Share a little biographical information to fill out your profile. This may be shown publicly.

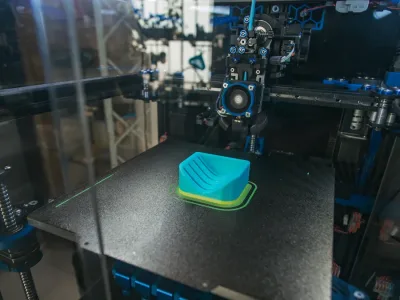

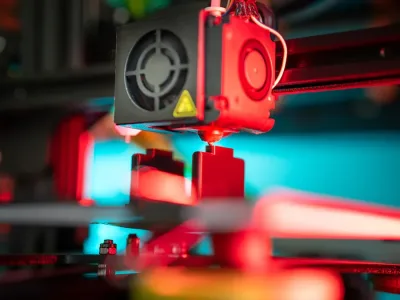

Additive manufacturing process involves creating objects by adding layers based on digital plans. Today, companies use this additive manufacturing process to produce car parts and medical tools. Imagine a designer with a new product idea—this additive manufacturing process allows them to quickly test models. They can begin mass production much sooner than before. Nearly 70% lower prototyping costs help companies save money. Lead times shrink from weeks to days, enabling faster responses. Up to 90% less wasted material benefits the environment. Every step in the additive manufacturing process is crucial. Designers select the best materials and settings to ensure parts…

You need to understand the contract manufacturing process to see how it works. Contract manufacturing is when you allow another company to produce your product. You provide your product design and requirements to the contract manufacturing company, and they handle the production for you. This contract manufacturing process helps many businesses save money and operate more efficiently. The table below shows that contract manufacturing is expanding worldwide. Metric/SegmentValue (2023/2024)Projected Growth/NotesGlobal contract manufacturing marketUSD 334.09 billion (2023)CAGR 9.32% (2024-2031), projected USD 676.76 billionPharmaceuticals & biopharmaceuticals32.35% market share (2023)Expected USD 225.24 billion by 2031End-to-end manufacturing segmentUSD 141.17 billion (2023)Highlights efficiency via integrated…

You can make your manufacturing work better by using five steps in the lean manufacturing process: Identify value Map the value stream Create flow Establish pull Pursue perfection Lean manufacturing is about getting rid of waste in the process. When you use lean principles, you remove waste, make more products, and work faster. Think about how each step helps you cut waste and get the most value in your work. Key Takeaways Lean manufacturing helps you get rid of waste. It lets you focus on what your customer wants most. Mapping your process helps you see slow or extra steps.…

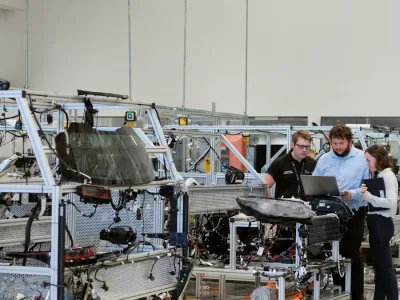

The manufacturing process means changing raw materials into products people can use. Manufacturing is very important for all industries. Factories and workers take materials, make parts, and build things people need every day. Manufacturing turns simple things into complex items like cars, phones, and furniture. People need manufacturing for jobs, new ideas, and a strong economy. Each type of manufacturing has its own steps and tools. Learning about manufacturing helps people see how products get to stores. Today, technology gives new machines and ideas to manufacturing, making things faster and smarter. Key Takeaways Manufacturing turns raw materials into useful products…

You can pick from many top moldable plastic materials for vacuum casting. These include urethane resins, ABS-like materials, polycarbonate-like materials, silicone rubber, and epoxy materials. Each moldable plastic material helps you make high-quality prototypes and end-use parts. Many engineers use vacuum casting to test design and function before using plastic injection molding resins. Studies show that picking the right materials for vacuum casting affects the quality of prototypes, casting performance, and product design. The common materials used in vacuum casting help you get accurate casting results for many uses. Key Takeaways Vacuum casting uses plastics like urethane, ABS-like, polycarbonate-like, silicone…

If you want to learn how to make mold 3d model for vacuum casting, you can follow some simple steps and guidelines. Start by creating a 3d model, as this is the foundation for how to make mold 3d model. Pay close attention to the mold design to ensure you can easily remove the finished part. The process of how to make mold 3d model involves having a precise model, careful mold making, and proper casting techniques. Many people achieve consistent and repeatable results by using this method. For instance, silicone molds made from a 3d model can be reused…

Choosing between vacuum casting and low volume injection molding depends on your specific needs for small batch production. Vacuum casting has a lower initial cost and allows for easier design changes. On the other hand, low volume injection molding produces parts faster and offers a lower cost per part when producing larger quantities. The table below highlights the key differences: FeatureVacuum CastingLow Volume Injection MoldingSetup CostLow to moderateHigher upfrontPer-Unit CostHigher at scaleLower with volumeLead TimeShorterLonger setup, faster cyclesTool LifeUp to 200 partsUp to 50,000 shots Key Takeaways Vacuum casting works well for small groups and fast samples. It costs less…

Metal injection molding combines fine metal powders with binders to form precise shapes, making it a key process for producing accurate components. This technique is essential for manufacturing small, complex parts with tight tolerances and high strength. Many industries rely on metal injection molding to produce millions of intricate parts each year. The table below highlights the expanding market for metal injection molding, reflecting its growing importance in high-volume production: Market StatisticValueSignificanceMarket size in 2024USD 5.75 billionThere is a big need for exact partsExpected market size by 2030USD 11.09 billionMore people are using metal injection moldingCAGR 2024-203011.6%It is growing fast…

You may ask, is it moulding or molding that is correct? Both spellings are right, but it depends on where you are. In the United States, people use molding, while in the UK, Canada, and Australia, moulding is preferred. This difference arose after American dictionaries updated the spelling. The meaning remains the same for both terms, so choose the one your readers are familiar with. When you wonder, is it moulding or molding, simply pick the spelling that fits your audience best. Key Takeaways Both 'molding' and 'moulding' have the same meaning. The spelling changes by where you live. Use…

You may see two ways to spell this word: molding or moulding. In the United States, people use "molding" for most manufacturing words. In the United Kingdom and other places, "moulding" is the usual spelling. This difference is important at work. Studies show that spelling mistakes can make people think you are less skilled. They may also think you do not pay close attention, even in manufacturing jobs. In manufacturing, molding or moulding means shaping things like plastic or metal. You do this by pressing the material into a mold. This process helps make many parts and products. Key Takeaways…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.