5 axis CNC routing transforms modern manufacturing by allowing the creation of complex geometries with high precision. Unlike the more common 3-axis CNC machines, 5-axis CNC routers offer two additional rotational movements, enabling the cutting tool to approach the workpiece from virtually any angle. This capability results in superior machining efficiency and precision, especially beneficial for industries like aerospace and automotive where intricate designs are essential.

Key Takeaways

5-axis CNC routing provides enhanced precision and efficiency by allowing simultaneous machining of multiple surfaces, reducing production time and minimizing the need for workpiece repositioning.

Key features such as continuous C-axis rotation, automatic tool changers, and advanced capabilities like volumetric laser compensation significantly improve productivity and precision in complex machining tasks.

5-axis CNC routers are essential across multiple industries, including aerospace, automotive, and medical device manufacturing, where high precision and intricate designs are critical for product quality and compliance.

Understanding 5 Axis CNC Routing

A 5-axis CNC machine represents a significant advancement in the realm of manufacturing, enabling the creation of detailed and complex shapes with high-level accuracy. In contrast to standard 3-axis CNC machines that operate along three linear axes, these advanced machines incorporate two extra axes of rotation (referred to as A and B), providing unparalleled versatility. This allows the tooling mechanism access to nearly any angle relative to the workpiece, thus facilitating machining processes for sophisticated geometries previously considered unattainable.

The quintuple movements inherent in a 5-axis CNC process afford manufacturers enhanced capabilities leading to improved outcomes using fewer setup phases. By mitigating the frequency at which it is necessary to reorient the workpiece within this machinery type, 5 axis CNC technology streamlines production workflows while boosting both precision levels and operational efficiency. Such technological innovation has become crucial across various sectors, demanding precise detail and intricate design execution. Consequently, transforming what can be achieved within contemporary manufacturing practices.

Key Benefits of 5 Axis CNC Machines

5-axis CNC machinery offers a multitude of advantages, notably their exceptional precision and operational efficiency in the realm of machining. Their primary strength lies in their capacity to concurrently machine various surfaces on a workpiece, dramatically decreasing the necessity for multiple setups and consequently conserving critical manufacturing time. This feature, paired with strategic cutting tool positioning, facilitates faster production velocities while boosting overall productivity.

These machines are adept at fabricating intricate shapes and configurations with advanced drilling functionality that permits access to more acute angles—yielding parts of superior quality. The integration of extra axes plays a vital role too by refining surface finishes through diminished machining vibrations—a key aspect for sectors requiring strict five-axes precision standards.

Industries such as aerospace or automotive that demand meticulous component fabrication stand to greatly enhance their production capabilities by harnessing 5-axis CNC technology’s sophisticated abilities.

Applications of 5 Axis CNC Routing

The use of 5-axis CNC machines spans a vast range of industries, where they play a crucial role in improving both precision and efficiency. Industries such as aerospace and woodworking benefit greatly from these machines’ ability to craft complex geometries with minimal setups, rendering them an essential part of the manufacturing process.

In areas demanding high levels of accuracy and intricate designs, 5-axis CNC routing is vital. It enables the swift production of complicated shapes, establishing itself as an indispensable tool within sectors that prioritize detail and sophistication in their outputs.

Aerospace Components

In the field of aerospace manufacturing, the utilization of 5-axis CNC machines is crucial for creating parts like engine components, landing gear, and fuselage sections. These machines possess the capability to craft complex geometries with elevated precision, providing expansive design versatility while guaranteeing that every component adheres to the stringent quality demands specific to aerospace uses.

The integration of this technology significantly improves both efficiency and product quality within aerospace production processes. It has become an indispensable instrument in this industry due to its superior functionality and output standards.

Composite Material Machining

Machining composite materials is a domain where 5-axis CNC machines excel, as they meet the specific demands these materials present. To effectively work with composites and maintain the required precision and durability throughout the machining process, it’s critical to use specialized tools.

Models such as Denali5, Mammoth5, and Everglade5 stand out in their ability to handle an extensive variety of materials beyond just composites—like wood, foam, and metals. The adaptability offered by these 5-axis CNC routers renders them indispensable across various industries that prioritize precise outcomes and flexibility in material usage.

Woodworking Projects

Within the woodworking industry, machines known as 5-axis CNCs unveil unprecedented opportunities for crafting intricate and tailor-made designs that traditional tools might struggle to accomplish. These advanced technologies afford craftsmen the capability to realize their most complex visions with intricate carvings or elaborate joinery due to the precision and versatility inherent in 5-axis CNC machining.

Not only does this technology elevate the caliber of finished pieces, but it also substantially diminishes the time and labor necessary to complete sophisticated woodworking endeavors.

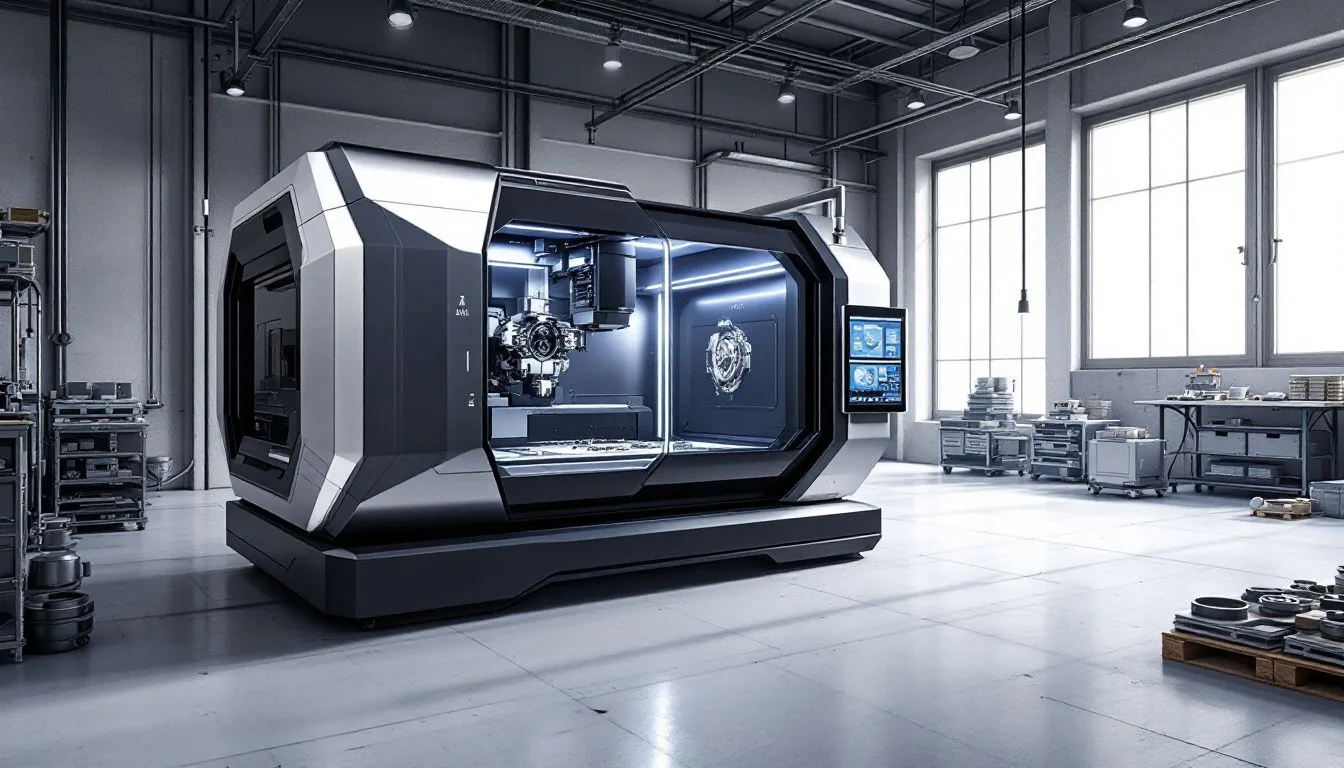

Essential Features of 5 Axis CNC Routers

Key attributes of 5-axis CNC routers significantly enhance their efficiency and versatility in use.

The longevity and reliability of the router are bolstered by a sturdy machine body typically constructed from precision-welded steel, promoting an extended operational lifespan.

For instance, the G-Series 5-axis CNC machines boast a robust build that includes:

A base made from precision-welded steel

A column crafted with precision-welded steel

A bridge composed of precision-welded steel

An expertly welded gantry also comprised of steel

This firm construction plays an essential role in preserving both stability and pinpoint accuracy during intricate machining operations.

Contemporary 5-axis CNC routers. Come equipped with user-friendly control panels such as standard FANUC® interfaces or interactive touchscreen displays. These advanced control systems enable varying processing speeds for controls, thus elevating both the quality and speediness of machining processes.

These vital characteristics synergistically improve the router’s ability to execute elaborate tasks more accurately and swiftly, rendering them indispensable tools across diverse manufacturing sectors.

Continuous C-Axis Rotation

Unhindered rotational movement of the C-axis is a crucial aspect of 5-axis CNC routers, as it permits the C-axis to rotate continuously. This characteristic is vital because it removes the necessity for conventional 5-axis spindles to reset their position after completing rotations, which in turn augments efficiency in machining processes by diminishing idle periods.

The capacity for constant rotational motion substantially increases both productivity and precision, rendering continuous C-axis rotation an indispensable attribute when executing intricate machining operations.

Automatic Tool Changers

In CNC machining, automatic tool changers are instrumental in swiftly and effortlessly swapping between various tools, which greatly diminishes downtime for the machine. This capability considerably accelerates the machining process and boosts efficiency. Automatic tool changers contribute to heightened productivity by ensuring that tool transitions do not disrupt the continuous flow of the machining operation.

Pendulum Processing

In environments where high-volume production is imperative, pendulum processing stands out as a highly beneficial feature due to its capacity for swift program continuation. This attribute ensures that the machine can alternate between two work zones while maintaining uninterrupted operations in the production process.

Consequently, this method markedly boosts efficiency and productivity within machining activities. For scenarios requiring substantial output, the inclusion of pendulum processing becomes an essential component.

Choosing the Right 5 Axis CNC Router

When choosing the appropriate 5-axis CNC router, it’s essential to take into account several elements including the size of your workpiece, your demands for precision and speed, as well as financial limitations. Grasping these components is vital for enhancing your machining activities and confirming that your investment aligns with your production objectives.

By examining the machine’s capabilities and weighing its cost efficiency, you will be positioned to make a knowledgeable choice that can lead to superior outcomes in your manufacturing operations.

Workpiece Size Considerations

When selecting a 5-axis CNC router, it’s crucial to take into account the dimensions of the workpieces you intend to process. Implementing features such as the quick-change fixture system found on routers like Denali5 can drastically improve efficiency in handling materials. By utilizing volumetric laser compensation that adjusts for mechanical and thermal deviations, precision across all axes is preserved.

To maximize your machining operations with an axis cnc router, ensure that it can proficiently handle various sizes of workpieces. This adaptability is essential for optimizing your production processes.

Accuracy and Speed Requirements

When choosing a 5-axis CNC router, it’s essential to consider both precision and high speed as vital elements. The degree of accuracy required can differ based on the particular project at hand, with various applications necessitating distinct levels of precision and capability for swift operation.

To boost the accuracy of such machines, CNC Volumetric Compensation is employed to adjust for possible deviations throughout the machining process. This assists in fabricating components that adhere to precise specifications. Probing systems are instrumental in verifying dimensional precision prior to commencing machining work—this ensures adherence to elevated standards of consistency.

Budget and Cost Efficiency

When considering the acquisition of a 5-axis CNC router, it’s crucial to weigh the upfront cost against ongoing operational expenses. Although opting for a higher-grade router may come with a steeper purchase price, its superior efficiency and robustness can lead to decreased expenses over time. Carefully comparing various models and their costs is essential for aligning with both your financial constraints and production needs while ensuring consistent reliability and enhanced productivity.

Improving cost effectiveness also entails aspects like diminishing waste, conserving energy, and expediting production cycles. Opting for features such as automated tool changers in your CNC router can Elevate productivity levels while reducing idle times – all contributing significantly to heightened cost effectiveness.

Ensuring regular upkeep and available support plays an integral role in maximizing both the functional lifespan of your investment and its performance capabilities—thereby mitigating expenditure over extended periods.

Maintenance and Support for 5 Axis CNC Machines

Regular upkeep and strong support from the manufacturer are crucial for preserving the exactitude of 5-axis CNC machinery. When investing in such machines, it’s vital to have thorough warranty services and support available, as these help maintain continuous dependability and productivity within your operations.

Ensuring that these machines stay in peak condition is key to reducing any potential halts in production while upholding the stringent quality necessary for intricate machining processes.

Regular Maintenance Practices

Ensuring the durability and efficiency of 5-axis CNC machines is essential, which can be achieved through consistent maintenance practices. By conducting routine inspections on all moving parts, it’s possible to detect and rectify issues early on before they escalate into major complications. Adequate lubrication of these components is equally crucial to minimize wear and guarantee smooth operation, thereby maintaining the machine’s optimal performance for an extended period.

Importance of Manufacturer Support

Having solid backing from the manufacturer is essential for efficient problem-solving and continuous maintenance aid. Opting for a CNC router with strong support from its maker guarantees that problems can be resolved swiftly, which minimizes interruptions and enhances overall productivity.

Continuous assistance from manufacturers is equally vital in preserving the machine’s operational efficiency and extending its lifespan, making it an important consideration when deciding on your investment.

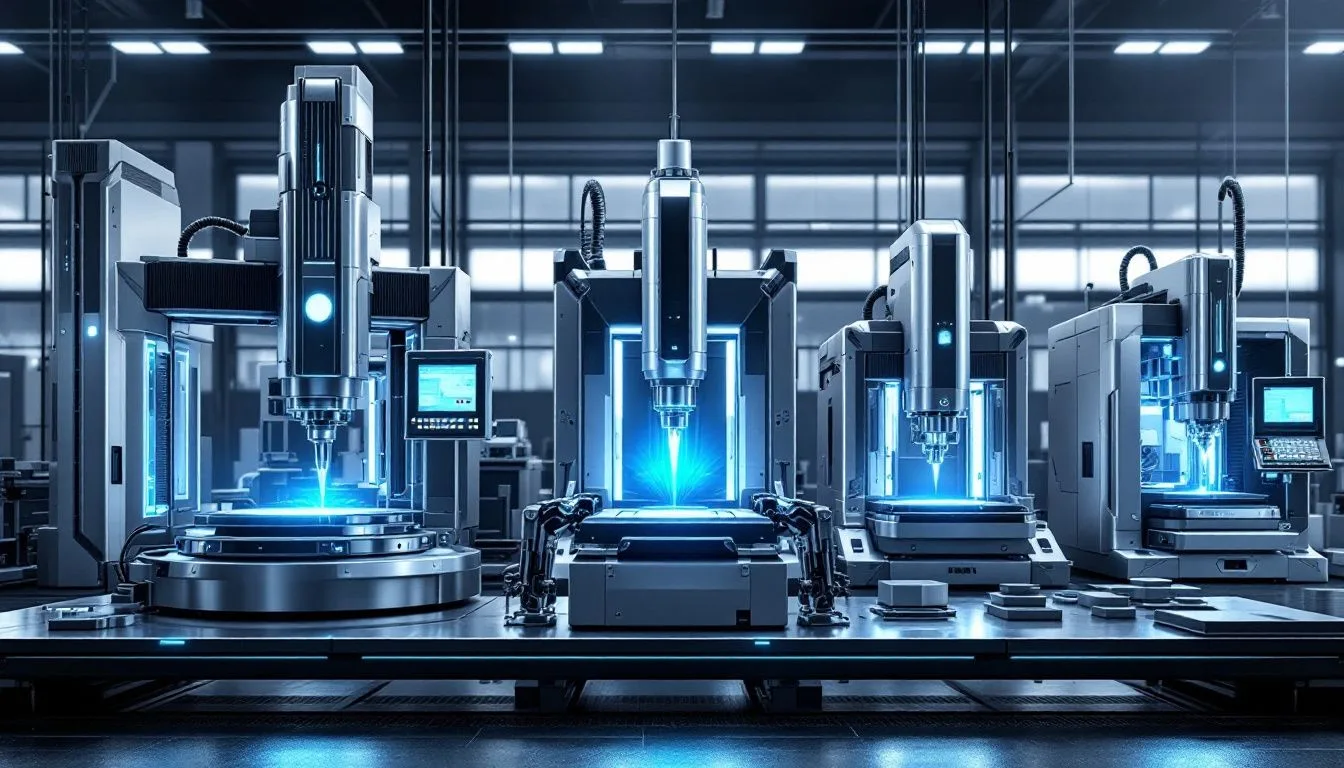

Advanced Capabilities of Modern 5 Axis CNC Machines

Contemporary 5-axis CNC machines possess advanced features that bolster both accuracy and efficiency during machining processes. Notably, machines such as the Yellowstone5 are outfitted with a universal fixture table, enabling them to execute various tasks continuously without pausing production.

Such enhanced capabilities empower manufacturers to attain an unmatched level of precision and productivity, ensuring they can effortlessly tackle even the most intricate machining operations.

Volumetric Laser Compensation

Laser volumetric compensation represents an advanced technology designed to autonomously calibrate tools used in machining and execute requisite modifications for sustaining high precision. This capability is exceedingly advantageous in scenarios where stringent tolerances are mandated, guaranteeing that the machine preserves a heightened level of accuracy during the entire production cycle.

By integrating laser compensation along with linear scales into their processes, manufacturers can achieve uniformly accurate outcomes reliably, even within challenging environments that involve intensive machining tasks.

Integrated Probing Systems

Probing systems integrated into the machining process are crucial for sustaining uniform accuracy in part dimensions. They facilitate instantaneous modifications to part origins and perform quality assessments during the process, guaranteeing adherence to predetermined criteria for each component.

The practice of gauging within the process, made possible by these probing systems, allows for ongoing quality monitoring. This substantially improves both the dependability and the exactness of the end product.

Industries Benefiting from 5 Axis CNC Routing

A multitude of industries, such as aerospace, automotive, and medical device production, reap the advantages offered by 5-axis CNC machines’ versatility and precision. The adoption of these advanced machines is on the rise across different sectors for improving the creation of complex components that require high precision.

Industries are tapping into the capabilities provided by axis cnc machinery to realize significant advancements in efficiency, quality, and the intricacy of designs.

Automotive Industry

In the realm of automotive manufacturing, 5-axis CNC machines play a pivotal role in fabricating complex components that conform to stringent precision criteria. These machines’ ability to sculpt intricate geometries with outstanding accuracy is essential for ensuring both vehicle performance and safety.

The deployment of 5-axis CNC machinery allows car producers to forge parts that comply with rigorous quality demands. This boosts not only the dependability but also the efficiency of their production processes, resulting in enhanced overall production standards.

Medical Device Manufacturing

The manufacturing of medical devices places a significant emphasis on the use of 5-axis CNC routing, which is instrumental in fabricating complex components with high precision that are vital for their dependable operation. This technology facilitates the production of detailed items, including surgical instruments and implants, that require adherence to precise specifications and elevated levels of accuracy.

In guaranteeing that every component conforms to stringent standards regarding accuracy and biocompatibility, 5-axis CNC routing becomes an essential element in maintaining both the safety and functionality of medical devices.

Surface Treatment Options for CNC Prototypes

Enhancing both the aesthetics and longevity of CNC machined components is crucial, which can be achieved through various surface treatment techniques. Options such as anodizing, sandblasting, electroplating, and polishing provide distinct benefits. For example, anodizing heightens resistance to corrosion and polishing improves the overall surface finish. These processes are essential in producing high-quality CNC prototypes.

Choosing the right surface treatment is key for ensuring that CNC machined parts fulfill their intended aesthetic appeal as well as functional demands.

Summary

To summarize, the advent of 5-axis CNC machines has revolutionized manufacturing by delivering unmatched precision and streamlining production processes. These machines come equipped with innovative features such as perpetual rotation on the C-axis and automated tool changing systems, alongside sophisticated elements like volumetric laser adjustments and comprehensive probing configurations. They are employed across a diverse spectrum of sectors including but not limited to aerospace, automotive, and medical equipment creation due to their critical role in achieving high-level accuracy and production efficiency.

When considering acquiring a 5-axis CNC router, it is imperative to evaluate aspects like the dimensions of the workpiece you intend to fabricate, specific needs for accuracy versus speed ratios as well as fiscal limitations. Ensuring consistent maintenance coupled with strong backing from manufacturers is vital for prolonging machine life span while maintaining peak performance levels. Capitalizing on what 5-axis CNC routing offers allows businesses to substantially enhance quality control within productions along with optimizing operational efficacy and elevating intricacy in design engineering—empowering your enterprise’s manufacturing segment towards groundbreaking growth and supremacy in craftsmanship standards.

Frequently Asked Questions

How much does 5-axis CNC machining cost per hour?

The cost of 5-axis CNC machining typically ranges from $75 to $125 per hour. This pricing reflects the advanced capabilities and precision of 5-axis machining.

What are the disadvantages of a 5-axis CNC machine?

The primary disadvantages of a 5-axis CNC machine include its high cost and the necessity for advanced programming skills.

These factors can pose significant challenges for users, limiting accessibility and usability.

What is the 5-axis CNC coordinate system?

The 5-axis CNC coordinate system enhances machining capabilities by allowing tools to move simultaneously around five axes—X, Y, Z, A, and B—enabling access to five sides of a part without requiring additional setup or repositioning.

This advanced technology significantly improves efficiency and precision in manufacturing.

What is a 5-axis CNC router?

A 5-axis CNC router is a machine that maneuvers a tool in five different directions (X, Y, Z, A, and B), allowing for comprehensive part machining in a single operation. This capability streamlines the process by eliminating the need for manual repositioning of the workpiece.

What are the key benefits of 5-axis CNC machines?

Machines utilizing 5-axis CNC technology deliver unmatched precision and increase production velocity by minimizing the necessity for repositioning. Consequently, they improve drilling efficiency and yield smoother surface textures.

Still, need help? Contact Us: [email protected]

Need a PROTOTYPE or PARTS machining quote? Quote now

LKprototype

LKprototype