Urethane and silicone casting involves using liquid urethane resin poured into silicone molds for creating parts or prototypes quickly and neatly. In contrast, silicone casting utilizes liquid silicone rubber to replicate objects or produce detailed components. Both urethane and silicone casting methods play a crucial role in modern manufacturing and prototyping.

These techniques are increasingly valuable across various industries. For instance:

The global urethane rubber market was valued at $1.5 billion in 2023 and is projected to grow to $2.6 billion by 2032.

The rising demand for custom products has led to an increase in the use of urethane and silicone casting in DIY projects.

Sectors such as automotive and medical equipment rely on these materials for creating strong and safe components.

Additionally, these processes empower hobbyists to craft impressive designs, making urethane and silicone casting excellent tools for both professionals and DIY enthusiasts.

Key Takeaways

Urethane casting is a cheap way to make custom parts fast. It works well for small amounts and test models.

Silicone casting is great for making detailed and bendable items. It is useful in healthcare and electronics.

Both urethane and silicone casting need careful prep and mixing. This helps make good-quality items without mistakes.

Picking the right materials is very important. Think about your project needs to choose the best resin or silicone.

Try both casting methods to learn their benefits. This will help you get better at making and designing things.

Urethane Casting: A Beginner’s Guide

What is urethane casting?

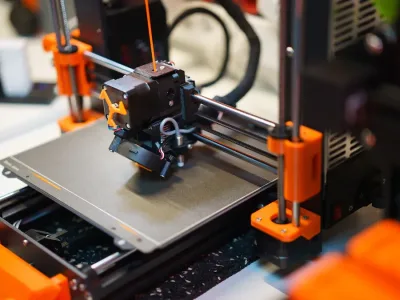

Urethane casting, also called vacuum casting, uses urethane resin and silicone molds to make parts. It is great for creating small batches of custom parts quickly and cheaply. This method is a good option instead of injection molding, especially for testing designs or making a few items.

Urethane casting is a low-cost way to make custom parts. It works well for testing ideas, small production runs, and creative projects.

This method is popular because it copies detailed designs very well. It can also make parts with different looks, colors, and textures. Whether you are new or experienced, urethane casting helps turn your ideas into real objects.

Step-by-step urethane casting process

The urethane casting process has several steps. Each step needs care to get the best results. Here’s a simple guide:

Make a 3D Model of the Part: Use 3D printing or CNC machining to create a master model. Make sure it looks smooth and finished.

Create the Silicone Mold: Put the model in a box. Pour liquid silicone rubber over it and let it harden. Take out the model to leave a mold.

Mix the Polyurethane Resin: Heat the resin and add color or other materials. Remove air bubbles from the mix.

Pour the Resin into the Mold: Warm the mold first. Pour the resin into it under vacuum to avoid air pockets.

Cure and Finish the Part: Let the resin harden completely. Take the part out, trim extra material, and polish it.

This process makes smooth, defect-free parts. By following these steps, you can create high-quality items easily.

Applications of urethane casting in prototyping and manufacturing

Urethane casting is used in many industries because it is flexible and efficient. Here are some examples:

It is a cheap way to test designs before making expensive tools.

Parts can be made in about a week, showing its speed.

Magellan Technology used urethane casting to make strong prototypes for testing. This helped them launch a successful product.

The prototypes allowed for design changes and were shown at global events, proving urethane casting's value in product development.

Urethane casting is a top choice for making high-quality prototypes, especially when paired with 3D printing.

This process is perfect for testing designs and making small batches of parts. It helps improve designs and create working items without spending too much. Whether for new products or custom parts, urethane casting is a smart and useful method.

Silicone Casting: A Beginner’s Guide

What is silicone casting?

Silicone casting uses liquid silicone rubber to make molds and copy objects. It is great for creating detailed parts with accuracy. Silicone molds are bendable, strong, and can capture tiny details. This makes them a favorite for both experts and hobbyists.

There are two main types of silicone: platinum-cured and tin-cured. Platinum-cured silicone handles heat better and lasts longer. Tin-cured silicone resists chemicals but shrinks more, which can change the final shape of your cast.

Step-by-step silicone casting process

Making parts with silicone casting has a few steps. Follow this guide to begin:

Prepare the Master Model: Pick or make a model to copy. Clean it well and fix any flaws.

Build the Mold Box: Put the model in a container. Leave space around it for the mold walls.

Mix the Silicone Rubber: Mix the silicone base with the curing agent. Remove air bubbles using vacuum degassing.

Pour the Silicone: Slowly pour the silicone over the model. Cover all details and let it harden fully.

Demold and Use: Gently take the hardened silicone mold out of the box. It is now ready to use for casting parts.

To avoid problems like bubbles or weak molds, clean everything well. Mix the materials carefully and use vacuum degassing to get smooth results.

Applications of silicone casting in various industries

Silicone casting is used in many fields because it is so useful. In healthcare, silicone is safe for the body, making it perfect for custom medical tools. The car industry uses silicone for strong seals and gaskets. In electronics, silicone parts protect and insulate devices.

Other industries also use silicone casting. Builders use silicone for weatherproof sealants. Everyday products like molds and kitchen tools are made with silicone. The silicone market in North America is growing fast because of these uses. This shows how important silicone casting is in today’s manufacturing world.

Comparing Urethane and Silicone Casting

Choosing between urethane and silicone casting depends on your project. Knowing their materials, uses, and differences helps you decide. Both methods have special benefits for different needs.

Materials used in urethane and silicone casting

Urethane casting uses liquid urethane resin and silicone molds. The resin hardens at room temperature, speeding up production. Silicone molds are bendable and strong, making detailed parts easily. Each mold can make many parts, perfect for small to medium projects.

Silicone casting uses liquid silicone rubber as its main material. Silicone molds from this process resist heat and last long. They capture tiny details, great for copying complex designs. Platinum-cured silicone lasts longer and handles heat better. Tin-cured silicone resists chemicals but might shrink a little.

Both methods use materials that ensure accuracy and good results. Urethane casting is cheaper for small projects because it needs less expensive tools.

Applications and outcomes of each process

Urethane casting is great for prototypes and working parts. It’s popular in car-making, electronics, and consumer goods. This method makes high-quality parts fast, ideal for testing or small batches. For example, urethane casting copies the look of injection molding but costs less.

Silicone casting is best for flexible and detailed items. It’s used in healthcare for custom tools, in construction for sealants, and in kitchens for tools. Artists also use silicone molds for sculptures and decorations.

Both methods work well, but your choice depends on your needs. Urethane casting saves money and time, while silicone casting offers detail and flexibility.

Durability, flexibility, and other key differences

Urethane and silicone casting differ in strength, flexibility, and quality. Urethane parts are hard and strong, good for prototypes and sturdy items. Silicone parts are stretchy and soft, great for bending or squeezing uses.

Silicone molds in urethane casting can make many parts without losing detail. This makes urethane casting reliable for small projects. Silicone casting focuses on molds or parts that handle heat or chemicals well.

Cost is another difference. Urethane casting is cheaper for small batches and makes precise parts fast. Silicone casting costs more but gives unmatched detail and flexibility.

Understanding these differences helps you pick the right method. Whether you need strong parts or detailed designs, both methods offer great solutions.

Advantages and Limitations of Urethane and Silicone Casting

Benefits of urethane casting

Urethane casting has many advantages for small production and prototypes. It makes parts with smooth surfaces that look professional. You can pick resins with special features like hardness or color.

This method is also cost-effective for making more prototypes. Silicone molds for urethane casting are ready in 1-2 weeks. Injection molds take much longer, about 4-12 weeks. Faster molds mean quicker production and meeting deadlines.

Urethane parts are strong and last well under normal use. This makes them great for working prototypes or finished parts.

Drawbacks of urethane casting

Urethane casting has some downsides too. It costs more than 3D printing for very few parts. If you need just one or two items, 3D printing is cheaper.

Urethane parts are strong but not great for heavy impacts. They may break under extreme stress, so they’re not for tough jobs.

Silicone molds wear out after making several parts. You’ll need to replace them, which adds to costs.

Benefits of silicone casting

Silicone casting is great for making detailed and flexible parts. Silicone molds are strong and capture tiny details perfectly. This makes them ideal for copying complex shapes or custom designs.

Silicone molds are easy to use. Removing parts is simple and doesn’t damage them. This saves time and effort compared to other methods.

Silicone casting works in many industries like healthcare and construction. Silicone parts are used for medical tools, seals, and weatherproof items. They resist heat and chemicals, making them very useful.

Tip: Use platinum-cured silicone for high heat and durability needs. Tin-cured silicone is good for simpler projects.

Drawbacks of silicone casting

Silicone casting has many advantages, but it also has some downsides. Knowing these problems can help you make better choices for your projects.

One problem is flash formation. This happens when silicone leaks through the mold’s edges, leaving extra material on your parts. To stop this, you need to clamp the mold tightly during casting. Another issue is material shrinkage. Silicone can shrink as it hardens, which might change the size or shape of your parts. Mold makers often test materials and adjust designs to fix this.

Keeping molds in good shape is also important. Silicone molds need regular care to stay in good condition. Without proper care, molds can wear out and make bad parts. Adding special coatings can help molds last longer and work better.

Picking the right silicone is very important too. Using the wrong type can cause problems or even be unsafe. For example, if you’re making medical items, the silicone must meet FDA rules. Ignoring these rules can cause big problems.

You also need to think about how your parts will be used. Silicone might not work well in very hot or chemical-filled places. These conditions can make your parts weaker or wear out faster.

Tip: Always test your materials and molds before you start making parts. This helps you find problems early and get better results.

Even though silicone casting is useful, these issues show why planning and care are so important. By solving these problems, you can make great parts for your projects.

Common Materials in Urethane and Silicone Casting

Materials for urethane casting

Urethane casting uses special resins to make parts with specific features. These resins differ in strength, flexibility, and look, so you can choose what fits your project. Here’s a table showing common resin types and their main features:

Resin Type | Key Features |

|---|---|

ABS-Like Resins | Hardness: 75-85, Heat resistance: 75-85°C, Strong and durable |

Glass-Filled Nylon-Like | Very stiff, Handles heat well, Resists wear, Minimal bending |

Elastomeric TPE-Like | Soft to firm (40-90), Stretches a lot, Good tear strength, Keeps shape well |

PC-Like | Tough, Handles heat, Clear, Resists UV light |

Clear Resins | Lets in 90% light, Stays clear, Smooth finish, Keeps shape |

High-Impact Resins | Very strong, Stiff, Resists chemicals, Handles heat |

These resins help make parts strong, flexible, or good-looking. For example, ABS-like resins are great for testing designs, while clear resins are perfect for stylish parts.

Materials for silicone casting

Silicone casting uses liquid silicone rubber to make molds or parts. The type of silicone depends on your project. Platinum-cured silicone is strong and handles heat well, making it great for tough jobs. Tin-cured silicone costs less and resists chemicals but might shrink a bit when it hardens.

Silicone molds made from these materials are soft and capture tiny details. This makes them great for copying complex shapes or making custom items. Whether you’re making medical tools or decorations, silicone is a flexible and useful choice.

Tips for selecting the right materials

Picking the right materials depends on what your project needs. Use this table to help decide:

Selection Criteria | Details |

|---|---|

Mechanical properties | Check strength, hardness, and toughness for good performance. |

Corrosion resistance | Think about weather, chemicals, and rust protection. |

Processing performance | Look at how easy it is to cast, melt, and shape. |

Cost considerations | Compare material prices and extra processing costs. |

For urethane casting, pick resins that match your part’s strength and flexibility needs. For silicone casting, choose silicone that fits your project’s durability and softness. Always test materials first to make sure they work well.

Tip: Use platinum-cured silicone for hot environments and tin-cured silicone for cheaper projects.

Urethane and silicone casting each have special advantages for making parts. Urethane casting is great for strong, accurate parts made quickly. Silicone casting is best for detailed and flexible designs. Both methods are useful for industries and DIY projects.

Think about your project’s needs to pick the right method. For strong and tough parts, urethane casting is ideal. For flexible or detailed items, silicone casting is a better choice. The table below shows real-world examples to help you decide:

Case Study/Project | Description | Key Focus Areas |

|---|---|---|

Studies to improve metalcasting methods. | Choosing processes, working with industries. | |

Investment Casting Technical Committee | Checks casting methods and testing rules. | Melting, gating, heat treatment. |

Casting Standards and Specifications Project | Creates searchable training tools. | Standards, design guides, material info. |

Tip: Try both methods to learn their benefits. Practice helps you get better and improve your skills.

FAQ

What makes urethane and silicone casting different?

Urethane casting uses liquid urethane resin to make hard, strong parts. Silicone casting uses liquid silicone rubber for soft, detailed items. Urethane is great for prototypes, while silicone is better for molds or flexible parts.

How long does it take to make a silicone mold?

Making a silicone mold takes about 1 to 2 days. This includes mixing, pouring, and letting the silicone harden. The time depends on the silicone type and room conditions.

Tip: Use a curing booster to make the process faster if needed.

Can silicone molds be reused for urethane casting?

Yes, you can reuse silicone molds many times for urethane casting. The number of uses depends on the mold's quality and how carefully you use it.

What safety steps should I follow during casting?

Wear gloves, goggles, and a mask to stay safe from fumes and chemicals. Work in a space with good airflow to avoid breathing harmful substances.

Note: Always check the safety instructions on the material labels before starting.

Which casting method is easier for beginners?

Silicone casting is simpler for beginners because it’s more flexible and forgiving. Urethane casting needs more care but works faster for making prototypes.

Emoji Tip: 🛠️ Try silicone casting first to gain confidence before using urethane casting.

Start your project with LKprototype

LKprototype company simplifies procurement for custom manufacturing, Suitable for making your products or prototypes with a variety of materials, such as metal or plastic, silicone rubber, from 3D Printing to CNC Machined Parts and Urethane Casting Service , with a focus on speed and efficiency. Our platform provides instant quotes. With LKprototype, You can connect with the team to communicate your project to ensure quality and on-time delivery.

Start with an instant quote and experience how our technology and expertise can make custom part procurement faster and easier.

LKprototype

LKprototype