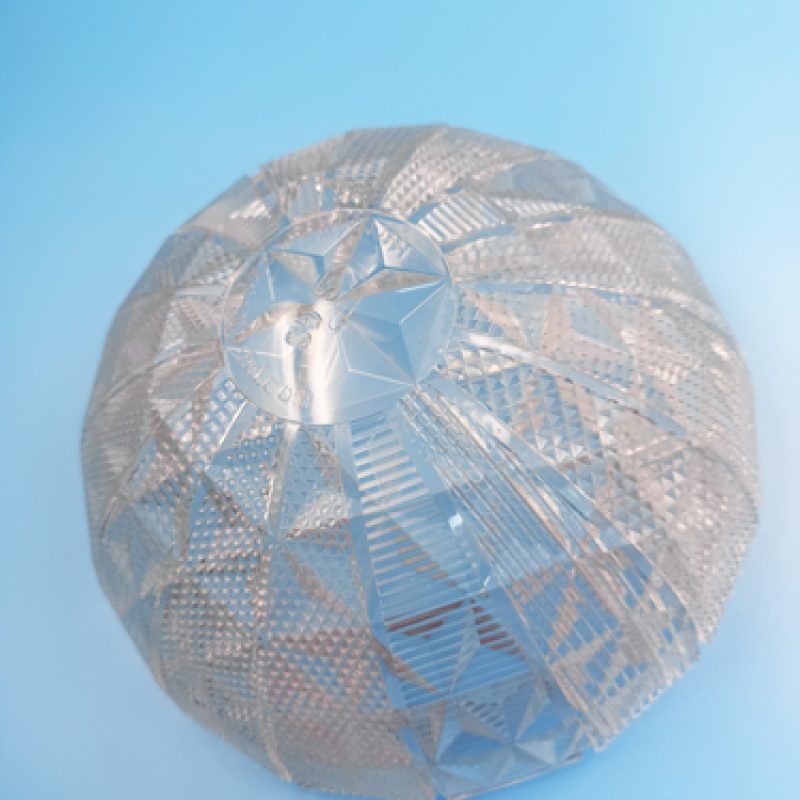

Discover the exceptional clarity and precision of Polyurethane Vacuum Casting Transparent Polished Parts. These parts are specifically engineered for industries that require outstanding transparency and detail. This innovative solution utilizes advanced vacuum casting techniques and high-quality polyurethane. It delivers remarkable durability, clarity, and a flawlessly smooth, polished finish. The vacuum casting process facilitates the production of intricate components with high reproducibility. It guarantees that every piece adheres to rigorous standards for transparency and dimensional accuracy.

Key Features

Unmatched Transparency: Our polyurethane vacuum casting method produces parts with near-glass clarity. This makes them perfect for applications where visual precision is essential.

High Precision and Detail: The use of vacuum casting technology ensures each component retains sharp details and uniform dimensions. This makes it suitable for prototyping and low-volume production.

Exceptional Surface Finish: Achieves a polished, smooth surface that requires minimal post-processing. It is ideal for display prototypes and functional evaluations.

Durability and Strength: Polyurethane provides excellent mechanical properties. It offers both flexibility and resilience in various environmental conditions.

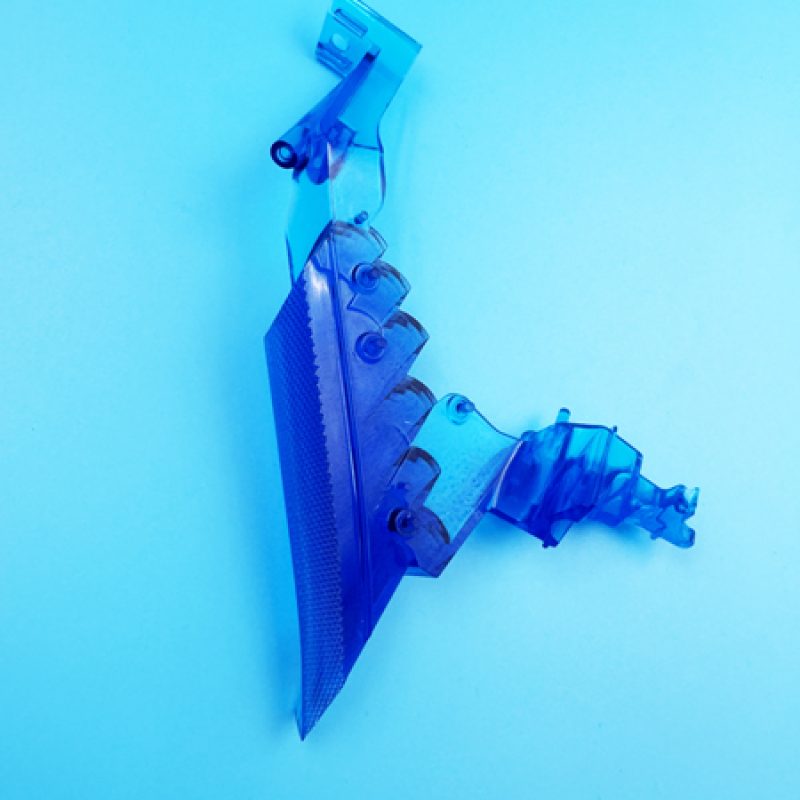

Polishing of transparent parts

Applications

Automotive and Aerospace: Clear indicator lenses, intricate fluid channels, and visual inspection models.

Consumer Electronics: Transparent enclosures for product prototypes, facilitating testing and presentation.

Medical Devices: Prototypes for diagnostic tools, allowing visibility into internal configurations.

Industrial Design and Research: Perfect for form, fit, and function assessments, enhancing the design validation process.

Medical Industry

Our polyurethane vacuum casting process guarantees each part delivers a unique blend of clarity, precision, and reliability. This makes them essential across a wide range of industries.

LKprototype

LKprototype