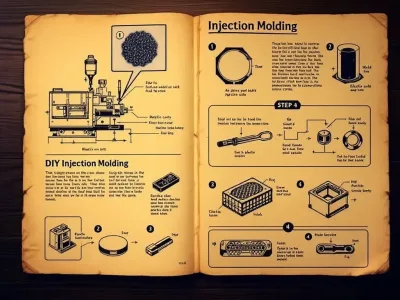

Have you ever thought about making your product ideas real? Injection molding machines, specifically desktop models, could help you do it. These machines make small amounts of plastic parts fast and easy. Their small size works well for home workshops or tiny businesses. They also don’t cost too much money. Some companies say they save thousands by using injection molding machines. You can use them to test new designs or make custom items. Desktop injection molding is simple and easy to use. It’s a big help for small-scale manufacturing. Key Takeaways Desktop injection molding machines are cheap and great for…

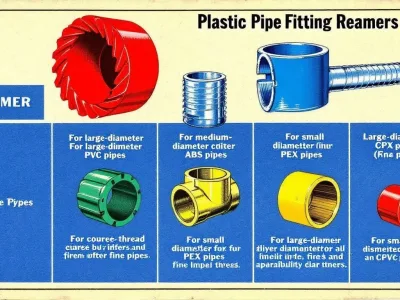

A plastic pipe reamer is a tool used to remove old fittings from plastic pipes, ensuring a clean surface for new connections. It’s essential for plumbing repairs and installations. In this article, we’ll explore how plastic pipe reamers work, different types available, key features to look for, and maintenance tips. Key Takeaways Plastic pipe reamers are essential for removing fittings and preparing pipes for new installations, enhancing efficiency in plumbing tasks.The Clean Ream Extreme® reamer is notable for its ability to clean and reuse fittings, which minimizes material costs and waste.High-quality reamers feature durable designs with carbide cutting inserts and…

Choosing the right prototype tooling plastics is essential for efficient and cost-effective prototype production. This guide covers the top methods and materials to help you create high-quality prototypes quickly, including 3D printing, CNC machining, and injection molding. Key Takeaways Prototype tooling plastics enable rapid and cost-effective production of prototypes, facilitating early design validation and testing.Key methods for creating prototype tooling include 3D printing, CNC machining, and injection molding, each offering unique benefits for different prototyping needs.The benefits of using prototype tooling plastics include faster time to market, significant cost savings, and improved design validation, making them essential in various industries.…

Selecting the right silicone rubber for mold-making is key to successful projects. Silicone rubber is flexible, durable, and easy to use, making it ideal for detailed molds. This guide details everything you need to know to make the best choice. Key Takeaways Selecting the right silicone rubber enhances mold quality. It emphasizes factors like flexibility, tear strength, and curing time for successful applications. A 1:1 mix ratio of silicone components simplifies the preparation process. It ensures consistent results while minimizing bubbles and imperfections. Fast-curing silicones facilitate quick production cycles. Their versatility allows for casting across various surfaces, making them essential…

The manufacturing process does affect the cost factors, time, quality, and size. Both cast urethane and injection molding are common techniques utilized in the making of parts for the automotive, aerospace, and consumer goods industries. They get to know the best method to use depending on their manufacturing, designing, and engineering requirements. What is Injection Molding: A Comparison with Cast Urethane? Cast Urethane is a casting process in which a liquid polymer is delivered in molds to form parts. It is often used for low production volume and initial part making because of the lower manufacturing cost, type of material,…

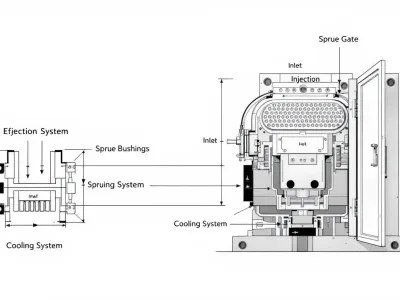

If you’re looking to learn how to make an injection mold, understanding the steps is crucial. The process includes designing the mold, prototyping, machining, and assembling. This guide will walk you through each stage, helping you create a functional injection mold. Key Takeaways Injection molding is a crucial manufacturing technique that involves injecting molten plastic into metal molds to produce high-quality parts efficiently. Key factors in mold design include the choice of materials, cooling channel optimization, and detailed design features such as draft angles and parting lines, all of which ensure product quality and production efficiency. Proper maintenance and care…

Injection moulding industries include automotive, medical, electronics, packaging, aerospace, and construction. This process produces precise, cost-effective parts crucial for each sector. This article explores how injection moulding enhances these industries and its key benefits. Key Takeaways Injection moulding is crucial across multiple industries such as automotive, medical, consumer electronics, packaging, aerospace, and construction, offering significant advantages like precision, cost efficiency, and customization. Emerging trends like automation, smart manufacturing, and sustainability practices are transforming injection moulding processes, enhancing productivity and reducing environmental impact. Choosing the right injection moulding company involves considering factors such as experience, technological capabilities, and customer support to…

Looking for plastic for injection moulding? This guide reviews the top 10 materials, their properties, and common uses. Get insights on ABS, PP, and PC, and more. Key Takeaways ABS is known for its impact resistance, heat tolerance, and versatility, making it ideal for applications in automotive, consumer electronics, and household appliances. Polypropylene (PP) offers high chemical resistance and flexibility, widely used in automotive parts, food packaging, and medical devices, but degrades under UV light. Polyoxymethylene (POM) provides rigidity and low friction properties, being a preferred choice for precise automotive and industrial components despite its limited outdoor use. Acrylonitrile Butadiene…

When selecting plastics for vacuum forming, choosing the right material is crucial for achieving the desired results in your project. This guide explores the most commonly used plastics, such as ABS, Polycarbonate, HDPE, and PVC, detailing their properties and applications. You’ll learn which plastic best suits your needs, whether for automotive parts, food packaging, or other applications. Key Takeaways Vacuum forming is a cost-effective and efficient manufacturing process that shapes plastic using heat and suction, widely used across various industries for producing lightweight and durable components. Commonly used plastics in vacuum forming include ABS, Polycarbonate, HDPE, and PVC, each offering…

Plastic moulding is the process of shaping plastics into precise forms using molds, a fundamental manufacturing technique. This article covers key plastic moulding methods like injection, extrusion, and blow molding. We will examine their benefits, and applications across various industries. Key Takeaways Plastic molding is a versatile manufacturing process for shaping materials like polymers into complex designs. This is achieved using various methods such as injection, extrusion, and blow molding. Injection molding is the most efficient and cost-effective method for high-volume production. Other methods like compression and rotational molding are better suited for prototypes and large hollow parts, respectively. Selecting…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.