Modern factories rely on tools that operate quickly and precisely, and a 4-axis CNC machine is a game-changer in this regard. By incorporating rotation into the standard three axes, a 4-axis CNC machine enables intricate work, making it ideal for crafting parts with complex shapes. This added capability enhances accuracy, saves time, and effortlessly manages advanced designs.

The adoption of 4-axis CNC machines is on the rise, with approximately 60% of businesses utilizing CNC tools. The 4-axis CNC market is projected to grow significantly, increasing from $3.2 billion in 2024 to $5.8 billion by 2033. This rapid growth highlights how 4-axis CNC machines accelerate production and boost precision, making them indispensable for industries such as aerospace and medical equipment manufacturing.

Key Takeaways

4-axis CNC machines cut from many angles without moving parts by hand. This makes them great for tricky designs.

These machines save time and lower mistakes by working automatically. This helps a lot in fields like airplanes and medical tools.

4-axis CNC machines can do many jobs. They work with different materials and make detailed shapes that 3-axis machines can't.

Buying a 4-axis CNC machine saves money. It works faster, wastes less, and needs fewer workers.

A 4-axis machine is best for jobs needing high detail and accuracy. 3-axis machines are better for easier tasks.

Understanding 3-Axis CNC Machining

Overview of 3-Axis CNC Systems

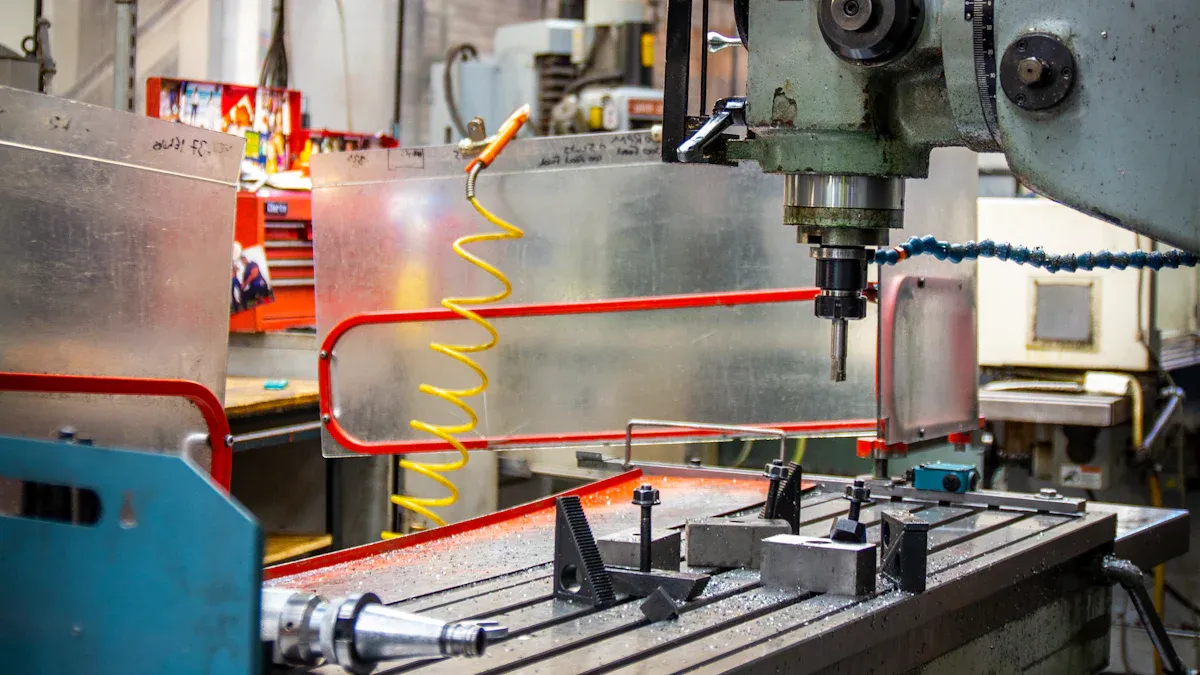

A 3-axis CNC machine moves in three directions: X, Y, and Z. These directions let the tool move sideways, up and down, and deeper into the material. This system is the basic type of CNC machining and is used for accurate and fast work.

The demand for 3-axis CNC machines is growing quickly. The market for 3-axis CNC controllers is expected to grow from $1.2 billion in 2023 to $2.8 billion by 2032, with a yearly growth rate of 9.5%. Also, the market for 3-axis CNC vertical machining centers will likely rise from $11.41 billion in 2024 to $16.43 billion by 2034, showing their importance in manufacturing.

Capabilities and Common Uses

3-axis machines are great for making flat surfaces, simple shapes, and holes. They are used for jobs like cutting, drilling, and milling, which are perfect for basic designs. Industries like car-making and airplane-making often use 3-axis CNC milling machines.

Car companies use 3-axis machines to make exact parts like engine pieces and gears. Airplane makers use them to shape strong materials into accurate designs. Because they can do many tasks, 3-axis machines are a popular choice for production.

Limitations of 3-Axis Machining

Even though 3-axis machines are precise, they have limits. They cannot turn the material, so they cannot handle very detailed shapes. Workers often have to move the material by hand, which takes time and lowers efficiency.

Also, 3-axis machines have trouble with designs that need cutting in many directions. For projects with curved shapes or hidden cuts, machines with more axes may be needed.

Exploring 4-Axis CNC Machining

What Is a 4-Axis CNC Machine?

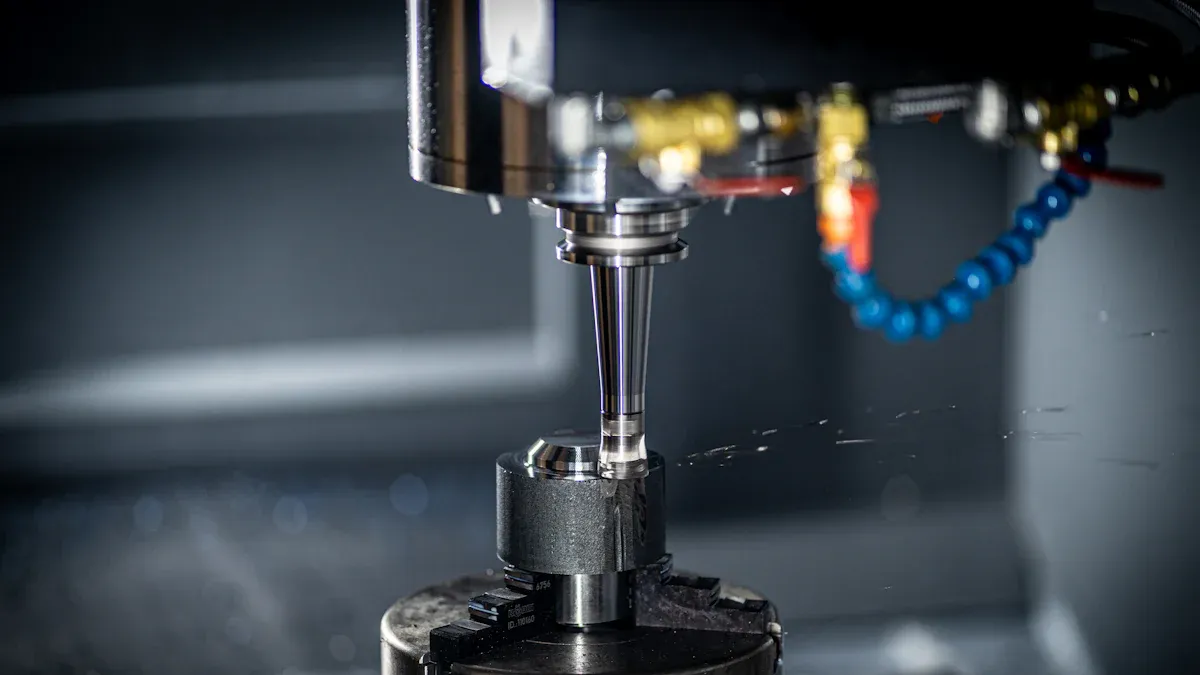

A 4-axis CNC machine is like a 3-axis machine but with an extra rotary axis called the A-axis. This axis lets the machine spin the material, giving full 360° access for cutting and shaping. You can work on many sides of a part without moving it by hand. This makes it perfect for detailed designs and tricky shapes.

These machines use clamps or plates to hold the material tightly while it spins. The A-axis can either move continuously or stop at set points, depending on the job. This makes the machine faster and more accurate, especially for round or curved surfaces.

How the Fourth Axis Enhances Machining

The fourth axis makes machining better by allowing more advanced movements. It helps create detailed shapes without stopping to move the material, saving time and avoiding mistakes. For example, it’s great for working on round parts like gears or pipes.

This extra axis also makes angled drilling and cutting on curved surfaces easier. These tasks are hard for 3-axis machines. By removing the need for manual adjustments, the fourth axis ensures steady results and speeds up work. Whether making airplane parts or artistic designs, 4-axis machining is very flexible and useful.

Key Features of 4-Axis Machining

Here are some important features of 4-axis machining:

Feature | Description |

|---|---|

Better Accuracy | 4-axis machines are very precise, great for detailed shapes. |

Less Mistakes | Automatic control of all axes reduces errors during work. |

Easy to Move | These machines are small and can be used in different places. |

Creative Designs | They allow making complex designs that 3-axis machines cannot do. |

These features make 4-axis CNC machines powerful tools for industries needing exact and fast work. From making medical tools to car parts, they are helpful in many areas.

Advantages of 4-Axis CNC Machining

Improved Precision and Accuracy

Using a 4-axis CNC machine improves precision greatly. The extra rotary axis lets the tool reach more angles without moving the material by hand. This ensures every cut matches the design perfectly. Whether making detailed parts or complex 3D shapes, 4-axis machines provide high-quality finishes.

These machines also reduce mistakes caused by human handling. For example, when making curved surfaces or detailed patterns, the fourth axis moves automatically, avoiding errors. This makes 4-axis CNC machines perfect for industries like aerospace and medical tools, where even tiny mistakes can ruin the product.

Reduced Repositioning and Setup Time

A big advantage of 4-axis CNC machines is less repositioning and setup time. With 3-axis machines, you often need to move the material by hand to reach different angles. This takes time and can lead to mistakes. A 4-axis machine adjusts the material automatically, saving time and effort.

Studies show advanced methods like QCD (Quick Changeover Design) cut setup times a lot. For example:

Methodology | Starting Changeover Time (min) | New Changeover Time (min) | Time Saved (%) |

|---|---|---|---|

QCD | 51.2 | 13.4 | 74% |

Also:

Quick locks and alignment pins save up to 21% of disassembly time.

Technical upgrades make up 84% of the total setup time saved, according to Singh and Khanduja.

By cutting setup time, you can work faster and focus on better results.

Enhanced Design Flexibility and Complex Geometries

The fourth axis allows creating more complex 3D shapes. Unlike 3-axis machines, which struggle with tricky designs, 4-axis machines handle advanced shapes easily. These include cam lobes, spirals, and other curved or angled designs.

There are two main types of 4-axis systems:

Type | Description |

|---|---|

Index | Rotates only when the tool stops, good for simpler designs. |

Continuous | Rotates while cutting, great for making complex shapes like spirals and cam lobes. |

Continuous systems are especially good for detailed designs. This makes 4-axis CNC machines popular for industries needing precision and creativity, like jewelry and art.

With 4-axis CNC machines, you can work faster, make better products, and handle tough designs easily.

Cost-Effectiveness and Efficiency

Buying a 4-axis CNC machine gives more than advanced features. It helps save money and work more efficiently. These machines make production faster, reduce waste, and use resources better. This makes them a smart choice for businesses wanting to earn more.

One big benefit is how they improve productivity. Switching to a 4-axis system can boost several key areas:

Metric | Improvement Range |

|---|---|

Equipment Effectiveness | |

Spindle Use | 65-80% on 4-axis vs. 45-60% on 3-axis |

Labor Savings | 30-50% for hard-to-make parts |

Fixture Cost Cuts | 40-60% for production runs |

Scrap Reduction | 15-30% with less handling |

These boosts lead to real money savings. For example, better spindle use means finishing more jobs faster. Lower fixture costs mean spending less on tools for production. Also, less handling means fewer mistakes, saving material costs.

4-axis machines also cut labor costs by automating tough tasks. They make detailed parts with little human help. This saves time and keeps quality steady. One aerospace company shared:

“We were unsure about buying at first,” said an aerospace partner. “But cutting production time by 47% for brackets made the upgrade worth it in under 8 months.”

Using 4-axis CNC machines helps businesses take on harder projects while keeping costs low. Whether making precise parts or handling big orders, these machines balance cost and efficiency perfectly.

Applications of 4-Axis CNC Machining

Aerospace and Automotive Manufacturing

The aerospace and car industries need precise and fast tools. Making parts like turbine blades and engine pieces requires advanced machines. A 4-axis CNC machine is great for handling tricky shapes and curves.

Smart factories and new tech have increased the use of 4-axis CNC machines.

Exact parts are important for airplanes and electric cars, boosting demand for these machines.

Big companies buy 4-axis machines to handle hard tasks and improve production.

For example, turbine blades need cutting at many angles with high accuracy. A 4-axis CNC machine does this without moving the material by hand. Car makers also use these machines to make strong, lightweight parts for electric cars. This helps improve performance and makes cars more eco-friendly.

Medical Device Production

In medicine, tools must be very accurate and high-quality. A 4-axis CNC machine is perfect for making detailed designs with few mistakes.

Think about making implants or surgical tools. These items have complex shapes and need exact measurements. A 4-axis CNC machine ensures every part matches the design perfectly. For example, a study showed how a 4-axis Wire Electric Discharge Machining (WEDM) machine works well for medical tools:

Parameter | Description |

|---|---|

Material | Ti-6Al-4V alloy |

Machining Process | Wire Electric Discharge Machining (WEDM) |

Key Performance Metrics | Material Removal Rate (MRR) and Surface Roughness (Ra) |

Accuracy of Machine |

This level of precision helps meet strict rules for medical devices. By adjusting machine settings, you can balance speed and surface quality, making the process better and more reliable.

Jewelry and Artistic Creations

Jewelry and art need both creativity and accuracy. A 4-axis CNC machine lets you make detailed designs that are hard to do by hand. You can create custom rings, sculptures, or decorations with ease.

Continuous 4-axis systems are great for making spirals, cam lobes, and other tricky shapes. Artists and jewelers can use these machines to make unique, high-quality items. The machine also helps copy designs perfectly, so every piece looks the same.

With a 4-axis CNC machine, you can create amazing designs while keeping them precise and high-quality. This makes it a must-have tool for creative industries.

Prototyping and Custom Manufacturing

Prototyping and custom manufacturing need tools that are fast and precise. A 4-axis CNC machine is great for these tasks. It helps make prototypes and custom parts with high quality. Whether creating a new product or a special part, this machine delivers excellent results.

Why 4-Axis CNC Machines Work Well for Prototyping

Prototypes often have detailed designs and strict size limits. A 4-axis CNC machine can easily handle these challenges. Its extra rotary axis lets you cut and shape parts from many angles. This means no manual repositioning, saving time and keeping accuracy steady.

For example, think about making a medical implant prototype. These parts have curved shapes and exact measurements. A 4-axis CNC machine can finish the job in one setup. This avoids mistakes and speeds up the process.

Advantages in Custom Manufacturing

Custom manufacturing involves making small batches or unique designs. A 4-axis CNC machine is flexible enough to handle these needs. It quickly switches between different materials and designs, helping meet customer demands.

Key benefits of using 4-axis CNC machines for custom manufacturing include:

Versatility: Works with metals, plastics, and other materials.

Precision: Makes detailed designs with tight size limits.

Efficiency: Cuts setup time and avoids manual adjustments.

Real-World Examples

Many industries use 4-axis CNC machining for prototyping and custom work. Aerospace, automotive, and medical fields rely on this technology for new ideas. For instance, car companies make engine prototypes, and medical makers create implants for specific patients.

Tip: Before buying a 4-axis CNC machine, think about your production needs. Check if your designs require this advanced technology.

Using 4-axis CNC machining improves prototyping and custom manufacturing. It makes work faster and ensures high-quality products every time.

Comparing 3-Axis and 4-Axis CNC Systems

Key Differences Between 3-Axis and 4-Axis Systems

Knowing the differences between 3-axis and 4-axis CNC machines helps you pick the right one. Both are good for machining, but they work differently.

Feature | 3-Axis CNC Machines | 4-Axis CNC Machines |

|---|---|---|

Movement | Moves in X, Y, Z directions only | Moves in X, Y, Z, and A (rotational) |

Setup Needs | Needs many setups for different sides | Machines many sides in one setup |

Precision | More errors due to extra setups | Fewer errors with better precision |

Efficiency | Slower for complex parts | Faster for tricky designs and big projects |

Cost | Lower starting cost | Costs more but saves money for big jobs |

A 3-axis machine is great for simple shapes. A 4-axis machine is better for detailed designs. The extra rotation in 4-axis systems cuts down on manual work, making them faster and more accurate.

When to Choose a 3-Axis CNC Machine

Pick a 3-axis CNC machine for easy tasks. It works best for flat surfaces or basic shapes. Follow these tips to decide if it’s right for you:

Check your part’s shape and adjust stock to avoid extra work.

Use cutting areas that match the part’s shape.

For simple cutouts, think about using 2½-axis machining instead.

These machines are cheaper for small jobs and simple designs. They’re also easier to use, making them good for beginners or small budgets.

When to Opt for a 4-Axis CNC Machine

Choose a 4-axis CNC machine for detailed designs or big projects. It spins the material, letting you cut many sides in one go. This is helpful for making 3D shapes, spirals, or cam lobes.

If your job needs tricky shapes or high accuracy, go with a 4-axis machine. It saves time by skipping manual adjustments, making it faster for large jobs. Industries like aerospace and car-making often use 4-axis machines for their advanced features.

By knowing these differences, you can pick the machine that fits your needs.

4-axis CNC machines give better precision, speed, and flexibility. They can make tricky parts, save time, and work with many materials. Here’s a table showing their main benefits:

Benefit | Explanation |

|---|---|

Better Abilities | Makes hard-to-create parts that 3-axis machines can’t handle. |

Faster Work | Cuts production time by machining from multiple angles without stopping. |

More Accuracy | Provides better control for precise and exact results. |

Flexible Use | Works with different materials and sizes, fitting many industries. |

Picking the right machine depends on your project’s needs. For detailed designs or quicker work, a 4-axis CNC machine is the best option. Using this tool helps you make better products and improve your production process.

FAQ

What makes 3-axis and 4-axis CNC machines different?

The main difference is the extra rotary axis (A-axis) in 4-axis machines. This axis lets the material spin, so you can machine several sides without moving it by hand. It’s great for making curved shapes and tricky designs.

Can 4-axis CNC machines work with all materials?

Yes, they can handle many materials like metals, plastics, and composites. But you should check the machine’s details to make sure it works with the material’s hardness and features.

Are 4-axis CNC machines good for small businesses?

Yes! They cost more at first, but they save time and reduce waste. This makes them a smart choice for small businesses that need to make detailed designs or custom parts.

How do you take care of a 4-axis CNC machine?

You need to clean it, oil the moving parts, and check the spindle and tools often. Follow the maker’s instructions to keep it working well and lasting longer. Good care helps avoid problems and keeps results steady.

Are 4-axis CNC machines hard to use?

Not really. New 4-axis CNC machines have easy-to-use software. With some training, you can learn to program and run the machine quickly. Many companies also give lessons and help to get you started.

LKprototype

LKprototype