Stanley Engineered Fastening delivers advanced fastening solutions for sectors like automotive, aerospace, and construction. This overview covers their innovative products and the engineering expertise that sets them apart. Key Takeaways Stanley Engineered Fastening provides innovative fastening solutions essential for various industries, enhancing efficiency, safety, and performance. The company tailors its products to meet specific industry needs, including automotive, aerospace, and construction, ensuring reliability and productivity. Stanley’s comprehensive support services and total system solutions streamline manufacturing processes, reduce complexity, and improve project outcomes. Revolutionizing Fastening and Assembly Technologies Stanley Engineered Fastening stands as a beacon of innovation and excellence within the…

If you’re navigating the world of product development, understanding the various rapid prototyping types is essential. From proof-of-concept and low-fidelity to high-fidelity, looks-like, and works-like prototypes, each type serves a unique function in design and testing. This article breaks down these types and shows you when and how to use them effectively. Key Takeaways Rapid prototyping is essential in product development, enabling quick iterations and varying levels of fidelity to validate design and functionality effectively. Different types of prototypes, including low-fidelity, high-fidelity, works-like, and looks-like, serve specific purposes in the development process, from concept validation to final testing. Material selection…

3D printing tolerances are crucial for ensuring your printed parts meet the desired dimensions and function as intended. Understanding and controlling these tolerances can significantly improve the accuracy and quality of your prints. This article explores what 3D printing tolerances are, why they matter, and how you can achieve precise results in your projects. Key Takeaways 3D printing tolerances are essential for ensuring dimensional accuracy and functional performance of printed parts, significantly impacting overall print quality. Factors influencing tolerances include material properties, printer calibration, and settings like layer thickness and print speed, which must be optimized for precision. Effective tolerance…

Selecting the right silicone rubber for mold-making is key to successful projects. Silicone rubber is flexible, durable, and easy to use, making it ideal for detailed molds. This guide details everything you need to know to make the best choice. Key Takeaways Selecting the right silicone rubber enhances mold quality. It emphasizes factors like flexibility, tear strength, and curing time for successful applications. A 1:1 mix ratio of silicone components simplifies the preparation process. It ensures consistent results while minimizing bubbles and imperfections. Fast-curing silicones facilitate quick production cycles. Their versatility allows for casting across various surfaces, making them essential…

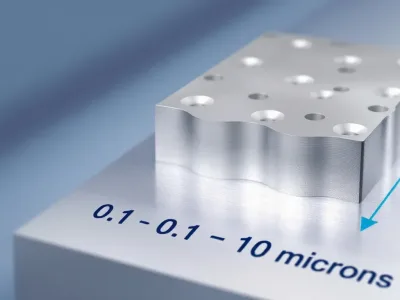

RMS surface finish quantifies the smoothness of a surface’s microscopic peaks and valleys. A lower RMS value indicates a smoother and higher-quality surface. This article explains what RMS surface finish is, its importance, and how to measure it. Key Takeaways RMS surface finish is a crucial measure of surface quality in manufacturing. It indicates smoother surfaces with lower roughness values compared to other metrics. Calculating RMS involves determining the square root of the average of the squared deviations from mean profile height. This offers a detailed analysis of surface texture. Various contact and non-contact methods exist for measuring RMS surface…

Precision CNC machined components are essential in creating parts with high accuracy and quality. Key industries such as automotive, aerospace, and medical rely on them. This article explores their importance, the machines and materials used, and their benefits and applications. Key Takeaways CNC precision machining transforms raw materials into high-quality components with exceptional accuracy, vital for industries like automotive, aerospace, and medical. Various specialized CNC machines, including milling machines, lathes, and EDMs, are used to achieve tighter tolerances and meet diverse manufacturing needs. Precision CNC machining offers multiple advantages, including enhanced accuracy, cost efficiency, and flexibility, making it a preferred…

Want to know how to make a CAD file for 3D printing? This guide will take you through the steps—from choosing CAD software to preparing your design for printing. Get ready to bring your ideas to life. Key Takeaways Selecting appropriate CAD software is crucial for effective 3D modeling, with options available for both beginners and advanced users.Understanding basic 3D printing concepts, such as file formats and material properties, is essential for creating compatible and successful CAD designs.Adhering to fundamental design principles, along with thorough preparation and testing of CAD models, enhances the likelihood of achieving quality 3D prints. Selecting…

CNC machining products are essential in automotive, aerospace, electronics, and healthcare industries. They are also crucial in the defense industry for producing weapons, ammunition, and military vehicles, as well as in the marine industry for creating durable, corrosion-resistant parts for vessels. These parts offer unparalleled precision and consistency. This article explores the key CNC machined components and their diverse applications. Key Takeaways CNC machining enhances efficiency, precision, and consistency in producing critical components across industries such as automotive, aerospace, electronics, healthcare, defense industry, and marine industry. The technology supports a wide range of materials, including metals and plastics, allowing manufacturers…

Medical device prototyping involves creating early models of medical devices to test, refine, and perfect designs before mass production. By quickly identifying and resolving design flaws, prototyping ensures that the final product is safe, effective, and meets regulatory standards. In this article, we will explore the key stages and advanced techniques of medical device prototyping, offering insights for anyone involved in the development of innovative medical technologies. Key Takeaways Medical device prototyping is essential for transforming concepts into functional products, allowing for early design validation and risk reduction.The prototyping process involves key stages such as conceptualization, material selection, and iterative…

Before electronic devices enter mass production, innovators develop prototypes as initial models to examine and improve their concepts. This crucial stage allows for the testing and perfecting of design details. It helps to confirm functionality, reduce potential risks, and certify that product standards are met. By having the devices prototyped, it becomes possible to determine cost-efficiency and identify potential defects early. Consequently, this helps prevent higher expenses during manufacturing. We will delve into the fundamental phases of electronic prototyping in this article and provide valuable advice for efficiently advancing your projects. Key Takeaways Electronic prototyping validates design and functionality, minimizing…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.