Choosing vacuum casting prototype parts China offers you a significant advantage. You can receive your initial prototypes within just 3 to 7 days, which is much faster compared to the typical 2 to 6 weeks elsewhere. Suppliers in China maintain low prices and don’t require large orders, helping you save money while providing more options. They utilize advanced technology and employ skilled workers, ensuring high precision and rapid production. The key benefits of vacuum casting are evident in every project. Vacuum casting prototype parts China enable you to work efficiently and stay ahead in your industry.

Key Takeaways

Vacuum casting from China gives you prototypes quickly, usually in 3 to 7 days. This helps you make your product faster.

This way saves money because it uses cheaper silicone molds. You can also order small amounts without spending a lot.

You get good parts with smooth surfaces and exact details. These parts look a lot like your designs.

Suppliers in China give expert help and use new technology. They also offer many materials for different needs.

Talking clearly and picking the right supplier keeps your ideas safe. It also helps your project go well.

Why Choose Vacuum Casting for Prototypes

Vacuum casting is a smart way to make prototypes. You do not need to buy expensive hard tooling. Instead, you use a master model to make detailed parts fast. The parts come out smooth and without bubbles. This method helps you move from one prototype to many parts. It gives you both speed and flexibility. If you wonder why vacuum casting is good for prototypes, think about its main benefits. These include saving money, using many materials, and getting high precision and nice surfaces.

Cost-Effective Production

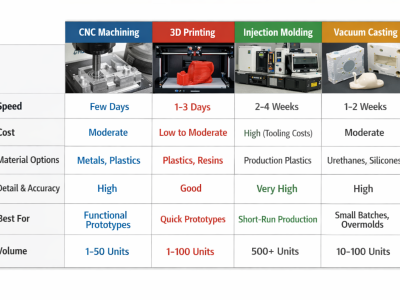

You want to spend less but still get good prototypes. Vacuum casting helps you do this. Here are ways it saves you money compared to CNC machining or injection molding:

Silicone molds cost less and are faster to make than metal molds.

You can make up to 100 parts without paying a lot.

Silicone molds set up fast, so you get parts sooner.

You do not need to make a lot of parts at once.

You can change your design often without extra cost.

Cost-Saving Factor | Explanation |

|---|---|

Lower Tooling Costs | Silicone molds are cheaper and faster to make than metal molds. |

Suitable for Small to Medium Runs | Good for up to 100 parts, unlike injection molding which needs more. |

Faster Turnaround Times | Setup and lead times are shorter than with metal molds. |

No Need for High-Volume Runs | Still a good price for prototypes and small batches. |

Design Flexibility | Lets you make complex shapes and change designs often. |

Vacuum casting is a good choice for making a small number of parts. You can test ideas, make changes, and keep costs low. This makes it great for making prototypes and production-grade samples.

Material Versatility

Choosing the right material is important for good prototypes. Vacuum casting lets you use many types of materials. You can pick polyurethane resins that act like plastics. You can use clear resins for see-through parts. Flexible resins are good for soft-touch parts. There are even special resins for heat or food use. This means you can test how your prototype looks and works early on.

Material Type | Benefits and Prototype Development Advantages |

|---|---|

Polyurethane Resins | Act like different plastics and can be hard or soft. |

Clear Resins | Look like glass or clear plastic for things like lenses. |

Flexible Resins | Feel like rubber, good for gaskets or seals. |

High-Temperature Resins | Work for parts that need to handle heat during tests. |

You can make prototypes that are almost like the real product. This helps you check the shape, fit, and use before making lots of them. Vacuum casting is used in many fields, like cars, planes, medical, and consumer goods. You can try new ideas and make changes quickly.

High Quality Results

You want your prototypes to be precise and look good. Vacuum casting gives you both. The process uses a master model to make a silicone mold. This mold copies every detail. When resin is poured in under vacuum, air bubbles go away. You get solid, smooth parts. The parts are accurate and meet strict rules.

Getting a smooth finish starts with careful mold work. It also needs sanding or polishing after. The sizes often match ISO and DIN standards for plastics. Studies show vacuum casting can reach a process capability index (Cpk) over 1.3. This means the process is very good and reliable.

You get quality like traditional molding. Suppliers in China use special finishing steps like anodizing, powder coating, and sandblasting. These steps fix problems and make sure your prototypes look and work well.

Tip: If you need top-quality prototypes for testing or user feedback, vacuum casting gives you the detail and consistency you want.

Vacuum casting helps you go from one prototype to many parts. You can make 10 to 1,000 parts with materials close to those used in mass production. This lets you test designs, get feedback, and improve before spending a lot on tools. Vacuum casting is useful from early models to bridge tooling. It supports your project at every stage.

Vacuum Casting Prototype Parts China

Quick Turnaround Time

You want your prototypes to arrive fast. Chinese suppliers can send vacuum casting prototype parts china in just 3 days. This is much quicker than many other countries. Most shipments from other places take 4 to 7 days. Chinese companies work hard and use smart methods to save time. This helps you finish your projects on time. You can go from an idea to a real part very quickly. This gives you a big advantage in your business.

When you pick a rapid prototyping service in China, you wait less. You get to try out your ideas sooner. Fast turnaround lets you make changes right away. Your project stays on schedule, and you do not lose money from delays. Many companies use this speed to beat their rivals and follow new trends.

Tip: Getting parts fast helps you launch new products and listen to customers quickly.

Supplier Expertise

Chinese factories are top experts in making prototypes. They buy the best machines and hire skilled workers. You get to use their knowledge and experience. Many suppliers mix CNC machining, 3D printing, and vacuum casting. This gives you great results and more choices.

You also spend less money. Vacuum casting prototype parts china cost about 30% less than injection molding for small runs. You do not need to pay for costly tools. This means you save money at the start. Companies like 3ERP and HLH Prototypes have ISO9001-2015 certificates. They keep your ideas safe and always give good quality. You get fast, safe, and steady prototype parts.

Chinese suppliers use new technology. They use robots, AI systems, and better materials. These tools make parts more exact and cut down on waste. You get parts that meet tough rules for detail and how they work.

Note: Many customers say Chinese suppliers answer fast, give smart design tips, and deliver on time. High customer happiness means you can trust them for your next job.

Wide Application Range

Vacuum casting prototype parts china are used in many fields. You find these parts in cars, medical tools, electronics, planes, and home products. The process helps make plastic parts for testing and small orders. You can check how things fit, work, and look before making lots of them.

Here is a table with common industries and uses:

Industry | Notable Application Examples | Supporting Company Examples and Capabilities |

|---|---|---|

Automotive | FOW Mould, Star Rapid, HLH Prototypes, 3ERP provide precise small-batch parts | |

Medical | Medical devices | FOW Mould, Star Rapid, HLH Prototypes, Proto Labs serve medical industry |

Electronics | FOW Mould, Star Rapid produce detailed electronic prototypes | |

Aerospace | Aerospace components | HLH Prototypes, 3ERP serve aerospace industry with rapid prototyping |

Consumer Goods | Home appliances and consumer products | FOW Mould supports home appliances and consumer product prototyping |

You can see many industries use vacuum casting for making prototypes. The process uses silicone molds and polyurethane resins to make parts that look like real products. You can order just one or a few parts. This makes it easy to test and change your designs.

Vacuum casting in China helps turn digital designs into real parts. You get different finishes, many materials, and quick shipping. This method is good for fast testing and small orders. You can go from an idea to a finished part with no worries.

Callout: Pick vacuum casting prototype parts china to get speed, save money, and use new technology for your next project.

Create Medical Products with Vacuum Casting

Precision and Consistency

You want your medical products to be exact and safe. Vacuum casting in China helps you get very precise parts. Chinese suppliers use advanced CNC milling for master patterns. These patterns can be made with tight tolerances, like ±0.01 mm. Vacuum casting molds can copy small details down to 0.1 mm. Some medical parts can even reach 0.001 mm tolerance. This means your prototypes are almost the same as your designs. You can trust each part to be accurate, which is important for medical devices.

Every prototype needs to look and work the same way. Vacuum casting makes sure each part has the same shape and size. The surface finish is always smooth and even. You can test your device and know the results will not change. This helps you avoid mistakes and keeps your project moving forward.

Tip: When your prototypes are very precise, you can find and fix design problems early.

Material Options for Medical Use

You need safe materials for medical products. Vacuum casting in China gives you many choices for medical prototypes. You can pick medical-grade polyurethane resins for strong parts. Clear resins are good for see-through pieces. Flexible resins work for soft-touch parts. Many of these materials meet safety rules like ISO 10993 for biocompatibility.

Here is a quick look at common material choices:

Material Type | Medical Application Example | Key Benefit |

|---|---|---|

Medical-grade PU | Device housings, covers | Safe, durable, easy to clean |

Clear resin | Diagnostic tools, fluid chambers | High clarity, non-toxic |

Flexible resin | Seals, gaskets, wearable parts | Soft, skin-friendly |

You can choose the best material for your project. This lets you test how your product feels and works. You can also check if the material is safe for medical use.

Note: Picking the right material and process helps your prototypes meet safety and performance needs.

Supplier Tips

Evaluate Experience

You want a supplier who does a good job every time. Start by checking how long they have worked in this field. Look for certificates like ISO 9001, IATF 16949, AS9100, or ISO 13485. These show the supplier follows important rules. Ask them to show you these certificates. You can also ask for reports from outside inspectors. Get customer references and read online reviews to see if people had problems. If you can, visit the factory or ask for pictures and videos. A good supplier will be happy to share this with you.

Tip: Always ask for a sample before a big order. This lets you check the quality and service yourself.

Check Quality Assurance

Quality is very important for your prototypes. Pick suppliers who use modern machines and have a team for quality checks. They should follow ISO 9001:2015 rules and use tools like CMMs to measure parts. Ask how they check quality—look for checks at the start, during, and at the end. Good suppliers track each step with ERP systems and improve from feedback. You want a partner who knows your industry’s rules and can change their process for you.

Quality Check | What to Look For |

|---|---|

Certifications | ISO 9001, IATF 16949, etc. |

Equipment | CMMs, image measuring tools |

Inspections | Multiple checks per production |

Team | Skilled quality control staff |

Manage Communication

Good communication helps your project go well. Use WeChat or DingTalk to get updates every day. Share big files with WeTransfer. Send short messages about one topic at a time. Use pictures with notes to explain things. Plan calls with apps that show both time zones. Learn a few Mandarin words and respect Chinese holidays to build trust. Always write down important points to make sure everyone agrees.

Note: Ask for photos at each step to find problems early and avoid surprises.

Handle Logistics

Shipping from China can be tricky. It may take longer and cost more. Plan for delays, especially with hard parts. Make a test batch before making many parts to find problems early. Protect your ideas by signing NNN agreements and using more than one supplier. Watch quality closely and have backup suppliers for important parts.

Stay involved during the first production run.

Never let one supplier handle everything.

Use safe payment methods and check addresses before sending money.

Callout: Careful planning and clear deals help you avoid mistakes and keep your project safe.

Picking vacuum casting prototype parts from China helps you a lot. You get your parts quickly and do not spend too much money. The parts are high quality and work well. Many companies like these benefits:

You get working prototypes in just a few days, even if you need them fast.

You save money because the molds can be used again and the materials do not cost a lot.

The parts are strong and have lots of detail, just like your designs.

You can sell your product sooner and make it better with help from experts.

Feel sure about starting your next project. Follow these tips to choose a good supplier and stay ahead of others.

FAQ

What is the typical lead time for vacuum casting prototype parts from China?

You can get your parts in just 3 to 7 days. Chinese suppliers work quickly and use smart ways to make things. This fast speed helps you start selling your products sooner. You can also stay ahead of other companies.

Tip: Getting parts fast lets you test and fix your designs quickly!

Can I order just a few prototype parts, or do I need a large batch?

You do not have to order a lot of parts. Most suppliers let you buy just a few, even only one. This makes it easy to try out new ideas without spending too much money.

Small orders help you save money

You can change your designs easily

Are the materials safe for medical or food-related prototypes?

Yes! You can pick medical-grade or food-safe resins. Chinese suppliers have materials that follow strict world rules. You get safe and strong parts for special uses.

✅ Always ask your supplier to show you safety certificates.

How do I protect my design and intellectual property?

You can sign an NNN agreement with your supplier. This keeps your design and ideas safe. Good suppliers will respect your privacy and keep your project safe.

Note: Pick suppliers who are known for protecting your ideas.

LKprototype

LKprototype