Soft rubber vacuum-molded components and hoses are tailored parts known for their durability and flexibility. They are suitable for applications that require vibration resistance, effective sealing, and adaptability. Produced through precision vacuum casting, these components provide exceptional detail reproduction and consistent quality. This makes them an ideal option for prototypes and low-volume manufacturing.

Product Features:

Outstanding Flexibility: Offers remarkable adaptability in confined spaces while maintaining structural integrity under varying pressure and temperature conditions.

High-Precision Detailing: Achieves intricate detail in complex designs, perfect for custom or elaborate shapes.

Robust Durability: Designed for superior wear resistance, ensuring longevity even in challenging environments.

Optimal Sealing: Guarantees excellent sealing performance in fluid and air transfer applications, effectively preventing leaks and contamination.

Medical industry soft hose

Applications: Soft rubber vacuum-molded parts and hoses find extensive use in the automotive, medical, electronics, and industrial machinery industries. They excel in applications such as fuel lines, air conditioning systems, medical devices, and industrial equipment. These components provide dependable performance and versatility.

Automobile soft hose

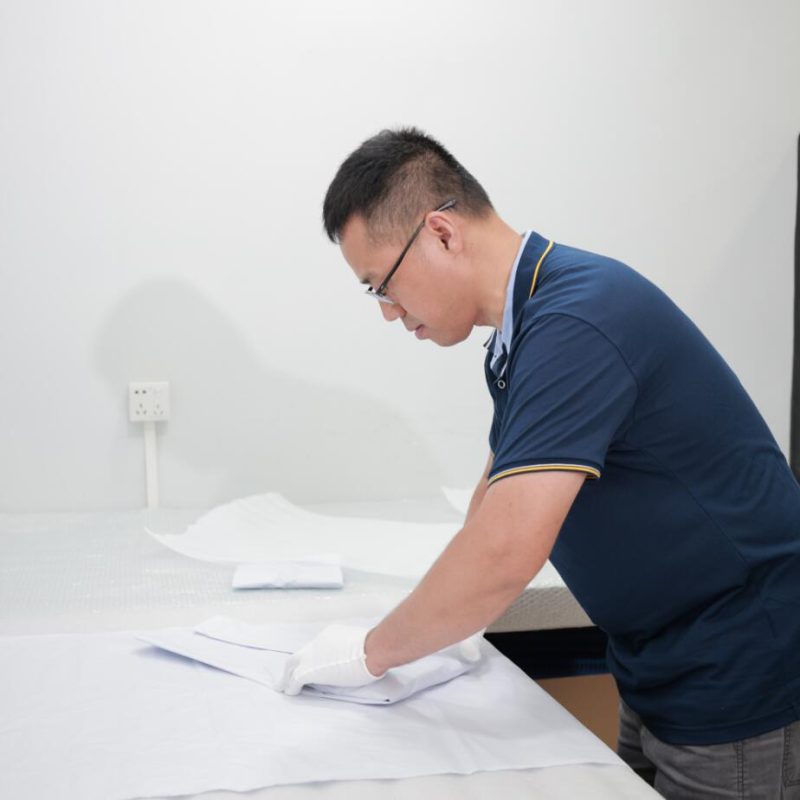

Process Advantage: The vacuum casting method ensures accuracy, quick production, and material flexibility. It is ideal for creating highly precise, adaptable parts without the expense associated with traditional molding methods.

This approach enables companies to efficiently produce accurate prototypes and functional components. It meets the current demand for fast, reliable, and versatile manufacturing solutions.

LKprototype

LKprototype