Acrylic CNC service uses computer-run machines to cut or shape acrylic. These machines can also engrave designs with great accuracy. This method makes sure the work is neat and allows for detailed designs. Many industries, like signage and manufacturing, use this service because it is fast and flexible.

The world market for acrylic edge bending machines was worth USD 723 million in 2023. It might grow to USD 1,012 million by 2032.

More need for accurate manufacturing and better automation tools are causing this growth.

Companies in the signage business buy these machines to make top-quality ads.

This rising use shows how important acrylic CNC service is today.

Key Takeaways

Acrylic CNC service gives accurate results with neat designs and cuts.

It works for many uses like signs, models, and art projects. This makes it helpful in different industries.

CNC machines are fast, cutting production time by half. This saves time and lowers costs for companies.

Picking a good provider is important. Choose one with experience, new tools, and good reviews for great results.

Knowing costs, like material type and design difficulty, helps plan and manage money well.

Benefits of Acrylic CNC Service

Precision and Accuracy

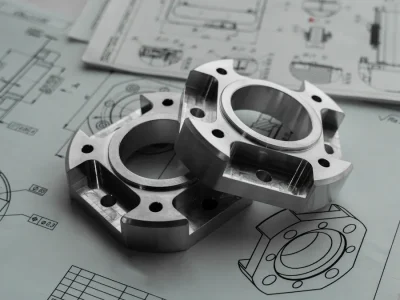

Acrylic CNC service gives very precise results. It helps create detailed designs and smooth cuts that older methods cannot do. The computer controls make sure every part is correct, avoiding mistakes people might make. This accuracy is crucial for industries like signage and prototypes, where small errors can ruin the product.

Here’s a comparison to explain:

Method | Precision Level | Benefits |

|---|---|---|

Traditional Cutting | Not clearly measured | Needs hand-polishing, which may change the design |

Acrylic CNC Machining | Very accurate | Smooth edges, no extra finishing required |

The table shows how acrylic CNC machining gives better results without extra work. This makes it a dependable option for projects needing high precision.

Versatility

Acrylic CNC service can be used in many ways. It works for things like signs and making parts for products. The machines can cut acrylic of different thicknesses and shapes, letting you create designs that fit your needs. Whether you need a simple shape or a detailed engraving, this service can do it.

Different industries also use this service. For example, advertising companies use it to make attractive displays. Manufacturers use it to make exact parts for their items. Its ability to meet various needs makes it useful for many businesses.

Efficiency

Acrylic CNC service is quick and saves time. It works faster than older methods, helping you finish projects sooner. The machines don’t wear out tools much, so maintenance costs stay low. Processes are improved to cut work time by up to 30%, speeding up production.

Here’s how it boosts efficiency:

Faster cutting speeds save time.

Less tool wear means lower repair costs.

Shorter work times help finish projects faster.

Lower production costs make it affordable.

These benefits make acrylic CNC service a smart choice for businesses. It saves time and money, letting you focus on making great products for your customers.

Applications of Acrylic CNC Service

Signage and Displays

Acrylic CNC service helps make signs and displays for many industries. It is used in shops, hotels, and city spaces. Acrylic signs are popular for indoor use, making up 35–40% of the global retail display market, which was worth over $18 billion in 2023. People want strong and eye-catching signs to stand out in busy places.

Cities are growing, increasing the need for clear signs. By 2050, 68% of people will live in cities, creating more demand for architectural signage. CNC machines speed up production by up to 50%, letting businesses, even small ones, get custom signs quickly and cheaply.

Whether it’s a shop sign or a detailed event display, acrylic CNC service ensures high quality. It creates smooth edges and detailed designs, making it a top choice for impressive signage.

Market Driver | Evidence |

|---|---|

Retail and Hospitality Growth | The retail display market was worth $18 billion in 2023, with acrylic signs making up 35–40% of indoor signage. |

Growing Cities and Infrastructure | A UN report says 68% of people will live in cities by 2050, increasing the need for city signage. |

Better Fabrication Technology | CNC machines cut production times by up to 50%, helping small businesses get custom signs faster. |

E-commerce and Marketing Importance | A Shopify study found 76% of shoppers visit stores after seeing physical ads, showing the value of signs. |

Prototyping and Manufacturing

Acrylic CNC service works well for making prototypes and small batches of products. It is ideal for creating fewer than ten models without needing expensive moulds, saving money for businesses.

This process delivers high-quality results with tight tolerances of +/-.005, ensuring all prototypes are consistent. This precision is important for testing new ideas or making parts that must fit perfectly. CNC machines also allow quick design changes, helping improve products easily.

Using acrylic CNC service saves time and money while keeping prototypes accurate. It’s a great choice for industries focused on innovation and detail.

CNC machines are perfect for small production runs, like fewer than ten prototypes.

They save money by removing the need for costly moulds, unlike injection moulding.

CNC machines ensure high-quality results with tight tolerances of +/-.005.

Decorative and Artistic Projects

Artists and designers use acrylic CNC service to create detailed and unique designs. This technology makes it easier to craft complex patterns that are hard to do by hand. For example, Jonathan Borofsky’s ‘Molecule Man’ sculpture shows how CNC machines can cut and align materials precisely.

Ruchika Grover also uses CNC machines to carve natural shapes into stone, showing how flexible this technology is. Whether working with acrylic, stone, or other materials, CNC machines ensure accuracy and detail.

For decorative projects, CNC machines can make complex designs and keep them consistent. This makes them great for art, sculptures, and custom home decorations. Turning digital ideas into real objects opens up endless creative possibilities.

CNC machines help artists make detailed designs with high accuracy, perfect for art and sculptures.

They can create complex patterns that are hard to make by hand.

Cost Factors in Acrylic CNC Service

Material and Design Complexity

The material type and design difficulty affect the cost of acrylic CNC service. Acrylic, especially PMMA, is clear and flexible, making it popular. But it can break easily, causing more waste during prototyping, which raises costs. Detailed designs or frequent changes also increase expenses. Restarting after changes takes extra time and effort.

Surface finishes also impact prices. For example, mirror polishing needs skilled workers and many steps for smooth results, making it pricier. The table below shows these cost factors:

Material Type | Prototype Cost |

|---|---|

Acrylic (PMMA) | Clear and flexible, but its brittleness leads to more waste during prototyping. |

Time Factor | Cost Description |

|---|---|

Design Revisions | Restarting due to changes adds costs and delays. |

Surface Finish | Prototype Cost |

|---|---|

Mirror Polishing | Costs more because it needs skilled labour and extra steps. |

Knowing these factors helps you plan better and control costs.

Production Volume

The number of items you make affects the overall cost. Making more units often lowers the price per item because of economies of scale. Producing in bulk reduces costs, making large orders cheaper.

Continuous production lines improve efficiency. Automated systems cut labour costs and increase output, which is great for big orders. For example, producing more items lets machines work non-stop, reducing downtime and boosting productivity.

Evidence | Explanation |

|---|---|

Larger production scales lower per-item costs due to economies of scale. | Making more items reduces the cost per unit, which is helpful for big orders. |

High-volume production uses continuous lines for better efficiency. | Non-stop production increases output and lowers costs, ideal for large orders. |

For big projects, bulk production can save money and improve efficiency.

Balancing Quality and Budget

Finding the right mix of quality and cost is important for acrylic CNC service. High-quality finishes and detailed designs cost more but give better results. You can still make smart choices to stay within budget.

Focus on key design features and choose simpler finishes when possible. Talk to the service provider about cost-saving options that keep quality high. By understanding your needs, you can balance cost and craftsmanship effectively.

Picking the Best Acrylic CNC Service Provider

Start your project with LKprototype

LKprototype company simplifies procurement for custom manufacturing, Suitable for making your products or prototypes with a variety of materials, such as metal or plastic, silicone rubber, from 3D Printing to CNC Machined Parts and Vacuum Casting , with a focus on speed and efficiency. Our platform provides instant quotes. With LKprototype, You can connect with the team to communicate your project to ensure quality and on-time delivery.

Start with an instant quote and experience how our technology and expertise can make custom part procurement faster and easier.

Choosing the right acrylic CNC provider ensures good quality and speed. Here are some important things to think about:

Skills and Experience

Pick providers with lots of experience in acrylic CNC work. Experts know how to handle acrylic well, giving accurate results. Look for those offering Design for Manufacturing (DFM) checks. This step finds problems early, saving time and money.

Good providers also focus on quality checks. Some inspect every step and share detailed reports. Others check measurements to ensure parts are made correctly.

Process/Check | What It Does |

|---|---|

DFM Check | Spots issues early and improves designs for better results. |

Measurement Checks | Makes sure parts meet exact sizes and improves production quality. |

Full Inspections | Quality experts check each stage and provide detailed reports. |

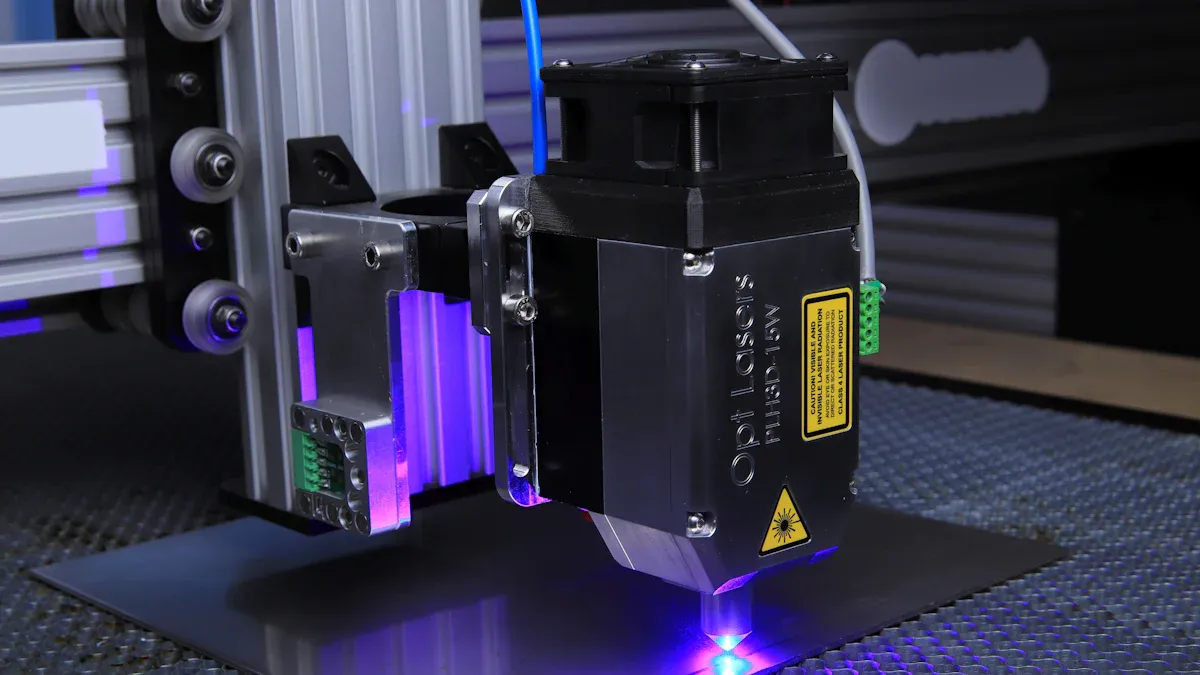

Tools and Machines

Modern machines are key for top-quality work. Providers with advanced tools can make very precise designs. For example, Germany GROB and Swiss GF Mikron machines can cut with a tolerance of +/-0.0015 mm. This is perfect for detailed and tricky projects.

Machine Type | Precision Level |

|---|---|

Germany GROB 5-axis machine | +/-0.0015 mm |

Swiss GF Mikron 5-axis machine | +/-0.0015 mm |

China Jingdiao 5-axis machine | +/-0.0015 mm |

US Haas 4-axis machine | +/-0.0015 mm |

General CNC Machine Tolerance | +/-0.0002 in (0.005 mm) |

Ask about the machines they use and their abilities. Advanced tools mean your project will be accurate and efficient.

Reviews and Past Work

Customer reviews and examples of past work help you judge a provider. Reviews show what they do well and where they can improve. A good portfolio shows they can handle different jobs, like signs or art pieces.

Check reviews for things like on-time delivery, steady quality, and problem-solving. Providers who fix issues quickly care about their customers. By reading reviews and checking portfolios, you can find a provider that fits your needs.

Acrylic CNC service provides great accuracy, flexibility, and speed. It can create very detailed designs with high precision. The service works on many materials, making it useful for different tasks. Automation reduces delays, allowing steady production and reliable results.

Advantage | Description |

|---|---|

Precision | Creates highly accurate designs, better than hand-cutting. |

Versatility | Works on many materials that are strong and durable. |

Efficiency | Fast production with little downtime due to automation. |

Complex Geometries | Makes detailed shapes that are hard to do by hand. |

Consistency | Produces identical parts with almost no differences, ideal for big projects. |

Think about your project needs carefully. Look at things like design details, how many items you need, and quality. Pick a provider with modern machines, good skills, and strong reviews for the best outcome.

FAQ

What is Acrylic CNC Service?

Acrylic CNC service uses machines controlled by computers to cut or shape acrylic. It gives accurate and quick results. This service is great for making signs, models, or creative designs.

How is Acrylic CNC different from old cutting methods?

CNC machines are more accurate and give smoother edges. They automate the work, which reduces mistakes and saves time. You also don’t need extra polishing after.

Can Acrylic CNC Service make detailed designs?

Yes, CNC machines can create very detailed patterns and engravings. They can handle different acrylic sizes and shapes, making them perfect for tricky projects.

Is Acrylic CNC Service good for small projects?

Yes, it works well for small projects and saves money. You don’t need costly moulds, and quick changes reduce waste and expenses.

How do I pick the best Acrylic CNC provider?

Choose providers with modern tools, good experience, and happy customers. Look at their past work to see if they can meet your project needs.

LKprototype

LKprototype