Choosing between a 3 Axis CNC and a 5 Axis CNC machine depends on your project’s complexity and precision needs. In this article, we will explore the key differences, benefits, and drawbacks of 3 axis CNC vs 5 axis machines to help you decide which is right for you.

Key Takeaways

3-axis CNC machines are cost-effective and suitable for simpler tasks, but they struggle with complex geometries and require multiple setups for intricate designs.

5-axis CNC machines excel in precision and efficiency, capable of machining complex shapes with fewer setups, making them ideal for industries demanding high accuracy like aerospace and medical.

Choosing between 3-axis and 5-axis CNC machines should be based on project requirements, budget, and desired complexity, with professional consultation recommended for informed decisions.

Understanding 3 Axis CNC Machines

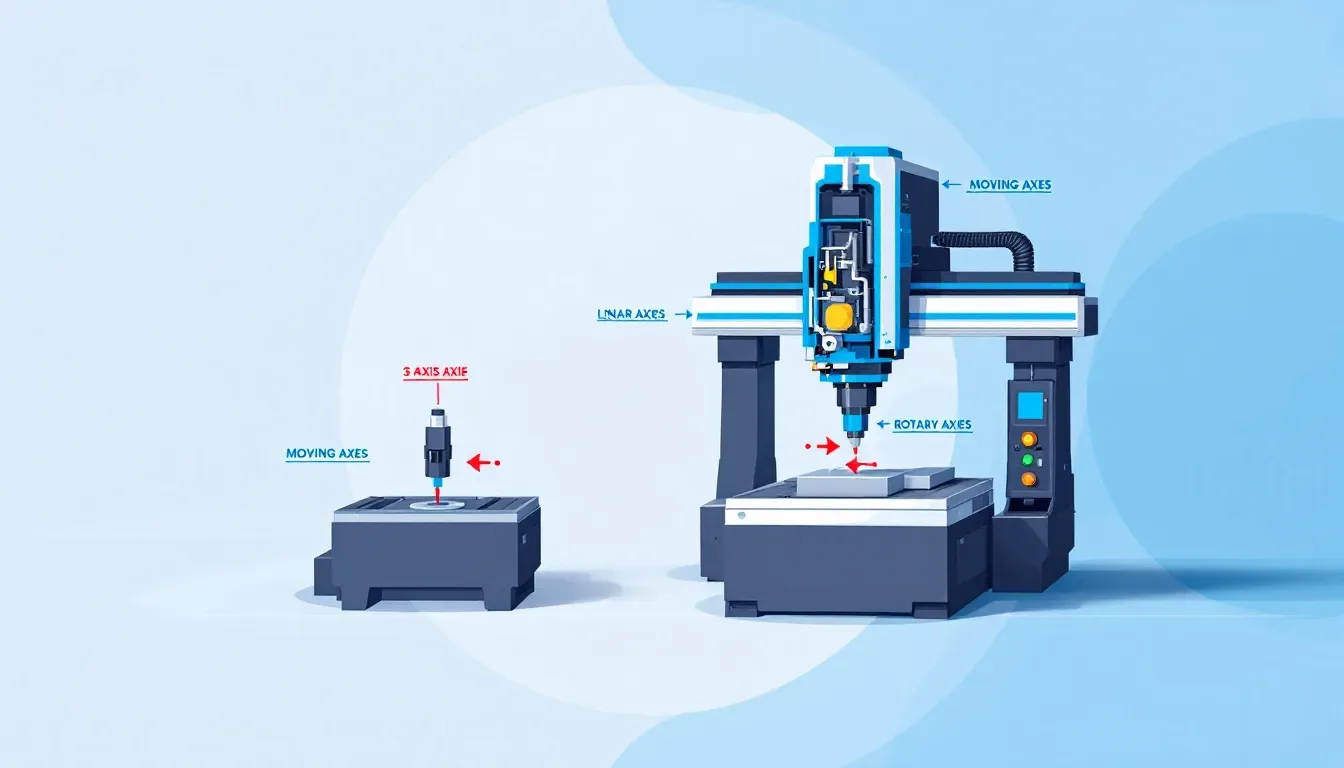

CNC machines that operate on three axes are fundamental to a multitude of manufacturing processes, especially when the task at hand is relatively straightforward and lacks elaborate details. These machines execute their functions along three principal axes—namely, the x axis, y axis, and z axis—with the cutting tool traversing these dimensions while maintaining the workpiece in a fixed position. This allows for various operations such as drilling holes, creating bores, or milling slots. The uncomplicated movements enable 3-axis CNC machining to be ideally suited for tasks like crafting flat surfaces or basic shapes required for molds or parts.

Such 3-axis CNC machinery showcases its adaptability by handling an array of materials ranging from metals to woods and plastics with ease. Due to this capability, they frequently serve as key equipment in fabricating mechanical components within industries focused on automation technologies. Nevertheless, one notable limitation of 3-axis CNC machining lies in its comparatively limited precision with more intricate features since movement is restricted to three linear directions only. Thus posing challenges when tasked with producing items encompassing complex geometries.

Despite these constraints related to complexity and detail resolution capabilities remain widely preferred choices across various applications owing largely to affordability user-friendliness inherent design principle Ideal scenarios where minimal rotation needs occur absence need fine intricacies Consequently find extensive usage sectors woodworking example enabling creation sophisticated decorative patterns pieces furniture comprehensive signage solutions.

Delving into 5 Axis CNC Machines

Compared to 3-axis CNC machines, 5-axis CNC machines offer a heightened level of sophistication and functionality. These advanced machines are capable of machining five faces in a single operation, making them suitable for crafting intricate forms and complex geometries that would be challenging or impossible with traditional 3-axis equipment. The arrangement of cutting tools on these versatile milling units allows for the removal of more material per tool rotation, which improves both precision and productivity.

One distinctive feature that sets apart 5-axis CNC machinery is their proficiency in executing cnc milling across two additional rotational axes—the A axis and B axis—beyond the standard three linear axes (X, Y, Z). This augmented movement grants the machine’s tool superior access to attack the workpiece from myriad angles. It can fabricate components featuring elaborate angled elements without requiring numerous setups, thus expediting production timelines while decreasing associated costs. This contributes significantly to elevating manufacturing efficiency within various sectors by leveraging sophisticated cnc milling techniques.

The benefits furnished by these multi-axial CNC systems become clearly apparent within industries where extreme precision coupled with complex part designs is paramount. Among them aerospace engineering, automotive manufacturing as well as medical device fabrication stand out prominently. By employing such state-of-the-art technology like the 5-axis variant for creating parts—even those presenting complicated configurations such as turbine blades or medical implants—they ensure outputs adhere strictly to rigorous quality control parameters essential for high-stakes applications demanding utmost accuracy and reliability.

Key Differences Between 3 Axis and 5 Axis CNC Machines

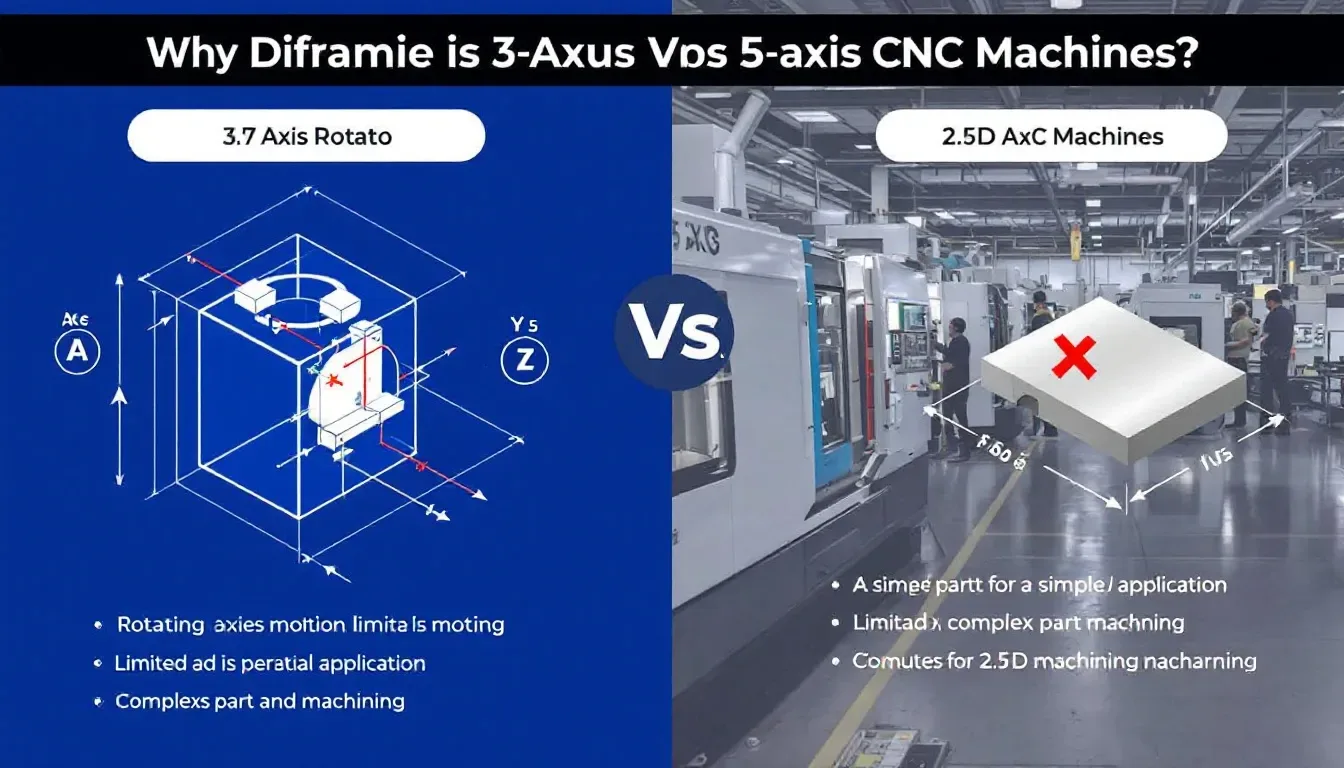

CNC machines come in different configurations, and a critical distinction to be aware of is the one between 3-axis and 5-axis CNC machines. The principal contrast pertains to their functional capacities and the intricacy of components they can fabricate. Contrary to the restricted linear movements along three planes—X, Y, and Z—that define 3-axis machines, 5-axis CNCs incorporate two additional rotational axes (A and B). This enhancement permits them not only continuous milling, but also the crafting of complex shapes at diverse angles.

One standout benefit of employing a 5-axis CNC machine lies in its superior operational efficiency. Unlike their 3-axis counterparts that often require multiple setups for detailed designs, these advanced machines largely eliminate such needs. Consequently, there’s an acceleration in production cycles which proves advantageous especially for sectors under stringent time constraints on deliveries. To speedier processes, this machinery’s capability enables attacking a workpiece from various perspectives—a feature instrumental in amplifying precision by diminishing error accumulation over successive operations.

It’s crucial to recognize that sophistication does bear its own price tag with respectors. Operating any axis cnc machine necessitates specific training alongside sophisticated programming acumen—the learning curve is steeper when compared to simplistic procedural requirements associated with traditional models.

In summary, choosing whether to opt or highly depends upon distinct objectives each project —considering both complexity sought-after degree fineness machined elements essential to arriving well-informed decision about right tool job.

Applications of 3 Axis CNC Machines

Due to their straightforward design and adaptability, 3-axis CNC machines have carved out a significant role across various sectors. In the realm of woodworking, these machines are pivotal for shaping elaborate patterns and elements used in furniture construction. They possess the capacity to process diverse materials such as metals, composites, and plastics with ease. This versatility extends their utility from creating detailed signage to manufacturing components for industries like automotive and electronics.

When it comes to prototyping, 3-axis CNC machines excel due to their simple operation coupled with an easy setup process. This advantage makes them perfectly suited for rapid iteration and evaluation of designs before advancing toward more intricate production methods. The speed at which they enable prototypes development holds particular importance in fields that place a premium on swift product evolution and breakthroughs in technology.

Applications of 5 Axis CNC Machines

CNC machines equipped with 5-axis machining capabilities are crucial for sectors that demand intricate shapes and high-precision parts. Industries such as aerospace and automotive depend on these machines for crafting components like turbine blades and sophisticated structural elements, which must meet stringent tolerance requirements. Similarly, the medical sector gains advantage from the use of 5-axis CNC machinery in creating complex medical implants characterized by their precise measurements and polished surfaces.

These advanced 5-axis CNC machines stand out in their ability to fabricate multifaceted structures from numerous angles while eliminating the necessity to reposition the workpiece. This capability not only boosts production velocity but also amplifies precision by reducing potential cumulative errors. Consequently, when a project necessitates utmost accuracy combined with intricacy within a single setup, 5-axis machining typically emerges as the go-to method.

Advantages and Disadvantages of 3 Axis CNC Machines

CNC machines with 3-axis capabilities are notably more affordable, making them an ideal option for operations mindful of costs. These types of machines offer a cost advantage over their advanced 5-axis counterparts and present less complexity in operation, which reduces the need for extensive training. This accessibility makes them particularly suitable for beginners or operations focused on simple tasks that involve flat surfaces or modest contours.

Nevertheless, when it comes to executing complex designs, the limitations of 3-axis CNC machinery become evident due to their restricted movement along three axes only. Crafting intricate three-dimensional shapes frequently necessitates several setups, which can extend production time significantly—a substantial disadvantage for sectors where precision and intricate geometries are crucial.

Despite these restrictions, many applications continue to favor 3-axis CNC machines because they strike a balance between simplicity and affordability. For projects not requiring the sophisticated features provided by 5-axis technology—such as simpler machining tasks or prototype development—these machines stand out as an optimal solution.

Advantages and Disadvantages of 5 Axis CNC Machines

CNC machines capable of 5-axis machining possess several noteworthy advantages in contrast to their 3-axis counterparts. Their ability to execute deep cuts on every side of a workpiece facilitates the crafting of detailed designs and intricate geometries. This superior function significantly reduces the necessity for repeated setups, thereby enhancing production speed while diminishing potential cumulative inaccuracies.

These enhancements do incur greater expenses. Machines with 5-axis capabilities carry a heftier price tag when compared to those limited to 3 axes, reflecting not only in initial purchase costs but also increased operational and upkeep expenditures due to their more complex structure and extra moving components. Managing and programming these sophisticated 5-axis CNC machines necessitates advanced training, making them more challenging to operate than simpler 3-axis variants.

Despite this downside, which includes an elevated risk of wear owing to additional moving parts within such systems. Industries that prize precision intricacy often find the advantages presented by utilizing machinery equipped for high-level axis cnc functions—like those seen in five axis cnc units—to be worth it despite any challenges faced.

Choosing the Right CNC Machine for Your Needs

When selecting a CNC machine, it’s crucial to assess your project demands, financial constraints, and the level of precision you seek. A 5-axis CNC machine may be more suitable for projects necessitating intricate geometries and high accuracy due to its superior functionality and shorter cycle times. Not all tasks require the extensive capabilities offered by a 5-axis model. In some instances, employing a 3+2 axis machining setup might prove more cost-effective.

A consultation with an experienced CNC machinist can offer personalized guidance based on your particular requirements. Such professionals are adept at advising whether your projects would benefit more from using either a 3-axis or 5-axis CNC system while assisting you in making an educated selection. Integrating additional manufacturing tools like 3D printers with traditional CNC equipment could expand production proficiency and streamline overall operations.

Deciding between utilizing a 3-axis or a 5-axis CNC machine hinges upon careful examination of specific factors such as part complexity that must be addressed within the project scope and existing budgetary limitations. Diligent consideration of these elements is key to choosing the most appropriate CNC device that aligns with your objectives—thereby bolstering manufacturing effectiveness and ensuring successful outcomes for future endeavors.

Future Trends in CNC Machining

The CNC machining landscape is swiftly changing thanks to several cutting-edge trends poised to revolutionize the sector. A noteworthy shift is towards higher spindle speeds and feed rates, with machines now capable of reaching a maximum of 200,000 RPM for spindle speed and a feed speed up to 240 m/min. This boost in velocity not only increases production efficiency, but also slashes cycle times significantly, enabling faster project completion.

The application of virtual reality (VR) and augmented reality (AR) within CNC machining marks another thrilling advancement. These technologies improve both training outcomes and operational precision by offering machinists an engaging learning environment as well as real-time instructional support throughout the tool’s engagement process. There has been an increased implementation of automation alongside robotics, which optimizes operations while diminishing labor expenses.

Artificial intelligence (AI) along with the Internet of Things (IoT) are increasingly influential in refining various aspects related to the execution of CNC machining processes. AI possesses the capability to scrutinize data for predicting maintenance requirements besides fine-tuning tool paths. Meanwhile, IoT contributes actively toward monitoring manufacturing procedures instantly, thus permitting informed decision-making based on live data analysis during production processes. These innovations propel us closer towards more effective & ecologically responsible manufacturing practices ensuring that CNC Machining stays at the vanguard position when it comes down modern industrial manufacture methods.

Summary

In summary, the choice between 3-axis and 5-axis CNC machines depends on various factors, including the complexity of the parts you need to produce, your budget, and your desired level of precision. 3-axis CNC machines are ideal for simpler tasks and are more affordable and easier to operate, making them a great choice for beginners and budget-conscious operations. On the other hand, 5-axis CNC machines offer advanced capabilities, allowing for the creation of intricate designs and complex geometries with higher precision and reduced cycle times.

As the CNC machining industry continues to evolve, staying informed about the latest trends and technologies is crucial for making the best choice for your manufacturing needs. Whether you choose a 3-axis or 5-axis CNC machine, understanding their advantages and limitations will help you optimize your production processes and achieve the highest standards of quality and efficiency. Make an informed decision and take your manufacturing capabilities to the next level.

Frequently Asked Questions

What is a 5 axis CNC machine used for?

Primarily utilized for the production of intricate components such as orthopedic implants and turbine blades, a 5-axis CNC machine enables precise machining at challenging angles, eliminating the necessity for supplementary fixtures.

Thanks to this advanced capability, compared with conventional 3-axis machines, a 5-axis CNC achieves superior surface finishes and closer adherence to specified tolerances.

What are the disadvantages of a 3 axis CNC machine?

The primary disadvantage of a 3-axis CNC machine is its inability to machine features that are angled relative to the X, Y, or Z axes.

This limitation may necessitate the use of a 5-axis machine for certain complex designs.

What are the disadvantages of a 5 axis CNC machine?

A major drawback of a 5-axis CNC machine is the substantial financial outlay it requires, with prices ranging from $200,000 to in excess of $500,000. Such an expense may render these machines unattainable for smaller enterprises and could restrict their availability to numerous companies due to this steep investment hurdle.

What are the main differences between 3-axis and 5-axis CNC machines?

3-axis CNC machines are designed for less complex tasks, whereas 5-axis CNC machines boast increased sophistication and capabilities, providing more versatility when working with complex designs and offering enhanced efficiency during setup.

Consequently, 5-axis CNC machines are perfectly suited for sophisticated manufacturing procedures due to their advanced features.

Which industries benefit most from 5-axis CNC machines?

Aerospace, automotive, and medical industries benefit significantly from 5-axis CNC machines as they excel at producing parts with tight tolerances and intricate geometries.

Still, need help? Contact Us: [email protected]

Need a PROTOTYPE or PARTS machining quote? Quote now

LKprototype

LKprototype