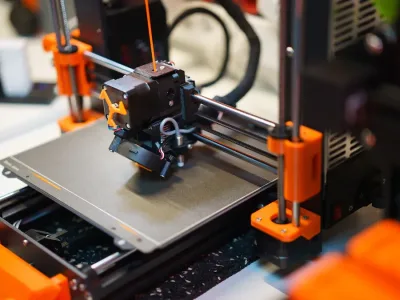

You should choose the best prototyping method for your project by considering how many parts you need, how quickly you need them, the material you want, and your budget. Urethane casting over 3D printing prototyping offers a smoother finish and stronger parts for small to medium quantities. It’s ideal if you want parts that resemble injection molding. On the other hand, 3D printing is fast and can create complex shapes quickly. Many companies now combine both methods, using 3D printing to create tools for urethane casting. This approach speeds up the process and reduces costs for custom parts. Key Takeaways…

Choosing a urethane casting service for prototyping needs careful thought. You should look at their skills, quality, material choices, support, and price. Make sure the provider can do what your project needs. Check if they fit your budget and timeline. Learn about mold life, picking materials, and how costs work. This helps you stop problems before they happen. Providers with a 99.96% quality success rate and ISO certifications give parts with almost no defects. MetricWhy It MattersQuality Success RateShows provider is reliableCustomer Satisfaction ScoreShows how good the service isISO CertificationsProves they follow strict rules Following steps and clear rules helps…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.