Silicone molds for resin are very useful in manufacturing today. They are flexible and help make accurate and detailed parts for many industries, like cars and healthcare. Silicone molds make production faster, which is great for custom designs and small batches. The Vacuum Casting Machine Market might reach 0.65 million USD in 2023. This shows how important silicone molds are. Industries like electronics and airplanes use these molds to make cheap prototypes. Silicone molds help make work easier while keeping quality and speed high. Key Takeaways Silicone molds are bendable and strong. They help make detailed parts for many industries,…

Resin art is all about creating shiny, beautiful items with liquid resin. You can make coasters, jewelry, or unique trays. It’s a blend of crafting and science! If you’re just starting out, silicone molds are incredibly useful. They are flexible, reusable, and shape resin perfectly. Consider them essential tools for beginners to learn the craft. They’re user-friendly, ensuring your projects turn out beautifully. For newcomers, using silicone molds is the simplest way to dive into resin art without any stress. Key Takeaways Silicone molds are great for beginners in resin art. They bend easily, can be reused, and are simple…

Urethane casting prototype Choosing the best vacuum casting factory is crucial for creating high-quality prototypes and parts for your project. A reliable factory equipped with advanced tools and experienced professionals ensures precise and consistent results. Their efficient processes save both time and money while offering custom solutions tailored to your specific needs. Selecting the right vacuum casting factory simplifies the process of transforming your ideas into tangible products. Key Takeaways Look up different vacuum casting companies. Check reviews and their work to ensure they are good and trustworthy. Pick a factory with trained workers and modern tools. This helps make…

Choosing a weed grinder as a beginner can feel tricky. However, it can significantly enhance your experience. A good grinder provides an even herb texture, making your sessions easier and more enjoyable. Now, consider adding your own style to it with personalised weed grinders. You could incorporate a design, your name, or a humorous quote. Personalised grinders not only look fantastic; they also reflect your personality. They make using them feel unique. Whether it’s for yourself or as a gift, select one that functions well and showcases your style. Key Takeaways Pick a basic grinder if you're new. A 2-piece…

Selecting the right urethane casting service is crucial for achieving durable and high-quality parts. Properly crafted molds play a key role in preventing issues like trapped air, which can compromise the strength of the final product. A reliable urethane casting service utilizes expertise and past project insights to deliver superior results. By choosing a trusted provider, you can meet your specific requirements, save costs, and ensure timely delivery, helping you complete your project successfully. Key Takeaways Know what your project needs. Decide the type and number of parts. Pick the right urethane materials. Think about strength, flexibility, and look. Set…

Prototyping car models play a crucial role in car design, enabling the testing of ideas, enhancement of features, and early resolution of safety concerns. Throughout the car development process, prototyping car models allow engineers to evaluate vehicle performance effectively. For instance, advanced simulation tools have significantly improved car safety and saved countless lives. Rigorous testing during the initial stages ensures vehicles operate more efficiently and comply with safety regulations, resulting in innovative and reliable automobiles. Key Takeaways Begin by thinking of ideas and drawing simple sketches. This helps find design problems early. Use CAD software to make precise 3D models.…

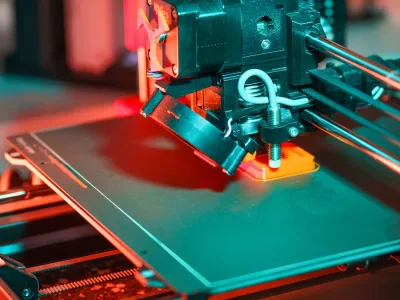

Urethane casting prototype Vacuum casting silicone mold is a meticulous process that ensures the creation of high-quality silicone molds. This technique utilizes reduced air pressure to eliminate bubbles, resulting in a smooth finish. It is particularly effective for testing ideas and producing small batches, as it captures intricate details with remarkable accuracy. The process involves placing mixed silicone in a vacuum chamber to remove air bubbles, which leads to a flawless surface. The steps include preparing materials, mixing and pouring the silicone, eliminating air bubbles, and allowing the mold to harden. This method enables you to produce vacuum casting silicone…

Urethane casting prototype Selecting the right silicone rapid prototyping manufacturers is crucial for the success of your project. Reliable manufacturers not only save time and money but also ensure top-notch quality. For instance, rapid prototyping can complete tasks in just 6 hours compared to the 14 hours traditional methods might take. Additionally, it is more cost-effective, as older vacuum molds can be four times more expensive. Beyond cost savings, trusted silicone rapid prototyping manufacturers focus on accuracy and material strength by thoroughly measuring errors and testing durability. Choosing the right manufacturer is key to achieving your project's goals. Key Takeaways…

Selecting the right silicone rubber for mold-making is key to successful projects. Silicone rubber is flexible, durable, and easy to use, making it ideal for detailed molds. This guide details everything you need to know to make the best choice. Key Takeaways Selecting the right silicone rubber enhances mold quality. It emphasizes factors like flexibility, tear strength, and curing time for successful applications. A 1:1 mix ratio of silicone components simplifies the preparation process. It ensures consistent results while minimizing bubbles and imperfections. Fast-curing silicones facilitate quick production cycles. Their versatility allows for casting across various surfaces, making them essential…

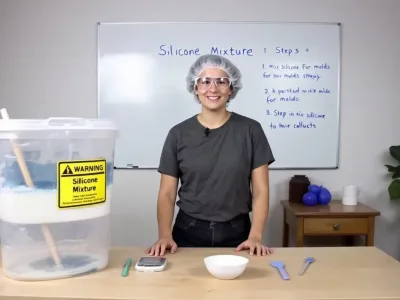

Looking to learn how to make silicone for molds at home? This guide will walk you through the necessary steps and materials, ensuring you can create high-quality molds easily. Key Takeaways Making silicone molds at home is cost-effective and allows for customization in crafting projects. Key materials for DIY silicone molds include silicone caulking, cornstarch, and mold release agents to ensure easy demolding. Curing time for molds varies, and safety precautions, like wearing gloves and ensuring good ventilation, are crucial during the process. Why Make Silicone Molds? Manufacturing silicone molds yourself can lead to significant savings over purchasing off-the-shelf options.…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.