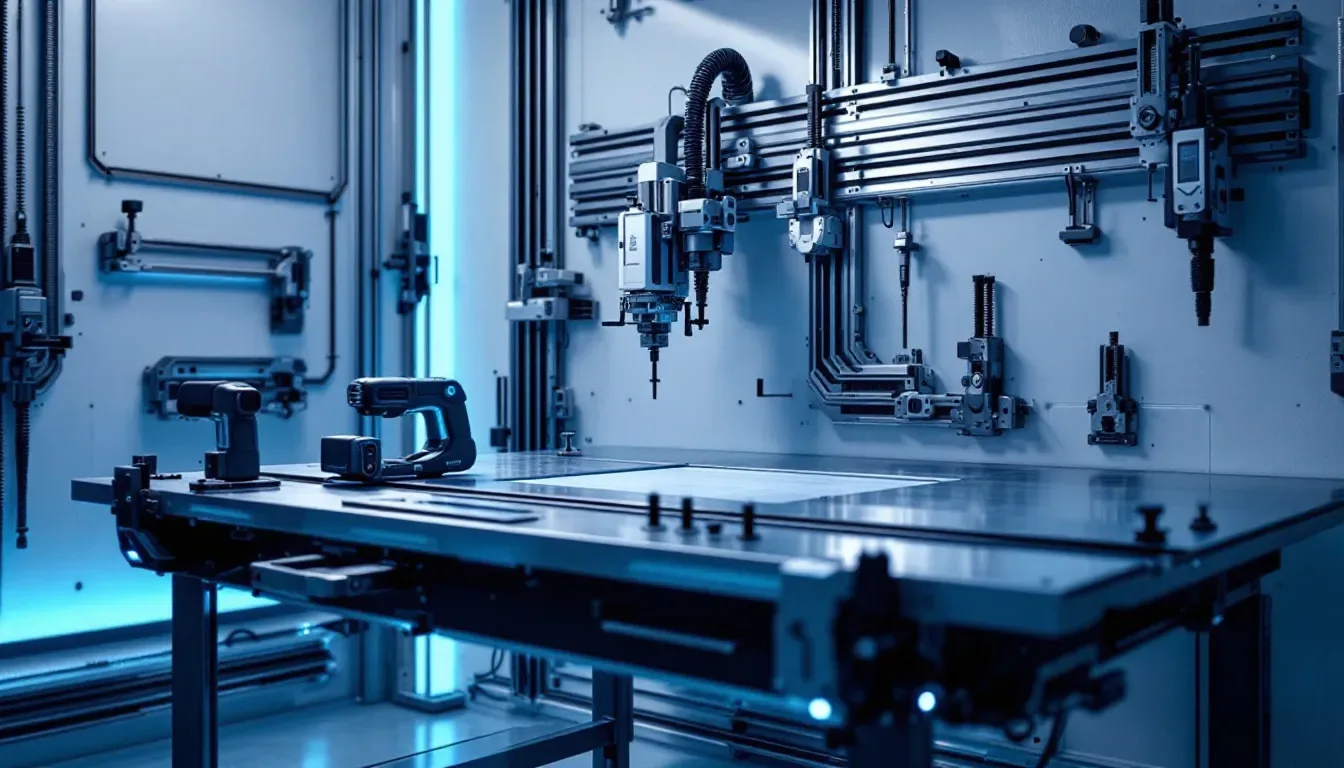

DIY CNC Kits

DIY CNC kits provide a practical and economical solution for constructing your personal CNC machine, accommodating various degrees of proficiency. These kits enable users to select one that aligns with their skill set, whether they are novices or seasoned aficionados in the realm of CNC.

The range spans from basic mechanical kits to fully tailored and comprehensive packages, presenting an array of choices to consider. Each kit variant brings distinct advantages to the table, facilitating a smooth initiation into the world of CNC for enthusiasts embarking on this venture.

Mechanical Kits

Mechanical kits, comprising pivotal elements like frames and axis drives, are crucial for constructing CNC machines. The selection of drive and transmission options within these kits plays a significant role in determining the precision and functioning capabilities of the machines.

Selecting an appropriate mechanical kit that aligns with the intended drive type and desired level of accuracy is vital to optimizing your CNC machine’s performance. It’s important to have a thorough understanding of the various mechanical components required when assembling a machine designed for either high-precision tasks or swift operations, ensuring its reliability and efficacy.

Complete CNC Kits

Complete CNC kits consolidate all the crucial parts needed for a DIY project, facilitating the construction of machines with ease for hobbyists. The kits are comprehensive, encompassing everything from mechanical pieces to electronic elements, allowing for a more efficient assembly experience.

By offering complete CNC kits that guarantee component compatibility and minimize the time spent hunting down separate parts, assembling these machines becomes less complicated. This method is especially advantageous for those new to CNC machine creation as it offers an all-inclusive package addressing every aspect of putting together a CNC machine.

Customizable Kits

CNC kits that are customizable provide the adaptability necessary for users to combine different components in accordance with the demands of particular projects. Such kits are perfect for skilled individuals who seek to modify their CNC machine according to exacting standards and special use cases.

By choosing from a range of components and setups, these customizable kits enable the construction of a machine tailored to meet specific needs. This customization capacity guarantees that the performance and precision of your CNC machine will be ideal when tackling an extensive variety of tasks.

Summary

Crafting an ideal CNC machine necessitates meticulous selection of every single element. The structure’s robustness, dependable axis drives, advanced electronic configurations, and exact spindles all contribute significantly to the overall functioning of the machine. Properly selecting and amalgamating precise mechanical kits with high-accuracy electronic systems is key to ensuring smooth and effective operation of your CNC device.

Selecting either complete mechanical kits or tailor-made options can make for a fulfilling DIY CNC endeavor. Armed with insights from this guide, you’re ready to embark on assembling a CNC apparatus tailored to your unique requirements, boosting your machining prowess in the process.

Frequently Asked Questions

What materials are commonly used for CNC machine frames?

Frames of CNC machines are typically made using materials like aluminum extrusions, plates of aluminum, steel, and wood. Aluminum is frequently chosen due to its excellent combination of low weight, adaptability, and rigidity.

What are the benefits of using high-frequency spindles in CNC machines?

Compared to conventional routers, high-frequency spindles deliver greater efficiency and operate more quietly, making them an excellent choice for diverse CNC tasks. This improved performance significantly boosts the quality and precision of machining processes.

Why is effective cable management important in CNC machines?

Effective cable management is crucial for preventing damage and ensuring organization of cables, which ultimately extends the lifespan of electrical components in CNC machines.

This attention to detail can enhance both safety and efficiency in operations.

What are the advantages of using vacuum tables in CNC operations?

Vacuum tables greatly improve CNC processes by firmly securing flat sheet materials, reducing motion and enabling detailed machining with high precision.

This stability leads to enhanced quality and productivity in the manufacturing workflow.

How do complete CNC kits benefit beginners?

Complete CNC kits offer beginners the advantage of having all necessary components in one package, ensuring compatibility and simplifying the assembly process.

This not only saves time, but also enhances the overall learning experience.

LKprototype has many years of experience manufacturing prototype parts for clients in the aerospace, automotive and consumer electronics industries, among others. Please contact us for a quick quote on any project.

Still, need help? Contact Us: [email protected] Need a PROTOTYPE or PARTS machining quote? Quote now

LKprototype

LKprototype