You might ask how much vacuum casting costs in 2026. The usual mold price is between $200 and $1000. Each part often costs from $10 to $100. Many things can change the price. These include the material you pick, how complex your part is, and what finishing you want.

Vacuum casting is a good choice for making a few items.

It costs less per part than injection molding for small batches.

Silicone molds are quicker and cheaper to make than using machines.

Making a small number of parts works best for prototypes and working pieces.

This vacuum casting price guide helps you find the right costs for your project. Use this guide to work with a skilled vacuum casting parts maker and plan your budget with confidence.

Key Takeaways

Vacuum casting saves money for small batches. It works well for prototypes.

Mold complexity and material choice change costs a lot. Simple designs cost less.

Ordering more parts can make each part cheaper. Bigger batches save money.

Watch out for extra fees like rush orders or special finishes. This helps you avoid surprise costs.

Plan your project early. This helps you make smart choices and spend less.

How Much Does Vacuum Casting Cost? ⭐⭐⭐

You want to know how much you will pay for vacuum casting. The answer depends on many things. This vacuum casting price guide helps you see what affects the final cost. You can use this price guide to plan your project and avoid surprises.

Vacuum casting gives you a way to make small batches of parts. You get high quality without the high price of other methods. Most people pay between $200 and $1000 for a silicone mold. Each part usually costs $10 to $100. The total vacuum casting cost changes based on your choices.

Tip: You can save money if you understand what drives the cost. Make smart choices early in your project.

Manufacturing experts say these things affect vacuum casting cost the most:

Material costs, like the type of polyurethane resin you pick.

Labor costs for making molds and casting parts.

Overhead expenses, such as factory space and energy.

The complexity of your part design.

Equipment and machine maintenance.

How long each production cycle takes.

You also need to think about:

The number of parts you want. Making more parts can lower the cost per part.

The mold design. Simple molds cost less.

The material you choose. Some materials cost more but give better results.

Vacuum casting uses special machines. These machines cost more than some other tools. They also need more care and time to run. This can make the process slower and add to the cost.

You can use this vacuum casting price guide to check each factor. When you know what affects the price, you can make better choices for your project. This helps you get the best value for your money.

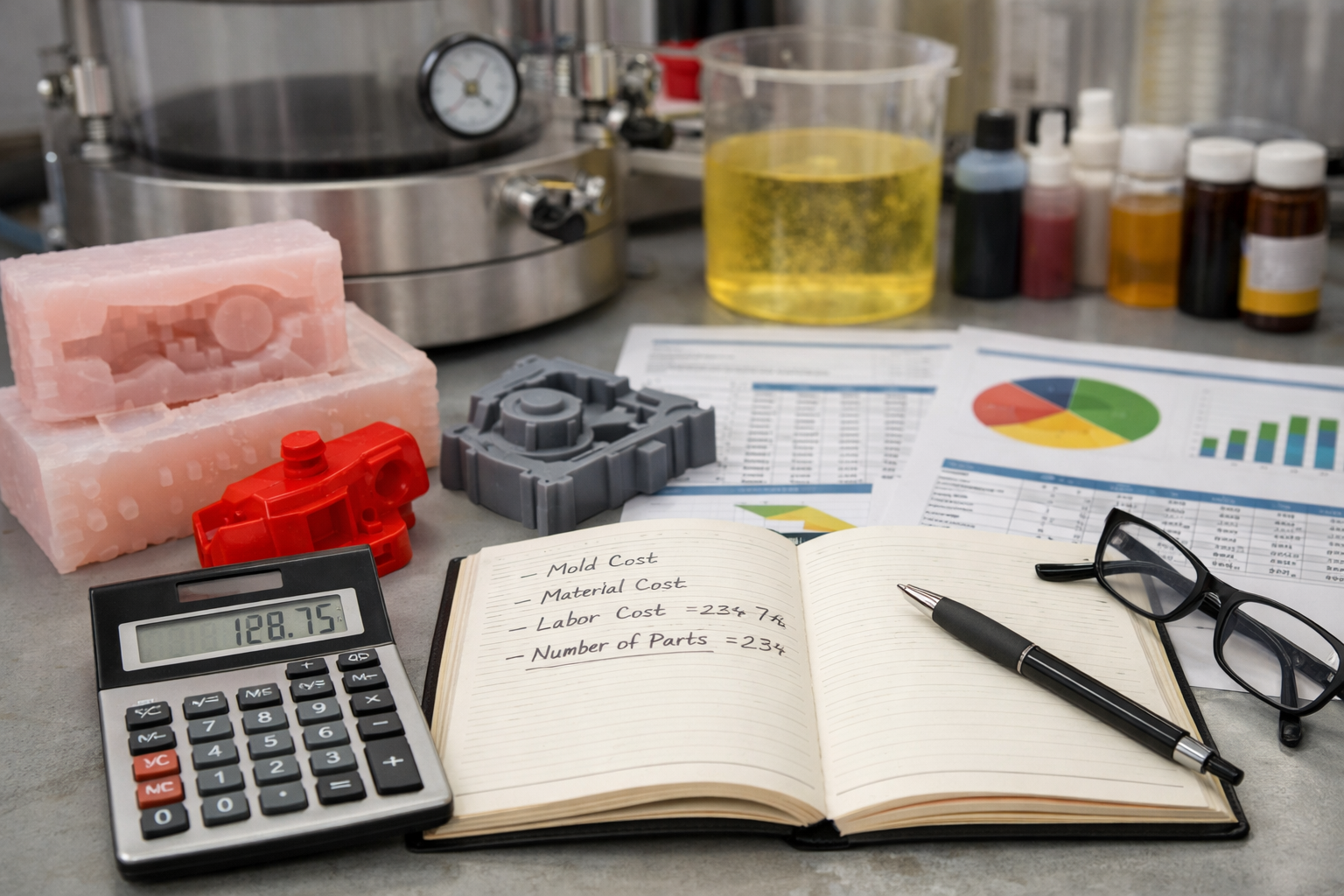

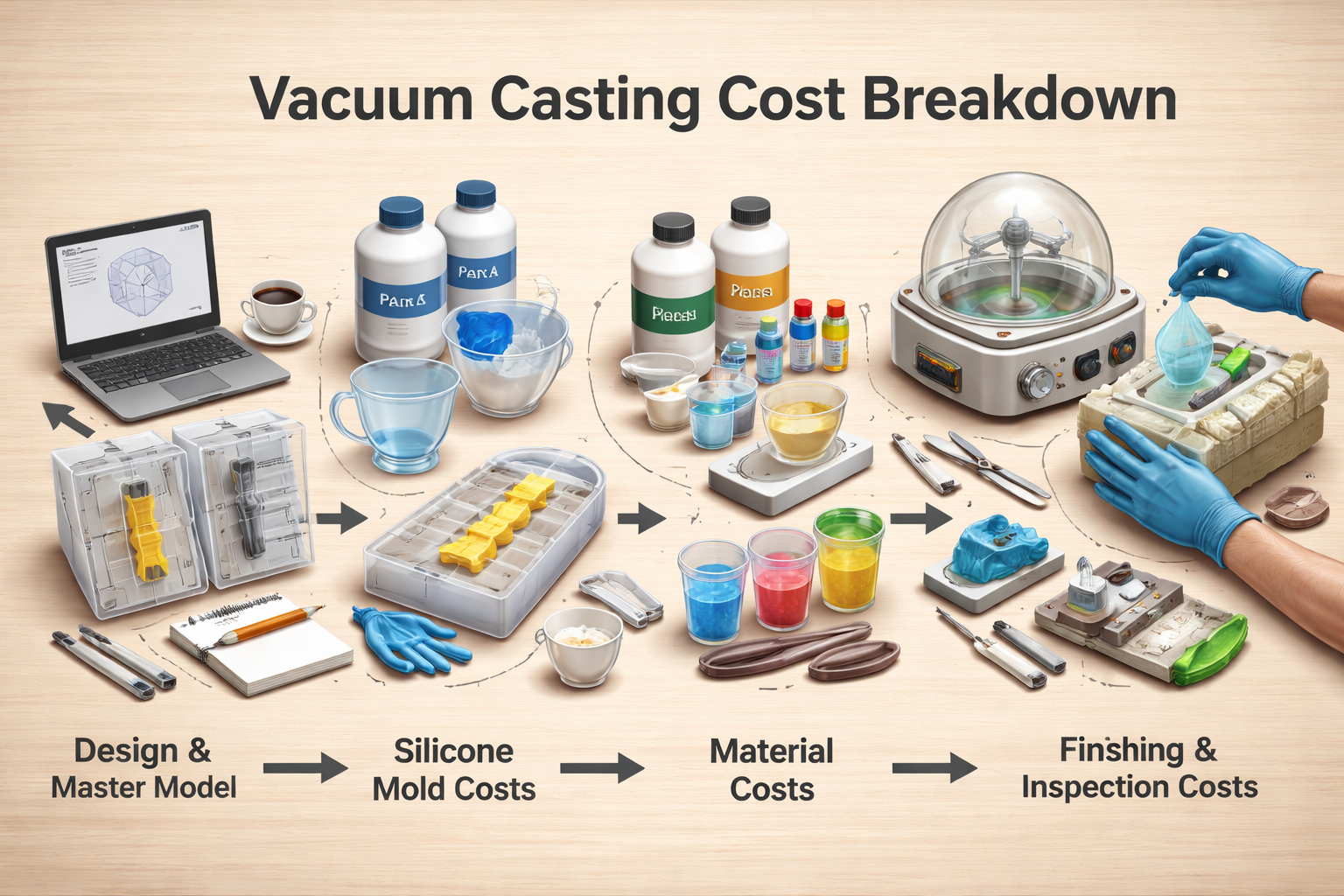

Vacuum Casting Cost Breakdown ⭐⭐⭐

Knowing how costs work helps you plan your project. Every step adds to the final price. This guide tells you what costs to expect.

Silicone Mold Cost

You begin with the silicone mold. Mold cost changes with size, shape, and detail. Simple molds are cheaper. Complex molds need more time and material. If you want very precise prototypes, you pay more. Most molds cost from $200 to $1000.

Part Production Cost

Part production cost means making each item. The number of prototypes you need changes this cost. Making more parts lowers the price for each one. Small batches are best for testing ideas. You pay for machine time and worker help for every part.

Material Fees

The material you pick changes your total cost. Some materials cost more but work better. The table below shows how different materials affect vacuum casting costs:

Material Type | Cost Impact on Vacuum Casting |

|---|---|

Polyurethane (PU) | Used a lot, costs a medium amount |

PMMA | Costs more for clear parts |

PP | Price changes, usually costs less |

ABS | |

Soft Rubber | Price changes, can cost more |

Labor and Setup Charges

Labor and setup charges pay for getting molds and machines ready. Skilled workers make sure your prototypes are good. Setup fees pay for machine checks and workspace prep.

Finishing and Post-Processing Costs

Finishing steps like painting or sanding add to your cost. You might want smooth surfaces or special colors. These steps need extra work and materials.

Other Fees (rush, shipping, QC)

Other fees can surprise you. Rush orders cost more if you need things fast. Shipping fees change with location and box size. Quality checks make sure your prototypes are good. The table below lists common hidden costs:

Cost Type | Description |

|---|---|

Material costs | Makes up 40-60% of total cost, changes with material type (like ABS, PP, PU). |

Mold cost | Bigger or harder molds need more material and time, so they cost more. |

Production volume | Making more parts lowers the price for each one by spreading setup and mold costs. |

Post-processing | Extra steps like painting and putting parts together add to worker and material costs, sometimes hidden. |

Tip: Always ask your supplier about hidden costs before you start your vacuum casting project.

Key Factors That Affect Vacuum Casting Price

Knowing what makes vacuum casting cost more helps you choose wisely. This guide shows the main things that change how much you pay.

Mold Complexity and Design

Molds with lots of details cost more money. Simple molds use less stuff and take less time. If your part has tricky shapes, the mold needs extra work. This means you pay more for labor and materials. Picking a simple design can help you save money.

Part Size and Geometry

How big and shaped your part is matters a lot. Bigger parts need more silicone and resin. Hard shapes take longer to get ready and make. The table below shows how these things change your cost:

Factor | Impact on Costs |

|---|---|

Master Model Fabrication | Costs change with how you make it; hard shapes cost more. |

Mold Complexity | Fancy shapes need more work, so labor and material go up. |

Material Selection | Different materials cost different amounts. |

Production Volume | Making more parts means you need more molds, so costs rise. |

Post-Processing and Finishing | Extra steps can make costs go up, especially for nice-looking models. |

Material Choice

You can pick from many materials for vacuum casting. Some resins cost more but are stronger or clearer. If you want special things like heat resistance, you may pay more. Always ask your vacuum casting parts maker about the best material for your project.

Order Volume (Cost Per Part)

How many parts you order changes the price for each one. Making more parts spreads out the mold and setup costs. If you only need a few, each part costs more. Here are some facts:

Vacuum casting uses people to make parts, so small batches cost more per part.

Silicone molds cost less than metal molds but do not last as long.

This way works best for making a few parts and quick, good prototypes.

Finishing Requirements

Extra finishing steps make your cost go up. You might want painting, dyeing, or a shiny look. The table below shows how finishes change your price:

Finishing Technique | Description | Cost Implication |

|---|---|---|

Mass-Dyeing | Color added for an even look | Makes material cost go up |

Painting | Custom color after making the part | Adds labor cost |

Mirror Polish | Shiny, smooth surface | Takes more time and costs more |

Chrome Plating | Metal look for style and strength | Adds material and work cost |

Limited VDI Textures | Special patterns on the surface | Can make production harder and cost more |

Lead Time and Urgency

If you need parts fast, you might pay a rush fee. How long it takes depends on part details, order size, and how busy the factory is. The table below shows what changes lead time and cost:

Factor | Description |

|---|---|

Complexity of the part | More details mean it takes longer to make |

Number of parts required | Big orders take more time to finish |

Specific project requirements | Special needs can change timing and cost |

Manufacturing capacity | Busy factories may charge more for fast delivery |

Cost-effectiveness | For big orders, other ways like injection molding may cost less overall |

Tip: Start your project early and talk to your maker to avoid extra fees.

This section helps you see what makes vacuum casting cost more. Use these ideas to get the best deal for your project.

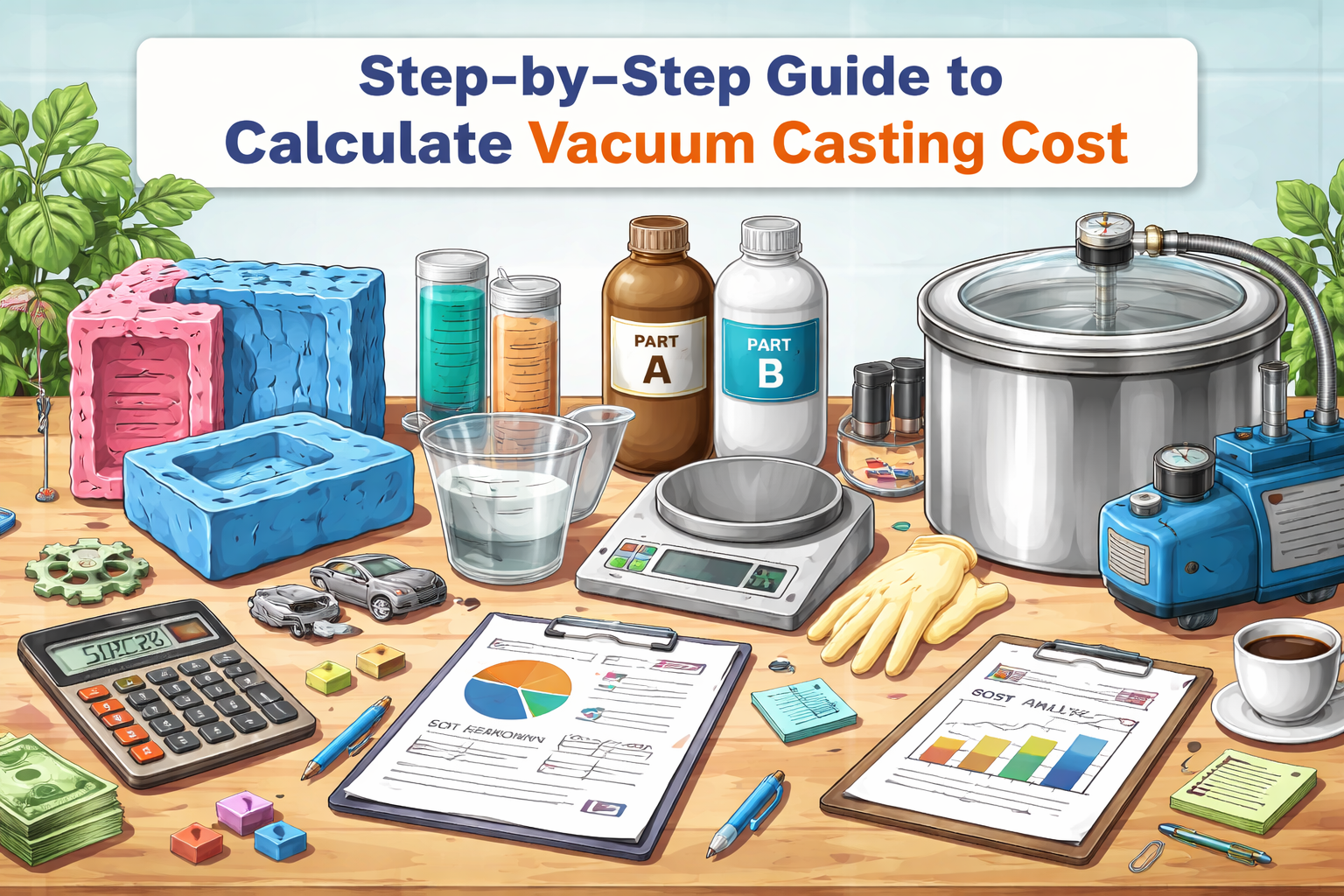

Step-by-Step Guide to Calculate Vacuum Casting Cost ⭐⭐⭐

If you want to know your vacuum casting cost, you can follow this simple guide. You will see how each step helps you plan your budget for prototyping or production.

Gather Project Information

Start by collecting all the details about your project. You need to know the size, shape, and number of parts you want. You should also check the limits for vacuum casting. Here is a table that shows what you need:

Requirement | Specification |

|---|---|

Standard lead time | Up to 10 copies within 15 working days |

Standard accuracy | ±0.3% (with a lower limit on ± 0.3 mm on dimensions smaller than 100 mm) |

Minimum wall thickness | At least 0.75 mm for proper mold filling; recommended at least 1.5 mm |

Maximum part dimensions | Limited by vacuum chamber dimensions (1900 x 900 x 750 mm) and max volume (10 liters) |

Typical quantities | Up to 25 copies per mold, depending on complexity and materials |

Surface structure | High-quality surface finish comparable to injection molding |

You should write down your part’s size, wall thickness, and how many copies you need. This helps you get the right price from your supplier.

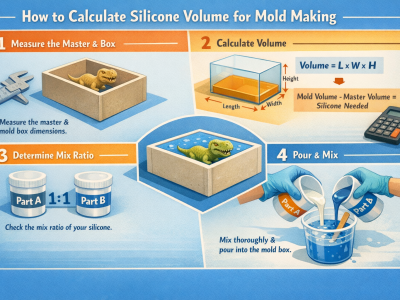

Estimate Silicone Mold Cost

Next, you need to estimate the cost of the silicone mold. The mold price depends on how complex your part is. Simple shapes cost less. If your part has many details, the mold will cost more. Most molds for vacuum casting cost between $200 and $1000.

Calculate Part Cost

Now, figure out the cost for each part. The price per part changes with the material you choose and the number of parts you order. Making more parts lowers the cost for each one. For prototyping, you may pay more per part if you only need a few.

Add Extra and Hidden Charges

You should always check for extra fees. These can include rush orders, shipping, or special finishes. Ask your supplier about all possible charges before you start. This keeps your vacuum casting price guide accurate.

Final Total and Cost Per Part

Add up all the costs: mold, parts, and extra fees. Divide the total by the number of parts to get your cost per part. This helps you see if vacuum casting fits your budget for prototyping or small batch production.

Tip: Use this guide to compare prices and make smart choices for your next project.

Vacuum Casting Price Example Calculation

Project Scenario

Imagine you want to make 30 custom plastic parts for a new device. You need high-quality prototypes to show your team and test the design. You choose vacuum casting because you want a fast and affordable way to get these parts. Many startups use this method to save money and time. One tech company saved 40% on costs for a prototype by picking vacuum casting instead of injection molding.

Mold Cost Example

You start by making a silicone mold. For a simple part, the mold cost is usually around $400. If your part has more details, the price can go up to $800. In this example, your part has a medium level of detail. You pay $600 for the mold. This mold can make up to 25 copies before it wears out. You need 30 parts, so you will need two molds.

Part Cost Example

Each part costs $30 to produce. This price includes the material and labor. You want 30 parts, so the total part cost is $900. Vacuum casting works well for small batches like this. Companies making 100 custom parts often find vacuum casting much cheaper than other methods.

Total Cost Summary

You can see how the costs add up in the table below:

Item | Quantity | Unit Cost | Total Cost |

|---|---|---|---|

2 | $600 | $1,200 | |

Parts | 30 | $30 | $900 |

Total Project Cost | $2,100 |

Vacuum casting gives you low tooling costs and fast production speed. It works best for small to medium batch sizes. You get high-quality prototypes without spending too much money.

Tip: Use vacuum casting when you need quick, affordable parts for testing or presentations.

How to Reduce Vacuum Casting Cost

Simplify Mold and Part Design

You can make vacuum casting cheaper by using simple designs. If you use less detail and avoid hard shapes, you save money and time. Simple designs also help you get better results. Making a good master pattern helps your parts turn out well and cuts down on waste. This step can stop extra costs from happening later.

Tip: Ask your supplier if your design can be simpler but still work well.

Choose Cost-Effective Materials

The material you pick can change your cost a lot. Some resins cost more because they have special features, but you do not always need the most expensive one. You should choose materials that fit your project and your budget. Many suppliers say to use materials that are both good and not too pricey, especially for testing and small batches. The right material gives you strong and nice-looking parts without spending too much.

Raw material prices are a big part of vacuum casting costs.

Picking the right material helps you keep your project price low.

Increase Order Quantity

If you order more parts at once, you can save money. In vacuum casting, making more parts in one run makes each part cost less. This works best for small batches, but bigger orders still get better prices. When you make more parts, you spread out the mold and setup costs.

Bigger orders usually mean each part costs less.

This is good for testing and small production runs.

Limit Finishing Operations

Extra steps like painting or polishing make your costs go up. You can save money by only picking the finishes you really need. Keeping finishing simple lowers both worker and material costs. Most projects do not need fancy finishes, especially when you are just testing ideas.

Plan Production Early

If you start your vacuum casting project early, you have more time to make smart choices. You can avoid rush fees and last-minute changes. Planning ahead lets you look at different suppliers, pick the best materials, and set your budget. This helps you get good prototypes and keep costs down. Vacuum casting is popular because it is fast and does not cost as much as other ways, so many companies use it.

Note: Planning early helps you avoid delays and extra costs.

FAQ – Vacuum Casting Pricing ⭐⭐⭐

You may have questions about how much vacuum casting costs and what affects the price. Here are answers to the most common questions people ask in 2026:

How much does urethane casting cost?

Urethane casting usually costs between a few hundred and a few thousand dollars. Most molds cost from $200 to $1000. Each part you make can cost $10 to $100. The total price depends on your project size and needs.What factors affect the cost of vacuum casting?

Many things can change the price. The main factors include:The cost of making the master model.

The cost to reproduce each part.

The type of material you choose.

The number of parts you want.

Any special finishes or rush orders.

How can I reduce vacuum casting costs?

You can save money by keeping your part design simple. Choose materials that fit your needs but do not cost too much. Order more parts at once to lower the price for each one. Limit extra finishes and plan your project early to avoid rush fees.

Tip: Always ask your supplier for a full price breakdown before you start. This helps you avoid hidden costs and plan your budget.

If you want to learn more about vacuum casting, you can talk to a supplier. They can help you pick the best options for your project and give you an exact quote.

Conclusion – Is Vacuum Casting Cost-Effective for Your Project?

You want to make smart choices for your project budget. Vacuum casting gives you a way to get high-quality parts without spending too much. You can use it for prototypes or small batches. Many people like this method because it is fast and flexible.

You should look at the main advantages and disadvantages before you decide. The table below shows what you gain and what you give up with vacuum casting:

Advantages | Disadvantages |

|---|---|

Limited Production Runs | |

High Precision | Material Restrictions |

Versatility | Not Suitable for Large Parts |

Quick Turnaround | Higher Per-Part Cost |

Excellent Surface Finish |

You get good value when you need a few parts quickly. You also get smooth surfaces and detailed shapes. You can use many types of plastic, but not all. If you want to make a lot of parts or very big parts, you may need another method.

Tip: Always talk to your supplier about your needs. They can help you pick the best way to make your parts.

You now know how to check each cost. You can use this guide to plan your budget and avoid surprises. If you want to save money and get great prototypes, vacuum casting is a smart choice for your next project.

You learned how to calculate your vacuum casting costs step by step.

You saw why knowing every cost factor helps you plan your budget.

You can use this guide and example to estimate your own project costs.

You should contact suppliers for exact quotes that match your needs.

Have questions or feedback? Share your thoughts below. Your ideas help others learn more about vacuum casting.

LKprototype

LKprototype