When it comes to precision engineering, custom CNC machine stainless steel milling prototype and parts are essential across many industries. These parts are created using advanced CNC (Computer Numerical Control) machining technology, which ensures that each component is made with remarkable accuracy and consistency. Stainless steel is the material of choice for many applications due to its strength, resistance to corrosion, and overall durability, making it ideal for demanding environments.

Key Applications

Custom CNC stainless steel milling prototype and parts serve a wide range of purposes in various fields:

- Aerospace: In the aerospace industry, every component must meet stringent safety and performance standards. CNC-machined stainless steel parts are critical for aircraft frames, engine components, and landing gear, where reliability is non-negotiable.

- Automotive: In the automotive sector, custom stainless steel parts are used for everything from engine mounts to transmission housings. Their durability and resistance to wear and tear ensure they can withstand harsh driving conditions.

- Medical Devices: Precision is paramount in the medical field. CNC-machined stainless steel components are widely used in surgical instruments and medical devices, where cleanliness and exact dimensions are crucial for safety and effectiveness.

- Industrial Equipment: Many machines rely on stainless steel milling parts for optimal performance. These parts can include brackets, housings, and fittings, all designed to enhance the functionality and efficiency of industrial equipment.

The Manufacturing Process

Creating custom CNC machine stainless steel milling prototype and parts involves several key steps:

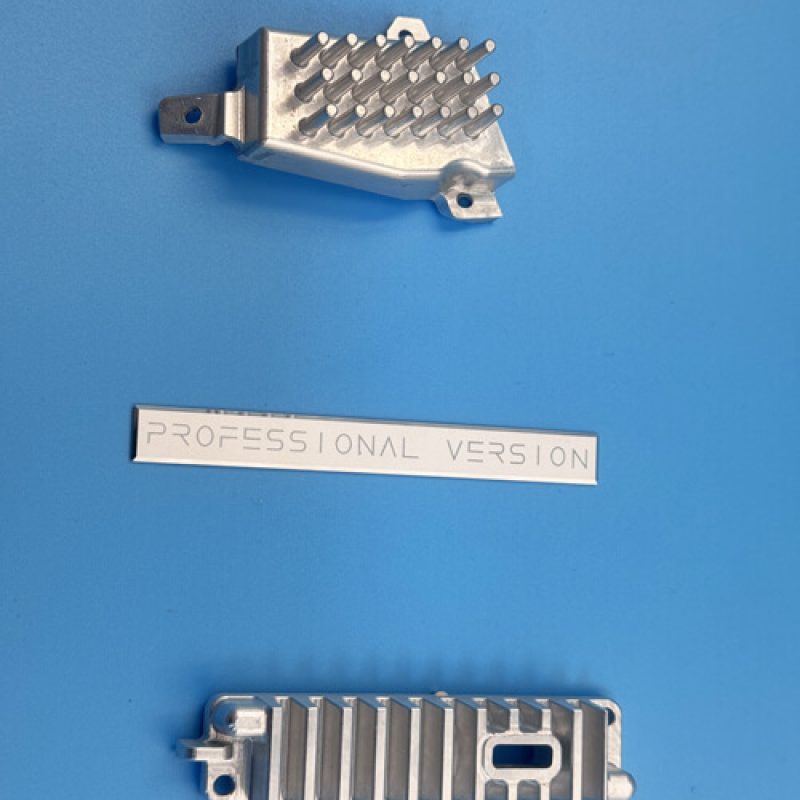

- Design and Prototyping: It all starts with a detailed design, often created with CAD (Computer-Aided Design) software. This stage may include prototyping to test the design and ensure it meets the required specifications.

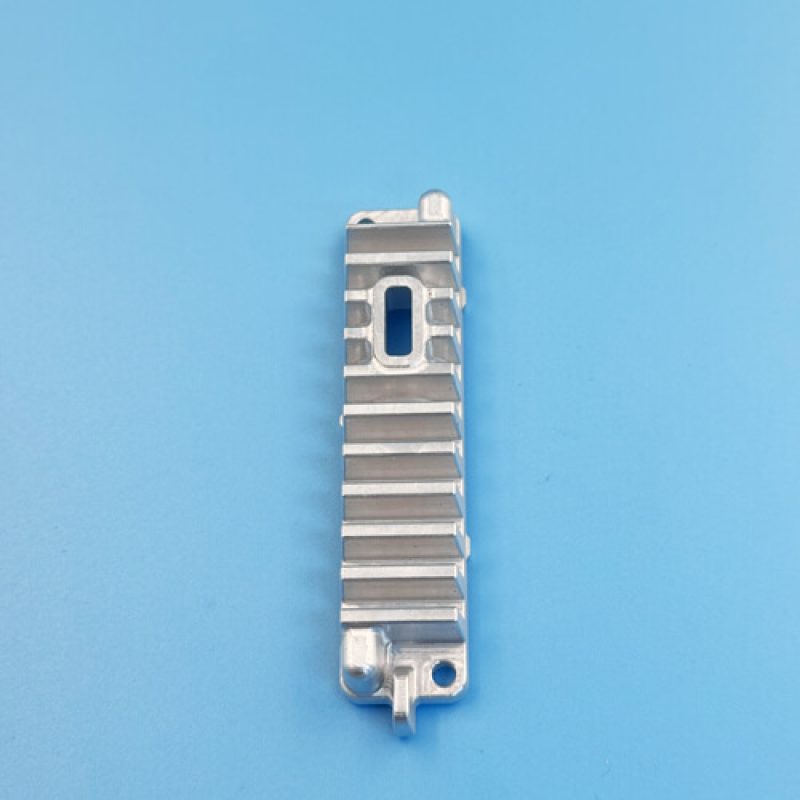

- CNC Machining: Once the design is finalized, CNC machines are used to cut the stainless steel precisely according to the specifications. This process allows for intricate details and tight tolerances, ensuring that each part is crafted to the highest standards.

- Finishing Touches: After machining, the parts often undergo finishing processes like polishing and deburring. These steps not only enhance the appearance of the parts but also add extra protection against corrosion.

- Quality Assurance: Quality control is vital in manufacturing. Each part is subjected to rigorous checks to ensure it meets industry standards, especially in sectors where safety is critical.

- Delivery: Finally, once the parts pass quality checks, they are carefully packaged and shipped to clients, often with quick turnaround times to meet market demands.

CNC Machine

Conclusion

In summary, custom CNC machine stainless steel milling prototype and parts are vital to modern manufacturing across diverse industries. Their unique combination of strength, durability, and precision makes them indispensable in applications ranging from aerospace to medical devices. By utilizing advanced CNC technology and maintaining strict quality control, manufacturers can produce parts that meet—and often exceed—customer expectations. Investing in these high-quality components ensures optimal performance and longevity, making them a smart choice for businesses focused on enhancing operational efficiency.

LKprototype

LKprototype