Choosing a urethane casting service for prototyping needs careful thought. You should look at their skills, quality, material choices, support, and price. Make sure the provider can do what your project needs. Check if they fit your budget and timeline. Learn about mold life, picking materials, and how costs work. This helps you stop problems before they happen.

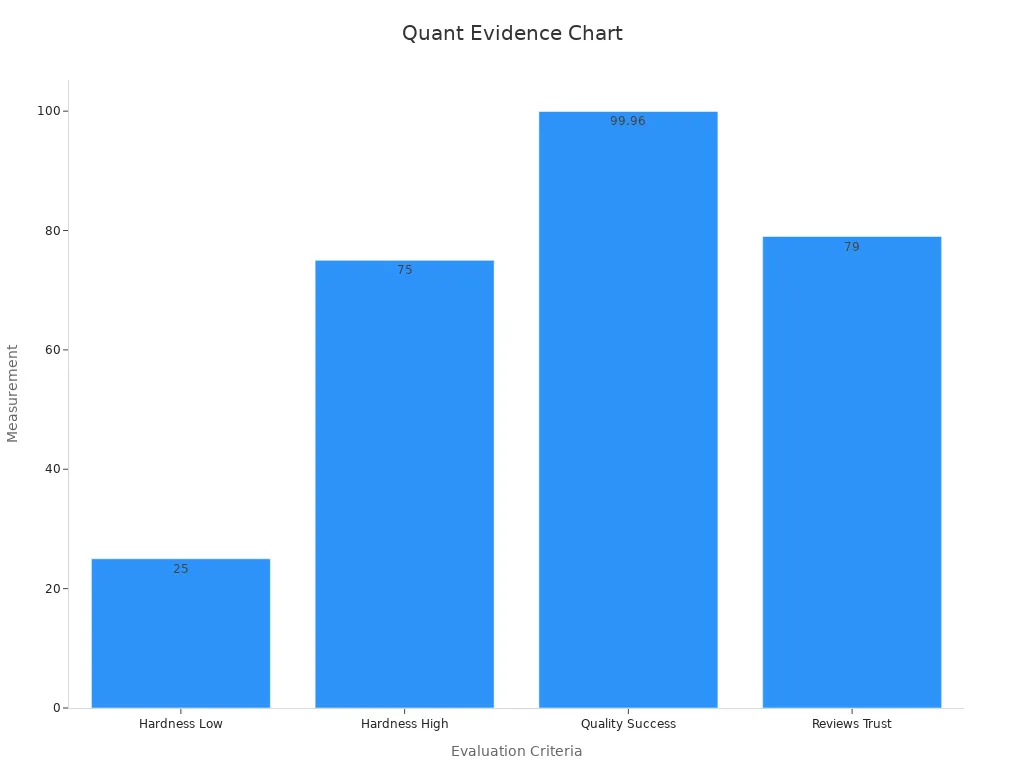

Providers with a 99.96% quality success rate and ISO certifications give parts with almost no defects.

Metric | Why It Matters |

|---|---|

Quality Success Rate | Shows provider is reliable |

Customer Satisfaction Score | Shows how good the service is |

ISO Certifications | Proves they follow strict rules |

Following steps and clear rules helps you feel sure about your choice.

Key Takeaways

Make sure you know your part’s shape, size, and how much space it takes. This helps match what urethane casting can do. It also helps stop mistakes. - Pick the right urethane material. Think about how strong, bendy, or tough it needs to be. This makes sure your prototype works well. - Choose providers with good quality records. Look for certifications and new equipment. This helps you get good parts you can trust. - Ask for clear quotes. Compare prices, how long it will take, and any extra costs. This helps you stay on budget and avoid surprises. - Talk clearly with providers. Check what other clients say and look at their references. This helps you find good help and service.

Project Requirements

Part Specs

First, decide what shape and details your part needs. Urethane casting is good for parts with some detail and close measurements. Make sure your design matches what urethane casting can do. For example, this process can keep sizes within +/-.010" for the first inch. For every extra inch, it can be within +/-.005". Thin walls can be as small as 0.040". If your part is small, walls can go down to 0.020". Draft angles between 3 and 5 degrees help take the part out of the mold. This also makes the mold last longer. Add ribs and bosses to make your part stronger. But do not make them too big or you might get defects.

Parameter | Typical Value | Notes |

|---|---|---|

Dimensional Tolerance | +/-.010" (first inch) | High accuracy for prototypes |

Minimum Wall Thickness | 0.040" (typical) | 0.020" for small parts |

Draft Angle | 3-5 degrees | Eases mold release |

Rib Height | ≤ 3 × rib thickness | Adds strength |

Boss Wall Thickness | < 60% of part thickness | Reduces shrinkage |

Tip: If you follow these tips, your parts will turn out better and have fewer problems.

Volume Needs

Figure out how many parts you want. Urethane casting works best for small or medium amounts, like 1 to 100 pieces. If you need more, the mold might wear out faster. This can make the parts not as good. How long the mold lasts depends on how hard your part is to make and what material you use. Simple parts last longer. Harder shapes can make the mold wear out sooner. Always ask the service how long the mold will last for your job.

Budget & Timeline

Plan your money and time before you start. Urethane casting is quick and does not cost as much at first as injection molding. But if you need lots of parts or tricky shapes, the price can go up. If the mold does not last long, you may need to pay for new ones. Ask for a price that shows all costs, like setup, materials, and finishing. This way, you will not be surprised and can finish on time.

Material Selection

Urethane Options

There are many urethane materials you can pick for prototyping. Each one has special features for different jobs. Polyester urethanes are good for sliding wear, like scraper blades. Polyether urethanes are better for parts that get hit a lot, like sandblast curtains. Makers test these materials with abrasion tests, such as DIN Abrasion and DSRW tests. These tests show how much the material wears down. This helps you compare which one is best. You can also pick standard, high-temperature, fire-resistant, or chemical-resistant urethanes. This lets you match the material to where your part will be used.

Tip: Ask your provider about abrasion resistance and hardness ratings for each urethane. This helps you choose the best one for your project.

Strength & Flexibility

Urethane materials are strong and flexible. Shear and tensile strength tests show polyurethane keeps its shape under stress. It stays strong even when it gets hot. Polyurethane keeps over 75% of its strength after UV light. It gets harder instead of breaking down. This means your parts last longer and do not crack. You can pick softer urethanes for bendy parts. Harder ones are good for stiff parts. The right mix of strength and flexibility helps your prototype work well.

Appearance

How your prototype looks is important. Urethane casting gives smooth and detailed surfaces. Providers check for bubbles, lines, or parts that do not line up. They use tools to make sure sizes are right. For big orders, they check samples to find problems. The quality of the silicone mold and master model affects the finish. Picking the right urethane and a skilled provider gives you parts that look good every time.

Visual checks find surface problems early.

Sample checks make sure each batch is good.

Good molds give your parts a smooth and correct look.

Urethane casting can fit many part needs. You can change the formula to get soft foams, hard parts, or special shapes. This makes urethane casting a great choice for many prototypes.

Urethane Casting Service Evaluation

Provider Expertise

Start by checking if the provider has lots of experience. Look for companies that have made many urethane parts before. A good provider trains their workers and tries new ways to solve problems. Ask about their team and how they fix issues. Providers who use new tools and keep learning can do better work.

You should also see if they have important certifications. These show the provider follows rules and does things the right way. Here is a table that lists some certifications and what they mean:

Certification / Standard / Quality Measure | Description / Relevance to Expertise in Urethane Casting |

|---|---|

ISO 13485:2016 | Medical device quality management, high-quality standards. |

ISO 14001:2015 | Environmental management, responsible manufacturing. |

ISO 9001:2015 | General quality management, consistent product quality. |

IATF 16949:2016 | Automotive quality, rigorous process control. |

FDA Registered Facilities | Compliance with FDA, important for medical-grade parts. |

Statistical Process Reports | Data to monitor and control processes, proof of expertise. |

Repeatability | Ability to reproduce parts within specifications. |

FMEAs (Failure Mode and Effects Analysis) | Risk assessment for process reliability. |

Lot Code Traceability and Product Retains | Tracking and quality assurance for production batches. |

Tip: Ask to see samples or stories about past projects. This helps you know if the provider can do your job.

Quality Standards

Pick a provider who checks every part for problems. They should have systems to find mistakes early. Certifications like ISO 9001 show they care about quality. Good providers keep records of their checks and share reports with you.

Here are some ways to see if they make good parts:

Scrap rate tells you how many bad parts they make.

On-time delivery shows if they finish work when promised.

Quality management system means they follow set rules.

Quality control paperwork includes reports and certificates.

Past performance shows how well they fixed old problems.

If a provider tracks these things and shares them, they want to do a good job.

Equipment & Process

Having the right machines helps make better parts. Providers with new machines can make smooth and exact parts. Look for companies that use CMM and optical tools to check their work. These tools help make sure every part is right.

The people using the machines should be well trained. Machines need to be checked and cleaned often to work well. Providers who follow ISO-9001 rules try to get better all the time.

Here is a table that shows what to look for in equipment and process:

Quality Assurance Aspect | Description |

|---|---|

Quality Management System | Based on ISO-9001, with documented procedures and process improvement. |

Metrology Calibration | Daily checks to keep measuring tools accurate. |

Inspection Techniques | Use of CMM and optical tools for first article and full batch checks. |

Inspection Reporting | Detailed reports for customer review and approval. |

Quality Control | Visual and dimensional checks, with documented data; very low return rates. |

Production Control | Monitoring of machines, materials, and temperatures for consistency. |

Corrective Actions | Formal analysis and action plans to fix quality issues. |

Preventative Maintenance | Regular programs to reduce downtime and keep equipment efficient. |

Providers who use these steps can make tricky parts and small batches. They can also change things if you need something special and still do a good job.

Note: Good machines and smart workers help providers meet tough rules and finish hard jobs.

Cost & Turnaround

Quotes

When you start a urethane casting project, always ask for a detailed quote. A good quote lists every cost, such as setup, materials, labor, and finishing. Some providers may leave out extra fees for rush orders or special finishes. If you do not check, you might pay more than you expect. Ask for a written quote that breaks down each part of the price. This helps you see where your money goes.

Tip: Request quotes from at least three providers. This gives you a clear view of the market and helps you spot hidden costs.

Pricing Structure

You need to understand how each provider sets their prices. Some charge a flat fee for the mold, while others add costs for each part made. Look for extra charges, like shipping, painting, or special inspections. Providers may also charge more for complex shapes or tight tolerances. Use a table to compare what each provider includes in their price.

Cost Item | Provider A | Provider B | Provider C |

|---|---|---|---|

Mold Fee | $ | $ | $ |

Per-Part Cost | $ | $ | $ |

Finishing | $ | $ | $ |

Shipping | $ | $ | $ |

Rush Fee | $ | $ | $ |

This table helps you see which provider gives the best value for your project.

Delivery Time

Turnaround times matter when you need parts fast. Ask each provider how long it takes from order to delivery. Some can finish in days, while others need weeks. Fast turnaround times can cost more, but they help you meet tight deadlines. Always check if the provider can keep their promise. Ask for examples of past projects with similar timelines.

Check if the provider offers updates during production.

Ask if they can handle urgent changes or delays.

Note: Reliable providers share clear schedules and keep you informed at every step.

Support & Reputation

Communication

You need to talk easily with your urethane casting provider. Good support helps fix problems fast. You should get updates during each step of your project. Ask if you will have one main contact person. This person can answer questions and help you. If you want changes or have problems, good support really helps. After your project, see if the provider will help with future needs or fixing issues.

Tip: Fast replies and clear answers mean the provider cares about you.

Client Feedback

Always check what other clients say before picking a provider. Online reviews on trusted sites show how the provider treats people. Look for comments about quality, delivery speed, and fixing mistakes. High ratings and good stories mean the provider does good work. Bad reviews or many complaints can warn you about problems.

Read reviews on forums and business websites.

See if the provider has won awards from industry groups.

References

Ask the provider for names of past clients. A good company will give you contact details. You can call or email these clients to ask about their experience. Prepare some questions, like:

Did the provider send parts on time?

Was the quality what you wanted?

Did the provider fix any problems?

A table helps you compare what different clients say:

Reference Name | Project Type | On-Time Delivery | Quality | Issue Resolution |

|---|---|---|---|---|

Client A | Prototype | Yes | High | Excellent |

Client B | Production | Yes | Good | Good |

Client C | Prototype | No | Fair | Poor |

Note: References give you real proof of the provider’s reputation and if you can trust them.

You can get better results if you follow clear steps. First, figure out what your project needs. Next, pick the right urethane material for your part. Check if providers have good quality certifications. Look at their prices and what other customers say. Compare costs and support to choose the best provider.

Evaluation Criteria | Description |

|---|---|

Cost Elements | Plan for labor, materials, and project duration to avoid surprises. |

Material Hardness Range | Choose from soft (25 shore 00) to hard (75 shore D) for your application. |

Customer Service Metrics | Fast response times build trust and satisfaction. |

Quality Certifications | ISO 9001 and ISO 13485 show high standards. |

Customer Reviews Trust |

If you use a step-by-step plan, you can make sure your prototype is good, works well, and is worth the money.

FAQ

What is the typical lead time for urethane casting prototypes?

Most providers can make prototypes in 7 to 15 business days. If your part is tricky or needs a special finish, it might take longer. Always check how long it will take before you order.

How many parts can one silicone mold produce?

One silicone mold usually makes 20 to 25 parts. The number depends on how hard your part is to make and what material you use. Ask your provider how many parts you can get from your mold.

Can you use urethane casting for functional testing?

Yes, you can use urethane cast parts to test if your part works. Urethane materials are strong and bendy. This lets you check if your part fits and works before making lots of them.

What surface finishes are available with urethane casting?

You can pick matte, shiny, or bumpy finishes. Providers can match colors and add special coatings. Ask to see samples so you know what your part will look like.

How do you choose the right urethane material?

First, write down what your part needs, like strength or heat resistance. Look at material data sheets. Ask your provider for help and get samples to see which one is best.

LKprototype

LKprototype