A CNC machine shop is a place where experts use special machines to make exact parts by cutting away material. These shops are very important for modern industries because they create parts that meet high-quality rules. CNC machine shops work with many materials like strong metals and advanced plastics, making them important for industries like airplanes, healthcare, and cars. Their accuracy makes sure parts work well in important uses, like medical tools and airplane systems. Fast prototyping helps improve designs quickly, speeding up product creation. In today’s busy market, a CNC machine shop makes parts fast and keeps them high…

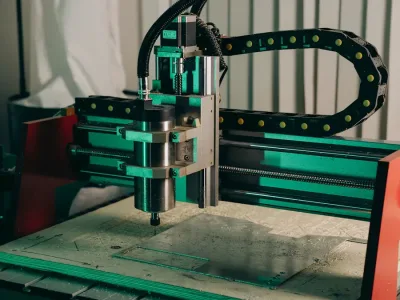

A CNC router, or to answer the question "what is a CNC router," is a machine operated by a computer that cuts and shapes materials with exceptional precision. It automates tasks that would otherwise require manual effort, making the process both faster and more accurate. Unlike traditional tools, CNC routers optimise material usage, helping to minimise waste and reduce costs. They ensure that every product is consistent in appearance and of high quality. Additionally, CNC routers significantly cut down production time, enabling quicker delivery and the effortless creation of intricate designs. These versatile machines can be used on materials such…

Finding the right CNC router CNC is very important for work. The right machine can help you work faster and waste less. You need a machine that fits your materials and goals. It should also meet your accuracy needs. Picking the best CNC router CNC helps your business grow now and later. Whether you use wood, metal, or other materials, CNC machines provide great accuracy and steady results. By understanding what you need, you can choose the best CNC machine and utilise it effectively. Key Takeaways Know your materials. Pick a CNC router that suits the type and thickness of…

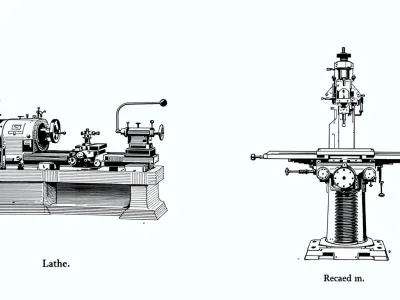

Are you trying to decide between using a lathe and a mill for your machining project? Understanding the key differences between these tools, including the lathe and mill, can help you choose the right one. This article will explain how lathes and mills operate, their unique features, and when to use each tool to achieve the best results. Key Takeaways Lathes are best suited for creating cylindrical shapes, while milling machines excel at producing complex geometries and intricate designs. Understanding the power requirements and efficiency of lathes and mills is crucial for optimal performance and safety in machining tasks. Selecting…

5-axis CNC machining services enable the creation of complex parts with high precision using advanced technology. This article explains what 5-axis machining is, why it’s beneficial, and what you should expect from these services. Key Takeaways 5-axis CNC machining offers superior precision and efficiency, enabling the production of intricate geometries and complex parts with fewer setups. The technology supports a wide variety of materials, including metals and plastics, making it versatile for applications across industries such as aerospace, automotive, and medical. Choosing a reliable 5-axis CNC machining service provider involves evaluating experience, customer satisfaction, and scalability to meet business production…

Bronze machining is the process of cutting and shaping bronze alloys, crucial for its corrosion resistance and machinability. This guide covers why bronze is preferred over other materials, the main types of bronze alloys, and key machining techniques for high-quality results. Key Takeaways Bronze machining offers high corrosion resistance, wear resistance, and strength, making it ideal for precision components in various industries. Selecting the appropriate bronze alloy and machining technique is crucial for optimizing performance and achieving desired outcomes in CNC machining. Implementing best practices and rigorous quality control measures enhances the efficiency and reliability of bronze machining projects. Understanding…

Want to build a CNC machine? This guide to CNC DIY parts covers everything you need, including mechanical components, electronic systems, and more. Find out how to choose the best parts for a reliable and precise machine. Key Takeaways Mechanical components, including frames, axis drives, and ways, are essential for building a reliable and efficient CNC machine. The integration of electronic systems, such as CNC controllers and microcontrollers, is crucial for ensuring precise machine operation and performance. DIY CNC kits vary in complexity and customization, providing options for all skill levels, from beginners to experienced enthusiasts. need help? Contact Us: [email protected] Need…

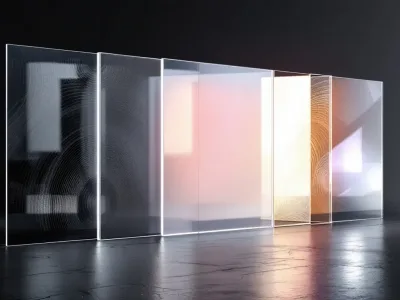

Acrylic CNC machining uses computer-controlled devices to accurately cut and shape acrylic materials. It provides precision, reduces material waste, and speeds up production compared to manual methods. In this article, you’ll learn about the advantages, key properties, and best practices for achieving high-quality results in acrylic CNC machining. Key Takeaways CNC machining offers high precision and speed for acrylic, significantly reducing material waste and production costs, making it an efficient manufacturing method. Key properties of acrylic, including its transparency, impact resistance, and lightweight nature, contribute to its widespread use in industries such as automotive, medical, and construction. Implementing best practices…

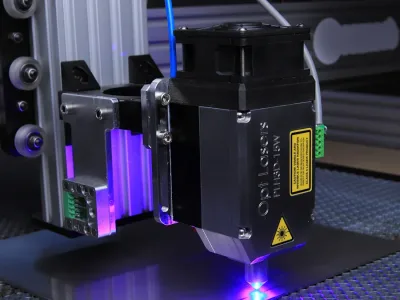

This guide will explore the most common CNC machining types and their applications in precision manufacturing. Key Takeaways CNC machining encompasses various machine types, including milling, lathes, and laser cutters, each suited for specific manufacturing processes and industries. The selection of the appropriate CNC machine depends on factors such as material type, part complexity, and required precision, crucial for optimizing manufacturing efficiency. CNC machining provides significant advantages like precision and uniformity, but it also poses challenges such as higher costs and system complexity, necessitating proper training for effective operation. CNC Milling Machines CNC machines, specifically CNC milling machines, are pivotal…

CNC machinists are essential in manufacturing and operating CNC machines to produce precision parts. This article explains the key CNC machinist duties and the skills needed for the job. Key Takeaways CNC machinists operate, program, and maintain CNC machines to produce precise metal or plastic parts, requiring a blend of technical expertise and hands-on skills. Effective communication and collaboration with engineers and designers are essential for CNC machinists to ensure project specifications and enhance production efficiency. Continuous learning and obtaining certifications are important for career advancement in CNC machining, as they help machinists stay competitive and adapt to technological advancements.…

Want to convert your CAD design into a sample prototype or small-batch production? Upload your files and get a fast and accurate quote.