ABS vacuum-formed parts are widely used in the medical industry for their durability, excellent forming performance and compliance with hygiene standards. ABS (Acrylonitrile Butadiene Styrene) is a lightweight, impact-resistant material. It can withstand high-temperature sterilization processes to ensure safe and reliable use in medical environments. Designed for high precision and functionality, our ABS vacuum-formed parts are ideal for the medical field for complex medical device needs.

Key Features and Benefits

1、High durability and impact resistance: ABS material is known for its excellent impact resistance. This makes it suitable for medical parts that need to withstand daily handling and cleaning operations without being easily damaged or deformed.

2、Biocompatibility and safety: ABS vacuum-formed parts meet strict health and safety standards and are not prone to bacterial growth. This makes them ideal for the high hygiene requirements of the medical industry.

3、Precision customization: The vacuum forming process supports the customization of parts with complex designs and precise dimensions. This allows meeting specific medical device specifications.

4、Cost-effectiveness: Vacuum forming is a cost-effective manufacturing process suitable for small and large-scale production. It helps medical institutions control budgets without sacrificing quality.

Applications in the Medical Industry

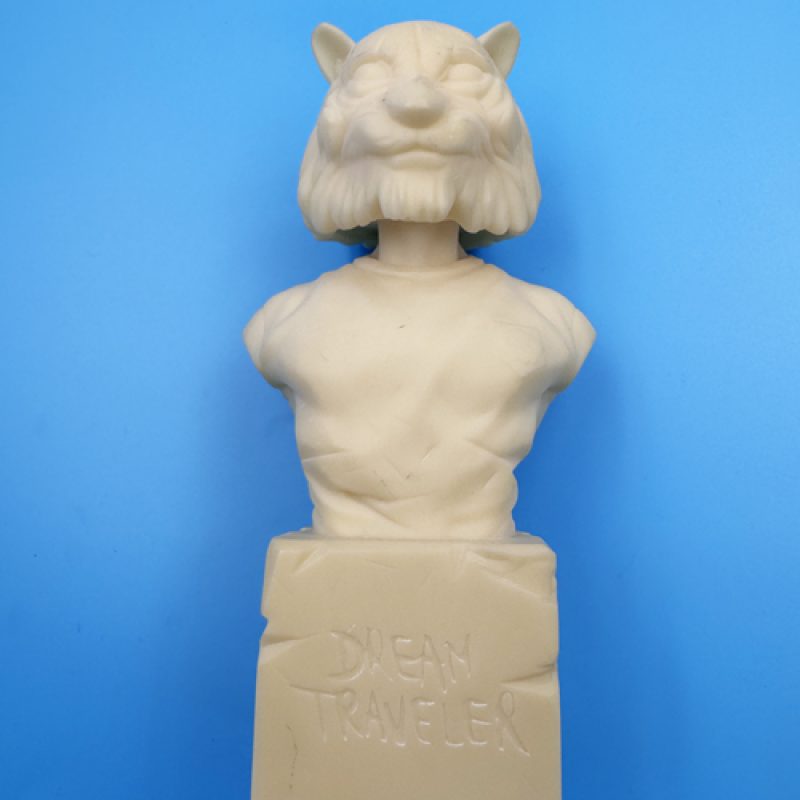

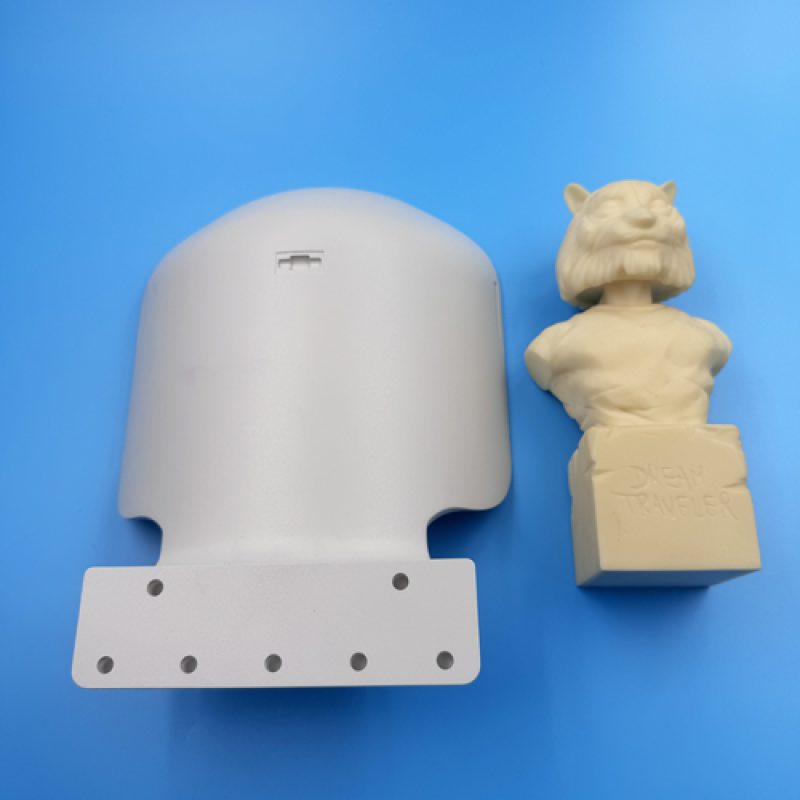

ABS vacuum-formed parts can be widely used in various medical devices. These include medical device housings, protective covers, and external parts of electronic medical devices. The strength and plasticity of the material ensure it meets the strict requirements of the medical industry for part durability and safety.

Production Process

Our production process starts with high-quality ABS materials, which are strictly vacuum-formed and dimensionally calibrated. This ensures that each part meets the precise needs of our customers. From design verification to final product testing, all parts undergo strict quality control. This ensures consistent performance and safety in medical applications.

Why choose our ABS vacuum-formed parts?

We are committed to providing high-quality ABS custom parts that meet the stringent needs of the medical industry. All products are manufactured in China with fast delivery services. This ensures that your medical device components are supplied in a timely manner when needed. Our ABS vacuum-formed parts strike a balance between quality and efficiency. They help you improve the reliability and service life of your equipment.

LKprototype

LKprototype